Title Page

-

Site conducted

-

Conducted on

-

Prepared by

-

Harness Serial Number:

Safety Harness Operator Inspection Checklist

-

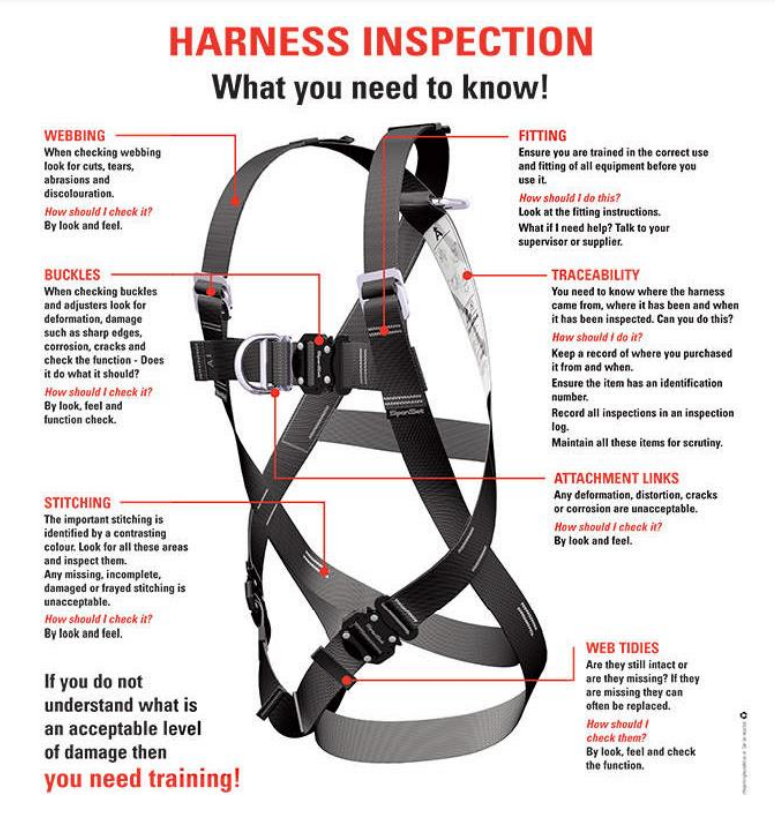

Harnesses are to be inspected before use by a competent person who has received formal training in the inspection of safety harnesses. The pre-use is to be recorded below and any defects are to be reported to Technical Services / H&S / Environmental manager or supervisor. Insurance inspections of harnesses will be undertaken at least every twelve months and the records will be retained.

-

CUTS

-

Are there multiple cuts close together or cuts longer than 1mm from the edge?

-

WEBBING

-

Are there multiple stains that have not washed out in the normal wash (may indicate damage from chemicals, liquid or paint?

-

Is there bobbling, fraying, strained of badly pulled webbing/paint or liquid stains?

-

Is there localised surface abrasion across the face of the webbing or at webbing loops or abrasion at edges?

-

Is there any missing, incomplete, damaged or frayed stitching – contrasting colours highlight important stitching?

-

BUCKLES

-

Is there any damage, deformation, sharp edges, cracks or corrosion?

-

Is there any damage to the buckle or not functional?

-

ATTACHMENT LINKS

-

Is there any evidence of distortion, deformation, cracks or corrosion on the links?

-

WEB TIDIES

-

Is there any damage to the web tidies or missing?

-

If you are unsure about any of the above checks consult your Supervisor or Manager. Harnesses that FAIL any of the above checks are to be removed from use, labelled as defective and locked away to prevent them being inadvertently used until they are either repaired or disposed of

Sign-off

-

I confirm I have checked the equipment before and after use, and it is in safe working order or has been placed out of order due to defects

-

Employee Name, Signature, Date:

-