Title Page

-

SWMS No

-

Conducted on

-

Prepared by

-

Location

My Company Details

-

Business Name:SA express painting service

-

Business Address:80 Springbank blvd burton SA 5110

-

Business Contact:Bashir Hussaini

-

Business #:painting

-

Phone No:0415401213

SWMS APPROVAL

-

SWMS APPROVED BY: (Employer/PCBU/Director/Owner)

-

SWMS amendments must be approved by

Person

-

Person/s Responsible for Reviewing the SWMS:

-

Name and Signature:

-

Date:

-

Name and Signature of person responsible for ensuring compliance with SWMS:

-

ALL PERSONS INVOLVED IN TASK MUST HAVE THIS SWMS COMMUNICATED TO THEM PRIOR TO WORK COMMENCING:

- Daily Tool Box Talks will be undertaken to identify, control and communicate additional site hazards.

- Work must cease immediately if incident or near miss occurs. SWMS must be amended in consultation with relevant persons.

- Amendments must be approved by nominated persons and communicated to all affected workers before work resumes.

- SWMS must be made available for inspection or review as required by WHS legislation.

- Record of SWMS must be kept as required by WHS legislation (until job is complete or for 2 years if involved in a notifiable incident). -

Select to acknowledge the above has been read and understood

Relevant Workers

Relevant workers must be consulted in the development, approval and communication of this SWMS.

-

Workers to be consulted:

Worker

-

Name and Signature:

-

Job Title:

Part 1: Principal Contractor Details

Principal Contractor details

-

The builder or the organisation you are working for.

-

Principal Contractor Company Name:

-

Project Name:

-

Job Address:

-

Project Manager Name and Signature:

-

Date SWMS provided to Principal Contractor:

High Risk Construction Work & PPE

SWMS Scope

-

SWMS SCOPE: This SWMS covers general painting procedures using ladders, scaffolding, trestles, hand tools, power tools, spray gun and working near mobile plant.

-

Document #: 10183

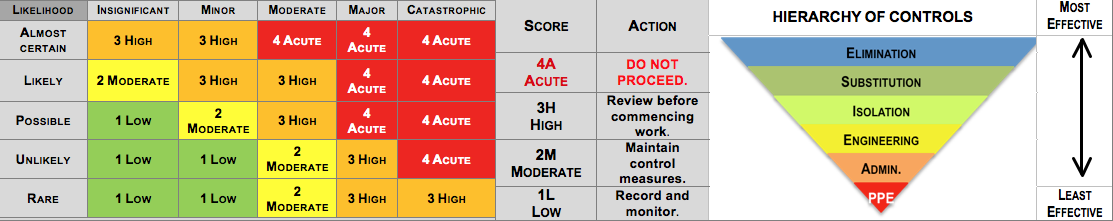

Risk Assessment Matrix & Controls

Personal Protective Equipment (PPE)

-

Ensure all PPE meets relevant Australian Standards. Inspect and replace PPE as needed.

-

Foot Protection

-

Hearing Protection

-

High Visibility

-

Head Protection

-

Eye Protection

-

Face Protection

-

Hand Protection

-

Breathing Protection

-

Protective Clothing

-

Fall Arrest

-

Sun Protection: Broad brimmed hat, UV rated clothing, SPF 30+ sunscreen, tinted safety glasses with adequate UV protection

-

Rings, watches, jewellery that may become entangled in machines must not be worn. Long and loose hair must be tied back.

JOB STEP 1. Planning and preparation

Potential Hazard: Lack of consultation may lead to potential outcomes for personal injury, property damage &/or environmental incident.

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· Liaise with Principal Contractor to establish the following on-site systems and procedures are in place and take note of:

o Health and Safety rules

o Induction for all workers - site specific and toolbox meetings

o Supervisory arrangements

o Communication arrangements

o All relevant workers are appraised for required competencies & for any pre-existing medical conditions if working in remote or isolated locations

o PPE required

o Site plans - showing no go zones for pedestrians

o Traffic Management Plan

o Exclusion Zones

o Risk Assessments

o SWMS and JSA's

o Injury reporting procedures

o Hazard reporting procedures.

Existing premises (commercial or private residence).

· Liaise with client to determine whether:

o Electrical devices, power points, switchboards etc. are in a safe condition and RCD protected

o Commercial premises - establish that the following on-site systems and procedures are in place:

" Site-specific induction including emergency procedures

· Consultation in relation to hazards and risks. Ensure:

o Consult with the person you are carrying out the work for on the potential hazards and risks associated with the task

o If represented by an elected Health and Safety Representative (HSR), they must be included in any consultation

o Any other persons on site who are affected by the same matter are consulted and co-operative arrangements are made

o Document consultation and action items

· It is advised that information be provided to client to advise them of the following:

o Excess clutter to be removed (if applicable)

o Sharps will not be collected and work will not proceed if sharps are observed (include other prohibited items as necessary)

o If safety shoes/boots are required for work they may need to be worn inside. Ensure work shoes are clean and acceptable to wear inside if needed

o Cash and any valuables must be removed from easily visible/accessible areas

· Animals must be secured / removed. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Contact with hazardous materials

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· Seek information from a competent person regarding the presence of lead and/or asbestos.

* If there is a presence of lead and/or asbestos, for this task, ensure there are separate, dedicated SWMS and that all workers/employees have relevant training and licensing. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Heritage breach

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· Ensure permits associated with Heritage Listed buildings are available on site. -

Risk-Rating (RR) after control measures have been put in place

-

Person responsible to implement control measures:

JOB STEP 2. Training and capabilities

Potential Hazard: Lack of training or the assessment of capability may lead to personal injury, property damage &/or environmental incident.

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

* Check workers are in fit condition to work i.e. no signs of fatigue, alcohol or drugs.

· Ensure all persons entering site have a General Construction Induction Card (white card)

· Ensure all relevant workers have undertaken training and/or received instruction in the use of control measures. Include:

o All workers are trained in this SWMS

o Correct use of equipment including selecting, fitting, use, care of and maintenance

o Use of supervision where required (e.g. new starters or new equipment)

o Using hazardous chemicals/atmospheres

o Material/Safety Data Sheets (M/SDS)

o Ensure supervisors, foremen etc. are suitably experienced in the type work to be conducted. -

Risk-Rating after control measures have been implemented

-

Person responsible to implement control measures:

JOB STEP 3. Transporting plants & equipment

Potential Hazard: Environmental incident/spills

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· Ensure all chemicals container lids are securely fitted

· Secure so paints cannot move / become damaged / spill during transit. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Struck by moving objects

-

-

CONTROL MEASURES TO REDUCE RISK

· Ensure to isolate main vehicle cabin from carrier area with a fixed barrier or transport paint and equipment on a trailer / tray back

· Secure so paints / equipment cannot move during transit. -

Risk-Rating before control measures have been implemented

-

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Injury to public / property damage

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· Ensure ladders/planks/scaffolding components are well secured to the transport vehicle:

o The overhang of horizontally stored ladders/planks beyond the support points of the rack should be minimised

o The support points should be constructed of material such as wood or rubber-covered pipe to minimise the effects of vibration, chafing and road shock

o Securing the ladder/planks to each support point will greatly reduce the damaging effects of road shock

o Ensure the vehicle is suitable for the type and size of the ladder/planks

o The ladder/planks must be restrained to prevent unacceptable movement during all expected conditions while in transit:

" The load restraint system must meet the Regulation Performance Standards (see relevant authority)

" Check with the relevant authority on the rules and regulations on attaching warning devices on long loads

* A ladder rack attached to your work vehicles is the best tool for the job

* Secure the ladders/planks/scaffolding components to the rack so that is has no chance of falling from the vehicle and can protect the ladder / planks from damage, and other commuters on the road while in transit.

· Walk to the side of the vehicle to see how well centered the ladder/plank is from front to back

· Adjust the ladder/plank so that the majority of its length is centered directly above the truck from front to back

· Tie a red flag (at least 300mm x 300mm) on the end of any ladder/plank that extends beyond the rear of the vehicle

· If transporting at night, ensure ladder / plank that extend beyond the vehicle > 1m have a red warning light or two reflectors attached to the end of the ladder

* For ladders/planks that extend beyond 1m of the front or rear of the vehicle, check your state regulations for specific allowable overhangs

· Slide the ladder/plank to the side of the ladder rack if additional ladders will be loaded

· Load each additional ladder in the same manner as the first

· Tie each side of each ladder / plank to the frame of the ladder rack using appropriate tie down method (e.g. straps)

· Ensure strap are placed over the sides of the ladders / planks and in between the rungs of the ladders to keep extension ladders from moving forward or backward. -

Risk-Rating (RR) after control measures have been put in place

-

Person responsible to implement control measures:

JOB STEP 4. Arrival at site - loading / unloading

Potential Hazard: Adjacent to road/powered mobile plant movement

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· Park working vehicle in driveway or allocated parking to avoid travelling across roads when delivery working equipment

· If setting up roadside - comply with local laws and permits

· Erect any barriers & signage necessary to keep others safe and aware

· Check constantly for changing hazards while working and monitor work position at all times. Ensure:

o High visibility clothing worn at all times

o Do not stand behind reversing vehicles

o Allow sufficient distance from plant during operation (allow sufficient room for equipment failure - such as arm/boom failure or plant rollover)

o No work is conducted in established "no go zones" for pedestrians

o Alertness at all times. Listen for:

" Reversing alarms/beepers " Calls from Plant Operators

o Safety/warning signs, Spotters, traffic barriers etc. must be obeyed as required

o Work positions should be in clear sight of plant operators

o Follow traffic management plan requirements

o NOTE: Some traffic management plans may say that pedestrians have right-of-way. Never assume this. Make visual and verbal contact with plant operator as required. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Personal injury, property damage &/or environmental incident.

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· Assess conditions at site on arrival. Ensure:

o Ensure site-specific induction is undertaken (include location of amenities, first aid facilities, emergency plans & evacuation points, communication, contact persons etc.)

o Assess mobile phone reception

o Work site is exactly as detailed in Terms of Agreement or contract

o Suitable access for all equipment required

o Suitable space for operation of equipment

o Suitable lighting, including night-works

· Conduct risk assessment to identify potential hazards such as:

o Work at heights (above 2m)

o Lighting

o Ventilation

o Presence of hazardous materials such as asbestos, lead, silica etc.

o Location of existing services (heating, water, pipes, electrical leads)

o Dust

o Temperature etc.

o Exposed electrical switchboards/power points

o Duration of manual handling tasks (such as working with arms above shoulder height). -

Risk-Rating (RR) after control measures have been put in place

-

Person responsible to implement control measures:

JOB STEP 5. Work area set up

Potential Hazard: Fire

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· DO NOT smoke during re-fuelling

· Ensure re-fueling is undertaken in well-ventilated area, clear of ignition sources

· Ensure fire extinguisher available and in date.

Diesel: Fire extinguisher - Water, foam, dry chemical powder, CO2

Unleaded petrol: Fire extinguisher - Dry chemical powder, foam, CO2. Never use water to extinguish an Unleaded Petrol fire.

-

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Contact with electricity

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· Avoid breathing vapours or contact with fuel

· If clothing is splashed with fuel, change immediately

· Do not siphon or swallow fuel as this can be fatal

· Do not eat, drink or smoke during/after-handling fuel until hands are carefully washed

· Shower and wash immediately after work. Wash clothes in separate wash from other clothes. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Property damage / injury to other worker/public

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· Ensure training in emergency response for chemical spill. Emergency response -fuel spill:

1. Stop the source of the spill or leak or release

a. If that is not possible & it is safe to do so - stop the spill or release from spreading

2. Turn off any ignition sources if safe to do so

3. Use gravel or other material to stop fuel entering drains/water courses

4. Clean up spill as required. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Falls from height

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· Ensure training in emergency response for chemical spill. Emergency response -fuel spill:

1. Stop the source of the spill or leak or release

a. If that is not possible & it is safe to do so - stop the spill or release from spreading

2. Turn off any ignition sources if safe to do so

3. Use gravel or other material to stop fuel entering drains/water courses

4. Clean up spill as required. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Falling objects

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· Ensure training in emergency response for chemical spill. Emergency response -fuel spill:

1. Stop the source of the spill or leak or release

a. If that is not possible & it is safe to do so - stop the spill or release from spreading

2. Turn off any ignition sources if safe to do so

3. Use gravel or other material to stop fuel entering drains/water courses

4. Clean up spill as required. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Slips, trips & falls on the same level

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· Ensure training in emergency response for chemical spill. Emergency response -fuel spill:

1. Stop the source of the spill or leak or release

a. If that is not possible & it is safe to do so - stop the spill or release from spreading

2. Turn off any ignition sources if safe to do so

3. Use gravel or other material to stop fuel entering drains/water courses

4. Clean up spill as required. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Noise

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· Ensure training in emergency response for chemical spill. Emergency response -fuel spill:

1. Stop the source of the spill or leak or release

a. If that is not possible & it is safe to do so - stop the spill or release from spreading

2. Turn off any ignition sources if safe to do so

3. Use gravel or other material to stop fuel entering drains/water courses

4. Clean up spill as required. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Lifting/carrying & setting down - Muscular stress/musculoskeletal disorder (MSD)

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· Ensure training in emergency response for chemical spill. Emergency response -fuel spill:

1. Stop the source of the spill or leak or release

a. If that is not possible & it is safe to do so - stop the spill or release from spreading

2. Turn off any ignition sources if safe to do so

3. Use gravel or other material to stop fuel entering drains/water courses

4. Clean up spill as required. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Outdoor work/damp

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· Ensure training in emergency response for chemical spill. Emergency response -fuel spill:

1. Stop the source of the spill or leak or release

a. If that is not possible & it is safe to do so - stop the spill or release from spreading

2. Turn off any ignition sources if safe to do so

3. Use gravel or other material to stop fuel entering drains/water courses

4. Clean up spill as required. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Contact with hazardous chemicals/substances/atmospheres

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· Ensure current Material/Safety Data Sheets (M/SDS) are obtained for all hazardous chemicals/substances and accessible on site

· PPE as prescribed in M/SDS for decanting is provided and used

· Ensure suitable respiratory protection & cartridge is selected as directed in M/SDS, inspect:

o Filters, seals, and valves

o Ensure filter and respirator are compatible

o Ensure respiratory equipment is regularly cleaned and maintained

o Inspect PPE for any sign of damage

o Replace filters if damaged, when resistance increases and as per manufacturer's instructions

Small spills:

o Shut off all possible sources of ignition

o Contain using sand and earth to prevent runoff into drains and waterways

o Collect and seal in properly labelled drums for disposal

o Ensure adequate ventilation

· For larger spills:

o Contain, take up with inert absorbent material (e.g. sand, soil)

o Place in secure labelled containers for disposal. -

Risk-Rating (RR) after control measures have been put in place

-

Person responsible to implement control measures:

JOB STEP 6. Mixing Paints

Potential Hazard: Muscular stress/musculoskeletal disorder (MSD)

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· Wear gloves. Do not use bare hands to clean or pack up equipment

· Check for damage and follow procedure for damaged equipment. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Exposure to hazardous chemicals/substances: occupational asthma, skin sensitisation, respiratory diseases, cancer

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· Return all rigging to stowed location

· Lock lift arm into safe travel position

· Ensure lifting attachment is secured for travel

· Retract and stow outriggers for travel

· Inspect plant for signs of malfunction (such as hydraulic leaks) and report as required. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Working with hand & power tools

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· Ensure leads are not damaged - along the entire length of the lead and extension lead

· Ensure all equipment and leads are tested and tagged as required for use

· Do not use electrical equipment in wet or damp areas

· Do not operate power tools in explosive atmospheres (i.e. presence of flammable liquids, gases or dust)

· Ensure operations manual is available, read and understood

· Pre-inspect and operate power tools as per manufacturer's instructions

· PPE worn as manufacturers recommendations

· Ensure equipment rated for atmospheric requirements (water, or explosion-proof for flammable zones)

· Ensure tool suitable for task:

o Suited to the material. E.g.: steel, wood, MDF, masonry

o Not too powerful for task. E.g.: don't use larger tool than needed

o Sufficient power for task - excessive force not required

· Safety Devices:

o Low impact tools where possible

o Single operation when trigger pressed

o Guards in place, undamaged, retracts and cover danger areas

o E-stops and other devices functional and tested

· Ensure tools are not carried in pockets or clothing (use sheaths, tool belts, etc.)

· Tool handles:

o Non-slip, good grip

o No sharp edges

o Guards or stoppers

o Clean, grease-free grips/handles. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Public and other worker safety

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· Remove all non-essential persons from area

· Barricade area and place caution signs as needed. -

Risk-Rating (RR) after control measures have been put in place

-

Person responsible to implement control measures:

JOB STEP 7. Surface preparation & painting (including sanding, caulking & patching)

Potential Hazard: Falls

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· Access ladders:

o Use only access provided, do not climb on railings or other scaffolding components

o Use only ladders provided for access to scaffolds

o When on a ladder, do not over-reach. Descend ladder & re-position as required

o Do not carry materials when ascending/descending a ladder

o Always face ladder when using

o Do not use step ladders to gain extra height

o Remove ground level ladder when unattended to prevent unauthorised access

o Only competent scaffolder to make changes to scaffold:

" Do not remove any scaffold component e.g. handrails or boards

" Do not remove scaffold ties to support structure

· Mobile Scaffold:

o Level, plumb

o Casters locked before accessing, not moved when persons on scaffold

o Accessed by internal ladder only, do not climb on scaffold

o Clear of penetrations or floor edges (by at least 1metre where possible)

o Do not use steps or ladders on top of the work platform to gain extra height

o Do not move the scaffold with persons or materials on it.

o Before moving the scaffold ensure that it is clear of obstructions, both overhead and, at ground level

· Trestle scaffold:

o Guardrails, toe board sides & ends are in place

o Erected as per manufacturer's specifications

o Purpose-designed pins

o Min 2 planks or 450mm wide

o Suitable span of plank (based on thickness). Example: Thickness of 38mm = 1.5m span, Thickness of 50mm = 2m span, Thickness of 63mm = 2.5m span)

· Platform ladder:

o Ensure industrial rating

o Non-slip treads

o Trestle back undamaged

o Suitable height hand rail (900mm)

o Triangular flat plate bracing

o Correct size for job (platform level)

o Large feet with non-slip mouldings

o If unfolding type, chains, rivets etc. are undamaged and functional

o Non-slip platform of sufficient strength for persons, tools and equipment. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Falls in opening

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· Holes or other openings through which a person can fall. Ensure:

o All holes or openings are protected/closed from falls immediately after creating (e.g. platform ladder hatches)

o Ensure the cover is secured to prevent movement

o Use signage or other clearly marked hazard alert to identify hazard. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Falling objects

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· Maintain awareness of other people on scaffold

· Do not exceed the specified Safe Working Load of the scaffold

· Stack items to prevent sliding or toppling

· Use tether on tools/equipment where appropriate to prevent object falling

· Keep tools and other equipment away from edges

· Determine where items may fall (in case of uncontrolled release) and ensure all personnel are clear of that area

· Never work directly below other workers or where equipment is being placed above

· Use tool lanyards to pass tools to persons at height and ensure tools cannot fall onto workers below

· Ensure kickboards installed on elevated work areas to prevent tools falling off. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Use of hand/power tools

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· Refer to step 6 (Working with hand & power tools) for controls. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Air under pressure

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

* Using high-pressure air can cause serious injury

* NEVER use compressed air for blowing dust off skin or clothing

* NEVER point the air hose at persons, or use to clean clothing, shoes, or any part of the body. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Fluid under pressure

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· Ensure:

o Spray gun hoses are routed as straight as possible to avoid kinking

o Any water condensate is drained from the compressed air system

o Satisfactory pressure for the operation of the spray gun

o Spray gun is held perpendicular to the surface area being sprayed at all times, with the airline held back away from the item

o Work arranged to minimise exposure. Be aware of wind direction, avoid spraying into wind (rotate work - not operator)

o Staggered work positions to avoid overspray of the operators

o Spray gun pointed only at the work - never at yourself or another person

o Spraying is not done in upward direction, as this directs spray into breathing zone and face. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Contact with electricity

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· Locate and maintain awareness aware of any power lines when working on ladders/trestles

· Locate and maintain awareness aware of any extension leads. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Repetitive, sustained tasks

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· Avoid overreaching

· Job rotation

· Sufficient breaks

· Take regular breaks

· Do not overreach

· Maintain good posture avoiding awkward twisting and side bending

· Practice stretching throughout the shift

· Use alternate arms for painting, and direction of painting strokes (vertical/ horizontal) when possible

· Ensure tool handles have extendable handles

· Refer to steps 5 & 6 (Lifting/carrying & setting down - Muscular stress / musculoskeletal disorder (MSD) for further controls. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Debris/dust

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· Ensure eye, breathing protection and protective clothing is worn. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Slips, trips & falls on the same level

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· Ensure:

o Non slip foot protection are worn

o Secure footing

o Safe access and egress

o Sufficient lighting

o Free of excess material

o Complete visibility of work area.

· When using plastic to protect floor surfaces cover the plastic with drop sheets, wet plastic will become very slippery. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Caulking & patching products

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· Follow directions of use

· Consult M/SDS for the product

· Use PPE as per the product safety sheet

· Use with adequate ventilation

· Chemical resistant gloves for prolonged exposure. -

Risk-Rating (RR) after control measures have been put in place

-

Person responsible to implement control measures:

Site specific hazards

-

Have you identified any further hazards on the job site?

Job Step

-

What job step does this hazard relate to?

-

Potential Hazard

-

Risk-Rating (IR) before control measures have been put in place<br>

Control Measures to Reduce Risk

-

Control measures used to reduce risk

-

Risk-Rating (RR) after control measures have been put in place.

-

Person responsible to implement control measures:

JOB STEP 8. On completion

Potential Hazard: Slips, trips, falls

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· Clean up tools and any waste ensuring the site is left in clean and tidy condition

· Clean debris and ensure it is removed from area. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Contact with electricity

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· Disconnect power tool/extension leads from power point before winding up, so that you don't get a shock if the lead is damaged

· Inspect leads and power equipment for damage

· If safe to do so, remove isolation locks/tags and test appliance for function

· Ensure:

o That no electrical appliances, light fittings, cables etc. have been damaged

o If damage suspected, do not turn power back on, seek advice from licensed electrician

o Reconnect services as required. Notify homeowner and/or site supervisor. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Contamination of waterways and water catchment

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· All paint products may be harmful to aquatic life. Prevent contamination of sewers, drains and waterways:

o Dispose of dried waste materials in approved landfill

o Dried empty cans can be recycled and should be disposed of via council metal recycling facilities

o Do not pour any leftover product down the drain

o Retain in a marked sealed container for future use of disposal via special chemical waste collection programs. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard: Public safety

-

-

Risk-Rating before control measures have been implemented

-

CONTROL MEASURES TO REDUCE RISK

· If acceptable, remove barricades, contact supervisor and return as agreed.

· Store leftover paint in the original container with the label intact. -

Risk-Rating (RR) after control measures have been put in place

-

Person responsible to implement control measures:

Emergency Response

Review & Monitor

-

To ensure controls are implemented and monitored effectively:

• Toolbox /pre-work meetings will be undertaken

• Relevant persons will be consulted on hazards and contents of SWMS, work plans and other applicable information

• Control measures will be monitored throughout works:

o Spot checks

o Consultation

o Scheduled audits

• Corrective actions will be recorded and rectified in a timely manner SWMS will be reviewed and updated accordingly (in consultation with relevant persons) -

Ensure all controls are reviewed as per the following:

• If controls fail to reduce risk adequately

• When changes to the workplace or work activity occur that create new / different risks where controls may no longer be effective

• New hazards identified

• After an incident involving work activities relevant to this SWMS

• During consultation with relevant persons indicate review is needed

• A Health and Safety Representative (HSR) requests a review in line with the requirements of the legislation. -

Review Number

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

Name & Initials

-

Date

Review & Monitor

Review & Monitor

-

To ensure controls are implemented and monitored effectively:

• Toolbox /pre-work meetings will be undertaken

• Relevant persons will be consulted on hazards and contents of SWMS, work plans and other applicable information

• Control measures will be monitored throughout works:

o Spot checks

o Consultation

o Scheduled audits

• Corrective actions will be recorded and rectified in a timely manner SWMS will be reviewed and updated accordingly (in consultation with relevant persons) -

Ensure all controls are reviewed as per the following:

• If controls fail to reduce risk adequately

• When changes to the workplace or work activity occur that create new / different risks where controls may no longer be effective

• New hazards identified

• After an incident involving work activities relevant to this SWMS

• During consultation with relevant persons indicate review is needed

• A Health and Safety Representative (HSR) requests a review in line with the requirements of the legislation. -

Review Number

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

Name & Initials

-

Date

Plant/Tools/Equipment Required For The Job

Plant/Tools/Equipment Required For The Job

-

Plant / Tools / Equipment are required to complete this job:

-

Plant / tools / equipment required:

Equipment / Tools / Plant

-

Make & Model

-

Photo of Equipment / Tools / Plant

Relevant Legislation & Codes of Practice

Country/State/Territory Specific References

-

Below you can add in relevant Legislation & Code of Practice references for your industry.

To help, SafetyCulture has put together a reference list which you can view by clicking the link below.

https://www.safetyculture.com.au/safe-work-method-statements-swms/1-ohs-legislation-and-codes-of-practice-reference-list-31105-1/ -

Select to manually add specific references where relevant

-

Country/State/Territory Specific References:

Part 2: Worker Sign Off & Licences/Competencies/Qualifications

Overall Risk Rating After Controls

-

Select risk rating

Worker Sign-off

-

This SWMS has been developed in consultation and cooperation with employee/workers and relevant Employer/Persons Conducting Business or Undertaking (PCBU). I have read the above SWMS and I understand its contents. I confirm that I have the skills and training, including relevant certification to conduct the task as described. I agree to comply with safety requirements within this SWMS including risk control measures, safe work instructions and PPE described.

Employee

-

Employee/Worker Name and Signature:

-

Job Role/Position

-

Employer/PCBU/Supervisor:

Licences/Competencies/Qualifications

-

Has the employee/worker completed any training or hold the licences required to complete this task?

-

Licence to Perform High Risk Work (operating certain plant, equipment)

-

Licence details

-

Photo of relevant licences

-

TAFE or other recognised training organisation

-

Licence details

-

Photo of relevant licences

-

Construction Induction Card (or equivalent)

-

Licence details

-

Photo of relevant licences

-

PPE

-

Licence details

-

Photo of relevant licences

-

Traffic Management Plan

-

Plan Details

-

Relevant photos

-

Other

-

Licences/training

Licences / Training

-

Licence details

-

Photo of relevant licences