Information

-

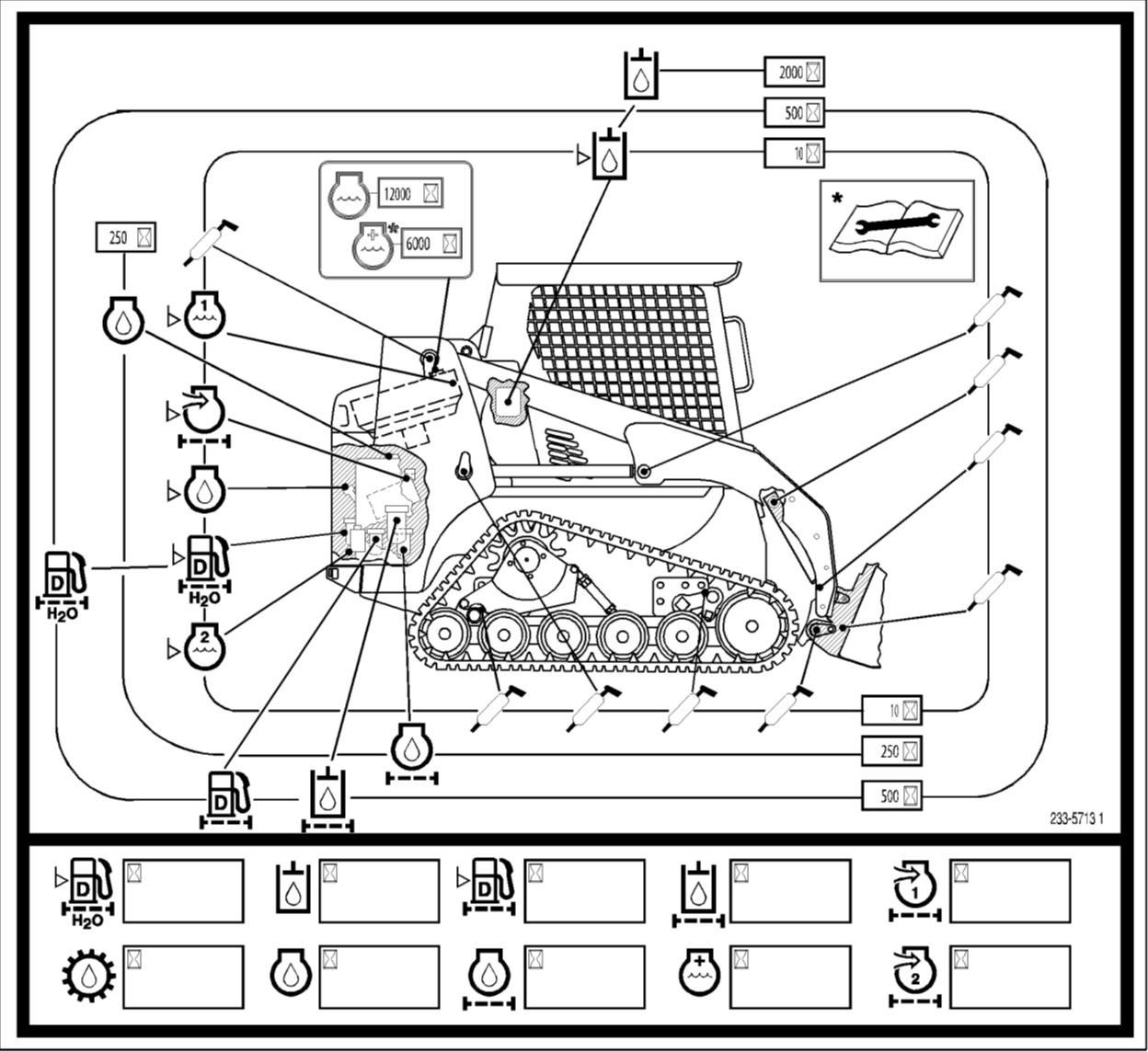

Pre-Operation Checklist - Skidsteer

-

Make / Model

-

Conducted on

-

Prepared by

Complete Machine

-

Visual Inpection (condition,leaks)

-

Add media

-

Clean (as required)

-

Add media

Exterior

-

Lubricate axle bearings

-

Add media

-

Lubricate lift arm and cylinder linkage

-

Add media

-

Lubricate tilt cylinder bearings and bucket linkage bearings

-

Add media

-

Inspect quick coupler

-

Add media

-

Inspect Bogie and idler (replace if necessary)

-

Add media

-

Check sprocket retaining nuts

-

Add media

-

Check hydraulic system oil level

-

Add media

-

Inspect track (adjust if necessary)

-

Add media

-

Inspect work tool mounting bracket

-

Add media

-

Lubricate work tool

-

Add media

Engine Compartment

-

Check cooling system level

-

Add media

-

Check engine oil level

-

Add media

-

Drain fuel system primary filter (water separator)

-

Add media

-

Clean radiator core

-

Add media

Operators Compartment

-

Inspect seat belt

-

Add media

-

Test Back-up Alarm

-

Add media

Monthly or every 250 operating hours

-

Complete on the first workday of every month or every 250 operating hours

-

Obtain engine oil sample

-

Add media

-

Check belts (adjust or replace if necessary)

-

Add media