Title Page

Document #: 810.04.067.F Revision Date: 2/28/2018

-

Conducted on

-

Prepared by

-

Crew:

-

Fryer:

-

Is the fryer empty? No water, oil or chemical (Photo)

-

This is what happens if chemical is left in the fryer after adding oil.

-

Is the envirodyne diverter valve in the correct location? Photo

-

Ideal location of diverter valve

-

Are the burner tubes free from significant build up? Photo

-

Does the oil sensor read zero on the panel view?

-

Did you contact maintenance?

-

-

Raise the fryer belt, are both belts running? Is the drive chain in place?

-

Inspect the top belt, are there any broken wires?

-

Inspect the bottom belt, are there any broken wires?

-

Is the crumb press connected correctly?

-

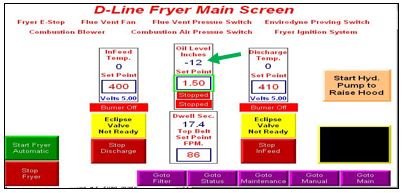

Set the Fryer to 1.5" on the level sensor (panel view setting)

-

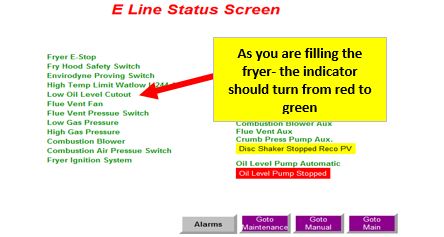

Confirm that the tuning fork sensor is working properly: as you are filling the fryer with oil does the indicator on the status screen turn from red to green?

-

-

Visually confirm with a flashlight that oil is covering the top belt ( just enough oil to cover the top belt, about 1/4")

-

Set the fryer to 250 F temp to start to allow for residual water expansion.

-

Are all valves in the fryer and filter room set up for normal production?

-

Do all valves move freely, all the way open and all the way closed?

-

Monitor oil level at the fryer, confirming that oil stays in the fryer after igniting. (minimum of 5 minutes)

-

Confirm that the fryer filter has oil coming in and belt is turning on when oil level is high.

-

Increase the fryer temp to 400 F, does it let you?

-

Did you notify maintenance?

-

Explain why you did not contact maintenance?

-

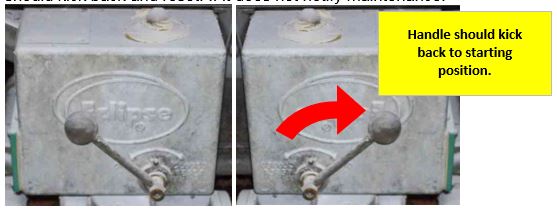

Shut the fryer down, do the eclipse valves reset to the off position?

-

Did you contact maintenance?

-

-

Confirm the fryer is at the desired temp & oil level, oil is still in the fryer, sign off on the inspection, and turn form into Supervisor.

Summary and Signoff

-

Comments:

-

Full Name & Sign

-

Completed on Date & Time (wait to select until ready to complete inspection)