Information

-

Document No.

-

Audit Title

-

Client / Site

-

Conducted on

-

Prepared by

-

Location

-

Personnel

Site safety inspection checklist audit form.

-

What worksite vessel or terminal?

- Queen of Alberni

- Queen of New Westminster

- Coastal Celebration

- Coastal Inspiration

- Coastal Renaissance

- Spirit of British Colombia

- Spirit of Vancouver Island

- Tsawwassen Terminal

- Swartz Bay Terminal

- Tsawwassen Terminal Maint.

- Sidney Terminal Terminal Maint.

-

Which department?

-

Purpose

-

The site safety checklist is sent to the occupational managers /directors to prepare them for the annual site safety inspection and audit conducted by the occupational safety and health team.

When completed the checklist will form a part of the work site inspection records available to work safe BC to support the ongoing functions of the occupational safety and health program.

General duties of the employer and workers

-

Do workers know their responsibilities under the act?

-

Are the workers aware of the right to refuse unsafe work?

-

Workers know where to obtain the OSH Regulations and Act?

Joint safety and health committees

-

Are the workers aware of the posting of minutes for site safety committee?

-

Are the workers are aware of current committee members for site safety?

-

Is there a posted meeting schedule for the site safety committee ?

-

As the site safety committee posted inspection reports?

-

Are the duties and the roles of the site safety committee posted?

Site safety committee inspection and departments.

-

Does the catering department provide inspection reports to the site safety committee?

-

Does the deck department provide inspection reports to the site safety committee?

-

Does the engineering department provide inspection reports to the site safety committee?

Risk assessed level of service

-

Are there procedures for summoning first aid?

-

Are the first aid procedures posted?

-

Is the OFA and the supervisor aware of the AED download and EMK procedures?

-

Are the eyewash stations appropriately checked?

-

Is the OFA room in good order?

-

Is the OFA first aid inventory current?

Records and reports

-

Are records and reports properly maintained for investigations and joint committee minutes?

Competencies

-

Is there adequate instruction and training to conduct job the job safely?

-

Are the ER competencies properly maintained by the workers?

-

Does the supervisor routinely check The Medbook Competencies?<br>

-

Are there competencies out of date?

-

Are there adequate checklists for the orientation and familiarization and training of employees?

New and young workers

-

Has the new worker been orientated in the location of first aid and how to summon first aid and reporting of accidents?

-

Has the new worker been orientated in evacuation plans?

-

Has the new worker been orientated in emergency procedures?

-

Has the new worker been orientated in personal risk assessments and the alert handbook training?

-

Are there written instructions available to all workers specifically SOP's for each worksite and access and knowledge of EFleet documents?

Manuals and information

-

Are the workers aware of operational manuals and their location?

Prevention of violence

-

Are the workers aware of violence in the workplace training and prevention techniques and reporting requirements?

-

Are the workers aware of violence in the workplace training material on the BC Ferries Academy site?

Ergonomics

-

Are the workers aware of how to ask for an ergonomics study specific to their work environment?

-

Are the workers aware of muscular skeletal injury prevention techniques?

-

Are the workers aware of information available on the BCFerries Academy site for muscular skeletal injury prevention?

WHMIS & MSDS

-

Have the workers received WHMIS training this year?

-

Have the workers received MSDS training this year?

-

Are the workers are aware of proper labeling process with products used on the vessels?

-

Are the workers aware of using proper protective measures when dealing with products used on the vessels?

Biological hazards

-

Are the workers aware of specific exposure control plans for HIV , hepatitis , avian flu , Norwalk and mould?

-

Are the workers aware of flu vaccination programs?

-

Are the workers aware of PPE required and response plans for biological hazards?

Chemical hazard identification

-

Are the workers aware of the signage for identifying asbestos on a vessel?

-

Do the workers have a common knowledge of exposure risks notification process protective measures and policy knowledge for chemical hazard identification on the vessel?

-

Does the worker have knowledge of an insulation survey for the vessel?

-

Is the worker aware of where they can obtain exposure control plans for chemical hazard identification?

Physical hazards

-

Is the worker aware of the current noise survey for the vessel?

-

Does the worker know where to obtain the current noise survey for the vessel?

-

Is the worker aware of heat stress plans for the vessel during hot periods?

-

Is the worker aware of thermal cold plans for the vessel during winter months?

Hearing conservation program

-

Are workers aware of noise surveys identifying risk for workers in the workplace?

-

Have workers been properly educated in the correct use of hearing protection PPE?

Personal protection equipment

-

Are workers adequately instructed in the use of personal protective equipment?

Respiratory fit program

-

Are the workers adequately instructed in the use of respirators?

-

Are workers aware of the current filters available for the condition for Respirator use?

-

Are workers knowledgeable in clean-shaven policy for respirator use?

-

Does the supervisor have a log for drill records on respirator use?

-

Can supervisor produce a log for SCBA inspections?

-

Can the supervisor produce a log for the inspections of fire suits?

-

Can the supervisor produce a log for the inspections of fire helmets and equipment?

Confined space

-

Can the supervisor produce a list of confined space inventory?

-

Is the confined space inventory up-to-date?

-

Can the supervisor produce written procedures for all confined space on the vessel?

-

Can the supervisor produce confined space rescue plans?

-

Can the supervisor produce a drill log for confined space?

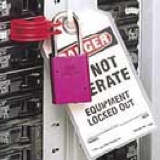

Lockout and Denergization and electrical safety

-

Have the workers received training and information and written procedures for electrical safety?

-

When was the most recent training for lock-out safety?<br>

-

Can the workers produce their personal lockout ?

Fall Protection

-

Do the workers understand the height at which fall protection must be adopted?

-

Are the workers knowledgeable regarding fall protection procedures in place?

-

Has there been any recent fall protection training on the vessel?

-

Can the supervisor produce a proper checklist for the fall protection equipment?

-

Is the fall protection equipment in good order?

Tools , Machinery and equipment

-

Are the machinery guards in place?

-

Is the welding equipment and cylinders properly secured?

-

Is the welding equipment properly turned off and pressure relieved from the equipment?

-

Has the flammable liquids paint thinners etc. been properly stored in a flammable liquid locker?

Ladders and scaffolds and temporary work platforms

-

Can the supervisor produce a proper ladder log checklist?

-

Have the ladders been inspected recently?

-

Have any of the moving platforms been inspected recently?

Mobile Equipment

-

Can the van driver produce the equipment checklist for the mobile tugger?

-

Can the supervisor produce inspection logs for the mobile Tugger?

Traffic control training and equipment

-

Are the workers aware of the current traffic variance?

-

Do the workers know the required PPE for directing traffic on deck?

-

Do the workers know the required PPE for directing traffic on terminal?

Diving fishing another Marine operations

-

Are there current records and checklists for past diving operations?

-

Do the records include notice of project for work safe BC?

Evacuation and rescue plans

-

Are there current records for evacuation drills on vessels?

-

Do workers know their muster stations?

Other

-

Is the housekeeping in good order on the vessel?

-

Are the storage lockers properly labeled?

-

Are the fire extinguishers expiring within six months?

-

Are the potable water hoses off the ground?

-

Are the tuggers and dollies in good condition?

-

Is the van driver aware of baggage handling techniques ?

-

Are workers aware of punt boats and working over water?

-

Do Engineering Workers bump test their Drager units daily?

-

Do engineering workers understand how to recalibrate their Drager unit?

-

Are supervisors in engineering aware of the video training at the BC ferries Academy site?

-

Are supervisors and workers aware of the multigas NO2 expiry dates on the calibration gas?

-

Are all Medbooks properly displayed?

-

Is the safety matters info board installed?

-

Are SailSafe action plans readily available?

-

Are workers aware of the hats material or Asbestos program?

-

Are workers aware of the waste sewage handling program?

-

Are workers aware of the training and safe work practices for both asbestos program and waste sewage handling program?

-

Have notice of deficiency forms been issued?

General comments

-

Comments

-

Supervisor

-

Safety officer

-

Select date