Title Page

-

Site conducted

-

Date of Audit

-

Scope the audit

-

Prepared by

-

Company

-

Site

General Information

-

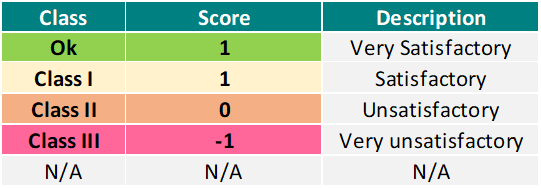

Score Ranking

-

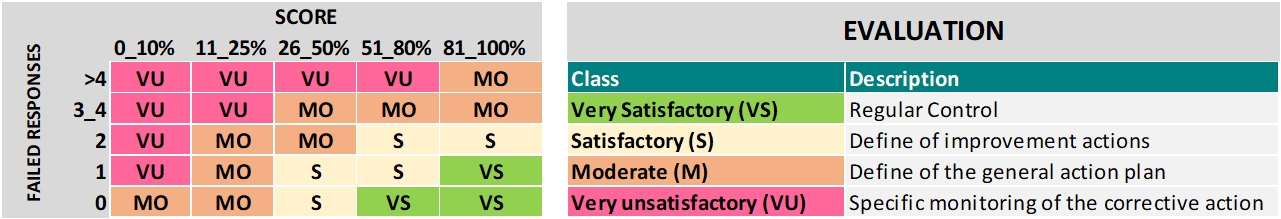

Evaluation Chart

-

All the items with Class III score must be defined at least one corrective action.

-

In the items with Class II & III score should be added an evidence or the issue description

A) HSE Management

1.0 HSE management system/Documentation

-

If lack of one or more documents or these documents are not updated to be identified as Class III with failed response ( 1.3 Safety documents)

-

1.1 QHSE Policy up to date and well publicized?

-

1.2 Does the site have a Health and Safety board and is all information correct and current? (take a pictures and add comments)

-

1.3 Review the general safety documents; Emergency Plan, Risk Assesment.. Check if is updated, is available on site

-

Emergency Plan, Risk Assesment, emergency contact numbers, Coordinates and evacuation map.

-

1.4 There is a control of the waste management records?

B) General Factilities; Command Building, subestation, WTG, PV Plant, Warehouse, etc.

2.0 Command Building, Access roads, ditches, vegetation... ( Check the H&S conditions)

-

If there ar not fire extingishers, first aids kit, or are not updated and completed (2.6, 2.10), if must be identified as Class III with failed response.

-

2.1 Check the conditions of the access roads, ditches, vegetation...

-

2.2 There is info Pannel or signs with the main access and the general safety norms of the site (take a picture and add comments)

-

2.3 General cleanliness of all areas

-

2.4 Unobstructed routes and width adequate for needs

-

2.5. Check safety signs (emergency posters, extinguishers posters, electrical risk, first-aid kit posters, signs of do not enter ins restricted areas, evacuation map, coordenates map of the site...)

-

2.6. Check First-aid kit (take a picture of the First-aid kit, add comments)

-

2.7 Emergency equipment and exits signage are free of obstruction

-

2.8 Emergency exit marked and checked for appropriateness

-

2.9 Fire detection system installed (smoke, heat detectors)

-

2.10 Validate the fire extinguishers state (take a picture to one of them, add comments)

-

Checked accessibility, good apparent condition of conservation, insurance, seals, inscriptions, hose, etc.

Checked the state of charge (weight and pressure) of the extinguisher and the gas pump bottle (if any) state of the mechanical parts (nozzles, valves, hoses, etc)

Check the correct fire control system, fire dections, (if is aplicable) -

2.11 Check de Emergency lights

-

2.12 Check the fire alarm

3.0. Environmental Conditions

-

If the waste disposal state is in a poor conditions,(3.1) and there are not segregation of the waste (3.2) must be identified the points with Class III with failed response

-

3.1 Check general waste disposal state (organisation, cleanliness, element disposal and identification, possible waste leaks...)

-

Take a picture and add comments

-

3.2 Waste segregated (chemical, contaminated packaging. Separate and labelling of waste types with MSDSs?

-

3.3 Spill kits available and fit for purpose? Who inspects and are records available? (Staff trained in use)

4.0. Welfare Management

-

No maintenance of the toilets facilites (4.5), water and septic tank (4.6), and not exist any policy or signs about the Smoking area control must be identified the points with Class III with failed response

-

4.1 Welfare facilities suitable for the needs of the area (take a picture one of them, add comments)

-

4.2 Housekeeping standard clearly set, inspected and enforced

-

4.3 Lighting ventilation etc. satisfactory for the area and working correctly

-

4.4 Smoking controls in place with designated smoking area.

-

4.5 The toilet facilities has sanitary water, cleaning papel dispenser...

-

4.6 Septic and Water tank are installed properly and there is a peridically maintenance and inspection systm

-

4.7. Check of intrusion alarm / CCTV

5.0 Sites

-

Type of the facilities on site to be audited

- Documentation

- Platform

- Emergency components

- Hazardous materials

- Waste Management

- Working at Height Equipement

- PPE

- Machinery

- Working Equipement

5.1 Documentation

-

If Forms have more that 3 missing/incorrect points, must be identified as Class III with failed response.

-

5.1.1. Toolbox Talks (TBT) form present and signed?

-

5.1.2 Last Minute Risk Assessment (LMRA) form complete

-

5.1.3 Ready for Lifting (RFL) and Good to GO (GTG) checklist completed

-

5.1.4 Residual Current Device (RCD) Check up to date

-

5.1.5 Emergency Plan present

-

5.1.5.1 Emergency plan up to date and posted

-

5.1.6 Health and Safety Plan

-

5.1.6.1 Health and Safety Plan up to date and posted

-

5.1.7 Medical Checks up to date

-

5.1.8 RAMS present in the office

-

Are RAMS up to date and signed

-

5.1.8 Training Sheet updated with the latest training

-

5.1.9 Technician Certificates valid

5.2 Platform

-

If the electrical safety equipments (5.2.2.1.) are not installated correctly and reviewed periodically, and the fire extinguisers are not in good state (5.2.2.2), must be marked the option class III as failed response

-

5.2.1 Markers present at the platform entrance

-

5.2.2 Sufficent lighting on the platform

-

5.2.3 Wellfare facilities present on the platform

-

Toilet paper, soap, hot water present

-

Facilities cleaned regularly

-

5.2.4 Site cleanliness status

-

Parking Rule being followed

Earthing

-

Crane Earthed

-

Generator Earthed

-

Container Earthed

-

Cable Integrity Visual Check

-

Socket Integrity Visual Check

-

Nominated Technician in charge of Electrical Checks

5.3 Emergency Components

-

5.3.1 Fire Extinguishers present on site

-

Checked accessibility, good apparent condition of conservation, insurance, seals, inscriptions, hose, etc.

-

Checked the state of charge (weight and pressure) of the extinguisher and the gas pump bottle (if any) state of the mechanical parts (nozzles, valves, hoses, etc)

-

5.3.1.1 Extinguishers labels present and undamaged

-

5.3.1.2 Extinguishers have valid inspections

-

5.3.1.3 Extinguishers seals intact

-

5.3.2 First aid kits present and valid

-

5.3.3 Eye Wash kits present and valid

-

5.3.4 Rescue equipement

5.4 Hazardous Materials

-

If the flammable/hazardous materials (5.4.9) are not stored correctly and the fuel sources have been not idedentified and controlled correctly (5.4.10), must be marked the option class III as failed response

-

5.4.1 The Storage Area is in correct status of clean and order, the shelf system is proper to the different material, components, etc.

-

Storage facilities neat, tidy, signed and accessible

-

5.4.2 Good housekeeping prevents building up of combustible, waste or chemicals spillage)

-

5.4.3 Segregation of inappropriate materials/ reactants

-

5.4.4 Enough ventilation on chemical storage facility

-

5.4.5 Overloaded racking/poor stacking practices (Pyramid stacking)

-

5.4.6 Hazardous Materials have valid labels (clean, visible, undamaged)

-

5.4.7 Safety Data Sheets present and up to date in correct languages

-

5.4.8 Hazardous Materials Register present and up to date with materials present and used on the platform

-

5.4.9 Oil Spill kit present, complete and usable

5.5 Waste Management

-

5.5.1 Waste Storage area isolated, clean, tidy

-

5.5.2 Waste segregation possible; containers present for all types of waste

5.6 Working at height Equipment

-

5.6.1 Harness has inspection label visible

-

5.6.1.1 Harness inspection valid

-

5.6.1.2 Harness has signs of damage

-

5.6.2 Shock Absorbing Lanyards (Y) has inspection label

-

5.6.2.1 "Y" inspection valid

-

5.6.2.2 "Y" has signs of damage

-

5.6.3 Runner has inspection label

-

5.6.3.1 Runner inspection valid

-

5.6.3.2 Runner has signs of damage

-

5.6.4 Positioning Rope has inspection label

-

5.6.4.1 Positioning Rope inspection valid

-

5.6.4.2 Positioning Rope has signs of damage

5.7 PPE

-

5.7.1 S3 Boots with metalic toecap protection

-

5.7.2 Helmet with chinstrap

-

5.7.3 Jacket

-

5.7.4 Pants

-

5.7.5 Reflective vest

-

5.7.6 Glasses

-

5.7.7 Gloves

-

5.7.8 Tool Lanyard

5.8 Machinery

-

5.8.1 Cherry Picker in used on the platform

-

5.8.1.1 Cherry Picker has periodic inspection valid

-

5.8.1.2 Cherry Picker has signs of damage

-

5.8.1.3 Cherry Picker shows signs of leakage (oil, fuel)

-

5.8.1.4 Cherry Picker is in good working condition

-

5.8.2 Man Basket present and used on the platform

-

5.8.2.1 Man Basket has periodic inspection valid

-

5.8.2.2 Man Basket has signs of damage

-

5.8.3 Mobile Elevated Working Platform (MEWP) present and used of the platform

-

5.8.3.1 MEWP has valid periodic inspection

-

5.8.3.2 MEWP has signs of damage

-

5.8.3.3 MEWP has signs of leakage (oil, fuel)

-

5.8.3.4 MEWP is in good working condition

-

5.8.4 Forklift present and used of the platform

-

5.8.4.1 Forklift has valid periodic inspection

-

5.8.4.2 Forklift has signs of damage

-

5.8.4.3 Forklift has signs of leakage (oil, fuel)

-

5.8.4.4 Forklift is in good working condition

5.9 Working Equipement

-

5.9.1 Shackales are in good working condition

-

5.9.2 Slings are valid and in good order (no cuts, no tearing)

-

5.9.3 Keys in good order (no bents, no cracks)

-

5.9.4 Electric Wrenchs in good working order

-

5.9.5 Hydraulic Wrench are in good working condition

-

5.9.5.1 No visual damages

-

5.9.5.2 No leakages

-

5.9.6 Generator is in good working order

C) Summary and Signature

-

Other Comments

-

Site Manager/ Supervisor

-

Auditor