Title Page

-

Site conducted

-

Conducted on

-

Location

-

Project Manager

-

Inspection Number

-

Inspector

-

Installer

- Aces

- Dorman Projects

- Elex Khanyisa

- Happy Solar

- Powerwize

- SmartSolar

- Tisol

- BDL

- Other

-

Is this a remedial action inspection

-

Give previous project inspection number

Project Information

EQUIPMENT DETAILS

-

Inverter Brand

-

System kWp

-

Modules Size

-

Number of inverters

-

Inverter size

-

Type

-

Monitoring Equipment ( OOB, Janitza, MeteoControl, Weather station)

Module Area

Module mounting

-

Is clamps in clamp zone?

-

Any Broken modules?

-

Is there clamps close to the edge of the shortrails?

-

Labels

-

String labels on roof are present

-

String labels at DC junction box and/or Inverters are present

-

String labels for DC High voltage present on cable trays

-

Layouts

-

Has modules installation been finished?

-

String layout is confirmed to match final design Commissioning Form should confirm this

-

If there have been changes, these have been communicated to the EE design team for update

-

String layout from Project Description is being followed

-

Is the Layout from PVSol followed?

-

Number of Modules per String match PVSol Design and SLD

-

List anomalies

-

Number of Strings match PVSol Design and SLD

-

String Input to Inverters matches PVSol Design and SLD

Earthing

-

An earthing and bonding arrangement has been established inter Array

-

Method of interconnecting earthing between sub arrays

-

Is there an Earth busbar or connection point on cable tray?

-

The earth conductor size from sub arrays to earth connection point on roof

- 6

- 10

- 16

- 25

-

The earth conductor size from earth connection point on roof to Main earth bar in PV Sub DB

- 6

- 10

- 16

- 25

-

Is the Earth wire terminated with a lug and serrated washer to roof clamp/rail?

-

Is a rayvolt clip used?

-

Any loose earthing/bonding connection?

-

Spot checks for loose bonding lugs has been done on the outside modules and no loose lugs found

-

Latest design has been confirmed and approved by EE Design team Natheera and Dayne

-

Earthing layout follows design

-

MC4's

-

All MC4 connectors have been crimped with correct tool and tightened to the correct torque

-

Exposed MC4s are sealed and not exposed to the weather while not connected

-

No MC4 connectors are touching the roof sheeting

-

Only original MC4s are being used on site Especially SolarEdge sites

-

Is this a SolarEdge system

-

SolarEdge optimiser layout is being followed

-

Optimiser sticker layout is complete and clear

-

No mistakes are found in optimiser spot checks (Check at least 5)

Cable Trays

-

Has the position of cable trays, bends, entry points been identified

-

Cable entries into trays are mechanically protected and not exposed to sunlight or sharp edges

-

Any joins or connection in the DC cable are identified and recorded for asbuilt

-

DC cable is protected from sharp edges in trunking

-

Has the joins and cuts been cold galvanised or protected from environment in some manner?

-

Cables are managed neatly in the cable trays and will not pinch in the lid and no sharp edges at cable tray joints

-

Is sprague used between modules, module arrays and leading to cable trays or junction boxes?

-

Is the sprague fixed properly at all places?

-

Is the same sprague used thoughout the project? Multiple sizes allowed but only one manufacturer and type

-

Cable trays are properly fixed and does not show excessive deflection

-

Walkways are properly fixed and does not show excessive deflection

-

Is the cable tray lids properly fixed?

-

Sharp bends or turns on the DC cable

-

Inverter / LV Area

-

Has the PV Sub DB been installed?

-

Take photo of PV DB location and surrounding area

-

Brief description of PV DB location

-

The SLD lines up with the physical site inspection

-

NRS 097 Warning Labels have been procured and the position is determined

-

Labelling is complete and permanent All devices are clearly labelled including Inverters, Circuit Breakers, Isolators and DB boards

-

Is the Installation finished

-

The EE Commissioning Forms have been filled in and returned by the installer

-

All the CoC tests have been performed and results recorded by someone on site Record the name of the person who performed the testing

-

The CoC has been issued

-

Inverter casings and all metal cableways are bonded less than 0.2Ω

-

All serial sumbers have been recorded in the commissioning forms

-

Main DB?

Main DB

-

The Tie-In point to client DB has been identified

-

Take photo of Busbars/connection point (AC and Earth)

-

Take photo of Motorised breaker (connections/ trip settings/Serial Number/motorising unit)

-

Is the connections torqued and have they been marked?

-

Current rating and setting applied

-

Is the breaker 3 or 4 Pole

-

Breaker Fault level in kA

-

Is there terminal blocks for control wiring from PV DB to main motorised breakers in Main DB

-

Is the control cable directly wired?

-

AC Cables size/ busbar size from Main busbar/connection point to Main DB motorized breaker

-

Evidence required

-

Type of cables

-

AC Cables size from Main DB motorized breaker to PV DB motorized breaker

- 6

- 10

- 16

- 25

- 35

- 50

- 70

- 95

- 120

- 150

- 185

- 240

- 300

-

Type of cables

-

Earth Cables size from Main DB to PV DB

- 6

- 10

- 16

- 25

- 35

- 50

- 70

- 95

- 120

- 150

- 185

- 240

- 300

-

Type of cables

-

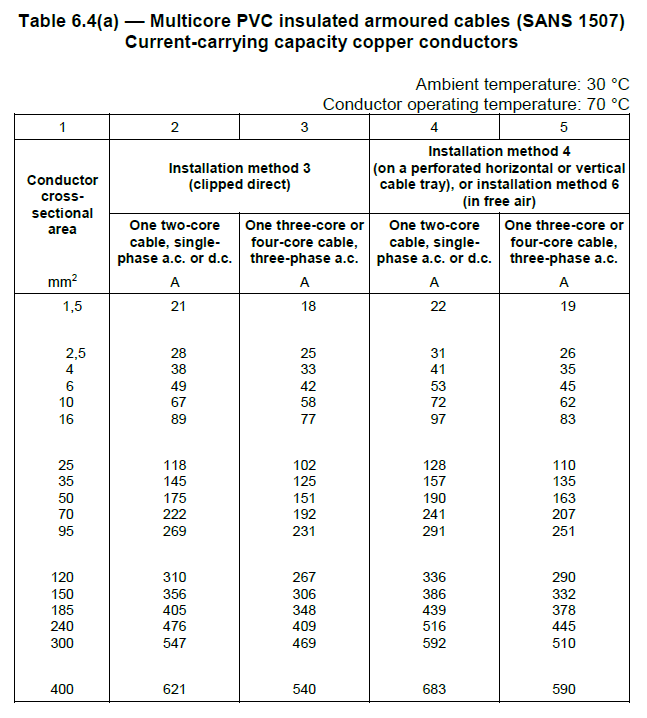

Cable sizes are sufficient to carry the current from the inverters/system. Refer to SANS 101421, Table 6.4(a) for SWA Armoured Cable

-

-

-

Does the Breaker and setting of breaker match SLD ( current and Fault rating)

-

Have the cables heatshrink been properly done?

-

Have the Breaker been labelled correctly?

-

Is there generator integration?

-

Take photo of generator tie in ( circuit breakers and wiring)

-

Is the Generator correct tie in correct?

-

Take photos of Generator integration conroller

-

Are the CT's in the correct location?

-

Where is the CTs located (Mains input/ generator input/ Automatic transfer switch output)

-

The grid consumption CTs are installed in the correct direction, ie. K or P1 towards the Grid For Solar Edge, Arrow points towards the grid

-

Take pictures of CT location, wiring and Serial Number/nameplate

-

Details of the CT's (Class/A rating/ VA rating/ 333mV or 5A output)

-

Main breaker in PV sub DB?

Main breaker in PV Sub DB

-

The Tie-In point to client Main DB has been identified

-

Take photo of Busbars/connection point (AC and Earth)

-

Take photo of Motorised breaker (connections/ trip settings/Serial Number/motorising unit)

-

Is there terminal blocks for control wiring from PV DB to main motorised breakers in Main DB

-

Is the control cable directly wired?

-

Is the connections torqued and have they been marked?

-

Current rating and setting applied

-

Is the breaker 3 or 4 Pole

-

Breaker Fault level in kA

-

AC Cables size from Main DB to PV DB motorised breaker

- 6

- 10

- 16

- 25

- 35

- 50

- 70

- 95

- 120

- 150

- 185

- 240

- 300

-

Cable sizes are sufficient to carry the current from the inverters/system. Refer to SANS 101421, Table 6.4(a) for SWA Armoured Cable

-

-

-

Does the Breaker and setting of breaker match SLD ( current and Fault rating)

-

Have the cables heatshrink been properly done?

-

Have the Breaker been labelled correctly?

-

PV DB?

PV DB

-

Any loose connections found in PV DB?

-

Is the modules connected directly to earth busbar?

-

Earth cable size

- 6

- 10

- 16

- 25

-

Evidence required

-

Earth cable type

- Bare copper

- Green Yellow

- Internal H07

- N/A

-

Evidence required

-

Type of termination on CB's and Terminals in PV DB

-

Take photo of all terminations on CB's, Terminal block, fuses and other equipment in DB

-

Is there a OOB Relay?

-

Type of Relay

-

Location of Voltage reference

-

Is there Relay voltage reference protection (type and size)

-

Are bootlace ferrules used on all connection on relay?

-

Is there terminal blocks for control wiring from OOB relay to motorised breakers

-

Are there bootlace ferrules used on the connections of the terminal blocks?

-

Is the control cable directly wired?

-

Take photo of serial numbers

-

Out of Bounds relay connection is correct and operates the MCCBs or contactors 2 in series. The OOB relay must be able to open and close the solar connection

-

Is the system smaller than 30kVA?

-

Solar DB design has been reviewed and is sized correctly for cooling etc

-

Is cooling equipment required?

-

Take photo of cooling equipment in DB

-

Is there AC SPD?

-

Type of SPD

-

Does the SPD have Fuse protection?

-

Fuze size

-

Cable size to fuse from Busbar

-

Cable size to fuse from SPD

-

Inverter Breakers

Inverter Breakers

-

Take photo of Busbars/connection point where inverter breakers are tied in to

-

Is the connections torqued and have they been marked?

-

Current rating and setting applied

-

Is the breakers 3 or 4 Pole

-

Breaker Fault level in kA

-

AC Cables size from Inverters to PV DB inverter breakers

- 6

- 10

- 16

- 25

- 35

- 50

- 70

- 95

- 120

- 150

- 185

- 240

- 300

-

Cable sizes are sufficient to carry the current from the inverters/system. Refer to SANS 101421, Table 6.4(a) for SWA Armoured Cable

-

-

-

Does the Breaker and setting of breaker match SLD ( current and Fault rating)

-

Have the cables heatshrink been properly done?

-

Have the Breakers been labelled correctly?

-

Earth cable size from earth busbar to inverters

- 6

- 10

- 16

- 25

- 35

- 50

- 70

- 95

- 120

- 150

- 185

- 240

- 300

-

Earth cable type from earth busbar to inverters

-

Inverters

Inverters

-

Take pictures of inverter Serial Numbers

-

Take Pictures of String Inputs to inverters

-

All strings are labelled on the roof and at inverter

-

Inverter mounting and spacing is as per the installation manual

-

Inverter installation manual is on site with the installation team

-

All inverters are producing energy and are communicating with the monitoring platform

-

Unused glands and holes are to be sealed with the blanks supplied in the inverter box

-

Is the inverters located outside

-

Does it require a cage and roof?

-

The inverter room has sufficient airflow and cooling

-

Inverter covers are mounted securely and all screws and glands are tightened correctly

-

Bonding, Earthing and insulation resistance test has been done and has passed before turning the power on

-

Production reading lines up with a manual measurement

-

Cable Trays

Cable trays

-

AC and DC cable trays separate?

-

Is the AC and DC cable trays mounted securely?

-

Is the AC and DC Cable tray lids mounted securely?

-

Is the AC and DC Cable trays bonded?

-

Comms Cable running separately from AC and DC conductors?

-

Cable bends are not too small in radius and are mechanically protected

-

Cable tray edges are deburred and or mechanically protected

-

Is the cuts cold galvanised?

-

Is the cuts cold galvanised?

-

Comms

Comms

-

Has the communication and metering equipment location been finalised

-

Take photo of Comms box inside and location

-

Datalogger type

-

Does the system require SCADA(>100kVA) (cape town)

-

For plants greater than 100kVA The Scada Device has been procured and the installation location is established

-

The connection between the inverters and the Scada device has been wired

-

Wiring method (RS485 or Modbus TCP)

-

Rs485 Cables used for Smartlogger/janitza/power meters/solaredge inverters ?

-

Does devices at start and end of chain have terminating resistor or switch?

-

Is the metal shielding connnected to ground on one side and disconnected on the other end?

-

Is there an Ethernet Switch?

-

Is there a power point in/nearby comms DB or in PV DB?

-

Is the installer aware that there is a need to install the techsitter meter

-

Is this a roof rental or PPA Has the Techsitter meter been ordered with the correct CTs

-

Does the monitoring system have its own router?

-

Is the router easily accessible for O&M?

-

Is the router set up and internet connectivity good?

-

Is the inverters running?

-

Inverter brand

-

IP Address of Smartlogger/Datalogger

-

IP Address of Inverters

-

IP Address of Datamanager/Datalogger

-

IP Address of Inverters

-

Is all the inverters set to static IP?

-

IP Address of Datamanager/Datalogger

-

IP Address of Inverters

-

Is all the inverters set to static IP?

-

Modbus ID's of inverters

General

-

Any additional remarks?

-

Is there boot marks on the modules

-

Is the site in neat condition and housekeeping done?

-

Is this site BUILT TO LAST