Information

-

Audit Title

-

Document No.

-

Client / Site

-

Conducted on

-

Prepared by

-

Location

-

Personnel

site information

-

task activity

-

date

-

Service order number SON

-

name of contractor/Subcontractor

Work Statement Checklist

-

Equipment to be installed or removed

-

Compatibility of proposed equipment with existing equipment.

-

The working which might be affected.

-

When working equipment will be taken out of service.

-

Proximity of power plants and disturbing systems

-

The steps requiring the presence of an on site representative.

-

Identify alarms to be disconnected and when.

-

Records and drawings to be corrected.

-

Protection of equipment, floor, walls, etc.

-

Storage of tools and materials.

-

Service restoration procedure and responsibility and back up plans

-

Detailed step by step procedure.

-

Stipulate normal shift time

-

Documentation approved

-

Equipment protection procedures

-

Dust containment procedures.

-

Emergency contact details

critical procedures: where work involves any of the following hazards must be incorporated into JSA

-

Work at heights above 1.5m

-

Confined space entry (includes tank cleaning)

-

Electrical/Mechanical lockout (live, isolation, lock out / tag out

-

Heavy equiptment lifting (cranes, boom trucks, excavators)

-

Entry into excavations/Trenches > 1.2 m (4ft) deep

ensure all hazards identified are addressed in JSA below

-

1. sequence of basic job Step in order

-

1.potential hazards. (Ex. underground services, hazard zone etc.)

-

1.safety controls to reduce or eliminate hazard

-

2. sequence of basic job Step in order

-

2. potential hazards. (Ex. underground services, hazard zone etc.)

-

2. safety controls to reduce or eliminate hazard

-

3. sequence of basic job Step in order

-

3. potential hazards. (Ex. underground services, hazard zone etc.)

-

3.safety controls to reduce or eliminate hazard

-

4. sequence of basic job Step in order

-

4. potential hazards. (Ex. underground services, hazard zone etc.)

-

4.safety controls to reduce or eliminate hazard

-

5. sequence of basic job Step in order

-

5. potential hazards. (Ex. underground services, hazard zone etc.)

-

5.safety controls to reduce or eliminate hazard

additional PPE ( minimum requirement: safety boots, hard hat, visi-vest, glasses, gloves)

-

Eye protection

-

Hearing protection

-

Fall protection

-

Rubber footwear and gloves if in a damp area

-

Protective gloves.

-

Full face shield.

-

Other (fire retardant coveralls, breathing apparatus, etc) specify :

Risk score before and after.

-

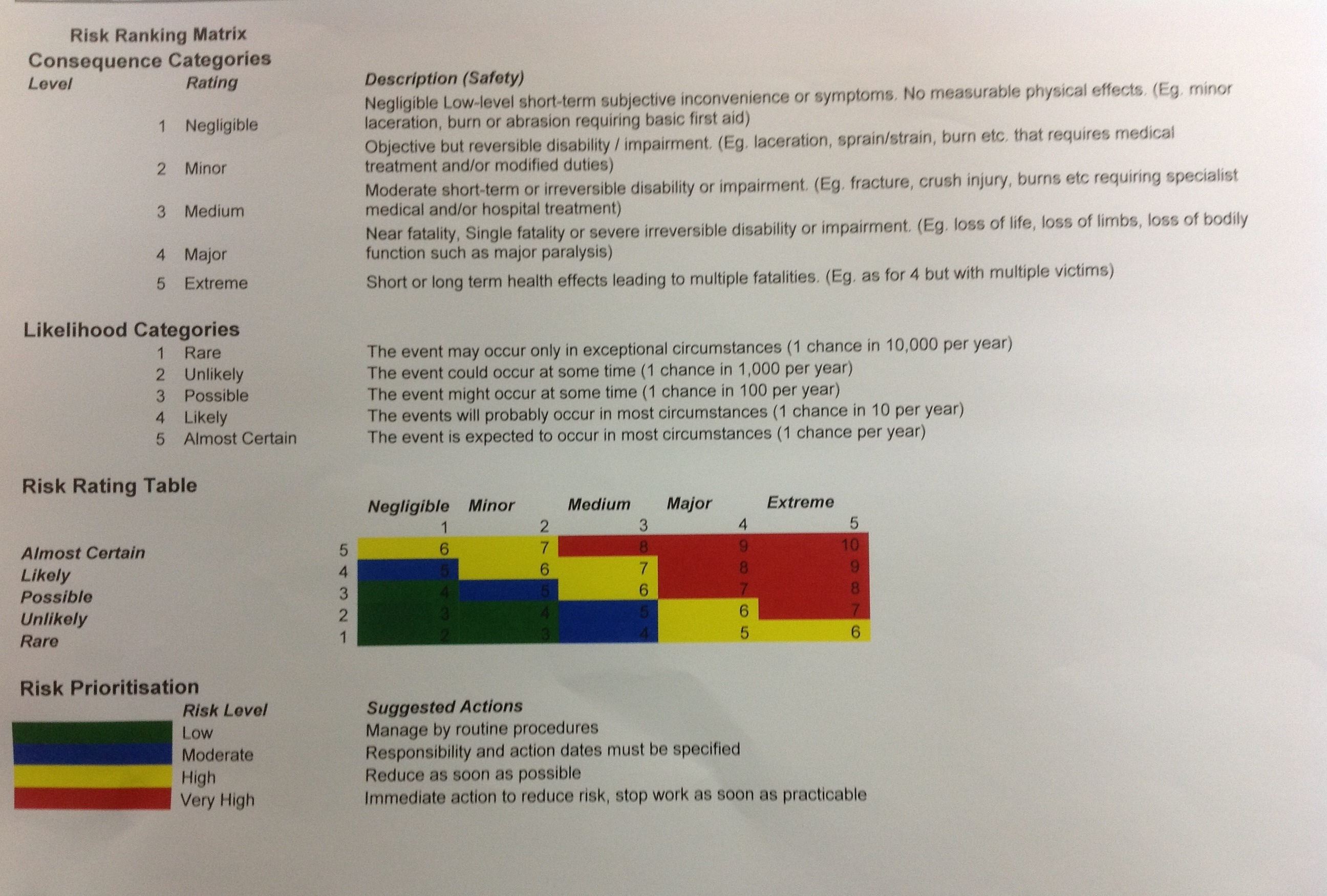

Risk Ranking Matrix

Local authorities:

-

outside authorities

disposal of designated substances, surplus, or impacted materials (disposal details, e.g when, where, how?)

-

Add signature

Service engineer/ technician

-

prepared by

-

date

-

person carrying out work

-

date

-

person carrying out work

-

date

-

person carrying out work

-

date

site supervisor

-

JSA client signature

-

date