Title Page

-

Project number

-

Location

-

Conducted on

-

Prepared by

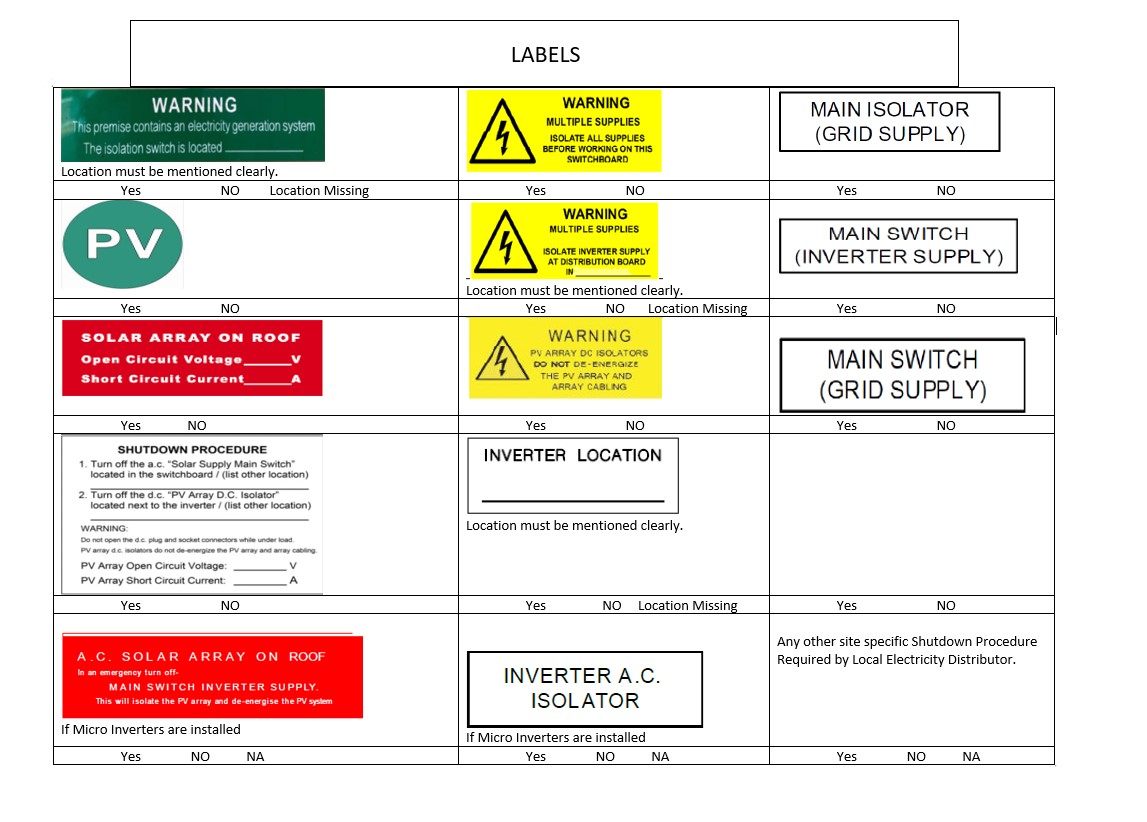

Labels

-

Disconnection Point

Switch Board-Inverter

-

Are the AC wiring losses less than 2% between the inverter terminals and the point of supply?

-

Is the array's maximum voltage VoC array max (at minimum temperature) less than 600vDC?

-

Any LV Cables have been found to be damaged?

-

Is all electrical equipment for the system installed in accordance with AS/NZS3000?

-

Are LV array and inverter cables not installed near building surfaces as per AS/NZS3000 requirements?

-

Are Isc and Voc ratings calculated correctly as per AS/NZS5033:2021 Clause 4.2.? These values should refer to the PV array maximum voltage (calculated at minimum temperature) and the sum of all array short circuit currents at standard test conditions (STC). Also should be clearly marked on label attached to inverter.

-

Does the clearance around the inverter meet the manufacturer’s minimum requirements?

-

Is the inverter securely and safely installed with all fixing/locking screws present?

Wiring

-

Are all cables/wiring in the installation securely fixed in place to minimise <br>any movement of the cable? (SS ties used as primary means of support)<br>

-

Are the roof/wall penetrations and/or the roof top components used in the wiring system suitably installed, sealed and waterproof?

-

Is the array wiring and wiring to the inverter protected from UV/mechanical<br> damage? <br>

-

Where conduit or other wiring enclosure is used, the wiring enclosure shall be visibly labelled ‘SOLAR’ on the exterior surface at an interval not exceeding 2m.

-

Wiring systems shall be fixed in position by suitable clips, SS cable ties, saddles or clamps or by means that will not damage the wiring system and that will not be affected by the wiring system material or any external influences.

-

Has double insulation been maintained between all live conductor(s) and all earthed or exposed conductive part(s)?

-

Is the installation arranged to prevent the spread of fire.

-

Are all array cables:(a) temperature rated for the application, (b) UV resistant if exposed to the environment, and (c) are flexible (multi-stranded) to allow for thermal/wind movement of arrays/modules?

-

Do the PV array mounting frames and modules have an equipotential bond connected to the earthing terminal on the switchboard/distribution board to which the inverter is connected, either directly or via the inverter main earth conductor?

-

Do the PV array frame and module earthing connections and methods comply with Australian Standards? (AS/NZS3000:2018 and AS/NZS5033:2014)

-

Are all DC cable(s) installed within the ceiling space, wall cavity or floor enclosed in heavy duty conduit or equivalent?

Isolators

-

Are there any signs of water ingress/damage observed in PV cable junction boxes or AC Isolators or DC Isolators?

-

Only manufacturer provided cable entries has been used and do all cable/conduit enter the lower face of the enclosure?

-

If multiple DC isolators are installed at the inverter a warning sign stating to operate ALL DC Isolators to isolate the equipment.

-

Is the DC isolator(s) near the inverter appropriately signed? (DC isolator(s) are correctly labelled and there is a label warning that switching off the DC isolator does not isolate all components of the system)

-

Are all the DC isolator(s) readily available?

-

Is weather resistant shroud installed and properly fitted over rooftop isolators in accordance with the CEC guidelines.

-

Are isolators installed with no direct exposure to sun or rain?

Roof-Ceiling

-

Is the array's maximum voltage VoC array max (at minimum temperature) less than 600vDC?

-

Does the designed array fit on the available roof area? (e.g. solar panels are not positioned over roof edges or gutters)

-

Do the PV mounting structure and attachments comply with the manufacturer’s instructions and AS/NZS 1170.2? And secure to the roof?

-

Are all array supports, brackets, screws and other metal parts either: <br>(a) of similar material or stainless steel to minimise corrosion; or <br>(b) where dissimilar metals that can have a galvanic reaction are used, they are galvanically isolated?"

-

Are LV array and inverter cables not installed near building surfaces as per AS/NZS3000 requirements?

-

Are there any signs of broken tiles or damage to tin? (PASS is no damage)

-

Are the array structure’s roof penetrations suitably sealed and waterproofed for the expected life of the system?

-

Is PV Array modules have been attached outside of manufacturers clamping zones?

-

Are DC connectors mated with those of the same type from the same manufacturer as required?