Information

-

Inspection Title. RMS CONCRETE (for general use), MORTAR AND GROUT. ILC-MI-TP3-405-SC-R53. Ed 2 / Rev2

-

Project Name: Tabulam New Bridge. .

-

Location: BRUXNER HIGHWAY TABULAM

-

Contractor .

-

Prepared by

-

Conducted on

Work Activity Record

QUALITY MANAGEMENT SYSTEM

-

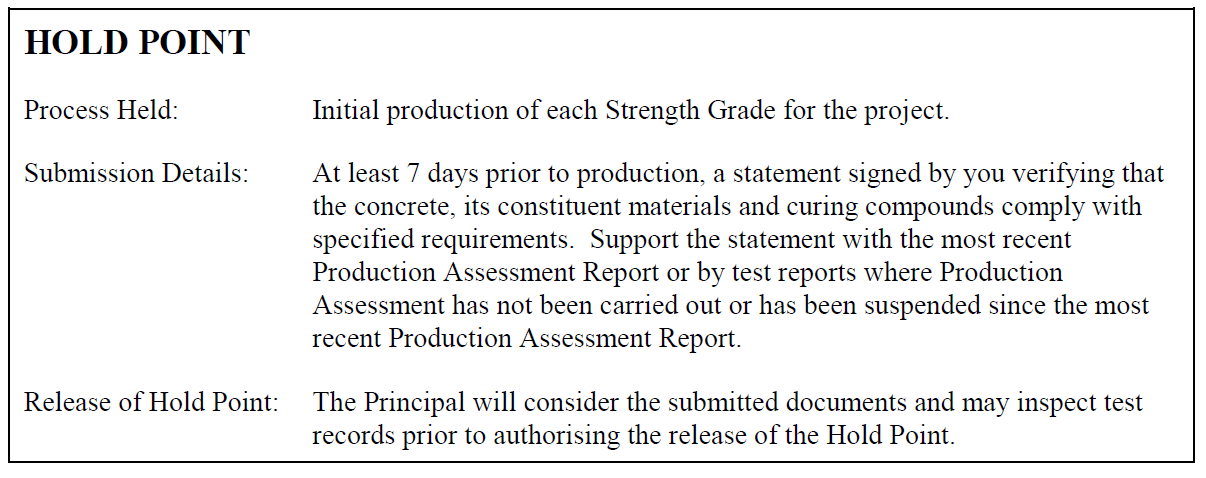

CL 1.4 Has the HOLD POINT been released.

-

Cl 1.4

Cl 2.6 SAMPLING AND TESTING.

-

Has sprayed concrete been tested in accordance with AS 1012 part 14 and tested to AS 1012.12 Method 2. <br>Has grout been sampled in accordance with AS 1012 part 8, Test in accordance with AS 1012.9

-

Cl 2.6 Has the sprayed concrete been tested using 75mm diameter cores and achieved acceptable 7 day compressive strength.

-

AS 1379 Cl 4.2.3 Has any water been added to the mix. If so, was it within the 75 minutes of batch time. <br>Was the amount of water added recorded and the correct mixing procedure followed. Has the concrete been re sampled and slumped.

-

Annexure 53/L Has the concrete been slump tested as specified in Annexure R53/L

-

Annexure R53/L Has the concrete sampled met the required compressive strength specified in AS 1012.9

-

Annexure R53/L has the grout sample met the required compressive strength specified in AS1012.9

Cl 3 FORMWORK

-

Cl 3.1 Has the formwork been erected and certified as per AS 3610. <br>Have construction joints been located as per drawings and prepared correctly. <br>Has a 50mm layer of unreinforced concrete been placed before placing reinforced concrete in an earth excavation.

-

Cl 3.2 Has the formwork been erected to produce the required concrete finish. <br>Has the erected formwork been checked by survey and is it within tolerance.

-

Cl 3.3 Has formwork been stripped in accordance with timeframes in AS 3610 Table 5.4.2.<br>In addition the minimum timeframe must be not less than.<br>(a) 2 days for vertical form on external surfaces.<br>(b) 1 day for vertical forms on permanently hidden surfaces.<br>Has a surface repair method been approved.

Cl 4 STEEL REINFORCEMENT.

-

Cl 4

-

Cl 4 The minimum cover of any steel bar, wire or fabric reinforcement is 50mm unless noted otherwise on the drawing. <br>

-

Cl 4 Has reinforcement been supported above ground while in storage.

-

Cl 4 Has the reinforcement been supported by concrete or plastic chairs, with NO use of wire chairs, bricks or timber pieces.

Cl 5 TRANSPORT AND DELIVERY OF CONCRETE

-

Has a concrete washout area been defined and used.

Cl 6 PLACING CONCRETE, MORTAR AND GROUT.

-

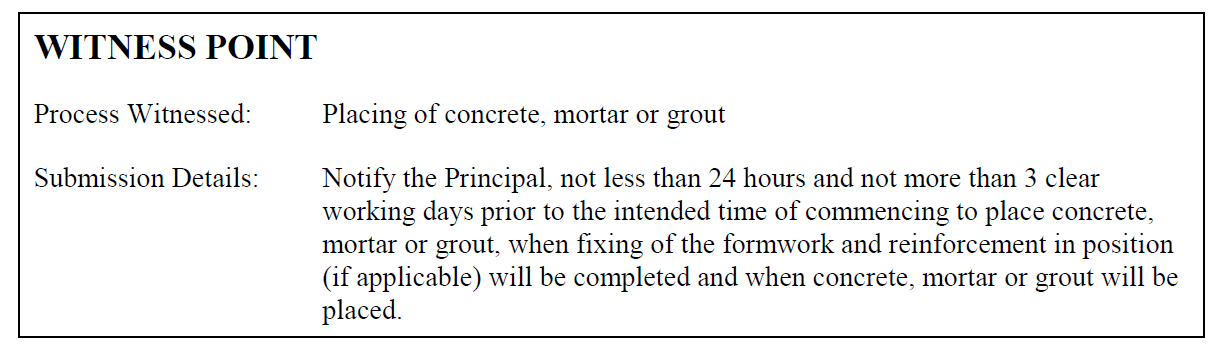

Was the Witness point notified

-

-

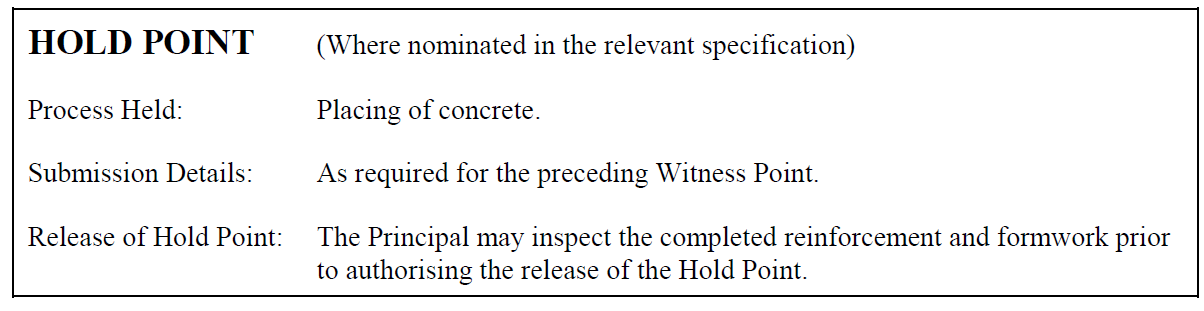

Was the Hold point released.

-

-

Cl 6.1 Has all dirt and other foreign matter been removed from the forms.

-

Cl 6.2 Has the concrete been placed and finished so as<br>(a) Limit segregation or loss of materials.

-

(b)Limit premature stiffening.

-

(c) Produce a dense homogeneous product which is monolithic between joints and edges.

-

(d) Expel entrapped air and closely surround all reinforcement and embedments.

-

(e) Provide the specified thickness and surface finish.

-

Cl 6.3 Has the concrete been placed when the air temperature in the shade is between 5 deg C and 38 deg C.

-

AS 1379 Cl 4.2.5.Has concrete been placed and compacted within 90 minutes of batching.

-

Cl 6.4 Has the unformed concrete surfaces been finished to achieve the specified:<br>(1) Dimension and grade.<br>(2) Cover from the surface to reinforcement and embedments.<br>(3) Texture of the surface and to avoid plastic or drying shrinkage cracks.

-

Cl 6.5 If evaporation retarder has been used:<br>Was it applied as a fine mist. <br>Was it NOT incorporated into the surface during subsequent finishing operations.

-

Cl 6.6 Have the surface of concrete joints been roughened prior to placing adjoining concrete.

Cl 7 CURING AND PROTECTION OF CONCRETE.

-

Cl 7.1 Was the freshly finished surface protected from rain or injury from other causes until hard set has occurred. <br>Has the concrete been cured for at least 7 days.

-

Cl 7.2 Moist curing: has the exposed surfaces been sprayed with water and kept continually wet for at least 7 days.

-

Cl 7.3 Has the curing compound been sprayed at the correct rate per m2.<br>If necessary are 2 coats being applied to ensure a complete and uniform cover. <br>Has the curing membrane been maintained intact for 7 days.<br>Has any damaged areas of the curing membrane had a further application of curing compound within 30 minutes of the damage occurring.

-

Cl 7.4 Have test results been received to show that the concrete has reached sufficient strength to carry loads without damage prior to backfilling or any other loading of the concrete structure.

Cl 8 CONCRETE CRACKING.

-

Cl 8 At the completion of the curing period are there any cracks greater than .05mm measured at the concrete surface.

G22 Safety and G36 Environmental

G22 SAFETY

-

Have operators demonstrated their competence to operate the plant/equipment to the satisfaction of the contractor. <br>

-

Has a SWMS been developed.

-

Is each and every item of plant being used for its designated and intended purposes.

-

Have the attachments for plant and processes been approved and used in accordance with their design and purposes.

-

Has certified rigger checked that the structural members are secure before the load is released.

-

Is the correct PPE being worn.<br>Is suitable PPE available and used

-

Are all accesses safe and sign posted.

-

Are all electrical equipment tested and tagged and in good condition.

-

Were any unsafe practices observed. <br>

-

Good safe practices observed.

G36 ENVIRONMENTAL

-

R44 Cl 1.7 Were erosion and sediment controls in place prior to the removal of any topsoil.

-

Are Erosion and Sediment controls measures being installed and maintained.

-

Has mud been prevented from being deposited on roadways.

-

Have nearby/adjacent water ways been protected from potential concrete, grout and curing compound spills.

-

Has a concrete washout area been defined and used.

-

Have any environmental incidents or potential incidents been observed.

-

Good environmental procedures observed.

Compliance and Follow-up action.

-

Is the activity compliant.

-

Surveillance Officer

-

NCPN or memo number.

-

Follow up action

-

Product Non Conformance

-

System Non Conformance

-

Contractor generated NCR

-

Contractor generated a CAR

Matters arising

-

NCPN no

-

Contractors NCR no

-

CAR no

-

Closed out.

-

RMS representative's name