Information

-

Equipment Type / ID #

-

Conducted on

-

Prepared by

-

Location

Daily Maintenance

-

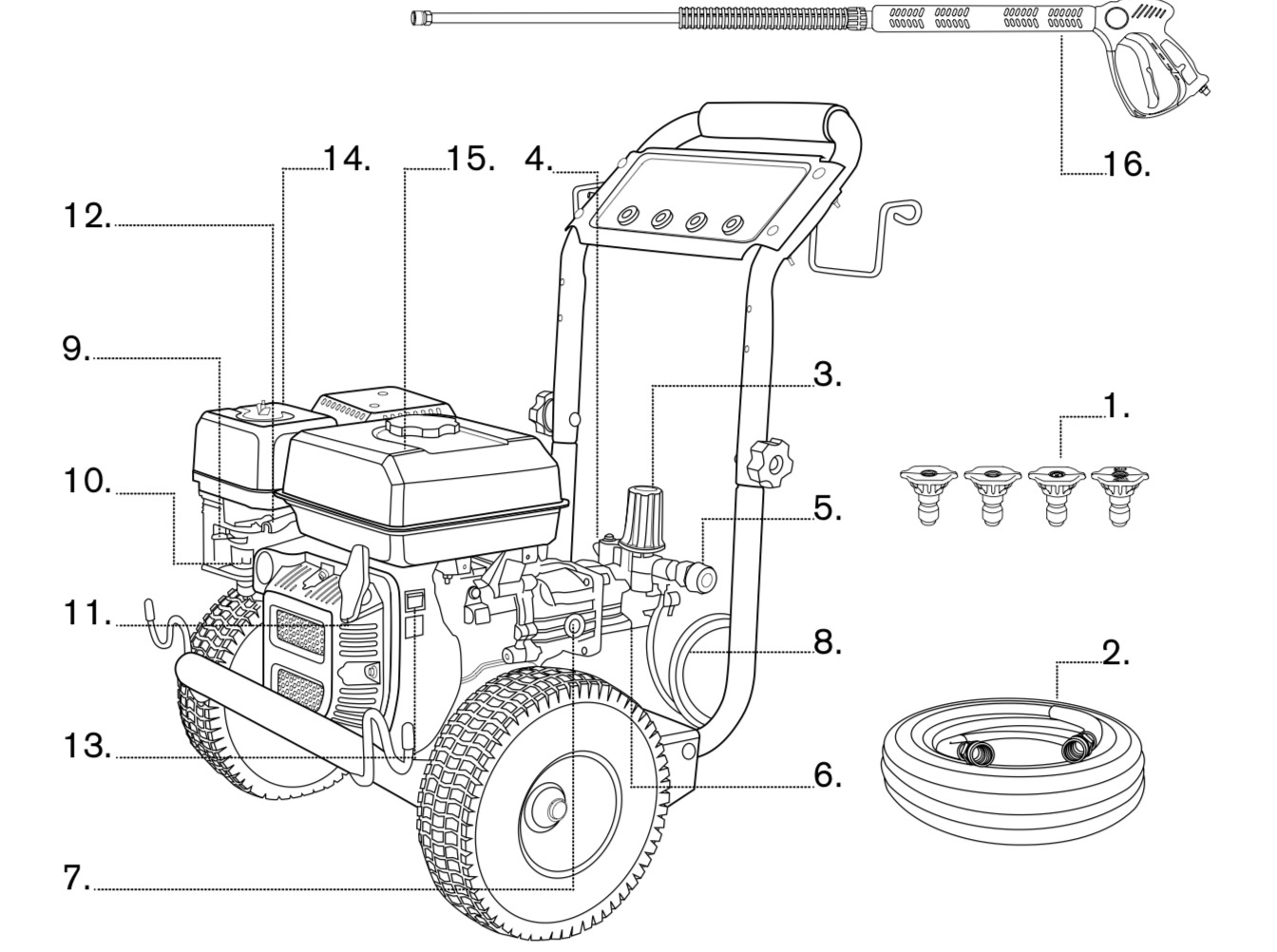

1. Spray Tips Detergent, 0°, 15°, and 40°: for various high pressure cleaning applications.

2. High Pressure Hose Connect one end to water pump and the other end to spray gun.

3. Pressure Control Knob Varies pressure of high pressure spray.

4. Water Inlet Connection for garden hose.

5. High Pressure Outlet Connection for high pressure hose.

6. Pump Develops high pressure.

7. Oil Level Indicator Level should be at halfway

8. Detergent Siphoning Tube/Filter Use to siphon pressure washer safe detergent into the low pressure stream.

9. Choke Lever Prepares a cold engine for starting.

10. Fuel Valve Used to turn fuel supply on and off to engine.

11. Recoil Starter Used for starting the engine manually.

12. Throttle Lever Sets engine in starting mode for recoil starter.

13. Engine Switch Set switch to “On” for recoil starting. Set switch to “Off” to stop a running engine.

14. Air Filter Protects engine by filtering dust and debris out of intake air.

15. Fuel Tank Fill tank with regular unleaded fuel. Always leave room for fuel expansion.

16. Spray Gun Extension with Quick Connect Nozzles Controls the application of water onto cleaning surface with trigger device. Includes trigger lock. Allows you to switch between five different spray tips. -

Check to ensure the engine oil is at the proper level. (Use SAE 10W30 Oil)<br>

-

Check the 2 handle knobs to ensure they are tight and will not vibrate loose.

-

Add fuel to the gas tank.<br>

-

Inspect and clean air cleaner<br>

-

Inspect and clean inlet filter with clear water

-

Inspect pressure hose nod hose couplings. Replace hose if any of the following is evident:<br>- Hose couplings is damaged, wire mesh is exposed or damaged, hose is permanently kinked or flattened, outer hose cover is blistered or loose.<br>- Hose cover is blistered or loose

-

Tighten any loose bolts

-

Connect and tighten the garden hose to the GHA (garden hose inlet) connection.

-

Water must be turned on prior to starting the washer, pull the spray trigger to ensure water is moving the through the lines and out the nozzle without any leaks before starting the unit.

Every 3 Months

-

Change Pump oil

-

Clean air filter

Every 6 Months

-

Change Engine Oil

Every Year

-

Check and adjust spark plug

-

Check spark arrester

-

Check and adjust idle speed

-

Clean fuel tank and filter

-

Check and adjust valve clearance

Every 2 Years

-

Replace air filter

-

Replace spark plug

-

Check fuel tube

-

Clean combustion chamber