Information

Description of Equipment

-

Machine Make

-

Serial No

- 353-174

- 353-175

- 353-176

- 353-177

- 353-178

- 353-179

- 353-180

- 353-181

- 353-182

- 353-183

- 353-184

- 353-185

- 353-186

- 353-187

- 347-248

- 347-249

- BT201601

- BT201602

- 2113

- MK16021561

- MK16021562

- MK16021563

- 10185752

- 3112808

- 4913

- 7061439

- 9071707

- 10185751

- 10185768

- 1123149

-

Model

- CX300VX

- CX600HFE

- MCP 20P

- Glass Bin Lift

- MRF Line Conveyer

- Bio Mass conveyer

- Compactor

- Freestanding Bin Lift

-

Location of Equipment

- GLCC- Landside

- Landside - North Dock

- Landside - South Dock

- Airside - 191

- Airside - Gate 30

- GDRC - Warehouse

- Airside - CRP

- Airside - 192

-

Date of Assessment

-

Assessed by

Who might be affected

Mechanical Hazards

-

Is the following Hazard present for the Work Equipment being assessed?

-

Shearing

-

Impact

-

Struck by Tools

-

Stabbing/Puncturing

-

Cutting/Severing

-

Friction/Abrasion

-

Entanglement

-

Drawing in

-

Ejection of tools/Objects

-

Ejection of high pressure fluids.

-

Stability

Electrical Hazards

-

Direct/Indirect shock

-

Ignition source

-

Electrostatic presence

-

Radiation

-

Short circuit

-

Overload

Other Hazards

-

Repetitive action

-

Hot surfaces

-

Vibration

-

Stressful posture

-

Lifting/Handling

-

Noise

-

Visibility

-

Lighting

-

Hazardous substances

-

Isolation

Reg 4 - Suitability of Work Equipment

-

Is the equipment suitable by design, construction for the work it is provided to do?

-

Is the equipment suitable for the conditions in which it is to be used?

-

Is the equipment used in such a manner where it does not cause risks in situations whereby it would otherwise be safe?

-

Is the equipment suitable for the purpose or conditions of use

Reg 5 Maintenance

-

Is the equipment maintained?

-

Is a record of maintenance kept?

Reg 6 - Inspection

-

Does the equipment require statutory inspection

-

Is the equipment inspected for safety, each time a major fault arises?

-

Are results of inspections recorded and kept until the next inspection occurs?

Reg 7 Specific Risks and Restrictions on Use

-

Is the use of this equipment restricted to competent persons?

Reg 8/9 Information, Instruction, Training

-

Have all users of work equipment received adequate information, instruction and training including:<br>Method<br>Risks<br>Precautions<br>(Special emphasis should be given to young persons under 18 years of age)

-

Have all supervisors/managers of work equipment received adequate information, instruction and training including:<br>Methods<br>Risks<br>Precautions

Reg 10 Conformity with EC Requirements

-

Is this New Equipment?

-

Does the equipment comply with Community Directives (eg does it display a CE Mark)

Reg 11 Dangerous Parts of Machinery

-

Have measures been taken to prevent access to dangerous parts of the machine via interlock safety devices to stop movement of any dangerous part before any part of a person enters a danger zone?

-

Where practicable have any guards or protection devices been provided?

-

So far as is practicable are guards and protection devices suitable and sufficient for the purpose for which they are provided (eg good construction, sound material, adequate strength maintained and in good repair?

-

Has adequate information, instruction, training and supervision been given?

Reg 12 Protection Against Specific Hazards

-

So far as is reasonable, have the risks associated with the following hazards been adequately controlled, by means other than PPE or information, instruction, training or supervision?

-

An article or substances falling or being ejected during bale out procedure?

-

Rupture or disintegration of parts?

-

Catching fire or overheating?

-

Unintended or premature discharge of any article or of any gas, dust, liquid, vapour, or other substance?

Reg 13. High or Very Low Temperature

-

Where appropriate, are all parts of work equipment, articles or substances in the equipment protected to prevent burns by contact?

Reg 14. Starting Controls

-

Is the equipment fitted with start, stop or operating controls which require a deliberate action to operate?

-

Does the equipment stop when the use of a protective device eg interlock is activated?

-

Are the controls protected against inadvertent operation (eg starter shrouded)?

Reg 15. Stop Controls

-

Does the stop control mechanism bring the work equipment to a safe condition in a safe manner?

-

Are all sources of energy switched off after stopping the equipment? (Compressed air/hydraulic pressure)?

-

Does the stop control equipment operate in priority to controls which start or change operating conditions?

Reg 16 Emergency Stop Controls

-

Is the equipment fitted with an emergency stop control which operates in priority to any other control mechanism?

Reg 17 Controls

-

Are all controls clearly visible?

-

Are they identifiable?

-

Are they appropriately marked?

-

Are control mechanisms in a safe position and operators free from danger?

Reg 18. Control Systems

-

Do control systems allow for failures, faults and constraints to be expected in the planned circumstances of use with no increased risk to health & safety?

-

Does a failure of any part on the control system or it's power supply lead to a 'fail-safe' condition, which will not impede the operation of the 'stop' controls?

Reg 19. Isolation

-

Are there means to isolate the equipment from all sources of energy, eg Isolation switch, removal of plug, etc?

-

Are the means of isolation clearly identifiable?

-

Are they accessible?

-

Are there appropriate measures to ensure that reconnection does not expose any person to a risk of injury eg reconnection initiating movement, adequate guards?

Reg 20. Stability

-

Is the equipment stabilised where necessary to prevent risk of injury (eg machines bolted to floor)?

Reg 21. Lighting

-

Are the places where this work equipment is to be used suitably and sufficiently lit?

Reg 22. Maintenance Operations

-

Is maintenance carried out with the machine stopped and isolated? By competent persons only and in accordance with the written procedures for the machine?

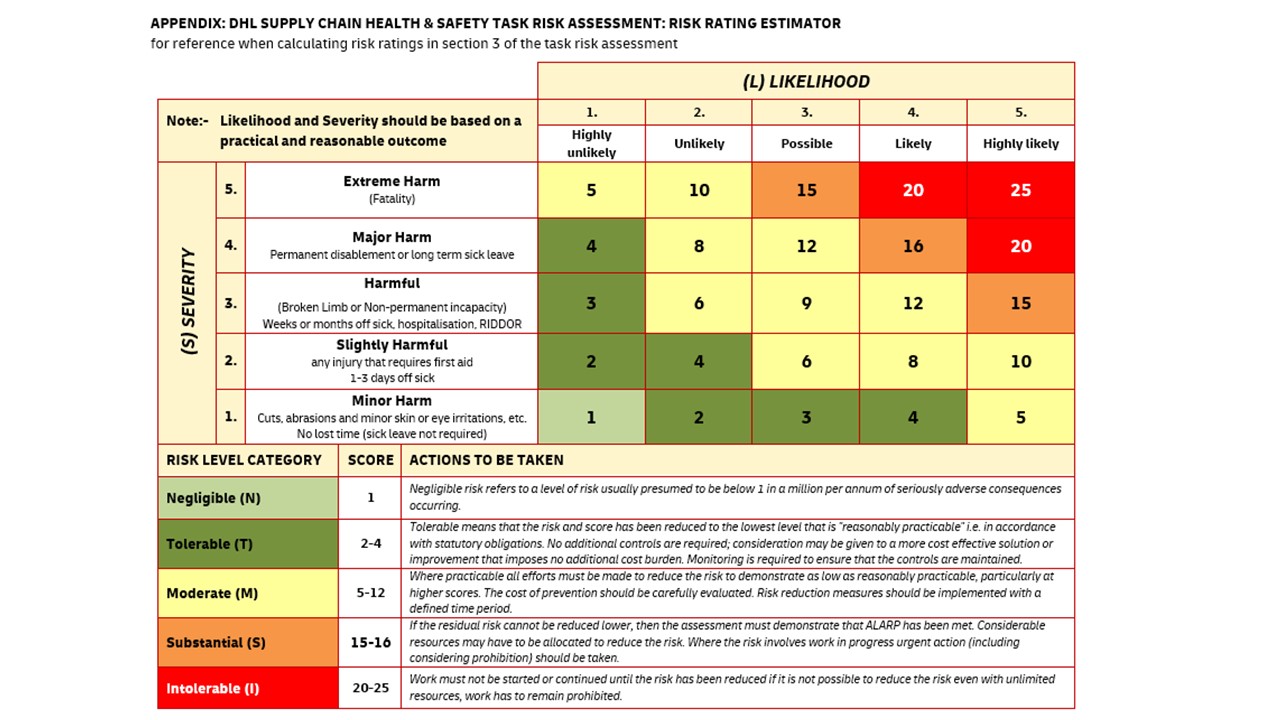

Risk Rating Estimator

Risk Level Category

-

Overall Assessment

-

Next Review Date

Signature

-

Enter Auditor's Name and Signature.