Information

-

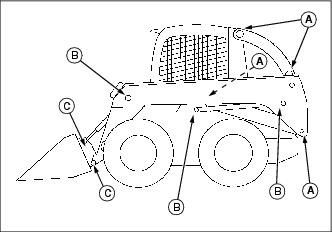

Pre-Operation Checklist - Skidsteer

-

Make / Model

-

Conducted on

-

Prepared by

Exterior

-

Visual Inpection (condition,leaks)

-

Add media

-

Clean (as required)

-

Add media

-

Check tire pressure

-

Add media

-

Check wheel lug nuts (secure, present)

-

Add media

-

Lubricate pivot points

-

Add media

-

-

Check attachment (secure)

-

Add media

Engine Compartment

-

Check fuel level

-

Add media

-

Check engine oil level

-

Add media

-

Check hydraulic oil level and hoses (leaks)

-

Add media

-

Check coolant level and hoses

-

Add media

-

Remove dirt and debris from radiator

-

Add media

-

Drain water and sediment from fuel filter.

-

Add media

Test Safety Systems

-

Test park brake switch

-

Add media

-

1. Park machine safely.

2. Sit on operator's seat, buckle seat belt, and disengage park brake switch.

3. Turn the key to start position.

Result: Engine must not crank -

Test boom and bucket interlock system

-

Add media

-

1. Park machine safely.

2. Sit on operator's seat, buckle seat belt, and engage park brake switch.

3. Start the engine.

4. Run engine at maximum engine speed.

5. Place park brake switch in the middle (run) position.

6. Push down on the back of the boom control pedal to slowly raise boom. Release pedal. Push down on the back of bucket control pedal to slowly curl bucket. Release pedal.

Unbuckle seat belt. Move pedals.

Result: Boom and bucket should lock as soon as the seat belt is released.

The operator must complete the following sequence, to release the boom and bucket

1. Sit in the seat.

2. Fasten seat belt.

3. Disengage the park brake switch. -

Test seat switch

-

Add media

-

1. Park machine safely.

2. Sit on operator's seat, buckle seat belt, and engage park brake switch.

3. Start the engine.

4. Disengage park brake switch.

5. Raise up off the seat, but do not unbuckle seat belt or get out of Skid steer.

Result: park brake will immediately be applied and the "Park Brake Engaged" indicator light will come on. -

Test seat belt switch

-

Add media

-

1. Park machine safely.

2. Sit on operator's seat, buckle seat belt, and engage park brake switch.

3. Start the engine.

4. Disengage park brake switch.

5. unbuckle seat belt, but do not get out of Skid steer.

Result: park brake will immediately be applied and the "Park Brake Engaged" indicator light will come on.

Every 50 hours

-

50 hour maintenance required

-

Check alternator belt tension

-

Check air conditioner/heater belt tension, if equipped

-

Lubricate boom linkage and cylinder pivot points

-

Lubricate Quick-Tatch mounting plate latches

-

Check tire pressure

Every 200 hours

-

200 hour maintenance required

-

Check wheel lug nut torque 237N-m

Every 250 hours

-

250 hour maintenance required

-

Change engine oil and filter

Every 500 hours or annually

-

500 hour maintenance required

-

Replace both in-line fuel filter and water separator filter

-

Replace primary air cleaner element

-

Check chain case oil level

-

Check/clean oil reservoir breather

-

Change hydraulic oil filter

Every 1000 hours

-

1000 hour maintenance required

-

Replace secondary air cleaner element

-

Change chain case oil

-

Replace in-line hydrostatic case drain filters

Every 1000 hours or annually

-

1000 hour maintenance required

-

Change hydraulic oil

-

Tighten all hardware

Every 2000 hours

-

2000 hour maintenance required

-

Flush cooling system

-

Check and adjust engine valve clearance