Audit Overview

-

Document No.

-

Audit Title

-

Client / Site

-

Conducted on

-

Prepared by

-

Location

-

Personnel

1.0 General Workplace

-

Containers are stored safely so as not to cause a tripping or fall hazard.

-

Wooden pallets must lie flat, and don't lean on edge.

-

Furniture is in sound condition.

-

Liquid spills are cleaned up quickly.

-

Clear access to eyewash stations are maintained.

-

Equipment and tools are put away when not in use, and have a designated home.

-

Are walkways adequately clear and free of congestion. All aisles maintained at 30" widths

-

Floors surfaces are even, clean, and dry.

-

Outside areas are regularly swept and organized.

-

All waste streams are managed correctly.

-

Hoses and cords must not present a trip hazard or obstruct walkways.

-

Stairs and risers are kept clear.

-

Are hand railings and horizontal safety chains in good condition?

-

Observe everyone on shop floor to be wearing appropriate PPE.

-

Personal Protection Equipment is stored in a clean location.

-

All carts and pallet jacks stored safely when not in use.

-

All shelving and racking must have no damage to uprights or cross-beams that would compromise its integrity.

-

All shelving and racking (5' or higher), must either be secured to each other, or if available, to the wall.

2.0 Fire Prevention

-

Evacuation plan is displayed and understood by associates.

-

Exit pathways and doors must be kept clear of tripping hazards and obstructions.

-

Emergency exit doors are visibly marked with lit signage.

-

Flammable materials are not stored next to exit doors.

-

Evacuation drill is conducted at least once every six months.

-

Fire alarm system functions normally and can be heard from all locations within the building.

-

Exit and exit pathways are clearly marked for emergency evacuation purposes.

-

Exit doors can be opened easily from the inside.

-

Fire extinguishers are hung off the floor and remain readily accessible.

-

Fire extinguishers are inspected monthly with the inspection date noted.

3.0 Electrical Safety

-

All 110 volt plugs require a grounding plug.

-

Extension cords are not used as replacement for permanent wiring.

-

Extension cords and power strips are not daisy chained in sequence.

-

Floor heaters are plugged directly into wall socket, and not into an extension cord or power strip.

-

Floor heaters must have rollover kill switch.

-

Electrical panels require at least 36" of frontal clearance.

-

Electrical cords do not have any exposed insulation or wires.

-

Electrical cords are not spliced together with wire nuts or tape outside of conduit.

-

Tension relief is required on flexible electrical cords to eliminate strain on connections.

-

Disconnect switches must be legibly and durably marked to indicate the purpose.

-

Breaker box doors remain closed when not in use.

-

Materials are not stored on top of electrical boxes, transformers, or service panels.

-

Plugs, sockets, switches, and cover plates are free from damage.

-

Emergency safety switches have been tested every 6 months.

4.0 Chemical Safety

-

All containers containing wastes, universal wastes, or process materials are in good condition, with no visible signs of leakage, and are clearly labeled.

-

Labels identify the contents of the container by name or chemical composition.

-

Container labels must be complete, clearly legible, and must include hazard warnings.

-

If a container can't be labeled, a sign, placard, batch ticket or process sheet must be utilized to identify container contents and hazards.

-

Spill response kits are adequately stocked and in good condition.

-

Drip pans on floor to prevent spillage.

5.0 Machine Safety

-

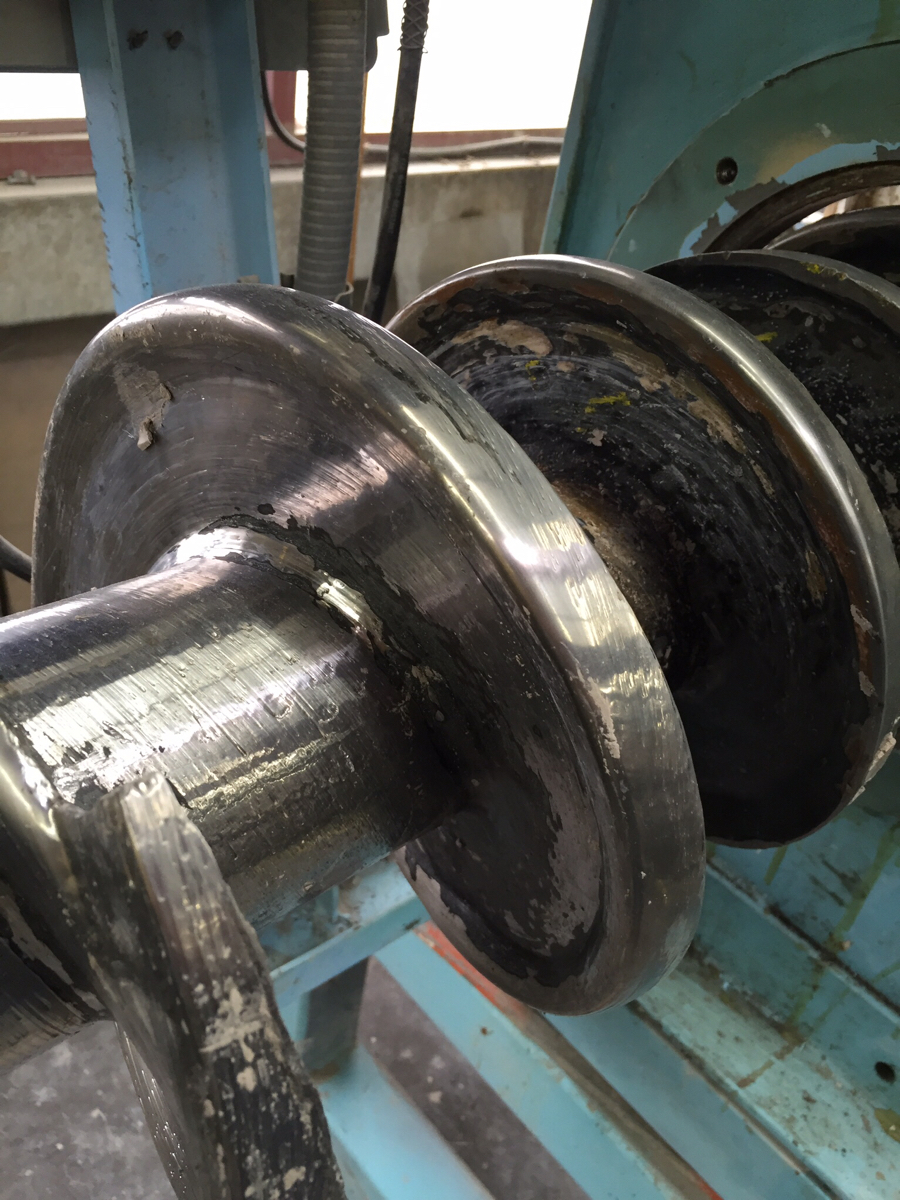

Equipment is kept clean.

-

Floors around machines are kept clean.

-

Existing guards in good condition.

-

Starting and stopping devices within easy reach of operator.

-

Noise level is managed.

-

Bending or stooping is not required.

-

Lighting is adequate to operate machine.

-

Operators are familiar with Job Hazard Analysis for operating equipment.

-

Pneumatic and hydraulic hoses are protected and free of damage.

-

Propane tanks are secured from falling over or being damaged.

6.0 Guarding and LO/TO

-

Pinch and shear points, rotating parts, flying chips, sparks, etc, must be effectively guarded by physical barriers, presence or pressure sensing devices, electrical interlocks, or other means.

-

Guards that require both hands to operate properly must not be by-passed.

-

Adequate visibility is maintained through guards, as necessary.

-

Overhead lighting and rotating fan blades located within seven feet of work level must be guarded.

-

Lockout procedures are implemented and followed.

-

Broken equipment is fully tagged and locked out, per LO/TO procedures. Smaller broken items are removed from production floor.

-

Compressed air blow off nozzles must have back pressure relief holes in the end of each nozzle.

7.0 Hand Tools

-

Tools in use are undamaged.

-

Tools are put away when not in use.

-

Tools are being used as intended.

-

Broken tools have been removed from production floor.

-

Power tools must have guards around rotating parts.

-

Electrical cords for hand held power tools must be maintained free of splices, cuts, and frays.

Summary

-

Overall comments supporting safety observations.

-

Provide any examples of best practices demonstrated or noticed during safety audit walkthrough.

-

Name of primary auditor conducting walkthrough.