Title Page

-

Location of the Workplace

-

Prepared on

-

Prepared by

Focus of the Workplace Risk Assessment

Goal of the Workplace Risk Assessment

-

Why is this workplace risk assessment needed? (Other than being legally required)

-

How could this workplace risk assessment help your business and your employees?

-

What is the intended result, effect, or output of this workplace risk assessment?

Scope of the Workplace Risk Assessment

-

What's included in this workplace risk assessment?

-

What's not included in this workplace risk assessment?

Important Details Regarding the Workplace Risk Assessment

-

Who will be involved in this workplace risk assessment and what level of responsibility or participation do they have?

-

Where (specific room, site, facility, building, or area) will this workplace risk assessment be performed?

- Hub

- Kitchen

- Single toilet

- Equipment store

- Classroom 1 (Main)

- Element Yard

- Double W@H Rig internal

- Internal scaffold W@H rig

- Internal slope/incline in W@H rig

- External scaffold structure

- CS Rig Horizontal entry

- CS rig Vertical entry

- Classroom 2 (Small)

- Double toilets

- Tool/ material store

- External W@H Rig

- Fixed vertical ladder (Hooped)

- Other: please specify

-

Other: please specify

-

When will this workplace risk assessment be performed?

Workplace Risk Assessment

-

To begin the workplace risk assessment, select the "+" icon next to Hazard:

Hazard

-

Description of hazard

-

Photo of the hazard (optional)

-

Activity associated with this hazard in this area

- Moving from one area to another

- Crawling through restricted access areas

- Working at Height training

- Working at height maintenance

- Ladder training

- Ladder inspections

- Confined space training

- Confined space entry

- Carrying out external site survey

- Theoretical/ classroom training

- Meetings

- Manual handling

- Lone Working

- Display Screen Equipment

- Lifting Heavy Items

- Repetitive lifting/ twisting/ lowering

- Making food/ drink

- Cleaning

- Using mechanical equipment i.e. leaf vacuum

- Using electrical equipment

- Routine equipment maintenance

- Routine building maintenance

- Charging BA cylinders

- Charging Escape set cylinders

- Other: please specify

-

Risk related to hazard

- Death

- Fall from height

- Crush injury

- Impact injury

- Slip, trip or fall

- Asphixiation

- Musculoskeletal injury

- Repetitive strain injury

- Entanglement

- Electrocution

- Ejection

- Penetration

- Fire

- Drowning

- Respiratory

- Noise

- Psychosocial (Panic, anxiety, stress. bullying, harassment, violence etc)

- Burns/ scalds

- Ingestion

- Absorbtion

- Injection

- Eye strain (Display Screen Equipment)

- Collapse of scaffold

- Dizziness

- Vibration

- Infection

- Fatigue

- Heat stress/ exhaustion

- Hypothermia

- Suspension syncope

- Splinters

- Struck by moving vehicle

- Struck by falling object

- Other: Please specify

-

Please specify

-

Who might be harmed?

- Instructor

- Maintenance staff

- Student

- Visitor

- Admin staff

- General public

- Contractor

- Other

-

Please specify

-

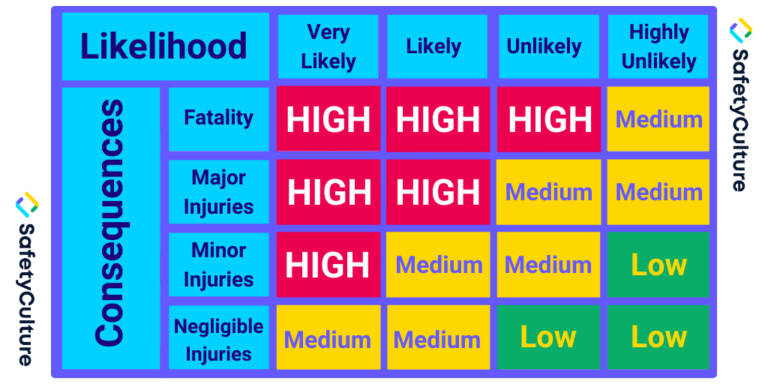

Risk likelihood

-

Risk consequences

-

Use this risk matrix to identify the risk level:

-

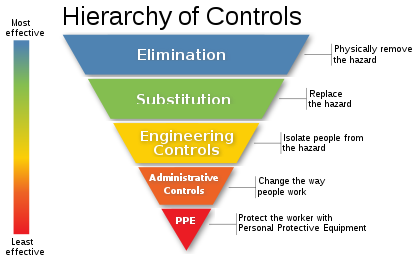

Hierarchy of control.

-

Risk level

-

Hazard causing risk can be eliminated?

-

Are you already doing something to control this risk to as low as reasonable practicable (ALARP)?

-

Apply control measures

- Close supervision

- Safety Brief

- Personal Protective Equipment

- In date with detailed inspection in accordance with manufacturers recommendations (LOLER)

- In date with detailed inspection in accordance with manufacturers recommendations (PUWER)

- Pre use check to be carried out

- Ensure safe barrier is in use

- Ensure W@H Safe System of Work (SSoW) is in use i.e. Work restraint, work positioning or Fall Arrest

- Tools/ equipment/ materials are tethered off/ secure

- Cordon area off

- Boulder mats in use

- Warm drinks available

- Cold drinks available

- Suitable foul weather clothing

- Fire extinguishing media at hand

- Correct manual handling techniques

- Manual handling equipment to be used

- Multiple people to lift/ carry/ move

- Isolate electrical supply

- Use of Residual Current Device (RCD)

- In date Portable Appliance Testing (PAT)

- Adequate rest period

- Isolate water supply

- Isolate gas supply/ gas cylinder

- Isolation of other services

- Hygiene i.e. wash hands/ alcohol gel or wipes

- Signage

- Ventilation

- Refer to COSHH assessment

- Intrinsically safe tools/equipment (ATEX)

- Adequate first aid provision including AED, o2 cylinder & airways.

- Lock out/ tag out system

- Trained personnel only

- First aid trained staff

- Confined space entry trained

- Working at height trained

- Manual handling trained

- Display Screen Equipment trained

- Fire extinguisher trained

- COSHH trained

- Other: Please specify

-

What PPE is required?

- Helmet

- W@H helmet with chinstrap

- Eye protection

- Full face protective visor

- Dust mask FFP1

- Dust mask FFP2

- Dust mask FFP3

- Breathing apparatus

- Ear Defenders

- Eye plugs

- Gloves

- High Visibility clothing

- Foul weather clothing

- Steel toe capped boots

- Steel sole footwear

- oil and chemical resistant sole footwear

- Anti slip footwear

- Knee pads

- Disposible paper suit

- Personal movement alarm

- Fall Arrest harness

- Work positioning harness

- Fall Arrest lanyards

- Work restraint device i.e. finch/ grillion

- Life jacket/ buoancy aid

- Apron

- Clothing that covers arms

- Overalls

-

Please specify what type of eye protection

-

Please specify what type of gloves

-

Please specify other control measure

-

When will control measures be implemented?

-

When will this be done by?

-

And by whom? Create an action

-

How will you monitor the effectiveness of these risk control measures?

- Audits

- Inspections

- Preventative maintenance

- Near miss reports

- Undesired circumstances

- Accident investigations

- Other

-

Please specify

-

What is the residual risk rating now after all steps taken to ensure risk is as low as reasonably practicable (ALARP)?

-

Move onto next hazard.

-

Please specify what other services are isolate

-

What existing control measures are in place?

- Close supervision

- Safety Brief

- Personal Protective Equipment

- In date with detailed inspection in accordance with manufacturers recommendations (LOLER)

- In date with detailed inspection in accordance with manufacturers recommendations (PUWER)

- Pre use check to be carried out

- Ensure safe barrier is in use

- Ensure W@H Safe System of Work (SSoW) is in use i.e. Work restraint, work positioning or Fall Arrest

- Tools/ equipment/ materials are tethered off/ secure

- Cordon area off

- Boulder mats in use

- Warm drinks available

- Cold drinks available

- Suitable foul weather clothing

- Fire extinguishing media at hand

- Correct manual handling techniques

- Manual handling equipment to be used

- Multiple people to lift/ carry/ move

- Isolate electrical supply

- Use of Residual Current Device (RCD)

- In date Portable Appliance Testing (PAT)

- Adequate rest period

- Isolate water supply

- Isolate gas supply/ gas cylinder

- Isolation of other services

- Hygiene i.e. wash hands/ alcohol gel or wipes

- Signage

- Ventilation

- Refer to COSHH assessment

- Intrinsically safe tools/equipment (ATEX)

- Adequate first aid provision including AED, o2 cylinder & airways.

- Lock out/ tag out system

- Trained personnel only

- First aid trained staff

- Confined space entry trained

- Working at height trained

- Manual handling trained

- Display Screen Equipment trained

- Fire extinguisher trained

- COSHH trained

- Other: Please specify

-

If answered Other, please specify

-

What PPE is required?

- Helmet

- W@H helmet with chinstrap

- Eye protection

- Full face protective visor

- Dust mask FFP1

- Dust mask FFP2

- Dust mask FFP3

- Breathing apparatus

- Ear Defenders

- Eye plugs

- Gloves

- High Visibility clothing

- Foul weather clothing

- Steel toe capped boots

- Steel sole footwear

- oil and chemical resistant sole footwear

- Anti slip footwear

- Knee pads

- Disposible paper suit

- Personal movement alarm

- Fall Arrest harness

- Work positioning harness

- Fall Arrest lanyards

- Work restraint device i.e. finch/ grillion

- Life jacket/ buoancy aid

- Apron

- Clothing that covers arms

- Overalls

-

Please specify what type of eye protection

-

Please specify what type of gloves

-

Please specify what other services are to be isolated

-

Is any further action needed to control the risk to as low as reasonably practicable (ALARP)?

-

Please type in what other control measures are required:

-

When will control measures be implemented?

-

When will this be done by?

-

And by whom? Create an action

-

How will you monitor the effectiveness of these risk control measures?

- Audits

- Inspections

- Preventative maintenance

- Near miss reports

- Undesired circumstances

- Accident investigations

- Other

-

Please specify

-

What is the residual risk rating now after all steps taken to ensure risk is as low as reasonably practicable (ALARP)?

-

Move onto next hazard in this area.

-

How will you monitor the effectiveness of these risk control measures?

- Audits

- Inspections

- Preventative maintenance

- Near miss reports

- Undesired circumstances

- Accident investigations

- Other

-

If other, please specify

-

What is the residual risk rating now after all steps taken to ensure risk is as low as reasonably practicable (ALARP)?

-

Move onto next hazard in this area.

-

When will control measures be implemented?

-

When will this be done by?

-

And by whom? Create an action.

-

How will you monitor the effectiveness of these risk control measures?

- Audits

- Inspections

- Preventative maintenance

- Near miss reports

- Undesired circumstances

- Accident investigations

- Other

-

Please specify

-

How will you monitor the effectiveness of these risk control measures?

- Audits

- Inspections

- Preventative maintenance

- Near miss reports

- Undesired circumstances

- Accident investigations

- Other

-

If other, please specify

-

What is the residual risk rating now after all steps taken to ensure risk is as low as reasonably practicable (ALARP)?

-

Move onto next hazard in this area.

-

Eliminate the hazard causing the risk. Move onto the next hazard.

-

To ADD another hazard to the workplace risk assessment, select the "+" icon next to Hazard.

To END the workplace risk assessment, select the "Next Page >" button at the bottom right.

Completion/Review

-

How often will you review this workplace risk assessment?

- Every 2 weeks

- Every month

- Every 3 months

- Every 6 months

- Every year

- Every 15 months

-

The HSE recommends reviewing workplace risk assessments at least annually.

-

Name and Signature of Employer/Owner/Manager of Workplace

-

Did the employer/owner/manager of the workplace perform the workplace risk assessment himself/herself?

-

Name and Signature of Appointed Person