Information

-

Document No.

-

Manufacturer

-

Model

-

Equipment Type

-

Asset/ Serial Number

-

Bay and location

-

Date of assesment

-

Assessor

Plant Risk Assessment

Physical hazards

-

Drawn in or Entrapment - Is there any risk of a person becoming trapped and/or crushed by the machine or any moving part/s of the machine?

-

Impact / Struck - Does any machine part move in such a way that it could strike the operator or anyone in the vicinity?

-

Crushing / Pinching - Is there any risk of a person becoming trapped and/or crushed by the machine or any moving part/s of the machine not guarded?

-

Shearing / Severing - Are there any areas within the operator’s reach where a shear hazard is created between parts of the machine or between the machine and work piece?

-

-

Parts Ejected / Pressure - Could work pieces, parts of the machine be ejected? Is there a potential hazard present relating to Release of stored energy?

-

Entanglement - Is there any potential for parts of the body, hair or clothing to become entangled in the plant?

-

Friction or Abrasion - Is there any potential for the operator to be exposed to height/low temperatures?

-

Cutting - Are there any parts of the machine that could cause a cutting or puncture injury?

-

Stabbing / Puncturing - Could the sharp objects puncture or stab the operator?

-

Unstable, movement - Can the machine become unstable or rosk when operated? i.e. is it bolted down?

-

Electrical / Static contact - Is there a potential for the operator to contact live electrical contactors? Either by exposed cables or damaged protected

-

High/Low Temps - Is there a potential hazard present relating to excessively high or low temperature?

-

Noise and Vibration - Is there a potential hazard present relating to noise or vibration?

-

Radiation - Is there a potential hazard present relating to radiation (x-ray, laser, microwave, EMF)?

-

Slip , Trip or Fall - Is there a risk of slips, trips falls around the machine?

-

Fire or explosion hazard - Any dusts, vapours, gases that could cause an explosion?

Chemicals and Biological hazards

-

Harmful gases, mists, fumes - Is there a potential hazard present from harmful substances - gas, fume, mist, vapour if inhaled?

-

Biological hazards - Is there a potential hazard present from biological infections, bacteria, fungus?

-

Fluid/air/gas injection hazard - Is there a potential hazard from injection? i.e. liquid, air or gas

-

Ergonomics - Is there a potential for long term upper or lower limb disorders due to poor ergonomics?

-

-

-

Behaviours

-

Are peoples hands in a safe place when operating the machine?

-

Is the method they are using to preform the task, safe?

-

Are they wearing correct PPE? Gloves as per glove charts, Glasses, mask, hearing protection?

-

Are they sat/stood in a safe/good position?

-

Hazard controls

-

Fixed Guards in place? If yes - Take photo

-

Interlocked guards in place? If yes - Take photo

-

Light guards/Sensors in place? If yes - Take photo

-

Lockable Isolator in place? If yes - Take photo

-

Are there isolators for each energy source?

-

Extraction in place? If Yes take photo

-

Signs and labels in place & legible? Take photo

-

Is there a SSW, Work Instruction for the machine? Check Q Pulse.

-

Is the person trained to the document? Check Q Pulse.

-

Is first line maintenance completed?

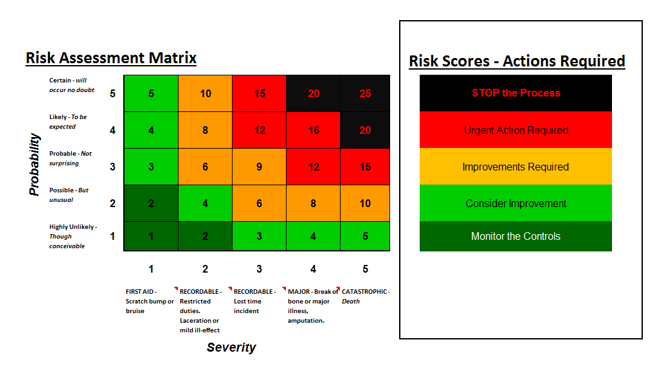

Frequency & likelihood

-

How many hours per day is the machines used?

-

How many people use the machine?

Finding/Comments

-

undefined

-

undefined