Title Page

-

Site

-

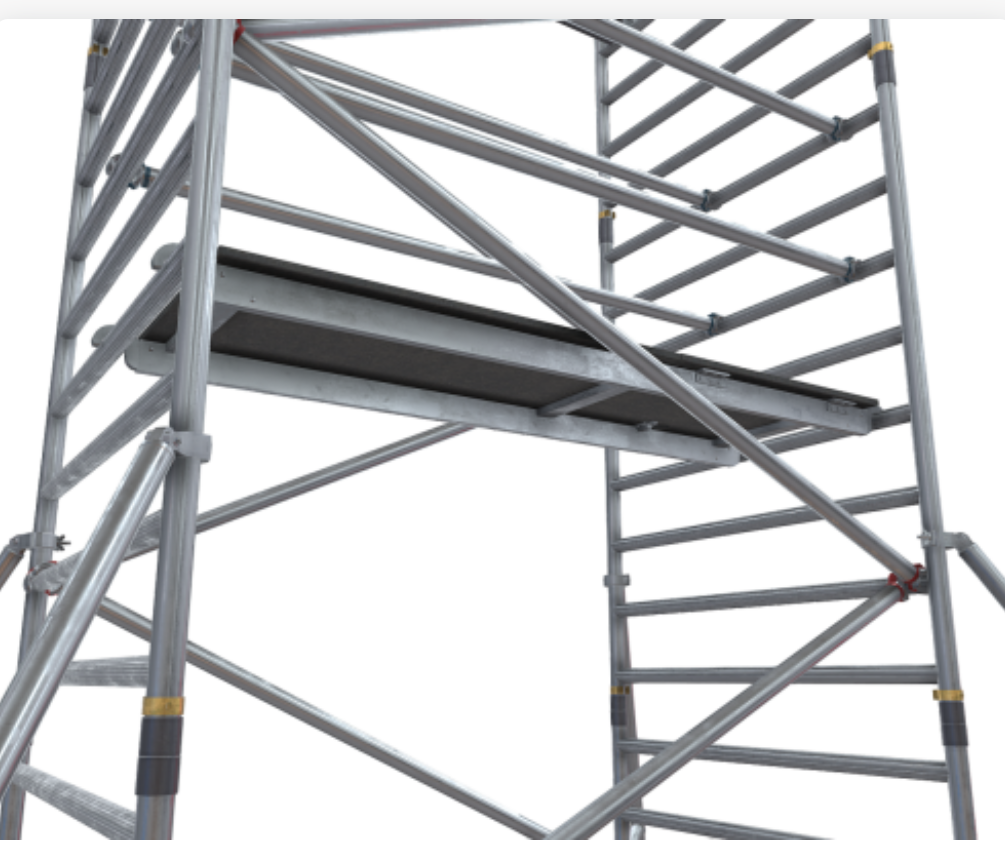

Conducted on

- Mobile Access Tower

-

Platform ID

-

Location & Task

-

1. Are ground conditions suitable, all castor brakes locked and wheels in contact with the ground?

-

-

2. Is the tower level and upright and are the adjustable legs set correctly but not used to gain extra height?

-

-

3. Is the tower stabilised as per the instruction manual, using the correct stabilisers or outriggers, or the correct type and position of ballast, or is the tower tied in using the right type of ties in the right position?

-

-

4. Are all horizontal and diagonal braces/advance guard rails positioned and secure as per the instruction manual?

-

-

5. Are all frames of the correct size and type, in the correct position with locking devices secured?

-

-

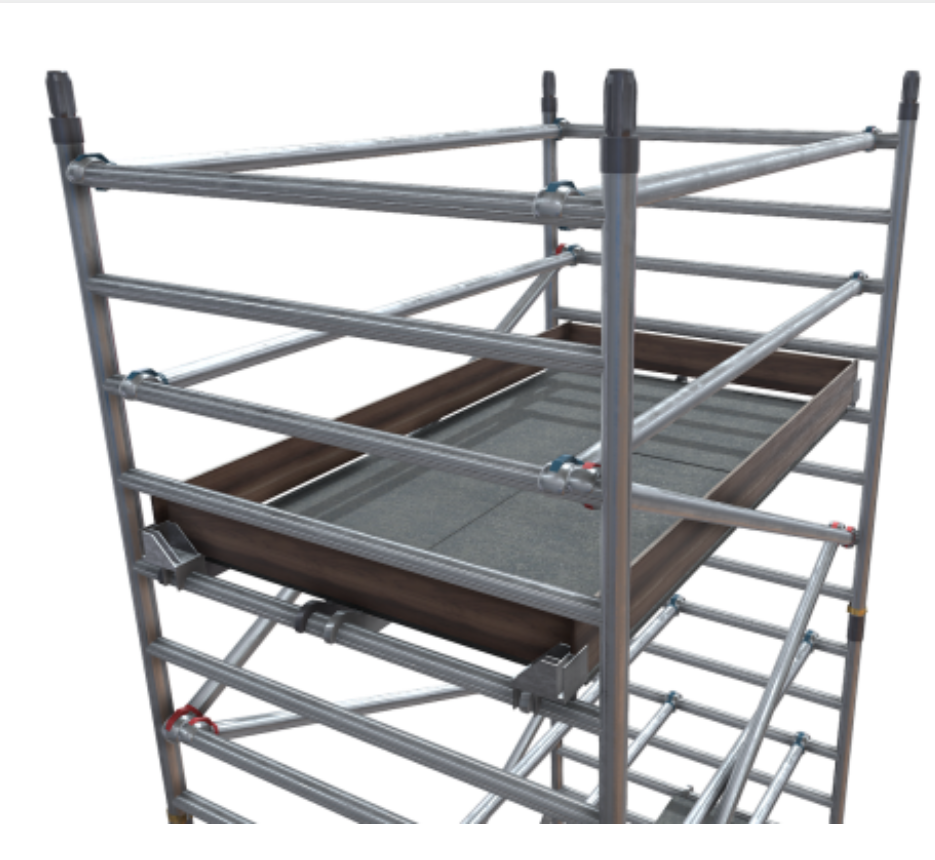

6. Are all platforms positioned correctly with trapdoor openings over the built in access and all windlocks engaged?

-

-

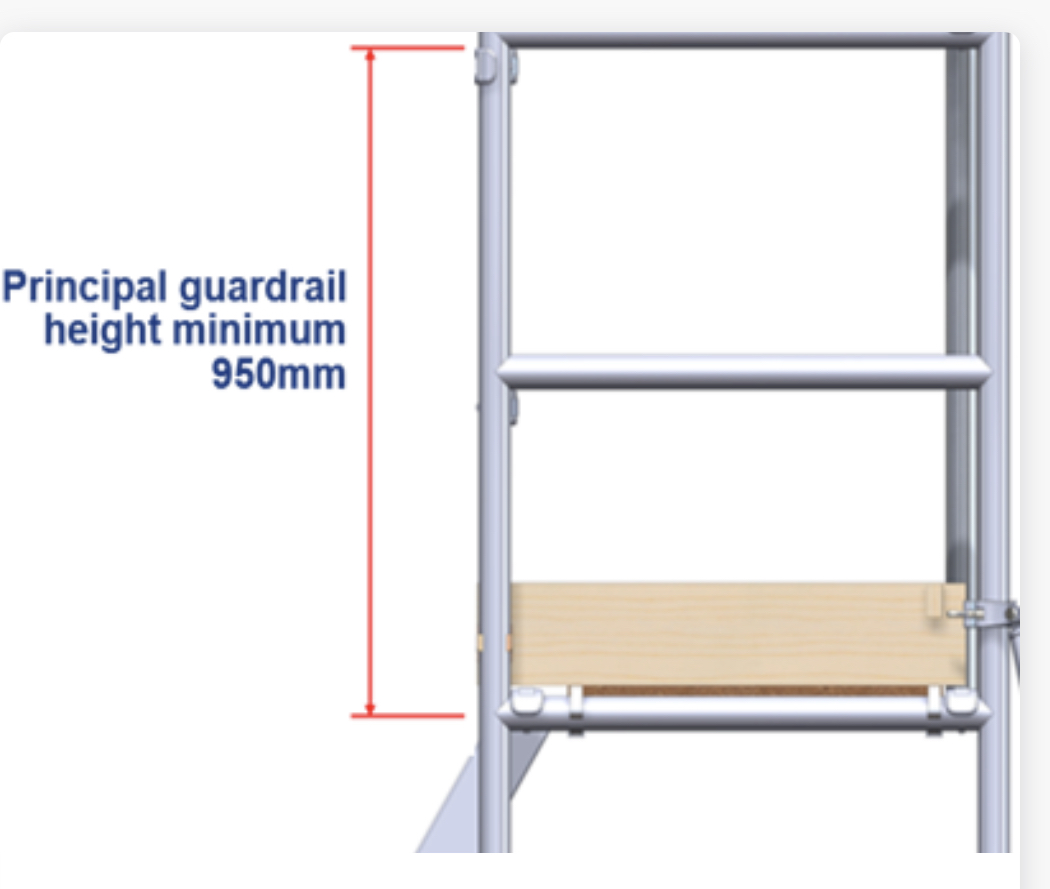

7. Do all platforms have double guardrails on all sides, fitted as per the instruction manual?

-

-

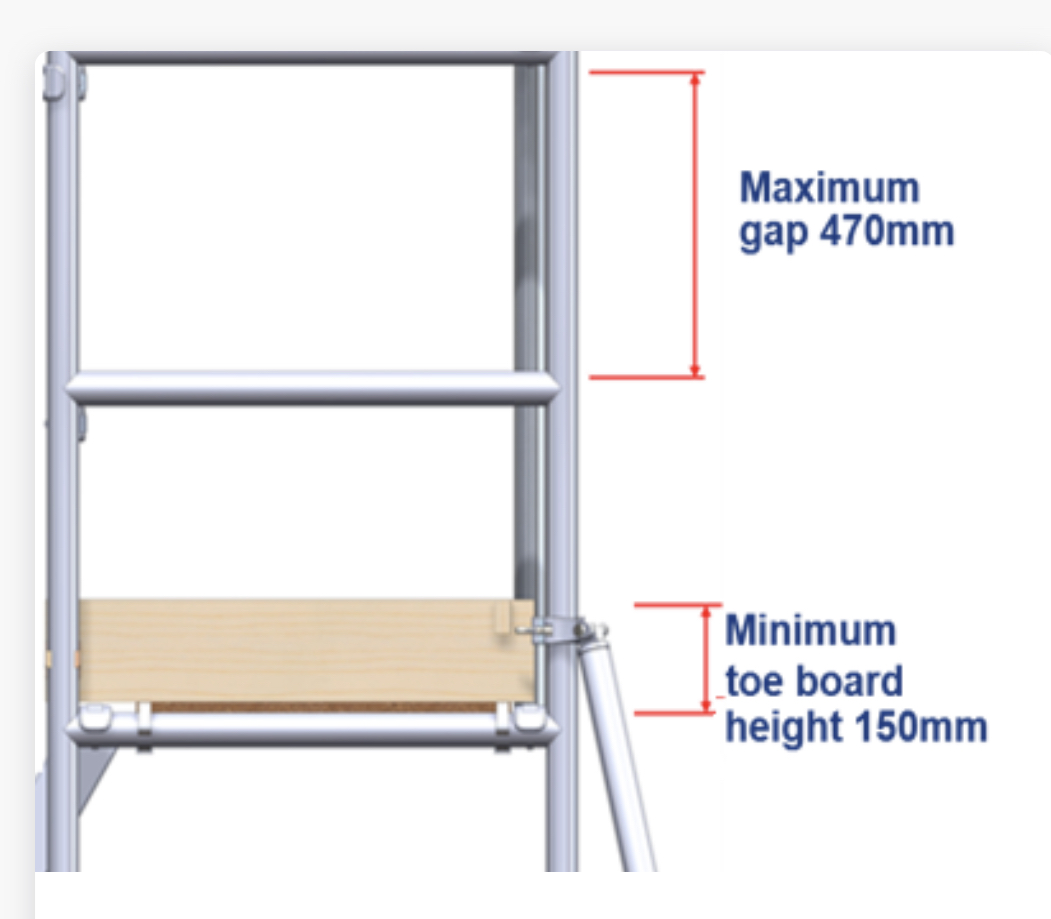

8. Are toeboards correctly fitted as per the instruction manual?

-

-

9. Is the tower the correct height for the task?

-

-

Upload an image of the tower at the time of inspection.

-

Name & Signature of PASMA holder inspecting the tower

Podium (Low level access)

-

Platform ID

-

Location & Task

-

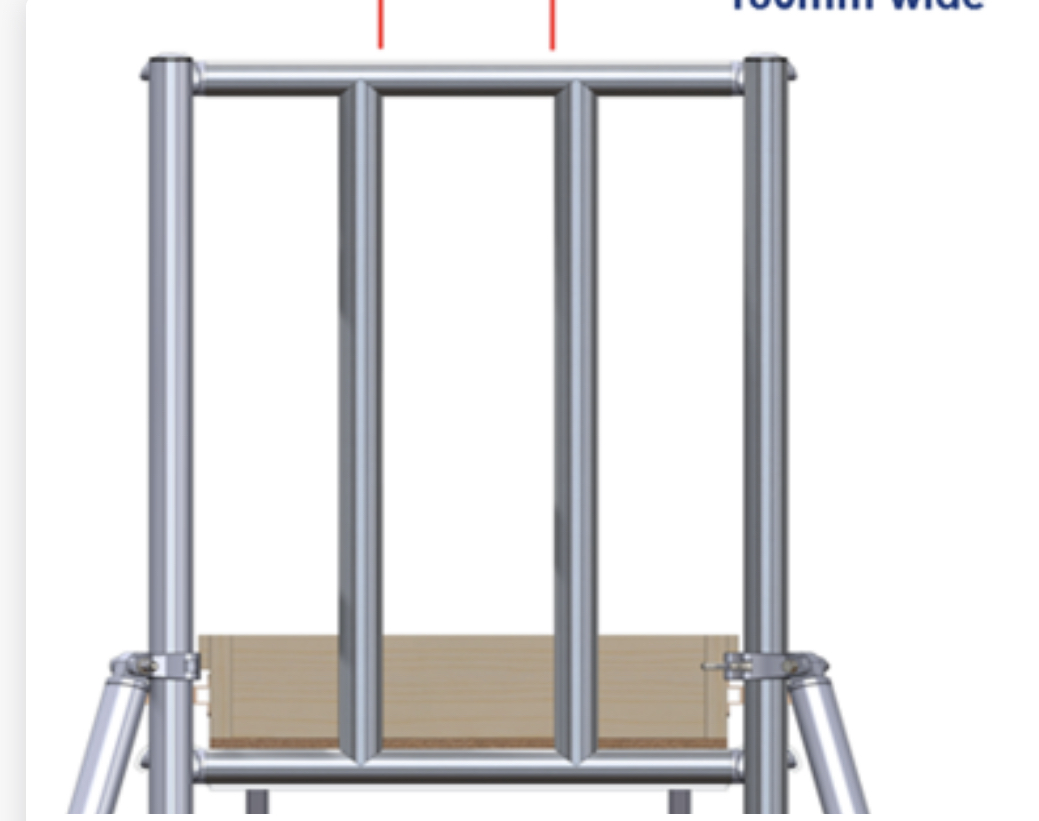

1. No horizontal gap more than 180mm?

-

-

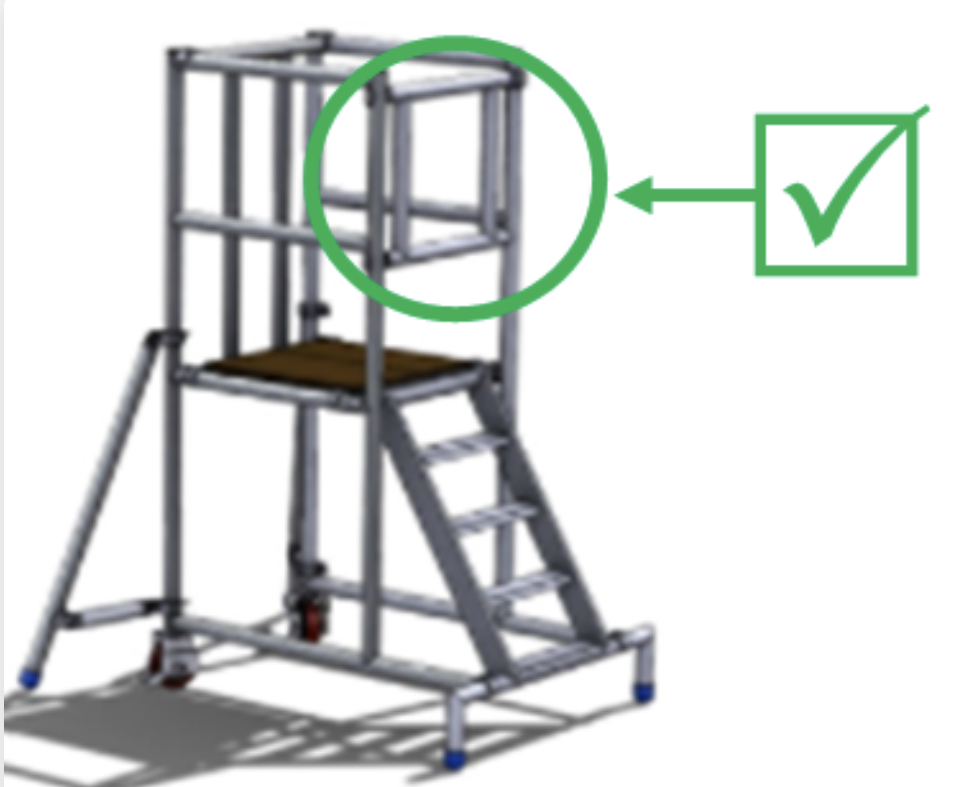

2. Podium gate operates correctly?

-

-

3. Toeboards fitted in accordance with instruction manual?

-

-

4. Podium stabilised correctly?

-

-

5. Podium access located correctly?

-

-

6. Platform height and maximum total load sufficient for task?

-

-

7. Correct instruction manual followed exactly and available on site?

-

-

8. Site checked for hazards - ground conditions suitable?

-

-

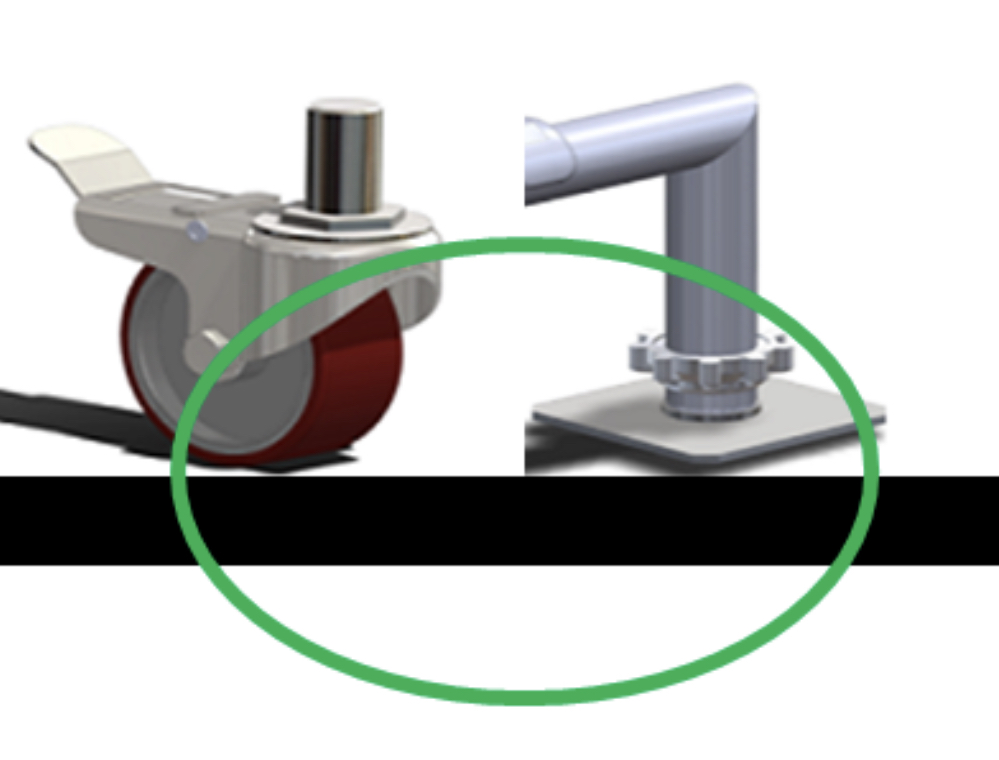

9. Castors/feet secured and all in contact with the ground/floor?

-

-

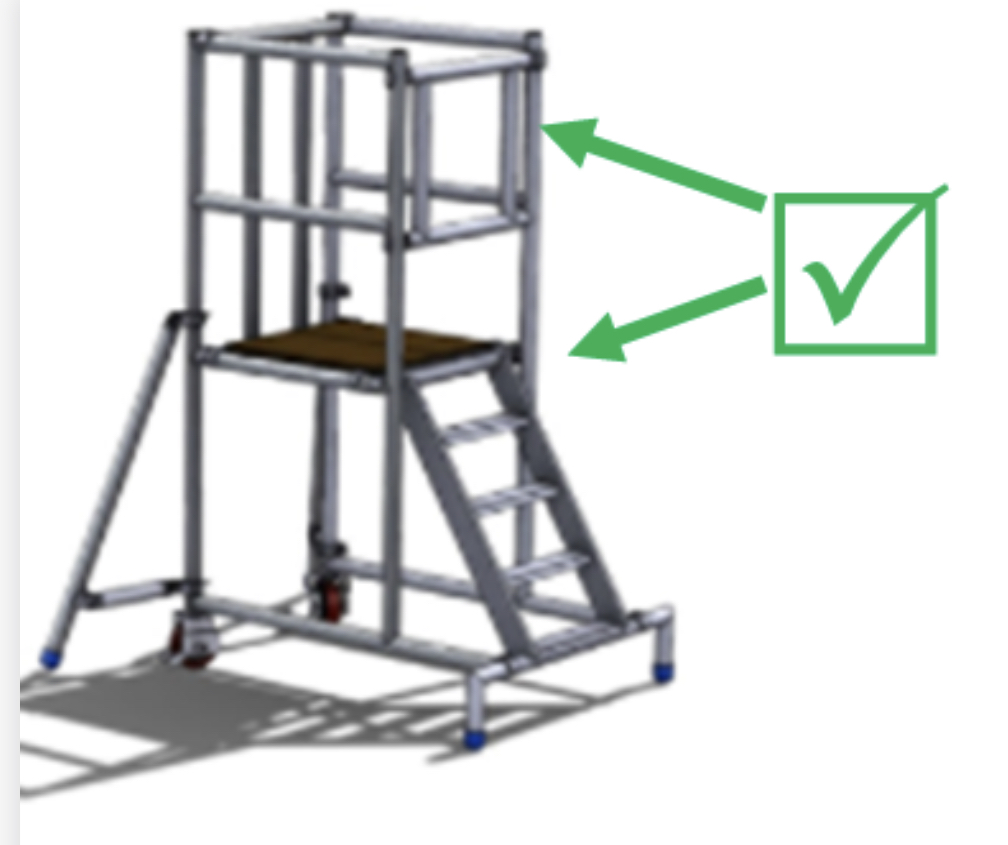

10. Platform and frame(s) correctly positioned and secured?

-

-

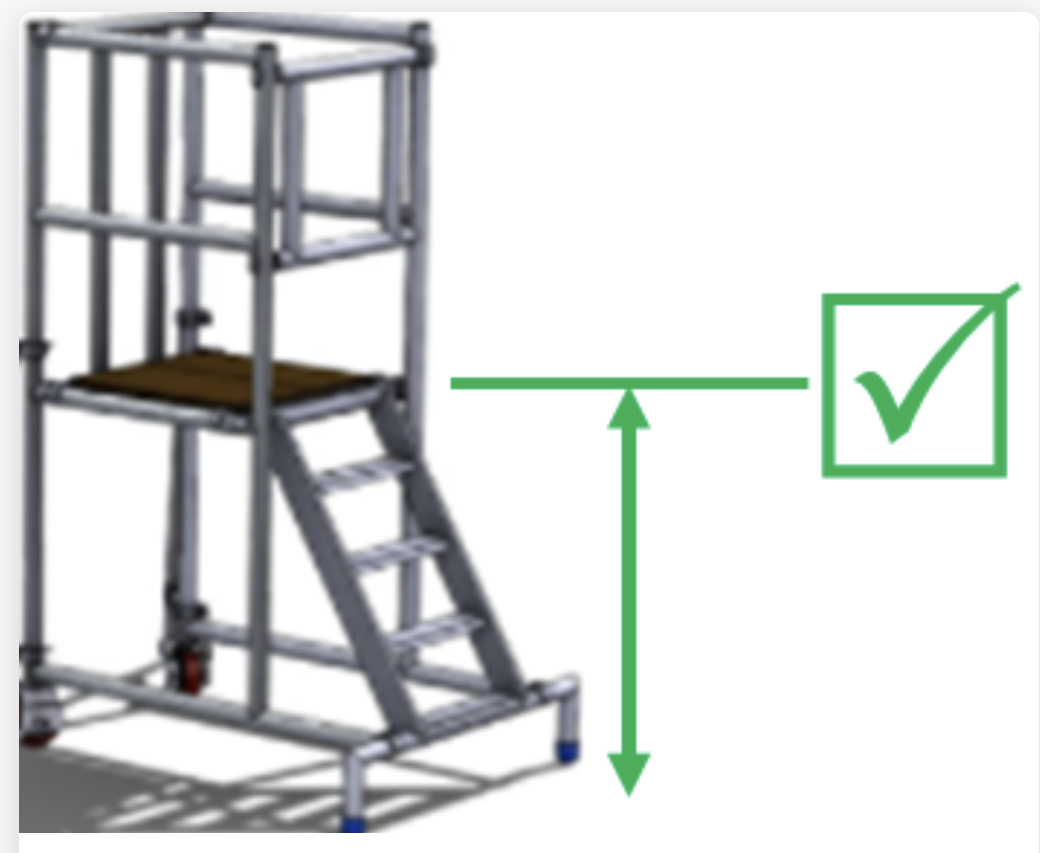

11. Top guard rail at least 950mm above the platform?

-

-

12. Intermediate guard rail with no vertical gap more than 470mm?

-

-

Upload an image of the podium at the time of inspection.

-

Name & Signature of PASMA holder inspecting the podium

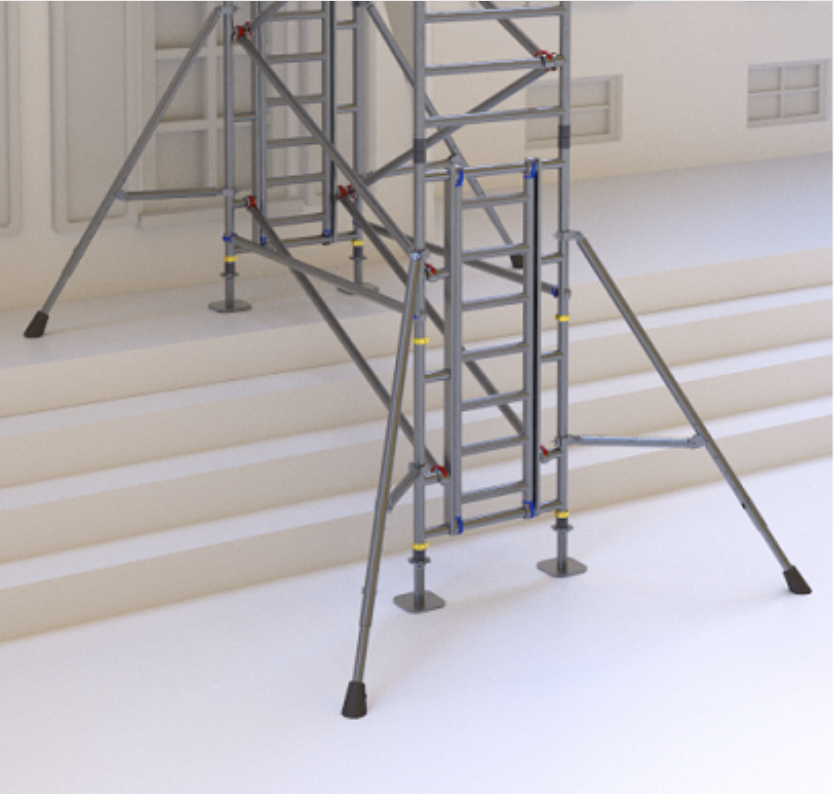

Stepped Tower - Tower on Stairs

-

Platform ID

-

Location & Task

-

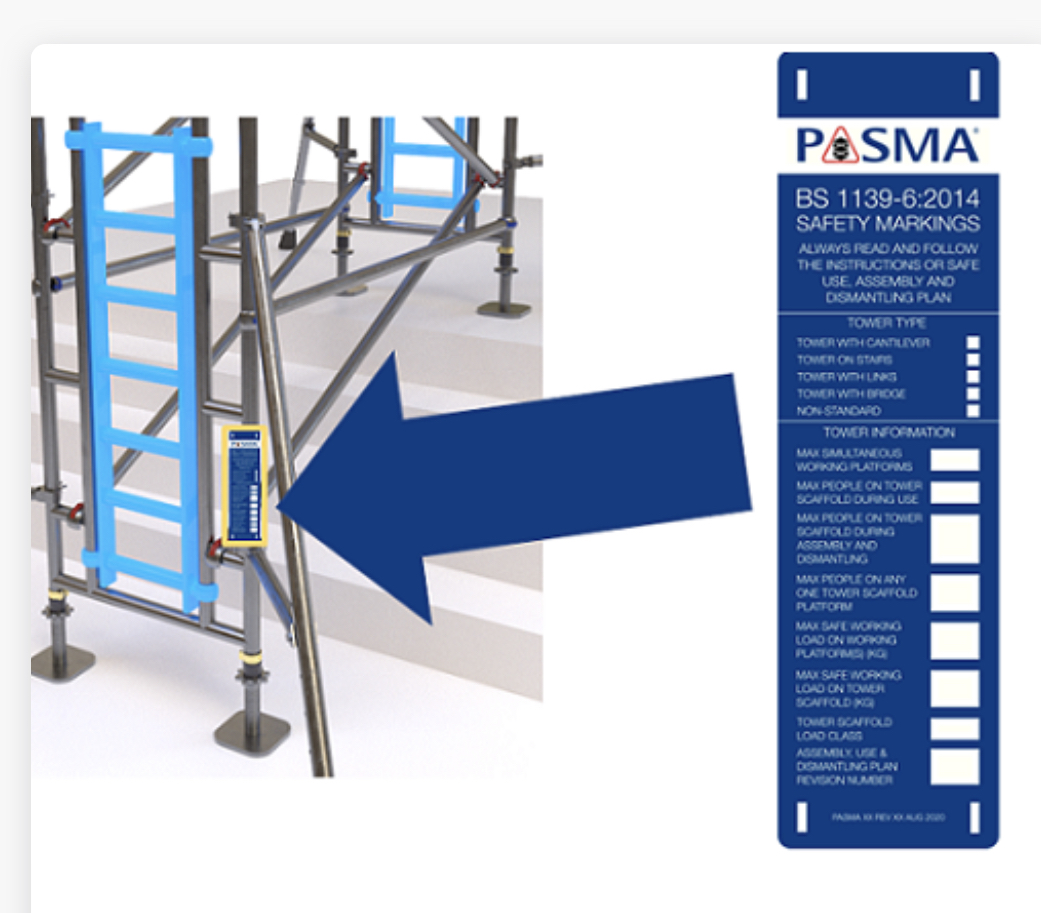

1. Is BS 1139-6 information displayed prominently at the base of the tower?

-

-

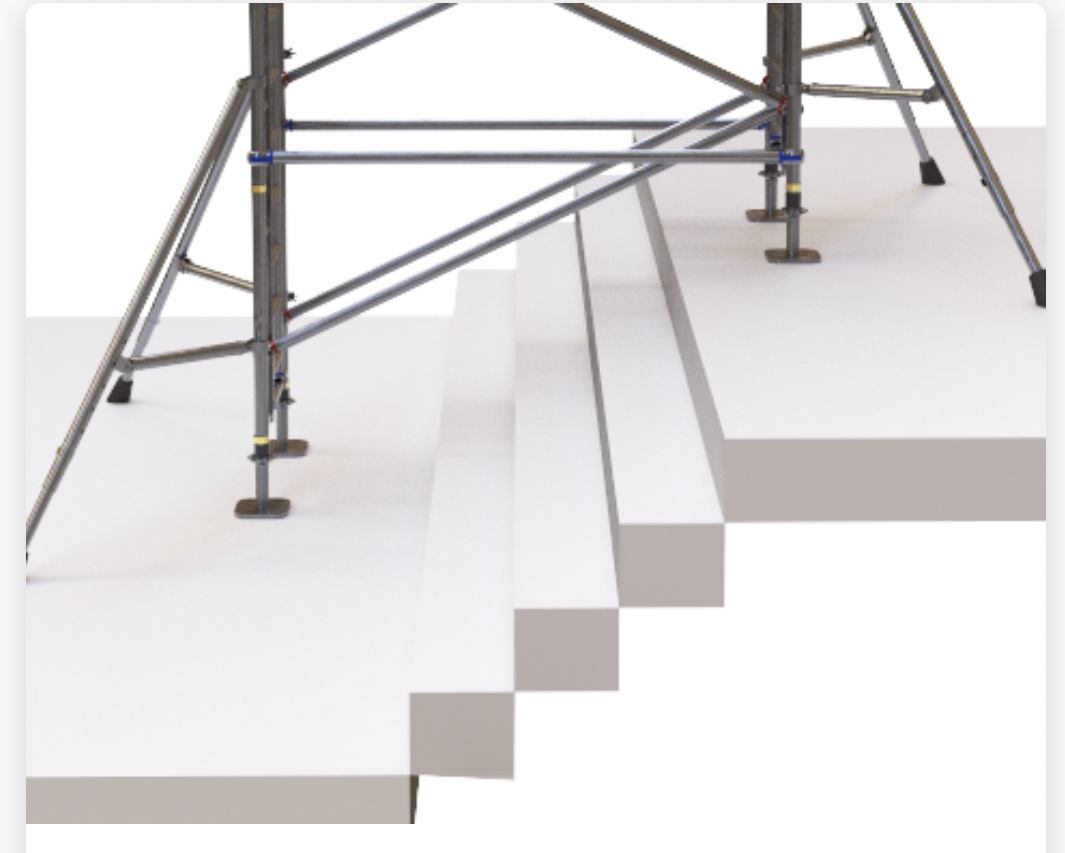

2. Are ground conditions suitable, base plates fitted and all in contact with the ground?

-

-

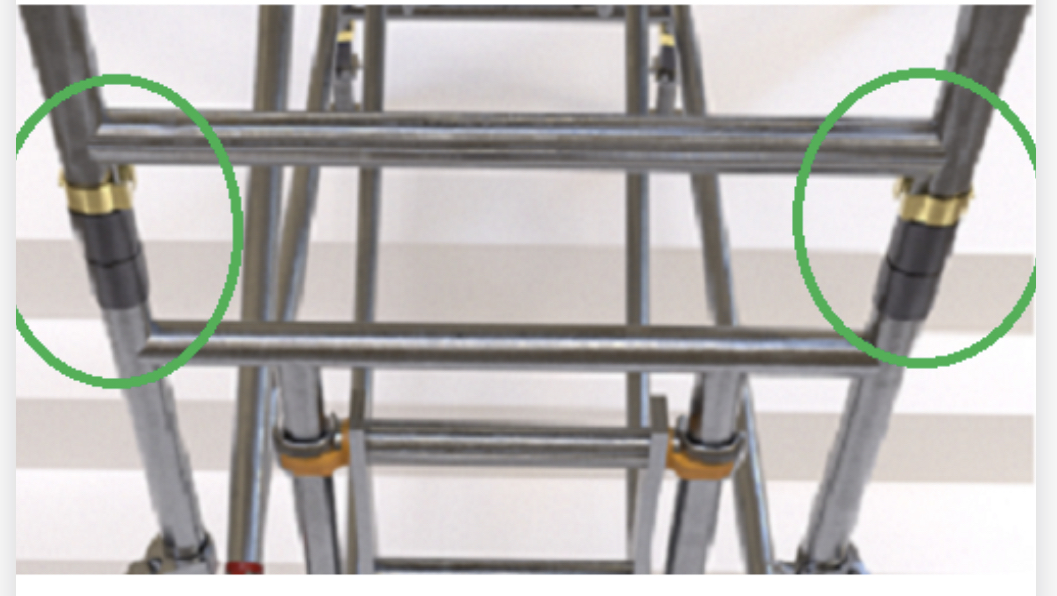

3. Is the tower level and upright, and are the adjustable legs set correctly but not used to gain extra height?

-

-

4. Is the tower stabilised as per the instruction manual, using the correct stabilisers or outriggers, or the correct type and position of ballast, or has the tower been tied in using the right type of ties in the right position?

-

-

5. Are all the horizontal and diagonal braces positioned and secure as per the instruction manual?

-

-

6. Are all frames of the correct size and type, in the correct position with locking devices secured?

-

-

7. Are all platforms positioned correctly, with trapdoor openings over the built in access, and all windlocks engaged?

-

-

8. Do all platforms have double guard rails on all sides, fitted as per the instruction manual?

-

-

9. Are toeboards correctly fitted as per the instruction manual?

-

-

10. Is the tower the correct height for the task?

-

-

Upload an image of the tower at the time of inspection.

-

Name & Signature of PASMA holder inspecting the tower