Title Page

-

Site conducted

-

Conducted on

-

Prepared by

-

Location

PRE-JOB BRIEF DISCUSSION

-

A job brief must be conducted by any multi-person crew before the start of each job, shift or when conditions change

-

Work Location/Address:

-

City/Town:

-

Date:

-

Gas Control Notified:

-

Nearest Landmark/Crossroad:

-

Dig Safe Ticket #:

-

Effective Date:

-

Expiration Date:

-

Emergency Permit(s):

-

Permit Number(s):

-

AED Location:

-

Fire Extinguisher Available:

-

Monthly Inspection Conducted:

-

Cable Avoidance Tool used to sweep the area for underground electric cables:

-

Are you working within 200 feet of a regulator or gate station?

-

If yes, notify Gas Control

-

Have emergency valves been located:

-

Location:

-

Accessible:

-

Supervisor has been contacted if working more than 14 consecutive hours:

Topics of Discussion: Understanding of Job and Potential Risks

-

Examples of Potential Hazards:

Slippery/Uneven Surfaces

High Voltage

Vertical Workspace

Machinery: Pinch Points

Flamm/Combust/Chemicals (SDS)

Flying Particles

Heat/Cold Stress / Weather Issues

Power & Hand Tools - Noise

Ladders, Scaffolds, Stairs, Falls

Pressurized Systems.

- Hydraulics / Gasses

Members of the Public

Lifting: Manual/Mechanical

Awkward Posture, Force, Repetition

Identify Potential to impact Env

and planned response to release. -

Job Description

-

Specific Hazards Associated with Job Tasks:

-

Additional Notes:

Personal Protective Equipment:

-

Standard PPE-HH, Safety glasses/shoes, hi vis

-

Cut/Puncture Resistant Gloves

-

Slip Resistant Footwear Required

-

Controlled Live Gas < 10’

-

Uncontrolled Live Gas < 25’

-

Refer to PPE Matrix

Rigging/Securement Inspections

-

Visual Inspection of slings, chains, hooks, and eye bolts for damage, kinks, corrosion, cuts

-

undefined

-

Load capacity of lifting equipment sufficient for task

-

All loads secured for transport

-

Atmospheric Testing

-

Dust Control (Silica)

-

Asbestos (Coal Tar Wrap)

-

Adequate illumination

-

IF YOU SEE SOMETHING, SAY SOMETHING, AND DO SOMETHING – REPORT NEAR MISSES

Abnormal Operating Conditions

-

Atmospheric Changes in a Confined Space

-

Component Failure

-

Damage to Facilities, Environmental, Incident

-

Escaping Gas

-

Excessive Pressure

-

Fire or Explosion

-

Improper Odorization

-

Inadequate Pressure

-

No gas

-

Ignition Sources

EXCAVATION LOG

-

All Excavations are to be evaluated by the competent person at least once per day, prior to entry, and as needed.

-

Excavation will be entered

-

If yes, excavation log required

-

Excavation Competent Person:

Soil Classification

-

All soil types are classified as Type C soil (least stable)

Benching Type C soils not permitted

NOTES:

-

Surface water present

-

Excavation exposed to vibration

-

Previously distributed soils

-

Excavation contains layered solid

-

Adjacent structures

-

Excavation Assess/Egress compliance

-

Protective System Required

-

Supervisor Notified:

-

Shoring

-

Trench Box (Modular)

-

Timber Shoring

-

Sloping

-

Other

-

Type C soil does not permit benching

-

Estimate excavation details during the main job brief based on prints and update prior to entry

-

Excavation estimated to be:

-

Depth FT’ In''

-

Length FT In"

-

Excavation prior to entry (actual)

-

Estimated Actual Depth FT’ in”

-

Stretch & Flex

-

To proactively reduce strains and sprains use * flex” Exercise

Arm Swings – Hold arms at shoulder height, swing around front of body

Windmills - Hold arms straight and make backward circular motions

Head Circles – Hands on hips. Drop head forward, circle right, move left.

Leg Stretch – Grasp leg in back of body with opposite hand. Don’t pull hard.

Repeat Arms Swings, Windmills, and Jumping Jacks

Soft Tissue Injury Prevention

-

Assess loads and job tasks

-

Use proper body position

-

Avoid twisting

-

Use mechanical means

-

Describe volunteer stretches

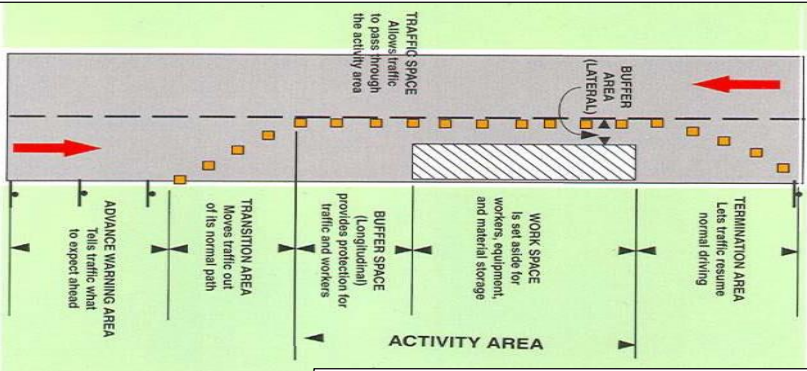

Work Zone Requirements

-

Work Zone Set up per MUTCD

-

# of Signs

-

# of Cones

-

Correct Signage

-

Pedestrian traffic Routing

-

Sidewalk Closed Yes No

-

Flagger(s)/Police Detail

-

Obstacles/Terrain (slips,trips,falls)

-

Swing radius of mechanical equip.

-

PJB DEVLOPED/DELIVERED BY:

-

Qualified Observer Assigned for those Not Qualified on tasks being performed.

Employee Name

-

Employee Name, Initials

Post Job Brief Discussion

-

1. Were there any near misses in your work environment today? (Supervisor must take immediate action if warranted and report to Safety

-

2. Do you have any specific pain or perceived health issues as a result of your work today? (If Yes, contact supervisor and EHS)

-

3. Did anyone speak to you today about the safety of your work practices?

-

4. Did you speak to anyone about the safety of their work practices?

-

ALL VISITORS TO THE JOBSITE MUST BE BRIEFED ON HAZARDS AND SIGN DOCUMENT. Signature verifies understanding of job brief and my stop work authority role.

Signature

-

Name and Signature

-

After lunch and/or significant delay or shift change, job review conducted by:

-

Time:

Coordination with Adjacent Work

-

Crew Leaders have reviewed scope and Sequence of work with adjacent work crew(s) to ensure Process Safety and eliminate AOC potential.

Crew

-

Name and Signature

-

Supervisor Quality Review (Name, Signature, Date)