Title Page

-

BIN

-

INSPECTION DATE

-

PREPARED BY

-

ADDRESS LOCATION

-

BUILDING NAME

-

WAREHOUSE / OFFICE NUMBER

VISIT

-

New Lease Pool

-

INITIAL INSPECTION

-

FINAL INSPECTION

-

RECERTIFICATION

-

INITIAL INSPECTION

-

FINAL INSPECTION

-

GOP

-

INITIAL INSPECTION

-

FINAL INSPECTION

-

TURN OVER

-

INITIAL INSPECTION

-

FINAL INSPECTION

-

Year of construction

June / 2022: This report has been updated according to Non-Residential Property POSHO Certification Requirements

-

THIS REPORT IS LIMITED TO POTENTIAL LEASED PREMISES AND IS NOT INTENEDED TO CONTROL OR ASSESS ON RELATED OR SURROUNDING AREAS (SUCH AS COMPLEX COMMON OR OTHER PRIVATE AREAS & FACILITIES) WHICH ARE UNDER THIRD PARTIES CONTROL AND MIGHT BE RULED WITH SPECIFIC LOCAL AND/OR INTERNATIONAL OPERATIONS AND REGULATIONS. THE PROPERTY SHALL ALSO IMPLEMENT ACTIONS AS DESCRIBED IN FAM 15-600/800.

-

POTENTIAL VISITORS NO SPECIFIED, NO HANDICAP STANDARIZED. POTENTIAL OPERATIONS INCLUDE STORAGE (TYPE TO BE DEFINED) AND OTHER NON DECLARED ACTIVITIES.

1- FUEL BURNING APPLIANCES AND EQUIPMENT - OTHER EQUIPMENT - AIR QUALITY

1.1 - RECOMMENDATIONS: AS FOLLOWS / AS APPLY - AGENCY

-

Review / keep venting of exhaust gases in outdoors away from air intakes and windows, additional fuel power plants supplied must be properly located to keep emissions under control. Flues shall be constructed and installed / inspected and maintained properly (per manufacturer)

-

Consider fire rated electrical components in supply storage areas, shops, fuel and volatil material storage and handling, etc.

-

Battery charging stations and storage must follow safety regulations to prevent associated risks (fire, chemical expossure) during related activities performed

-

Install an acid spill kit / Instalar un kit de derrames para acidos

-

- Liquefied Petroleum (Propane) Gases (LPG) Cylinders during use: Must be located on the exterior of the building. Equipped with a pressure regulator having a pressure relief valve. Upright and securely anchored or chained in place. At least 7.6meters (25ft) from sources of ignition and 1.5meters (5ft) <br>- Cylinder storage: Outside within a fenced enclosure. Outlet valves closed with cap or cover. Steel posts or barriers if vehicle damage is possible. “No Smoking” signs clearly displayed around the storage enclosure with universal symbols or local language and English. <br>- Secure tanks to ensure they cannot be used as weapons of opportunity <br>- Trained employees for LPG installation and cylinder replacement <br>- Refilled tanks or bottles delivered, no recharging or filling of tanks or bottles at the site. Post Facility Manager or Post Occupational Safety and Health Officers (POSHO) must coordinate inspections of residences / apartment buildings, which have natural gas and ensure the local gas authority has certified lines and valves. References; FPG, Section F-2

-

RELOCATE GAS CYLINDER TO THE PROPER AUTHORIZED STORAGE AREA / Reubicar los cilindros de gas a las areas destinada para su almacenamiento segun la normativa. OSHA 1910.50

RECOMMENDATIONS: AS FOLLOWS / AS APPLY - AGENCY (CONT.)

-

No coffee makers, space heaters or alike with heating elements are allowed in work stations.

-

Keep all the office equipment properly maintained and ventilated as required

-

Depending on A/C units supplied (if), verify and impement realated installations to maintain a clean and healthy environment (pressure, temperature, quality, etc.)

1.2 - Combustion Air

-

- Adequate combustion air ducted to unit or unobstructed area large enough to provide adequate combustion air. <br>- Small mechanical areas have sufficient combustion air and ventilation openings. - No hazardous or flammable vapor sources near combustion equipment - Implement acordingly in case the rooms are considered as CAA areas

-

REMOVE ALL OBSTRUCTIONS FROM THE VENT COVERINGS / Remover cualquier obstrucción de las rejillas de ventilación

-

PERMANENT VENTILATION REQUIRED / Requiere ventilacion permanente.

-

OTHERS / Otros

1.3 - Operation and Maintenance

-

- Instructions available for proper operation and maintenance <br>- Equipment operated and maintained as intended within design limits <br>- Warning labels (English and local language) present on combustion appliances.

-

PREVENTIVE MAINTENANCE REQUIRED / Mantenimiento preventivo requerido a gasodomesticos

-

All present gas appliances are in good working conditions, have all the original parts and instructions manual. Include: stove, oven, dryer, water heaters (accumulation/flash), etc.

1.4 - Clearance to Combustibles

-

- Adequate clearance from exhaust flue to combustible materials at least 1m(3ft) <br>- Adequate clearance from equipment to combustible materials boiler and furnace rooms not used for storage areas at least 1m(3ft). FPG, Section I-6

1.5 - Fuel flammable Type and Storage

-

- Fuel used is appropriate for equipment(s) <br>- Proper type and location of fuel storage container (including tanks) - Protect fuel storage containers from damage and secure them for protection against weapons of opportunity. - Although propane gas supply is not considered as an ESP (locally Empresa de Servicios Públicos) but a supply service only / meaning no local stringent regulation involved, all gas installations must comply with equivalent local Natural Gas regulations as a minimum requirement. Reference; NFPA 30 / 15 FAM833 / 12FAM530<br>

1.6 - Generator

-

-if there is adequate space available, and landlord agrees to allow installation or provide the generator, it needs to be consider: <br>- Placed outdoors as far away as practical and a minimum of 1.5 meters (5 feet) from any building <br>- Exhaust outlets >= 1meter (3 ft) from exterior walls and roofs, 3meters (10 ft) from operable openings into buildings, and 10 feet above adjoining grade. <br>- If distance and direction of exhaust is not feasible, then extend 3 ft above the building. (See “Venting of Exhaust Gases” section).

1.7 - All Gas Service

-

- Supply through rigid pipe (iron or steel), or tubing (steel, brass or copper). Exceptions for seismically active areas see Seismic Safety . <br>-Manual shut-off valve accesible and within 1.8meter (6ft) - Secured to ensure safe against weapons of opportunity.<br>-Leak detection using soapy water or other means must be conducted over al fittings and connections during cylinder or appliance replacement or anytime supply line works is done.<br>-Post Facility Manager or Post Occupational Safety and Health Officers (POSHO) must coordinate inspections of residences / apartment buildings, which have natural gas and ensure the local gas authority has certified lines and valves. References; FPG, Section F-2

-

REVIERW AND CORRECT GAS LEAK IN GAS LINE / Revisar y corregir fugas de gas en lineas de suministro

-

INSTALL APPROVED GAS SUPPLY HOSE / Instalar manguera aprobada y/o certificada para gas natural

-

INSTALL MANUAL SHUT-OFF VALVE WITHIN 1.8 M (6 FT) OF APPLIANCE / Instalar válvula de corte a 1.8 m de gasodomésticos

-

CAP UNUSED GAS CONNECTIONS / Taponar toda salida de gas sin uso:

-

Leak detection using soapy water or other means must be conducted over all fittings and connections during cylinder or appliance replacement or anytime supply line work is done.

SOLICITAR A LA ADMINISTRACIÓN DE LA COPROPIEDAD MANIFIESTO DEL PLAN DE REVISIÓN Y MANTENIMIENTO DE LOS EQUIPOS, COMPONENTES Y DUCTOS COMUNALES (CALDERAS, PLANTAS ELECTRICAS, EQUIPOS DE COMBUSTION, ETC.)

2.0 - FIRE AND LIFE SAFETY

-

Life Safety Code/NFPA 101 · several factors influence automatic fire alarm detection and/or automatic fire suppression system requirements.

- consult the Fire Protection Guide (FPG) and contact OBO/OPS/FIRE. -

SOLICITAR A LA ADMINISTRACIÓN EL CUMPLIMIENTO DE LAS REGULACIONES PERTINENTES EN CUANTO AL TRATAMIENTO DE ZONAS COMUNES Y PLANIFICACIÓN (INFRAESTRUCTURA, EQUIPOS, CONTROLES, ETC.) PARA EVENTOS DE MANEJO DE EMERGENCIAS POR INCENDIOS. SOLICITAR COMPROBANTES DEL MANTENIMIENTO PREVENTIVO Y PRUEBAS DE LOS SISTEMAS DE CONTRAINCENDIO

2.1 - Emergency Egress

-

- Adequate emergency egress can vary with the type of building. Consult the Fire Protection Guide (FPG) for guidance

-

First response equipment must be available on site. Assigned personnel must be trained in equipment use and first aid procedures. Assembly points, drills program, evacuation paths, emergency response procedures must be implemented. Safety plans, lighting, access, warning and orientation signs and labels, general instructions must be placed as required (EMBASSY PROVIDED AND INSTALLED)

2.2 - Maximum Travel Distance to an Exit

-

Life Safety Code/NFPA 101

-

- Without fire suppression or detection systems: 30meters (100ft)<br>- With complete fire detection system and sprinkler protection in selected areas: 46 meters (150ft)<br>- With complete fire sprinkler system: 61 meters (200 ft) -The evacuation plan must clearly lead to approved egress and consider any eventual operation in the premises (maintenance) and flammables in storage areas. -Additional exit points are required if distance exceeds 200 ft (61m) (LANDLORD)

-

L<100 ft TO STAIRCASE

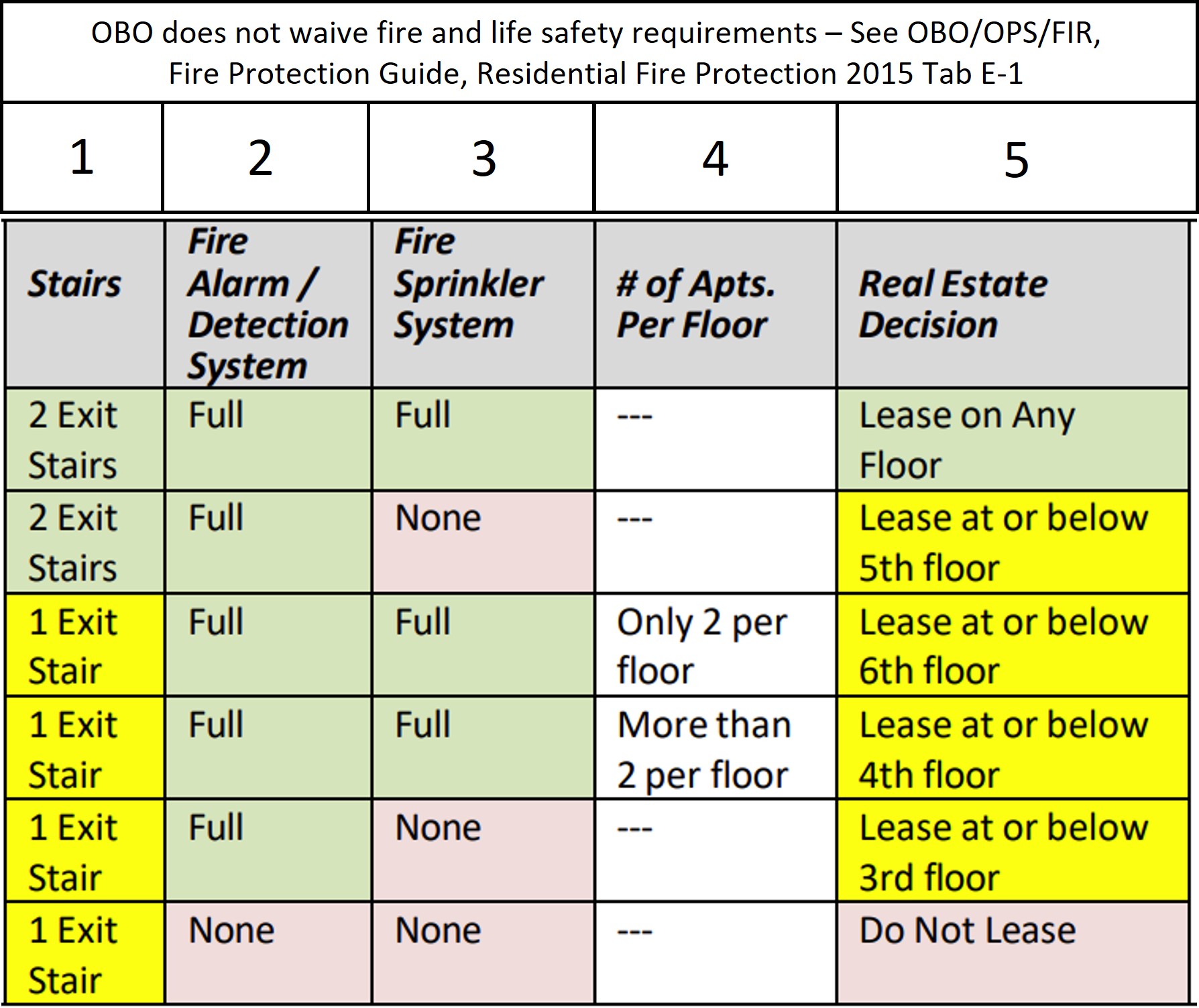

2.3 - High-Rise Properties Matrix

-

-

The property meets the requirements outlined in 15FAM 813.7. If not, has the COM/DCM signed a request for mitigation to the Office of Fire Protection, and are mitigation factors in the lease file?

2.3.1- Building Description

-

LEVELS ABOVE GROUND/Pisos sobre nivel de piso

-

LEVELS BELOW GROUND/ Piso bajo nivel de superficie

-

TOTAL LEVELS/ Total pisos

2.4 - Alarm Systems

-

FIRE ALARMS (COMMON AREAS / AREAS COMUNES)

-

SPRINKLERS / Aspersores

-

PULL STATION / Estaciones manuales

-

STROBES / LIGHTS / Luces estroboscópicas

-

SMOKE DETECTORS / Detectores de humo

-

ALARM (SOUND) / Alarmas / Sirenas

-

FIRE CABINET / Gabinetes contra-incendios

-

In Buildings with fire cabinets available (axe, extinguisher and hose included), cabinet locks must be replaced to key free locking mechanisms and glass has to be replaced to tempered type. Additional fire extinguishers shall be installed as required as a secondary mean for small fires at no more than 75' apart, must be wall mountred (3.5-5 feet to top from the floor level), preferible in recessed wall openings, labeled, and accessible / clear at all times, department standard 10 lb. (4.45 kg) extinguisher (4-A:40-B:C), and/or adequate to the specific use for special purposes as approved/required. Location, clearance, type, density as required for operartions purposes.

-

EXTINGUISHERS / Extinguidores

-

TESTING RECURRENT OF INSTALL "FIRE SUPPRESSION" EQUIPMENT / Realizar periódicamente test al sistema de supresión de fuego.

2.5 - Handycap

-

Premises shall include infraestructure considerations for handicaped personel / incidentals according to specific requirements and needs. / Los locales deberán incluir consideraciones de infraestructura para personal discapacitado/accesorios de acuerdo con los requisitos y necesidades específicos.

2.6 - Portable Fire Extinguishers

-

- One Department standard 10 lb. (4.45 kg) extinguisher (4A:40B:C) <br>- Wall mounted in or near each kitchen <br>- Fire extinguishers must be installed as required as a secondary mean for small fires at no more than 75 feet apart, must be wall mounted (3.5-5 feet to top from the floor level), preferable in recessed wall openings, labeled, and accessible / clear at all times, department standard 10 lb. (4.45 kg) extinguisher (4-A:40-B:C), and/or adequate to the specific use for special purposes as approved/required. Location, clearance, type, density as required for operations purposes. (EMBASSY PROVIDED AND INSTALLED)

-

ANSUL EXTINGUISHER REVISION REQUIRED / Revision de Extintor ANSUL

-

ANSUL EXTINGUISHER REQUIRED SUPPLIED BY THE EMBASSY / Requiere instalar Extinguidor ANSUL suministrado por la Embajada

2.7 - Lighting

-

- Emergency lighting shall be installed to provide 1 foot candle power at floor level in common spaces, hallways, stairways and other means of egress. <br>- If emergency generator is not available to provide emergency lighting, provide battery-packed emergency lights in public spaces, hallway, stair way or other means of egress <br>- Installed and maintained correctly

-

BACK UP POWER PLANT / Planta Electrica de respaldo

-

BUILDING MUST COMPLY WITH REQUIREMENTS / Edificio debe cumplir con los requerimientos

-

REVIEW NIGHT TIME LIGHTING SUPPLY IN PARKING AND SURROUNDINGS AREAS / Revisar el suministro de iluminación nocturna en estacionamientos y áreas circundantes

2.8 - Exit Signs

-

- Exit doors in public corridors on floors with sleeping accommodations: Illuminated exit signs. Directional signs if path is not straight or the exit is less than obvious.

-

BUILDING MUST COMPLY WITH REQUIREMENTS / Edificio debe cumplir con los requerimientos

2.9 - Window Grilles

-

- Life Safety Code/NFPA 101 <br>- Operable from the inside <br>- Minimum opening: 5.7 ft.2 (0.529 m2) <br>- Minimum dimension: 24” (61 cm) x 20” (51 cm) and not be more than 44” (112 cm) from the floor <br>- Bars or grilles must have inside release mechanism

3.0 - WATER HEATER PROTECTION

3.1 - Temperature and Pressure Relief Valves

-

- Separate temperature and pressure relief valves (PRV and TRV) or combination temperature and pressure relief valves (TPRV) installed <br>- TPRV drain piping installed to direct discharge to floor <br>- TPRV drain piping is not reduced, threaded at the end and has no uphill runs <br>- TPRV drain piping has no other valve downstream of TPRV <br>- Water temperature is not above 120 degrees F (49 degrees C)

-

Install TPRV valve to water heater tank / Instalar válvula TPRV a calentador de agua de acumulacion

-

Install drain pipe directly to the floor (max 5 cm from floor)/ Instalar tubo de drenaje directamente al piso y/o sifón max. 5 cm del piso

-

TPRV valve requires maintenance / la valvula TPVR requiere mantenimiento

-

PROVIDE INSTRUCTIONS TO TRANSITION FROM EMERGENCY WATER HEATERS TO BOILER AND VICE VERSA / Suministrar instructivo sobre la forma de hacer transición de calderas comunales a sistemas internos y viceversa

-

Others / otros

3.2 - Water heater assembly and installation

-

Main valve in cold side, no galvanic corrosion condition, seismic arrested, TPRV/discharge /drain properly installed, ground protected, GFCI for forced draft type, CO duct properly installed, ventilated area.

-

Clear instructions to activate / deactivate emergency water heaters while the main supply is provided by central boilers / other means. Diagram and/or instructions available.

3.2.1 - RECOMMENDATIONS: AS FOLLOWS / AS APPLY

-

Removed shower head heater from every bathroom and replace by an electrical water heater / Remover los calentadores de duchas presente en los baños y sustituir por calentadores electricos de agua por acumulacion

4 - PLATE GLASS SAFETY

Tempered / Safety Glass Locations

-

- Entry and exit doors, storm doors, glass sliding doors <br>- Windows located within 18” (46 cm) of the floor <br>- Doors and enclosures for bathtubs, showers, <br>- Stairway enclosures and handrail panels

-

INSTALL DECALS IN BALCONY GLASS PANES (DOORS / WINDOWS) / Instalar cintas tipo sandblasting sobre acristalamientos (puertas y ventanas) que confinan balcones y terrazas, de no menos de 10 cm de ancho a una altura media de 92 cm desde el piso

-

INSTALL RAILGUARDS AS REQUIRED IN LOW PARAPET FAÇADE WINDOWS / En antepechos menores a 45 cm, instalar barreras con la estetica necesaria, con altura no menor a 1.07 m (42") y aberturas entre elementos no escalables cuya separacion libre no sea mayor a 10 cm

-

REVIEW STABILITY TO ALL GLAZING. IMPROVE IF REQUIRED / revisar estabilidad de todos los acristalamientos. corregir si requiere

-

REPLACE BROKEN GLASS WINDOW / reemplazar vidrios rotos

-

locations listed above without tempered glass, need safety glass or non-breakable replacement materials, or protection with barriers. Doors at ground level may be treated with a Mylar coating or with decals or markings

5 - ELECTRICAL SAFETY

5.1 - Ground Fault Circuit Interrupters

-

- Installed for wet locations (indoors or outdoors) and all kitchen countertop outlets at the outlet or the circuit breaker: - 110-volt systems, installed GFCIs of 20 amp (trip at 4 to 6 mA) - 220-volt systems, installed GFCIs trip at 10 mA <br>- Do not install outlets where local code prohibits them in certain wet locations

-

INSTALL GFCIs IN APPLIANCES WITHIN 6 ft FROM WATER SUPPLY CONNECTIONS / Instalar tomas GFCI y/o breaker GFCI de 20 amp (4-6 miliamperios) en zonas húmedas (baños, cuarto de servicio, lavandería y cocina), en mesones, en receptáculos / cajas ubicados a menos de 1.8 mts de cualquier punto de suministro o descarga de agua, o tomas a la intemperie

-

KITCHEN / cocina

-

BATHROOMS / Baños

-

JANITORIAL ROOM / Cuarto de limpieza

-

BALCONY / Balcon

-

LAUNDRY / Lavanderia

-

OUTDOOR ELECTRICAL OUTLETS / Tomas eléctricas en intemperie

-

GFCI,s MUST BE RELOCATED IN AN ACCESSIBLE PLACE / Instalar tomas GFCI en lugares de fácil acceso e instaladas correctamente sin conductores expuestos, con accesorios, conductos y cajas para zonas húmedas.

-

DISHWASHER / LAVAVAJILLAS

-

CHECK CORRECT OPERATION OF ALL GFCI INSTALLED, REPLACE IF THERE ARE 15 AMP LOAD GFCI / revisar el correcto funcionamiento de todas las tomas GFCI instaladas, Reemplazar tomas GFCI de 15 amp a 20 amp.

5.2 - Grounding

-

- An effective grounding system for a typical apartment or house includes a grounding electrode conductor (GEC) to connect the main service ground terminal to a grounding electrode system. Impedance of the ground path for any made electrodes may not exceed 25 ohms, as measured using the 3 terminal resistance measurement method and an earth electrode tester. verify and, if missing, contact the FIR/FAC Help Desk via e-mail (obo@cesengineers.com) or call 866-949-6751 for assistance with grounding system installation

-

CHECK GROUNDING SYSTEM / revisar sistema de puesta a tierra

-

Measurement could be changed by contractor intervention /Mediciones sujetas a cambios por arreglos e intervenciones de contratistas

-

REVIEW OR IMPROVE GROUND SYSTEM TO EQUIPMENTS / Aterrizar, Revisar y/o corregir puesta a tierra equipos

-

KITCHEN RANGE HOOD / Campana extractora cocina

-

Freezer / Refrigerador

-

STOVE / Estufa

-

OVEN / Horno

-

WATER HEATERS / Calentadores de agua

-

INDIRECT LIGHTING/Iluminacion indirecta

5.2.1 - LIGHTNING PROTECTION

-

VERIFY / VALIDATE CURRENT LIGHNING PROTECTION WITH UPCOMMING ACTIVITIES AND MATCHING OR ADJUSTMENTS NEEDED WITH AVAILABLE SYSTEMS. CERTIFICATE IF EXISTING LIGHTNING PROTECTION IS PROPERLY INSTALLED AND PROVIDED (FRANKLIN RODS, INDIVIDUAL RAISED RODS, GRID, GROUND, COLECTORS, ETC.) FOR THIS PARTICULAR FACILITY AND SORROUNDING AREAS WHERE VOLATILE AND COMBUSTIBLE MATERIALS ARE PRESENT (FUEL AND OTHER VOLATIL CHEMICALS). WAREHOUSE ROOFING STRUCTURE SHALL BE BONDED TO A PROPER AND INDEPENDENT GROUND. VERIFY ELECTRICAL SUB-STATION LIGHTNING PROTECTION / Verifique / valide la protección contra rayos actual con las próximas actividades y la combinación o los ajustes necesarios con los sistemas disponibles. Certificado si la protección contra rayos existente está correctamente instalada y provista (varillas de franklin, varillas elevadas individuales, rejilla, tierra, colectores, etc.) para esta instalación en particular y las áreas circundantes donde están presentes materiales volátiles y combustibles (combustible y otros químicos volátiles). La estructura del techo del almacén deberá estar unida a un suelo adecuado e independiente. Verificar la protección contra rayos de la subestación eléctrica

5.3 - Electric Service Supply & Panels Boards

-

Individual circuits protected by single breakers, two and three phases breakers interlocked with valid means. No circuit/wire splices in the circuit box. All bars (live, neutrall, ground) are independent ans stable in the chasis. Panel board properly grounded. All terminals and bond points are tightened and properly secured. All unused wire ends are protected with wire nuts and insulating tape. - Missing knock-outs and twist-outs in breaker/fuse panel(s) must have fill plates <br>- Breaker/fuse panel front working clearance of 30" (76cm) wide x 36" (92cm) deep <br>- Breaker and fuses labeled as to function/area served

-

PREVENTIVE MAINTENANCE REQUIRED / Mantenimiento general a tablero electrico

-

REMOVE ALL OBSTRUCTIONS FROM ELECTRICAL PANEL / Retirar toda obstrucción del frente del panel eléctrico

-

BREAKER AND FUSES SHALL BE LABELED AS TO FUNCTION/AREA SERVED / Identificar circuitos en Espanol e Ingles.

-

CHECK MAIN BREAKER IN BASEMENT AND REPLACE IF REQUIRED ACCORDINGLY WITH MAIN FEEDER / Revisar el totalizador en el sótano este acorde con el calibre de la acometida, cambiar si requiere.

-

WIRE MUST BE LABELED WITH COLOR CODE / Cables deben ser marcados con codigo de colores

-

PANEL NUMBERS NEED TO BE LABELED / Numerar circuitos

-

CORRECT DOUBLE CIRCUITS AND SPLIT IN SINGLE PROTECTED ONES / Corregir doble cableado y separar protegido por breaker independiente

-

REMOVE AND CORRECT WIRE SPLICES IN THE CIRCUIT BOX / Eliminar empalmes en tablero eléctrico

-

INSTALL FILL PLATES IN MISSING KNOCK-OUTS/ Instalar tapas faltantes

-

FREE WIRES MUST BE ISOLATED WITH PLASTIC CAP AND ELECTRICAL TAPE / Cables libres deben estar aislados con capuchon y cinta aislante

-

REPLACE ELECTRICAL PANEL (CERTIFIED/HOMOLOGATED BY RETIE/NEC) / Cambiar el panel eléctrico por panel electrico certificado/homologado de acuerdo a las normas (RETIE/NTC/NEC).

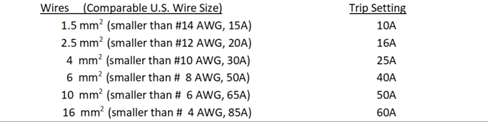

5.4 - Circuit Capacity

-

-

Circuits (conductors and protection) are adjusted according to NEC table 310.16 for insulated conductors and temperature. Also grounded and wired according to NEC tables 250.122 and 310.16

-

review usage and capacity and avoid excessive electrical loads. Verify that the following most commonly used branch circuit connectors in warehouse, business are protected by fuses or circuit breakers having trip elements not larger than:

-

INSTALL CIRCUIT TO DRYER 2X30 AMP. ( 2 PHASES # 10 AWG + NEUTRAL+GROUND BREAKER 2X30 AMP) / Instalar circuito secadora 2x 30 amp (2 fases #10 AWG + Neutro + Tierra. Breaker 2 x 30 Amp).

-

IDENTIFY SIZE AND MATERIAL COMPOSITION OF MAIN ELECTRICAL FEED FROM UTILITY ROOM TO ELECTRICAL MAIN PANEL. / Identificar el calibre y el material de la acometida de alimentación desde el utility o sitio de acometida hasta el tablero principal.

-

REPLACE BREAKER ACCORDING WITH POWER / Reemplaze breaker de acuerdo a la capacidad

5.5 - Electrical - Overall

-

Panel board, pull boxes and devices properly grounded, balanced loads, 20 amp min single phase interruptors and outlets (GFCI included) properly grounded and correct polarity, two and three phases (20, 30, 50 amp) acoording to requirements and wire/protection, all appliances fed thru plug-outlet connection with appropriated flex raceways, light fixtures properly mounted / type, grounded and enclosed. - Any outdoor service entrance, outlets and switch boxes have weatherproof covers

-

INSTALL OUTLET L14-30 TO DRYER (2 PHASES, NEUTRAL, GROUND) / Instalar toma L14 - 30 en toma de secadora (2 fases + neutro + tierra)

-

OUTLETS FLOOR MUST BE MEDIUM TRAFIC OUTSIDE FROM CIRCULATION AREAS, DO NOT ALLOW OUTLETS FLOOR ON WET AREAS /Tomas de piso deben ser de tráfico medio, fuera de areas de circulación, no se permiten tomas de piso en zonas húmedas.

-

REMOVE EXPOSED WIRE AND PANDUIT RACEWAY / Retirar cables expuestos, tomas sobrepuestas y canaletas plasticas.

-

CHECK EXPOSED WIRES OR ELECTRICAL JUNCTION BOXES INSIDE FURNITURE OR CLOSETS / Revisar cables expuestos o cajas de paso electricas dentro de muebles o closets

-

IMPROVE EXPOSED CONDUCTOR IN PLUG / Corregir cables expuestos en clavijas

-

INSTALL WATERTIGHT COVERS / Instalar tapas tipo hidrobox y/o tapa tipo intemperie.

-

GFCI OUTLETS NEAR TO ANY WATER SUPPLY / Tomas GFCI cercana a fuentes de agua o en areas externas.

-

All wall mounted outlets, interruptors, distribution boxes, raceways, pipes and trays must be metal / standard type, grounded, stable and accordingt to standards and specifications. Plastic raceways and mounting pull boxes are not acceptable. Unused devices must be properly dismantled and disposed off.

-

OTHERS / Otros

5.6 - Electrical appliances

-

All present electrical appliances are in good working conditions, have all the original parts and instructions manual. Properly grounded and powered. Include: stove, oven, washer, dryer, freezer, fridge, range hood, ventilation fan, ceiling fan, water heaters (accumulation/flash), HVAC/MSPU, space heaters, any office electrical equipment, any lighting, any workshop electrical tool equipment, etc.

-

OVEN / Horno

-

Power / Potencia

-

CHECK THE ELECTRICAL CIRCUIT AND CONNECTION FROM THE OVEN THAT CUMPLIES WITH THE ELECTRICAL CODE /Revisar el circuito y la conexión elèctrica del Horno que cumpla con la norma y este acorde con la potencia.

-

STOVE / Estufa

-

Power / Potencia

-

CHECK THE ELECTRICAL CIRCUIT AND CONNECTION FROM THE STOVE THAT CUMPLIES WITH THE ELECTRICAL CODE/Revisar el circuito y la conexión eléctrica de la estufa que cumpla con la norma y este acorde con la potencia

-

PREVENTIVE MAINTENANCE REQUIRED / Mantenimiento preventivo requerido a equipos electricos

6 - FALL PROTECTION

6.1 - Railings

-

- Installed on all porches, balconies and raised floor surfaces more than 30" (76cm) above the floor or grade below <br>- Sturdy supports (balusters) with no openings larger than 4" (10cm) and bottom of railing assembly no more than 4" (10cm) from the floor <br>- Top of railing is 42” (107cm) or more from floor or grade level

-

INSTALL RAILGUARDS IN BALCONIES & TERRACES AS REQUIRED / Ajustar la geometría de barandas / barreras permanentes en balcones, terrazas, etc.: altura no menos de 1.07 m de altura, con aberturas menores a 10 cm, no escalables. Considerar la estabilidad y estetica necesarias

-

REDUCE RAILGUARD GAP / Reducir aberturas mayores a 10 cm en baranda balcon

-

OTHERS / Otros

-

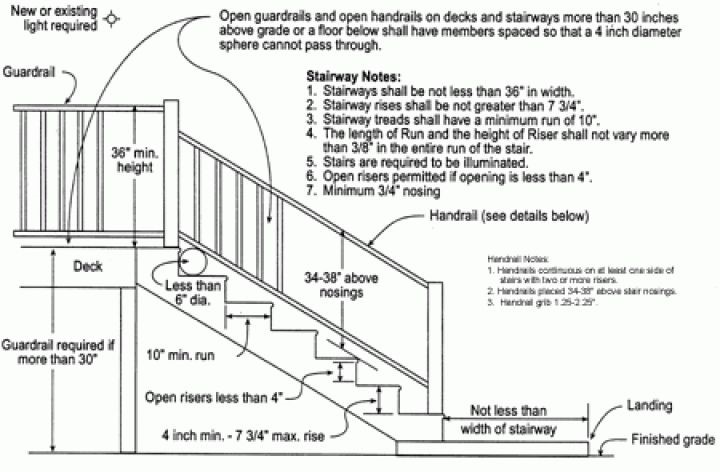

installed handrails, typically for stairways, at 34-38 inches and guardrails at a minimum height of 36 inches (42 inches is recommended) for balconies, decks, elevated patios, and other similar structures. Guardrail installation at business and representational areas open to the public must be 42 inches high. Guardrails are required where the fall would be greater than 30 inches and must not have openings of greater than 4 inches.

-

KEEP FREE SAFETY DISTANCE (3 FT) FROM THE GUARDRAIL TO ANY FOURNITURE / MANTENGA DESPEJADA LA DISTANCIA DE SEGURIDAD (3 FT) DESDE LA BARANDILLA HASTA CUALQUIER MOBILIARIO.

6.2 - Stairs and Handrails

-

-

where there are 4 or more risers (steps), at least one handrail installed (right-side descending preferred) for any enclosed stairway. For stairs open on one or both sides, a handrail is installed on the open side(s). Installed handrails are 34-38” (86 - 96 cm) from the top of the stair tread nosing and can withstand a force of 200 lbs. (91 kg) in any direction. Triangle formed by riser, trad and bottom guardrail element does not allow passage of sphere 152mm (6 in) in diameter.

-

- Steps have evenly spaced risers <br>- Any open risers between steps do not have an opening larger that 4" (10 cm) <br>- For open stairways, supports (balusters) no more than 4" (10 cm) apart

-

INSTALL OR UPGRADE STAIRWAY RAILGUARDS / Instalar o mejorar barandas de la escalera

-

Modificar altura de la baranda horizontal hasta alcanzar una altura mínima de 1.07 m (42'')

-

Modificar la altura de la baranda tramo inclinado hasta alcanzar una altura minima de 92 cm ( 36'') medidos desde la punta del escalon

-

Adicionar barandas en escaleras sin confinamiento con la estética y condiciones necesarias, cuando exista más de cuatro escalones sin cerramiento.

-

Cerrar espacios entre elementos mayores de 10 cm (4'') en barandas

-

Modificar o eliminar escalabilidad de la baranda

-

Estabilizar y/o asegurar las barandas

-

Modificar paso de escaleras en el caso que las contrahuellas presenten aberturas de mas de 10 cm

-

INSTALL OR UPGRADE HANDRAILS AS REQUIRED / Instalar o mejorar pasamanos de la escalera

-

Instalar pasamanos en escalera, preferible lado derecho descendiendo, con altura 86 - 96 cm desde la nariz de los escalones (ancho mayor a 90 cm o con confinamientos laterales / muros / pantallas sin apoyo)

-

Modificar altura de pasamanos altura media entre 86 - 96 cm ( 34" - 38")

-

Instalar pasamanos en escalera separados del muro al menos 3 cm y deben rematar no menos de 11 cm dentro de la escalera

-

OTHERS / Otros

-

IMPROVE STAIRS SURFACE / Mejorar superficie de la escalera

-

INSTALAR PIRLANES / CINTAS ANTIDESLIZANTES EN LOS PASOS / HUELLAS DE LA ESCALERA CON SUPERFICIES RESBALOZAS

-

STAIR RISER HEIGHT MAXIMUM 196 MILLIMETERS(7.75 IN), TREADS MINIMUM DEPTH 254 MILLIMETERS(10 IN) / Altura maxima de la contra huella debe ser de 196 milimetros (7.75 pulg) y la profundidad de la huella de 254 milimetros (10 pulg)

-

STAIRWAYS ARE NOT TO BE LESS THAN 91 CENTIMETERS (36 IN) IN CLEAR WIDTH AT ALL POINTS ABOVE THE HANDRAIL HEIGHT / Las escaleras no deben tener menos de 91 centímetros (36 in) de ancho libre en todos los puntos por encima de la altura del pasamanos

-

SPIRAL STAIRWAY TREADS MUST HAVE A MINIMUM TREAD WIDTH OF 66 CENTIMETERS (26 IN). TREADS SHALL HAVE A MINIMUM TREAD DEPTH OF 254 MILLIMETERS (10 IN) MEASURED AT A POINT 305 MILLIMETERS (12 IN) FROM THE SIDE WHERE THE TREADS ARE NARROWER / Los peldaños de las escaleras de caracol deben tener un ancho de peldaño mínimo de 66 centímetros (26 pulgadas). Los peldaños tendrán una profundidad mínima de peldaño de 254 milímetros (10 pulgadas) medidos en un punto 305 milímetros (12 in) desde el lado donde las huellas son más estrechas

6.3 - Windows Fall Protection

-

- latching device on windows allows opening no more than 4-5” (10-13cm), but window remains operable <br>- Furniture away from windows and railings

-

RESTRICT WINDOWS OPENING MAX. 4" (10 CM) / Restringir apertura de ventanas a maximo 10 cm (4").

-

STABILIZE WINDOW FRAME / estabilizar y/o asegurar marco de la ventana

-

PLACE / Lugar

-

REMOVE FLOWERPOT OR FURNITURE FROM BALCONY / Retirar materas o mobiliario que pueda servir como escalera hacia ventanas de fachada o barandas de terrazas y balcones

6.4 BUILDING COMMON AREAS DESCRIPTION

-

Others

6.5- ROOF ACCESS GUARDING

-

Guardrails 42 inches (1067 mm) in height are provided where appliances, equipment, fans, roof-hatch openings, or other components requiring service are within 10 feet (3048 mm) of a roof edge or open side of a walking surface. The guardrail must prevent the passage of a sphere 4 inches (102 mm) in diameter. The guardrail must extend not less than 30 inches (762 mm) beyond each end of such equipment.

-

ACCESS (LADDERS) FROM EXTERIOR FOR ROOF MAINTENANCE PURPOSES. PROVIDE ADEQUATE CONTROLLED ACCESS ENCAGED ACORDINGLY, INSTALL ADEQUATE RAILGUARDS AND VALID SAFETY MEANS FOR ROOFING ACCESS AND MAINTENANCE / Acceso (escaleras) desde el exterior para fines de mantenimiento del techo. Proporcione acceso controlado adecuado enjaulado en consecuencia, instale protectores de rieles adecuados y medios de seguridad válidos para el acceso y mantenimiento del techo

7 - SWIMMING POOLS

-

REVIEW SWIMMING POOL INSPECTION REPORT / Revisar reporte inspecciones de piscinas

7.1 - Barrier and Safety Equipment

-

- A non-climbable isolation barrier (fence, wall, etc.) ≥ 4 ft. (122cm) minimum height surrounding the pool that prevents direct access from living areas and excludes ancillary activities (e.g., barbecues, bars, ping pong tables). <br>- Self-closing, self-latching, lockable hardware on all access points (gates/doors) with latch release ≥ 54” (137cm) . Alternatively, the latch release can be on the pool side of the gate if ≥3 inches (7.6 centimeters) below the top with no opening >½ inch (1.3 cm) within 18 inches (4.5 cm) of the release. - Rescue equipment available (shepherd’s crook, pole, ring buoy) and in plain view <br>- Depth markings and no diving indicated. Safety rules posted. <br>- First aid kits and emergency communication means <br>- Outlets equipped with Ground Fault Circuit Interrupters (GFCI) and covers <br>- Pool chemicals stored separate from other materials in a cool, dry, ventilated area with restricted access

-

- Swimming pool complies with local regulation as a minimum requirement (Colombia: Ley 1209 - 2008) <br>- Swimming pool has two access points - Two sided accesses with non slippery surface in decks, stairs, sloped ramps, etc.

-

Si la propiedad contiene area de piscina solicitar a la administración el cumplimiento de las normas de seguridad para el uso de piscinas (ley 1209 de 2008) o en su defecto las normas americanas aplicables, entre otras: dos puntos de ingreso, superficies no deslizantes, confinamiento con barreras de no menos de 1.22 m, puertas de ingreso con cierre automático exterior, altura de cerraduras no menos de 1.37 m, equipos de rescate, marcas de profundidad, equipo y plan de asistencia y rescate, instrucciones de uso, control de ingreso y asistencia según se requiera, manejo de equipos y químicos, botón de pánico.

8 - ELEVATORS

8.1 - Elevator & Cabin

-

- All elevator cars have functional doors independent of shaft doors <br>- Elevator doors (car & shaft) reverse direction when an object is either contacted by the leading edge of the door or detected by an electronic door protection device <br>- All external car operating features, lobby controls and hardware are intact and function properly <br>- Car operating buttons, including the emergency alarm button, function properly. <br>- Car lights are on and bulbs or tubes are secure. <br>- Car service panel is locked · car emergency phone is connected to a 24-hour operator and car’s audible signals are operating <br>- All door mechanisms are enclosed to avoid pinch/shear points

8.2 - Machine Room & Maintenance

-

- Machine room access door is locked and keys stored securely <br>- Good housekeeping, no trash, not being used as a storage area, no excessive oil leaks, control cabinet(s) intact <br>- Illumination is adequate to perform inspection <br>- ABC fire extinguisher located in machine room <br>- Temperature is not above 120 degrees F (49 degrees C) <br>- Elevator is under a service contract and service logbook is utilized and up to date

-

Elevator has a current safety certificate

-

EXPIRATION DATE / Fecha de vencimiento

-

SEND LETTER TO BUILDING ADMINISTRATION / Solicitar a la administración la certificación anual al día de los elevadores (resolución 092 de 2014 - FOPAE), la revisión de los componentes comunales de la circulación vertical / elevadores (sistema de alarma, anti-atrapamiento, asistencia por emergencias, etc.), cuartos de máquinas (aseo, mantenimiento, señalización, extinguidores y temperaturas no mayores a 49 Celsius, etc.). Deben ser revisado según programación por personal técnico autorizado y capacitado

-

CARGO LIFT / Elevador de cargas

9 - ENVIRONMENTAL

9.1 - Air Pollution (for level 1 or higher air pollution posts) 2018

-

15 FAM 900 (Pending)

-

- At least 150 m away from major roadway (recommended) <br>- No other nearby air pollution sources [e.g., drycleaner or large fueling station (14M l/year) within 100m] <br>- Property barrier and vegetation (recommended) <br>- Centralized air filtration (otherwise room air cleaners may be needed)

-

Para llevar a cabo la mitigación de la polución del aire se recomienda que la propiedad se encuentre al menos a 150 m de vías principales de circulación vehicular y de otras instalaciones que puedan ser fuentes de polución tales como lavanderías, estaciones de combustible, etc. Que estén dentro de un perímetro de 100m. Se recomienda la mitigación con material vegetal o el uso de filtros y purificadores de aire

9.2 - Asbestos

-

OBO Directive FAC001

-

- Acquisitions: asbestos inspection conducted and impact of asbestos determined<br>- Asbestos materials identified and maintained in good condition<br>- Maintenance and minor renovations avoid disturbance of asbestos materials <br>- If asbestos material is to be disturbed, it is removed properly and records of removal and disposal are maintained -Conduct asbestos inspection and follow recommendations (water store tank and ceiling tiles)

-

Identificar la presencia de asbestos, no perturbar ni modificar nada en caso de hallazgo positivo y dar aviso inmediato para dar el tratamiento requerido de acuerdo con la normatividad vigente

9.3 - Leaded Paint

-

ALDAC 93 State 120625

-

- Only lead-free paint is applied<br>- Paint in good condition with minimal damage <br>- Paint sampled prior to renovation or major maintenance work<br>- Leaded paint removed prior to start of work or minimize disturbance

-

Identificar la presencia de pinturas o recubrimientos con base en plomo , no perturbar ni modificar nada en caso de hallazgo positivo y dar aviso inmediato para dar el tratamiento requerido de acuerdo con las regulaciones

9.4 - Pesticides

-

- Building conditions or location not inviting to common local pests <br>- No history of chronic pest problems or extensive pesticide use 15 FAM 957.2 <br>- Willing and capable to implement Integrated Pest Management (IPM) program in USG occupied space <br>- Habitats and attractants to common pests avoided <br>- Self-help measures to control pests (if control measures are not effective) <br>- Professional pesticides only as a last resort and limited to Department-authorized products -Review and implement trash disposal based on current plan available

-

Realizar procedimientos de control de plagas (hormigas, mosquitos, ratones, cucarachas, lepismas, termitas, gorgojos, comejen, polillas, otros). Dar aviso sobre procedimientos y pesticidas a usar

9.5 - Drinking Water Quality

-

- Tap water is potable (microbiologically safe and within acceptable contaminant levels listed in the Department’s drinking water standards)

-

El agua para consumo humano debe ser potable y debidamente ajustada en calidad de acuerdo con los estandares establecidos. Solicitar a la administracion revisar / corregir / adecuar los depositos de almacenamiento de agua potable incluido el plan de mantenimiento y pruebas de potabilidad

-

If tap water is not potable, then supplemental means (e.g., point of use device such as a distiller) are used to render the water potable and quality control monitoring is done. Water used for bathing water and other contact uses meets recreational water criteria. If supplemental treatment is employed, O&M and QC programs are in place. Unless a lead‐removing POU is employed, water from the main taps is confirmed by testing to have lead levels below 15 ppb

9.6 - HAZMAT AND CHEMICAL PRODUCTS

-

IF HAZMAT CAGES ARE PROVIDED AS PART OF THE INVENTORY, THEY NEED TO BE EVALUATED BY LESSORS WHO, DEPENDING ON THE NATURE OF UPCOMING OPERATION HAZMAT, MUST ACCOMODATE AND ADAPT EACH FUTURE STORAGE. PRODUCT SHALL BE HANDLED, STORED, MOVED , IDENTIFIED, LABELED, CONTROLLED, INVENTORIED AND USED PROPERLY (STORAGE AND MAINTENANCE AREAS). EVERY CHEMICAL PRODUCT SHOULD HAVE MSDS AVAILABLE AND MUST BE MANAGED BY TRAINED PERSONEL ONLY. HAZMAT SHALL BE FULLY ISOLATED FROM POTABLE WATER, FOOD AND OTHER SENSITIVE PRODUCTS FOR DIRECT HUMAN USE. HEALTH RISK AND FIRE PROTECTION / CONTROLS NEEDS TO BE TOP PRIORITY WITH HAZMAT INCLUDYING SECURITY THREATS ASSOCIATED TO THE OPERATION. HAZMAT DISPOSAL SHALL COMPLY WITH RELATED STANDARDS AND REGULATIONS ASSOCIATED TO ENVIRONMENTAL POLICIES. / Si se proporcionan jaulas HAZMAT como parte del inventario, deben ser evaluadas por los arrendadores quienes, según la naturaleza de la próxima operación de materiales peligrosos, deben acomodar y adaptar cada almacenamiento futuro. El producto deberá ser manipulado, almacenado, movido, identificado, etiquetado, controlado, inventariado y utilizado adecuadamente (áreas de almacenamiento y mantenimiento). Todo producto químico debe tener MSDS disponible y debe ser manejado únicamente por personal capacitado. HAZMAT deberá estar completamente aislado del agua potable, los alimentos y otros productos sensibles para uso humano directo. El riesgo para la salud y la protección/controles contra incendios deben ser la máxima prioridad con HAZMAT, incluidas las amenazas de seguridad asociadas a la operación. La eliminación de HAZMAT deberá cumplir con las normas y reglamentos relacionados asociados con las políticas ambientales.

-

ACCORDING TO THE TYPE OF CHEMICAL PRODUCTS STORED, MSDS, SUITABLE AREAS, PROPER VENTILATION, ADEQUATE SHELVES AND CONTAINERS, SURFACES, GROUNDING, WEIGHT, NATURE OF MATERIALS, ETC. MUST BE CONSIDDERED AND PREVENTIVE ACTIONS MUST BE IMPLEMENTED ACCORDINGLY. SPILL KITS, EMERGENCY SHOWERS AND EYE-WASH STATIONS MUST BE PROVIDED IF APPLIES. / De acuerdo con el tipo de productos químicos almacenados, MSDS, áreas adecuadas, ventilación adecuada, estantes y contenedores adecuados, superficies, puesta a tierra, peso, naturaleza de los materiales, etc., se deben considerar y se deben implementar las acciones preventivas correspondientes. Se deben proporcionar kits para derrames, duchas de emergencia y estaciones de lavado de ojos, si corresponde.

10 - SEISMIC ISSUES (FOR POSTS IN SEISMIC ZONES 2 OR HIGHER)

10.1 - Seismic Safety

-

- Seek seismically best available structures in accordance with expectations outlined in 19 STATE 74458 and in collaboration with OBO's Climate Security & Resilience Program -Generators should be securely anchored (ground or slab) at all anchorage points of the frame, and generator connections should be flexible (earthquake resistant). <br>- Propane tanks, kerosene heaters: use flexible connections to the tank and anchor storage tanks to the ground. <br>- Water heaters, propane (LPG) gas cylinders and natural gas: <br>- Use flexible, metallic connections for water and gas lines. <br>- Use metal straps which are bolted using expansion bolts to a masonry wall, or lag bolts to a wood stud wall, at the top and bottom of the water heater and propane cylinders. <br>- Block in space between water heater and wall to prevent rocking tall, <br> -Heavy and tall furniture such as bookcases should be secured to prevent sliding or tipping, using L-brackets or other device and remove casters or wheels to prevent roll. - Ensure cabinet latches are strong enough, especially in the kitchen, to prevent contents from falling out; install safety latches for added security. <br>- Brace and bolt storage racks and shelves to the floor and walls and secure contents so they can’t slide off. -Mini‐split HVAC Units: To prevent tipping, confirm secure<br>anchorage/attachments to all anchorage points for the unit. -Special consideration shall be observed in raised water / other liquid containers, storage shelving and platforms, also in hazmat cabinets and flammable containers. Ceiling tiles intact, undamaged and in place

-

AVOID BUILDINGS BUILT BEFORE 2009 / Evitar rentar apartamentos construidos antes del 2009 (Sin norma NSR 10)

-

INSTALL ADDITIONAL FLOOR SUPPORT TO WALL MOUNTED CABINETS / Instalar bases adicionales a muebles flotados.

-

INSTALL SEISMIC RESTRAINS TO ACCUMULATION WATER HEATER TANKS / Instalar soporte adicional a calentador de agua de acumulacion.

-

STABILIZE OR FASTEN WOOD SHELVES / estabilizar o asegurar entrepaños de madera

-

FASTEN THE OVEN TO CABINET / Asegurar el horno al gabinete

-

CHECK STABILITY TO SINKS. UPGRADE IF REQUIRED. / Compruebe la estabilidad de los lavamanos. Actualice si es necesario.

-

HANG CEILING MOUNTED LIGHT FIXTURES TO INDEPENDENT STRUCTURE / Asegurar lamparas de techo a una estructura independiente.

-

SECURE ALL STORAGE STRUCTURES (RACKS, METAL SHELVES) TO EACH OTHER, TO THE FLOOR AND TO THE WALL TO PREVENT THEM FROM FALLING IN THE EVENT OF EARTHQUAKES, STABILITY MUST BE GRANTED. PROVIDE TECHNICAL DATA SHEET ABOUT CAPACITY AND OTHER RELATED INFORMATION FOR FURTHER USE. CONSIDDER SEISMIC ASPECTS DURING STABILITY ASSESSMENT / Asegurar toda estructura de almacenamiento (Racks, estanterias metalicas) entre ellas, al piso y a la pared para evitar la caida de las mimas en caso de sismos. Se debe otorgar estabilidad. Proporcionar ficha técnica de capacidad y otra información relacionada para su uso posterior. Considerar los aspectos sísmicos durante la evaluación de la estabilidad

-

Solicitar a la administracion el cumplimiento de las regulaciones pertinentes a zonas comunes y planificacion para eventos de manejo de emergencias por eventos sismicos (infraestructura, equipos, planes de evacuacion y atencion de emergencias, etc.) Y la revision periodica de las condiciones antisismicas y de estabilidad de los componentes comunales de la copropiedad.

-

Proposed property should be evaluated in coordination with the OBO Natural Hazards team (OBO/PDCS/DE/CSE) . Colombia is seismically active and many structures were built before the full implementation of seismic standards (NSR 1998 - 2010 Colombia) . The POSHO needs approval from OBO/PDCS/DE/CSE to proceed with the POSHO Certificate for Non- Residential properties. Prepare relevant documentation (MEP, structual plans, ground study, pics, OBO checklist, etc..) and submit available documentation related to the properties seismic conditions to OBO/PDCS/DE/CSE for initial analysis. Documentation includes but not limited to pictures of the structure, MEP, construction materials used, structural & architectural blueprints, structural analisis & design files, etc... / La propiedad propuesta debe evaluarse en coordinación con el equipo de peligros naturales de OBO (OBO/PDCS/DE/CSE) . Colombia es sísmicamente activa y muchas estructuras se construyeron antes de la implementación total de los estándares sísmicos (NSR 1998 - 2010 Colombia). El POSHO necesita la aprobación de OBO/PDCS/DE/CSE para proceder con el Certificado POSHO para propiedades no residenciales. Preparar la documentación pertinente (MEP, planos estructurales, estudio de terreno, fotos, lista de verificación de OBO, etc.) y enviar la documentación disponible relacionada con las condiciones sísmicas de las propiedades a OBO/PDCS/DE/CSE para el análisis inicial. La documentación incluye, entre otros, imágenes de la estructura, MEP, materiales de construcción utilizados, planos estructurales y arquitectónicos, archivos de diseño y análisis estructural, etc.

-

OTHERS / Otros

11 - LOCAL CONSIDERATIONS (List any additional local considerations)

11.1 - Mechanical

-

- All valves are properly identified (gas, potable water/cold/hot, etc.), type and use as required. <br>- All valves are secured with handhole covers, handles provided and functional. <br>- Plumbing fixtures and hardware are properly mounted, rated as required, leak free, stable. <br>- Drain points (floor/sinks/showers/tubs/etc.) are clean, tested and functional.

-

IDENTIFY WATER AND GAS SHUT OFF VALVES ON THE EXTERNAL SURFACE WITH COLORS AND LETTERS IN SPANISH AND ENGLISH / Identificar valvulas de corte de Agua y Gas en la parte externa de la caja registro en letras y colores en Español e Ingles.

11.2 - Dryer vent

-

- Dryer vents to exterior, semi-rigid aluminum duct/rigid galvanized metal sheet duct, fittings, flange, hood and backdraft deflector. <br>- Embed transition lines to exterior are clean and easy to maintain, lint trap free. <br>- Duct is not connected to common or combined exhaust pipes/ducts, difficult to maintain. <br>- Indoor kits with semi-rigid aluminum duct is used in well ventilated areas accepted as last resource.

-

PREVENTIVE MAINTENANCE REQUIRED / Hacer mantenimiento al sistema de descarga de la secadora

-

INSTALL INDOOR KITS WITH SEMI-RIGID ALUMINUM DUCT / Instalar sistema indoor kit con ducto semi-rigido en aluminio.

11.3 - HVAC/MSPU

-

All HVAC and MSPU maintained and in good working conditions, in adequate controlled spaces. Electrical water tight raceway - Direct connection to cover plate pull box, insulation to condens. water and refrig. gas lines - Filters - Cicles - Thermostats, drain lines - Electrical feder and protection acordingly

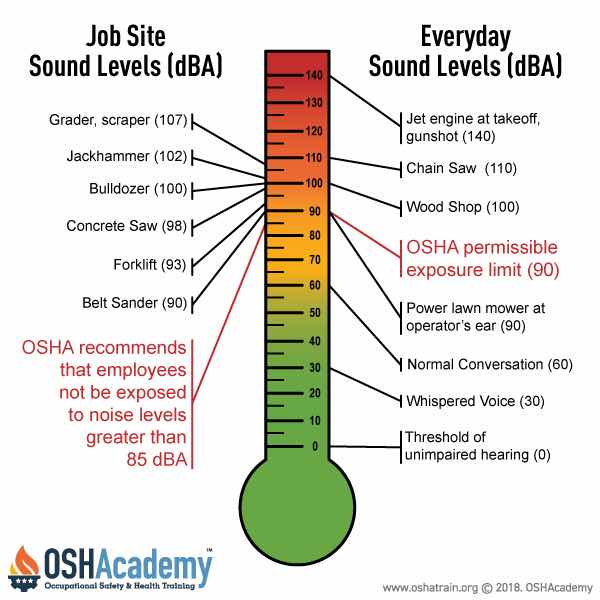

11.4 - Noise Control

-

-

Noise limits are within acceptable limits.

-

Atenuar efectos de polución por sonidos exteriores. Tomar los correctivos necesarios.

-

Noise limits must be within acceptable limits. Max: 45 dBA / Living areas, 55dBA / Offices. 85 dBA/8hours exposure as max. limit. Noise control means shall be implemented as needed

11.5 - Anti panic door locks

-

Exit doors, bedroom doors, walk in closets, storage rooms, hallways and other interior access doors are provided with key-free locking systems. Exits thru common stairways are anti-panic or key-free lock system provided.

-

INSTALL INSIDE KEY FREE LOCK MECHANISMS / Suministrar manejos de cerradura tipo antipánico en puertas de seguridad de acceso e internas, alcobas, vestieres, corredores, depósitos, etc., libres de apertura con llave por la parte interna

-

INSTALL OR MODIFY INTERNAL DOOR LOCKS (NOT INCLUDE SECURITY DOORS), CLOSETS, SO THAT THEY CAN BE OPENED FROM OUTSIDE WITHOUT THE USE OF KEYS (BATHROOM TYPE) / Suministrar / modificar cerraduras de puertas internas (no incluye puertas de seguridad), vestieres, corredores, baños, etc., de manera que puedan abrirse desde afuera sin el uso de llaves (tipo baño)

11.6 - CONFINED SPACES

-

Confined spaces such as water reservoir, areas under stairways, small mechanical rooms, etc. must be labeled, controlled and secured. Maintenance, monitoring, operartions or any other associated access required must follow related safety procedures and protocols

11.7 - Hardware & Locks

-

All carpentry and millwork hardware, includying handles, doorknobs, hinges, bearings, latches, locks are in good working conditions, smooth and adjusted and accomplish for the use they're inteneded for.

11.8 - Drapery

-

Tie hooks (cleat type), pulleys or alike are provided and mounted to control drapery cords and strings long / loose hanging ends.

-

Instalar cornamusas / tensores / argollas, etc. Para asegurar manejos de cortineria. Opcional, cintas de sujecion (en velcro o similares) adheridas a los manejos mismos para el enrollamiento de los excedentes sueltos

11.9 - Special provisions

-

IT IS RECOMMENDED TO CHANGE THE TOILET FOR A WATER SAVING TYPE (HIGH EFFICIENCY / WATER SENSE ) OF A LOCALLY RECOGNIZED AND COMMERCIAL BRAND WITH LOCAL PARTS AND WARRANTY SERVICE, IN ORDER TO LOWER CONSUMPTION OF WATER / Se recomienda hacer cambio de sanitarios a tipo ahorrador (alta eficiencia) de marca reconocida y comercial, con el fin de bajar el consumo de agua potable

-

IT IS RECOMMENDED TO CHANGE ELECTRIC AND GAS APPLIANCES FOR ENERGY SAVING TYPE OF A RECOGNIZED BRAND AND THAT IS COMMERCIALLY AVAILABLE WITH LOCAL PARTS AND WARRANTY SERVICE AVAILABLE IN ORDER TO REDUCE THE CONSUMPTION OF ENERGY AND FUEL GAS / Se recomienda el cambio de electro y gasodomésticos de marca localmente reconocida y comercial, por aparatos de tipo ahorradores de energía con el fin de reducir el consumo de energía y gas combustible

-

REPLACE METAL HALIDE ARTIFICIAL LIGHTING SYSTEM THROUGH ADDITIONAL LED LIGHTING, ETC., SO THAT THE MINIMUM LUX LEVELS RECOMMENDED (APPROX 100-300 LUX) ARE MAINTAINED DEPENDING ON THE AREAS / Mejorar el sistema de iluminación artificial del apartamento mediante luminarias adicionales, etc., de manera que se mantengan los mínimos recomendados (aprox 100-300 lux) dependiendo de las áreas de que se trate

12 - SPECIAL GUIDELINES

-

Item 2.3 of the inspection report, this property does not comply with OBO fire egress standards (See OBO/OPS/FIRE, Fire Protection Guide, and Residential Fire Protection section E-1). - Please have DCM acknowledgement to continue leasing action and OBO Mitigation response in the RPA leasing file - Please send pre-formatted letter to Building Administration regarding Testing requirements of installed fire protection systems

-

Item 7.1 requires swimming pool compliance as indicated by local law (LEY 1209 DE 2008 – Resolución 4113 de 2012 – Decreto 554 de 27 Marzo 2015). - Please send pre-formatted letter to Building Administration and Landlords regarding pool compliance and deficiencies. - Specific deficiencies are also attached to this email

-

Item 8.1 and 8.2 requires current valid certification of compliance for elevators as indicated in local law (Acuerdo 470 de 2011, Decreto 663 de 2011, Resolución 092 de 2014 FOPAE, Resolución 221 de 2014 FOPAE). - Please send pre-formatted letter to Building Administration regarding elevator certification requirements.

Please inform Office of Facility Management when the apartment is ready for the Certification Inspection.

-

FAC MANAGER / POSHO OFFICER

-

DEPUTY FAC MANAGER / POSHO OFFICER

-

FAC INSPECTOR / POSHO ASSISTANT

-

FAC ELECTRICAL TECHNICIAN