Title Page

-

RCA #

-

Corrective Action Preventive Action

-

Complaint / non-conformity : notice & issue date

-

By email

-

By phone / chat

-

By inspection

-

Customer representative

COMPLAINT / NON-CONFORMITY

-

SKU#, item code, item type

-

Reference : PO/Batch/RPO#, item name-description & quantity

-

Discrepancy / non-conformity description

-

Defect classification of non-conformity

-

Picture & video attachment

ROOT CAUSE ANALYSIS

-

Fishbone diagram :

-

As determined 4 factors in fishbone diagram, what is possible cause of non-conformity?

-

Man power ?

-

Material ?

-

Machine ?

-

Method ?

-

5Why possible main/basic cause :

-

As determined by the 5Why, what is the basic root cause of Man power non-conformity?

-

Why-1?

-

Why-2?

-

Why-3?

-

Why-4?

-

Why-5?

CONTAINMENT & CORRECTIVE ACTION

-

Where is the non-conformity found? How many quantity?

-

Area where defect found :

-

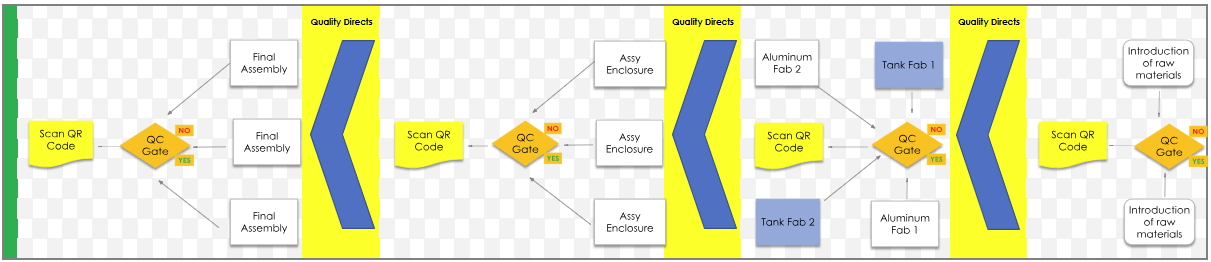

Where is the defect found in the process:

-

What has been put in place to stop the non-conformity?

-

Corrective Action

-

Timeline (due date) / Status

PREVENTIVE ACTION

-

Has one point lesson been written ? If No, What is the other solution?

-

What is the solution?

-

Timeline (due date) / Status

-

Has the standard, procedure, work instruction been created, review or updated? If No, What is the other solution?

-

What is the solution?

-

Timeline (due date) / Status

-

Have trained, socialization the new or updated standard, SOP, WI? If No, What is the other solution?

-

What is the solution?

-

Timeline (due date) / Status

-

Confirm the team has been involved.

-

Team / Timeline (due date) / Status

-

Have the results and improvements been communicated to all affected persons?

-

Who hasn't been communicated with?

-

Timeline (due date) / Status

-

If the answer is YES and DONE to all of the above in this section, the RCA-CPA is ready to be closed.

COMPLETION & VALIDATION

-

Verified QC Supervisor:

-

QA Manager : PRANOWO I.

-

Production Manager Unit-1 : M. KARTONO

-

Production Manager Unit-2 : AMBANG DJENDRA

-

PPIC Manager : M. AGUS

-

General Manager : AGUS SANTOSO LAUW

-

This report is valid without being signed.