Information

-

Document No.

-

Client / Site

-

Conducted on

-

Prepared by

-

Location

Task Analysis and Hazard id

SITE EXCAVATIONS & SITE WORKS

-

EXCAVATOR / MACHINERY

-

Potential harm. Various. Significant Hazard. Controls are P

- Experienced operators only

- Keep swing area clear

- Roll over cages fitted

- Seat belt worn

-

Loading and unloading excavator from transporter or truck

-

Potential harm being crushed killed or sever injury Significant Hazard, Minimise, Controls are

- Experienced operators only

- Unload and load on level and stable ground only

- Never have transporter facing up hill

- Use ramps with a high enough rating for the machine being unloaded

- Do a visual check on ramps for damage and or stress cracks

- Always use bolts or pins to secure ramps to truck

- Travel strait on ramps don't turn or screw

-

Steep Ground / Topography

-

Potential harm. Roll over causing severe injury or death significant hazard minimize. Controls are

- Know gradability of excavator

- Travel either straight up or down the slope

- use existing contour tracks

- Cut new tracks if slope to steep

- Don't move across steep ground

-

Steep slops /Rig sliding down slop

-

Potential harm. Roll over causing injury or death Significant hazard. Minimize Controls are

- Keep machinery back from top of batters and banks

- Work from level ground or slope within gradability of excavator

-

Cut batters

-

Potential harm. Being crushed by ground collapsing. Significant hazard. Minimize. Controls are

- Cut ground to stable batters

- Keep machinery back from top of batter

-

Open Excavations

-

Potential harm. Excavator sliding into excavation causing injury or death Significant hazard. Isolate. Controls are

- Keep at least 2.5 m clear of excavations

- Work from slope within gradability of excavator

- Cut excavations to stable batter

-

Working Alone

-

Potential harm. Dying as a result of not being missed until it was to late after a accident. Significant hazard. Eliminate. Controls are

- Advise DDP office your location and expected time of return

- till farm owner and what to do if you don't make contact on time

-

Soft ground

-

Potential harm. Excavator track sinking causing machine to roll over resulting in crushing.Significant hazard. Controls are

- Work over new work areas to check ground conditions

- Roll cages fitted and seat belt worn

- Recheck work area after significant rain

Drilling

-

Drilling rig operation

-

Potential harm. Being hit struck /Crushing /run-over Significant hazard. Isolate Controls are

- Experience operators with machine operating correctly

- Drilling crew only within 10m of rig when drilling

- Offsider stays in visual contact

- Keep clear of swing area

- Correct hand signals for rig operation use

-

Open holes

-

Potential harm. Scrapes or bruising from tripping into open pile. Severe injury from machinery rollover

- Cover open holes when not being worked on

- Keep machinery back from pile edge

- Use casing to stabilize loose or collapsing ground

- Holes over .6m diameter Offsider must wear a harness and be tied off

- Barricade large diameter hole off wile working on them

-

Swinging pendulum auger

-

Potential harm. Being hit causing Broken bones and or bruising. Significant hazard. Controls are

- Hard hats worn

- Offsider stays in visual contact

- Drilling crew only with in 10 m of rig when operating

-

Spinning of tailings

-

Potential harm. Being hit by flying stones or rock causing bruising minor hazard minimize. Controls are

- Drilling crew only within 10 m of rig when operating

- Keep swing area clear

Driving of poles, casings and irons with a excavator

-

Piling rig operation

-

Potential harm. Being hit or struck / Crushed / Run over. Significant Hazard. Isolate. Controls are

- Experienced operators with machines operated correctly

- Piling staff only within 1Om of piling rig

- Offsider stays in visual contact

- Keep clear of swing area on excavator mounts

- Correct hand signals for rig operation

-

Rail or pole breaking while driving

-

Potential harm. Being hit by broken section of pole or rail causing crush injury, broken bones and/or bruising. Significant Hazard. Isolate. Controls are

- Offsider to keep at least 5m clear of post or rail wile being driven

- Offsider watch rail or post for cracks and stresses never turn your back on job

- All others to stay 10m away from pile being driven

-

Recording sets

-

Potential harm. Being hit on head or hands causing crush injury, broken bones and/or bruising. Significant hazard. Minimize

- Offsider visible to operator while sets being taken

- Offsider to be comfortable positioned no reaching

- Sets measured and written on pile only while rig is static

-

Helmet, lifting strop or fixing pin breaking

-

Potential harm. Being hit on head or hands causing crush injury, broken bones and/or bruising. Significant hazard. Minimize

- Hard hats (with ear muffs) worn at all times

- Never place hands on top of piles

- Piling staff only within 10m of rig

- Replace worn fixing pins

-

Noise during pile driving

-

Potential harm. Hearing loss. Significant hazard. Eliminate Controls are

- Hard hats fitted with ear muffs to be worn

Other Hazard associated with handling of poles, timber, irons, beams and cages casings and concrete

-

Pitching piles irons and casings<br>

-

Potential Hazard Being hit by rail pile casing slipping from lifting chain. Being hit by swinging rail, pile or casing Significant Hazard. Minimize. Controls are

- Use approved lifting chains and strops . use hook correct way round tags current and correct SWL and visual inspection

- Ensure pitching pin on breaker driver is fully inserted

- Piling staff only within 10m of piling rig

- Offsider to control bottom end of pile being lifted

- Experienced operators US 20875 or equivalent

- Lifting plan must be filled (not necessary for everyday minor lifts i.e. drilling gear and small poles)

-

Machine hoisting while loading or unloading

-

Potential harm. Being hit or crushed by falling or swinging load. Significant hazard. Controls are

- Keep clear of suspended loads

- Use approved slings must have current tag correct SWL and visual inspection

- Hard hats worn

- experienced operators only us 20875 or equivalent

- Use appropriate hand signals and directions

- Machines over 7 ton must have ante burst valves certified lifting point and loading chart at hand

- Lifting plan filled out and communicated to all involved (not necessary for every day minor lifts i.e drilling gear and small poles)

-

Gas cutting

-

Potential harm. Eye injury & burns. Significant hazard. Controls are.

- Gas cutting eye protection worn

- Gloves and non flammable overalls warn

- Keep clear of others cutting

- have fire extinguisher close by clear any flammable away from cutting area

- Is hot work permit required

-

Grinder

-

Potential harm, Eye injury, cuts and abrasions to hands arms legs and torso. Hearing loss. Significant hazard, minimise. Controls are

- use appropriate size grinder for job

- Use in safe manor, working in stable stance

- Wear eye and hearing protection and safety boots

- tools and leads must have currant test tag

- Use a RCD

-

Concrete vibrator<br>

-

Potential harm, eye irritation electrocution Significant Hazard Isolate, controls are

- Wear safety glasses

- Only use tools and leads that have current test tag

- Use a RCD

-

Chainsaw use

-

Potential harm, Feet or legs and torso severely cut. Hearing loss. Significant Hazard. Minimize. Controls are

- Approved users only

- Use in a safe manner, working in stable stance

- wear safety boots and chain saw chaps

- Wear hard hat ear muffs and eye protection

- No lose clothing or hair

- not to be used if working alone

-

Concrete / Cement<br>

-

Potential Harm. Being hit struck /Crushing / Run-over. Skin or eye irritation Significant Hazard. Isolate Controls are

- Guide reversing trucks using a spotter

- Don't clime up on truck or try and fitt shoots let driver do it

- Avoid skin contact

- Wash any skin that has been contact

- Wear safety glasses to avoid splash's

-

Stockpiled Material

-

Potential harm being crushed from rolling rails, posts, cages or casings. Significant Hazard. Isolate controls are

- Stack on stable ground and use suitable dunnage

- Stack clear of traffic and footpaths

- Use appropriate bars and levers when positioning lifting chains

TIMBERING UP WALLS

-

Chainsaw use fill out in section above

-

Nail gun use

-

Potential harm. Nail penetrating eye hands or limbs Significant Harm. Minimize. Controls are

- Trained and Approved users only

- Wear eye protection

-

Power tools

-

Potential harm .eye injury cuts and grazes loss off fingers and limbs, hearing loss, electrocution. Significant hazard. Minimize. Controls are

- Trained and Approved users only

- wear eye and hearing protection

- Use currant tagged tools and leads only

- Use RCD

- inspect tools for damage i.e. guards and safety devices before use

-

Unstable batter behind wall

-

Potential harm. Being pinned or crushed behind wall Significant hazard . Isolate Controls are

- Cut to stable batter

- Work in front of wall as much as you can

- never timber more than waste height backfill and work on top of backfill

-

Treated timber

-

Potential harm. Poisoning from timber treatment. Significant Hazard. Minimise. Controls are

- Wash hands after handling and before eating or smoking

- Wear gloves if treatment is fresh (wet or green)

- Wear gloves and glasses if using any brush on treatment

General site and environment Hazards

-

Public, clients, engineers, visitors and other contractors entering your work zone

-

Potential harm is hurting them self or distracting the operator and or offsider causing harm

- Ask client or main contractor to remedy site security if not up to scratch before we can do the job

- Induct visitors and other contractors to this hazard id

- Get all DDP Employees on this site inducted on to other contractors hazard id

- Read site hazard board

- Keep visitors and other contractors at least 10m away from rig

-

Hot weather

-

Potential harm is Sunburn, heat stroke and dehydration Minor hazard Isolate. Controls are

- Cover up use sunhat light clothing and sun hat

- Drink plenty of water

-

Cold and /or wet weather

-

Potential harm. Getting wet and cold - Hypothermia Minor Hazard Isolate. Controls are

- Wear warm clothing

- Put on wet weather gear before getting wet

- Sit it out if rain gets to heavy

-

Over head wires

-

Potential harm. Equipment touching wires causing electrocution of operator or offsider. Significant hazard. Minimise. Controls are

- Maintain 4m clearance from any mains cables

- Obtain close proximity permit if need to work closer but no closer than what is on permits an use a dedicated spotter

-

Underground services

-

Potential harm. Electrocution from power cables. Burns if gas explodes due to rupture, Water under pressure conducting electricity from over head wires

- Private property -confirm with client services have been located

- Close services have been marked out and exposed

- Work on road -service plans obtained, mark out done & potholed

-

Traffic

-

Potential harm is injury from traffic accident. Significant hazard. minimise .Controls are

- Traffic Management Plan to Transit standards to apply

- Transit approved Hi-Vis clothing worn at all times

- Traffic Controller on site at all times, STMS within travel times

- Signage and cones to TMP diagrams. Check though out day

-

Are there there any transformers power pillars gas meters or other energy source on site that could be a hazard

-

Potential harm is electrocution or burns from explosion ,Significant hazard ,Controls are

- Identify and make everyone aware

- Make visible with cones

- Isolate with barriers

-

Has a emergency plan been discussed

Sign off

-

Are there any other hazards. What is the potential harm. What controls are we putting in place to eliminate, isolate or minimise

Site Minimum PPE

-

Minimum PPE

- hard hat

- Hearing protection

- Safety glasses

- Hi vis clothing

- Gloves

- Safety boots

- Flame retardant overalls

- Harness and safety rope to be used when working around large diameter holes

Hazard sheet to be filed out as team persons entering site after hazard sheet filed out must read it and be briefed by supervised of the site then sign on

-

DDP employees have read and understood this hazard ID

-

Employee

Other contractors either working for or with DDP in our work zone have read and understood this hazard ID

-

Person

Client or main contractor to confirm that there are no services present or they have all been located and marked clearly

-

Client or main contractor

Plant pre start

-

Plant onsite

plant

-

Plant type

- Sk235

- Sh120

- Zx 75

- Vio 57

- Merlo

- Bobcat

- Canter

- Nissan pk205

- Nissan 385

- Nissan 400

- Other

-

Description of plant

-

Service sticker currant

-

COF RUC and Rego Current

-

Hydraulic - leaks connections

-

Components - damaged, broken

-

Weeks / Tracks -Tyers Suspension

-

Pins, Pivots , Rams, lift arms, bucket pins, Ground engagement tools

-

Quick hitch independent connectors secure

-

Guards in place secure warnings

-

Condition of hooks,sheaves chains, slings

-

Cabin - controls, lose, objects, seat belts, windscreen, visibility rear view mirrors seat functions

-

Operation of brakes steering controls wipers leavers buckets before moving off

-

Fire ext

-

Any Damage to report and or any repairs needed

-

Please fill out this section the first Monday of month or when plant first arrives on site

-

Hour meter reading

-

Hubo reading

-

Odometer reading

-

RUC sticker end

-

Service due od or hr

-

COF due

Lifting plans and Hot works permits

Lifting plan

-

A lifting plan must be filled out on every excavator over 7t except for every day lifts i.e. drilling gear and light timber poles

-

Lift plan

Plan

-

Machine being used

-

ZX75

-

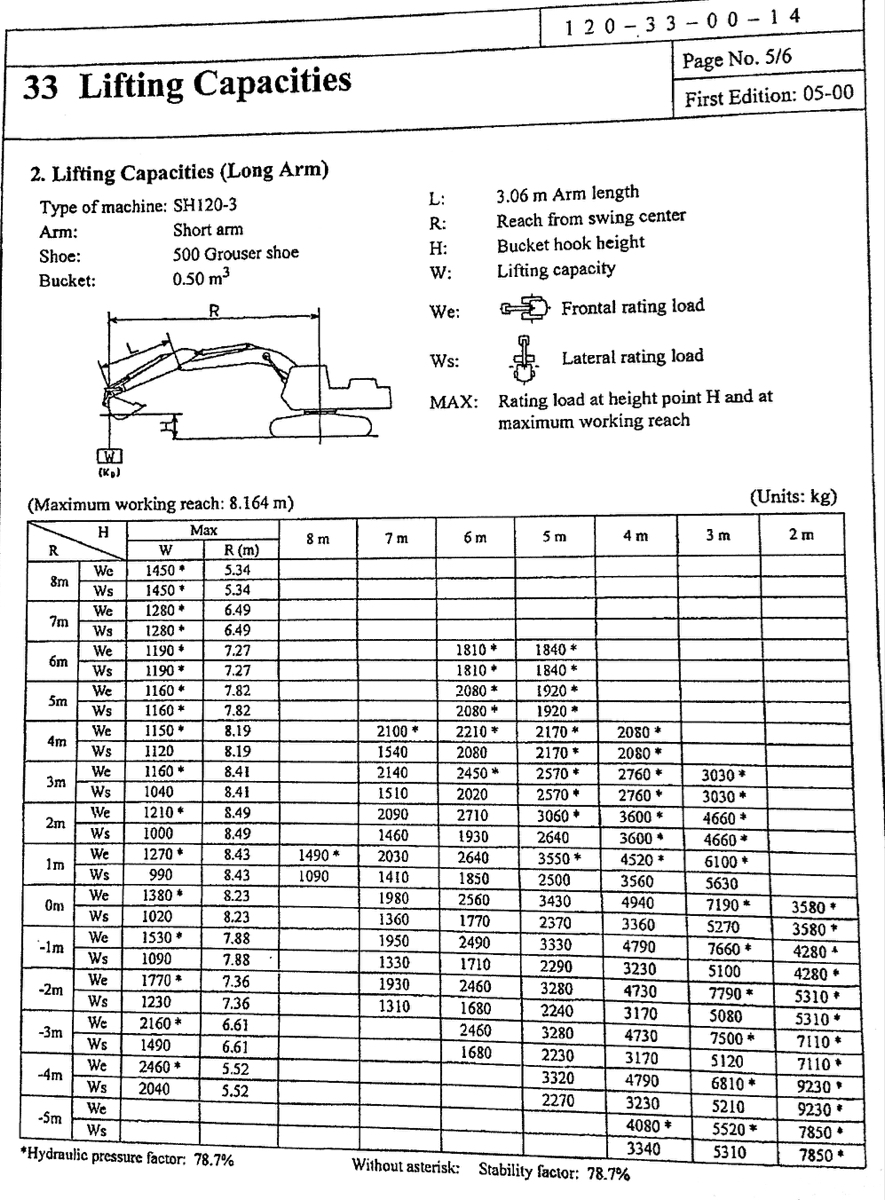

SH120 lifting chart

-

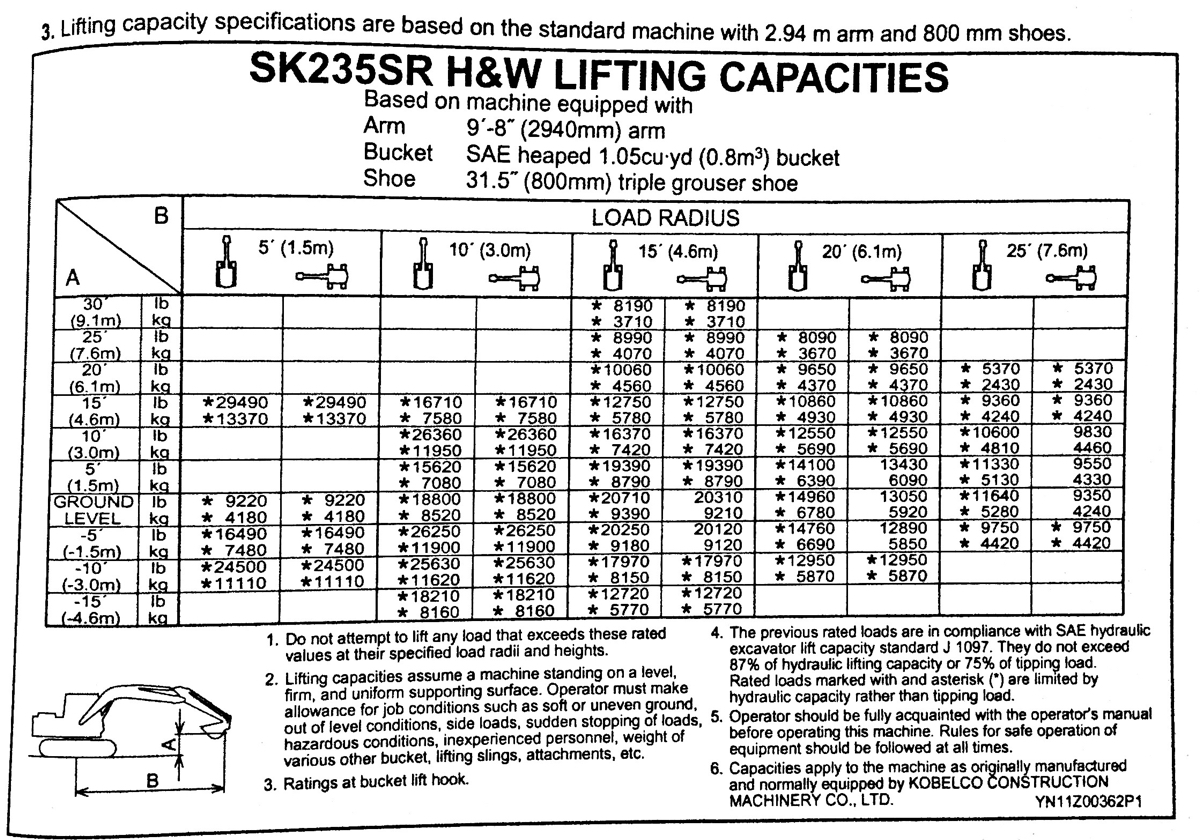

SK235 lifting chart

-

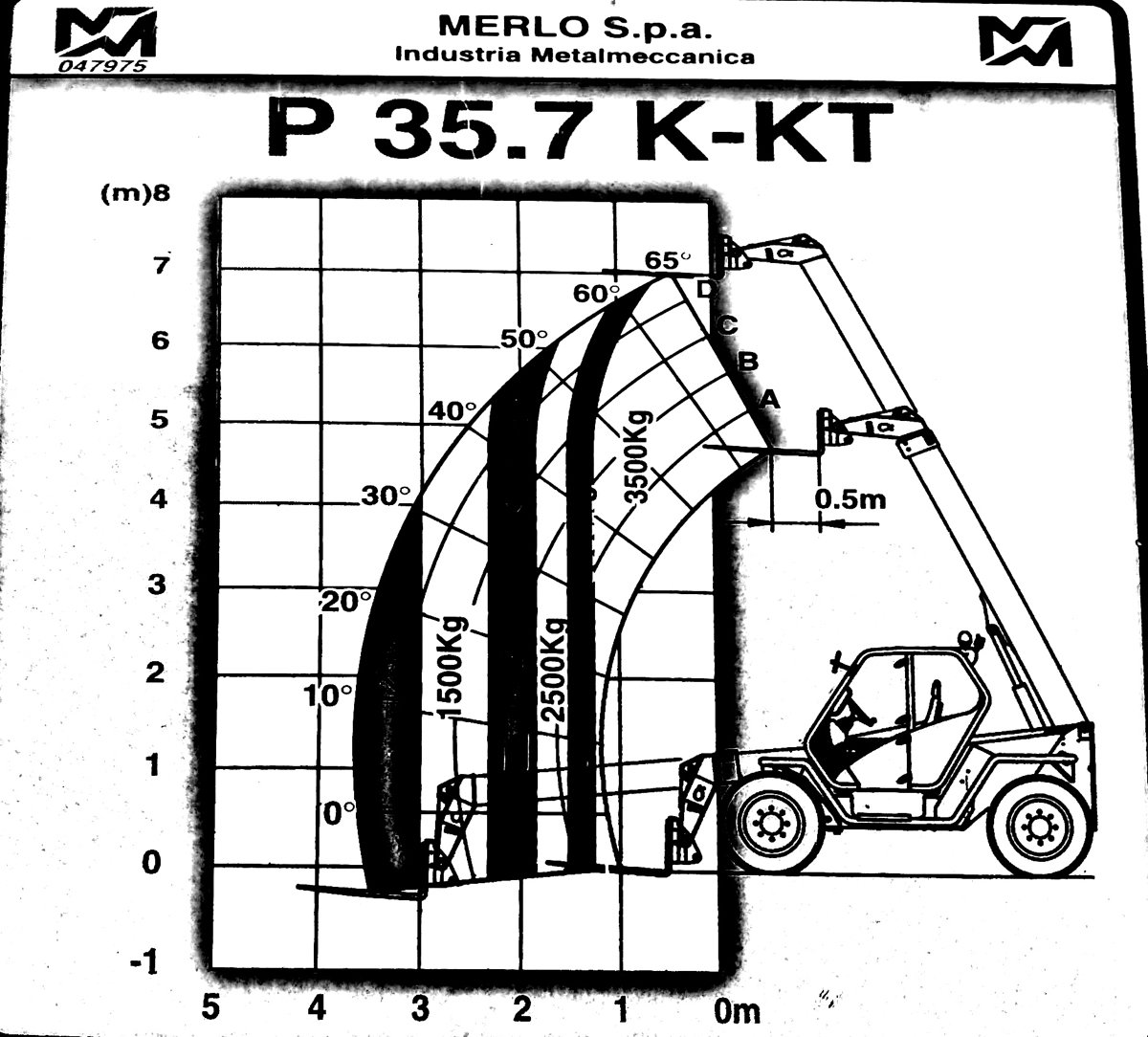

Merlo lifting chart

-

Model of machine

-

Have you checked lifting point cert and have a copy of lifting chart

-

Take photo of lifting chart

-

Communication

- Visual hand signals

- Verbal

- Raidio

-

Ground conditions- Flat and able to support without sliding

-

Electrical hazards -overhead wires present

-

Control of hazard

- Maintain 4m clearance from any mains cables

- Obtain close proximity permit if need to work closer but no closer than what is on permits an use a dedicated spotter

-

Pre start completed

-

Lifting equipment - Visual inspection - currant test tag - Sufficient SWL Rating for load being lifted

-

Description of item being lifted

-

Lift must be supervised a employee with a lifting and slinging unit standard

Hot works permit

-

Hot work permit

permit

-

Do we need a permitted issued by client or main contractor

-

Photo of completed permit

-

Employee this permit is issued to

- Alex Robertson

- Johnny Flavell

- Shannon Smith

- Hamish Keene

- Eliot Harper

- Michael Menchi

- Jack Griffith

- David Omundsen

- Kevin Menchi

- David MacGregor

- Hira Harris

- Other

-

Name

-

Start time of hot works

-

Finish time of hot works

-

Description of work and equipment being used

- Welding

- Gas cutting

- Heating

- Cutting and grinding with abrasive equipment

-

Fire fighting equipment at hand

- Fire extinguishers

- Water

- Sand

- fire hose

- Mandatory fire watch

-

All combustible material within 10 m removed or protected with non combustible curtains, metal guards or flame proof covers

-

This hot works area and surrounding area has been patrolled and inspected for at least 30 minuets after after completion of work by the person responsible for this permit and that there were no fires or smouldering present

Daily dairy sheet

-

Location

-

Select date

-

Employees on site

employee

-

Name

- Alex Robertson

- Johnny Flavell

- Shannon Smith

- Hamish Keene

- Eliot Harper

- Michael Menchi

- Jack Griffith

- David Omundsen

- Kevin Menchi

- David MacGregor

- Hira Harris

- Other

-

Name

-

Yard

-

On site

-

Off site

-

Yard

-

Lunch break taken

-

Was the client or the main contractor onsite

-

Was the engineer on site

-

Name

-

Plant on site

- Sk235

- Sh120

- Zx 75

- Vio 57

- Merlo

- Bobcat

- Canter

- Nissan pk205

- Nissan 385

- Nissan 400

- Other

-

Plant

-

Small plant on site

- Generator welder

- Generator

- Gas cutting gear

- Hydraulic breaker

- M4 pump

- Fire pump

- Chainsaw

- Electric breaker

- Concrete vibrator

- Power tools

- Other

-

Small plant

-

Hire equipment on site

-

Sub contractors on site

Materials

-

Poles

-

Supplier

-

Supplied by

-

Sed

- 150

- 200

- 225

- 250

- 275

- 300

- 325

- 350

- 375

- 400

- Other

-

Sed

-

Length

- 1.8m

- 2.1m

- 2.4m

- 2.7m

- 3.0m

- 3.6m

- 4.2m

- 4.9m

- 5.5m

- 6.0m

- 7.0m

- 8.0m

- 9.0m

- Other

-

Length

-

Quanity

Rail

-

Length

- 3.0m

- 4.0m

- 5.0m

- 6.0m

- 6.4m

- 7.0m

- 8.0m

- Other

-

Length

-

Wieght

-

Type of irion

-

Quantity

-

Concrete

concrete

-

Supplier

- Higgins Wellington

- Higgins kapiti

- Higgins masterton

- Allied Wellington

- Allied Kapiti

- Allied masterton

- Firth Wellington

- Firth Kapiti

- Other

-

Supplier

-

Mix design

- 17/19 standard

- 17/13 pump

- 20/19 standard

- 20/13 pump

- 25/19 standard

- 25/13 pump

- 30/19 standard

- 30/19 pump

- 30/13 pump

- Other

-

Mix design

-

Additives

-

No of trucks

-

Total quantity in m3

-

Docket number's

-

Dockets

-

Timber

Timber

-

Supplied by

-

Supplier

-

Timber size

- 100-25

- 100-50

- 75-50

- 150-25

- 150-50

- 150-75

- 150-100

- 200-25

- 200-50

- 200-75

- 200-100

- 100-100

- 125-125

- 150-150

- Other

-

Size

-

Type of timber

-

Description of timber

-

Treatment

-

Description of treatment

-

Quarry products

Quarry product

-

Supplier

- EX Yard

- Winstones Belmont

- Winstones waikanea

- Wnstones Otaki

- KIwi point

- Higgins Horokiwi

- Higgins Kapiti

- Gary Holland

- Ablaze

- Other

-

Supplier

-

Product

- Over burden

- face metal

- 65 basecorse

- 40 base cause domestic

- 40 base cause standard

- 40 base cause m4

- pea metal

- 20mm drainage

- 20/40mm drainage

- 40/mm drainage

- 65mm drainage

- crib 80

- fill sand

- dune sand

- manufactured sand

- top soil

- 20mm top couse

- Other

-

Quantity in tons or cm3

-

Dockets

Tip fees

-

Tip

- T&T

- Wellington council

- spicer land fill

- dry creek

- Higgins clean fill kapiti

- NZ Composting kapiti

- Kapiti Transfer station

- Goodman's concrete disposal

- Burn pile kapiti

- kiwi point

- Other

-

Name of tip

-

Type of waste

- Clean fill

- Broken concrete

- green waste

- demo

- general rubbish

- burnable material

- Wet clean fill

- Other

-

Description of waste

-

Truck use to deliver waste to tip

- UTE

- zippy

- canter

- Nissan 205

- Nissan 385

- Nissan 400

- Other

-

Description of plant use to deliver waste to tip

-

Number of loads today

-

Dockets

-

Amount of waste in tons or cm3

Other materals

-

Description on material

-

Quantity

-

Supplied by

-

Docket if outside the norm

-

Description of work carried out today

-

Variation /Day works any variation to start up sheet or plans

Variation

-

Description of work carried out employees and plant involved and time spent on it

-

Instructed by

-

Problems ,Obstructions and/or any work not complying to standard/specification

Proplem

-

Description of problem and time spent on it

-

Any evidence of problem or obstruction.

-

Weather am

-

Weather pm