Information

-

Site

-

Location

-

Conducted on

-

Prepared by

-

Personnel present

General Scaffold

Documentation

-

Has steel wire mesh/shade cloth or containment sheeting been provided where workers are exposed to a risk of falling materials from the scaffolding

-

Are procedures in place to inspect scaffolding every 30 days

-

Are there handover or checklists in place

-

System in place to inspect the scaffolding after trades have used it e.g. formworkers, concretes, bricklayers and tilers

-

Is a work method statement or appropriate documentation available for the management of scaffolding on site once erected

-

Is there a system in place to prevent damage from loads suspended from a crane and is it recorded in SWMS

-

Have workers been inducted on the safe use of the scaffolding

-

Tagging system on scaffolds above 4 metres and located at each access point

-

Tagging system legible and up to date

Construction of scaffolding

-

Is scaffold over 4m erected by a certified/licensed scaffolder

-

Where the working platform is less than 4m was it erected by a competent person

-

Have trades completed a Working at Heights course

-

During construction of the scaffold is the immediate area around the base barricaded off or otherwise controlled to minimise risk of injury from falling objects

-

Are harnesses required for the safe construction/dismantling of scaffold

Supporting Structure

-

Is the supporting structure in good condition and adequate strength/has it been assessed by a competent person/engineers certificate obtained

-

Is there a risk of the supporting structure being overloaded from other sources adequately controlled

Foundation

-

Scaffolding erected on suitable foundation/footings e.g. Not adjacent to trenches, excavation, underground services, soft ground

-

Base plates used are a minimum 100mm x 100mm and 6mm thick

-

If on soft ground are sole boards bing used to distribute the load evenly e.g. unstable ground, gaps

-

Are the sole boards continuous and where ever possible support 2 standards and a minimum 220mm

-

Are sole boards a minimum 220mm wide

-

Is packing used under sole boards suitable e.g. hard wood

-

Screw jacks not to extend more than 600mm or as per manufacturers requirements

Openings in scaffolding e.g. driveways

-

System in place to prevent scaffolding being struck by vehicles and/or plant e.g. concrete blocks, guards, fenders, traffic management

Steel wire mesh/shade cloth/containment sheeting/ signage

-

Has the scaffolding been designed for wind loading where signage is being tied to scaffolding

-

Is the sheeting adequately fixed/tied

-

Are there any rips or gaps in sheeting

-

Is there an engineers certificate for the ties

-

Is there a minimum 50mm overlap

-

Signs on scaffolding - any engineering calculations - wind loading design

Overhead power lines (OHPL)

-

Is scaffolding erected close to OHPL

-

Has OHPL been de energised

-

If the OHPL have not been de energised, is there a system of work to ensure the scaffolding complies with local requirements during erection, altering, use and dismantling

Mixed Components

-

Are mixed components being used

-

Are they compatible

-

Engineers certificate available if required

Ties

-

Have ties been installed as per manufacturers/suppliers instructions/information and AS/NZS 1576

-

System in place to monitor ties as other trades progress e.g. formworkers, bricklayers, tilers, etc

-

System in place to monitor ties as the structure is demolished

-

Do the ties pick up 2 standards or ledgers

-

Are single leg ties used - is relevant documentation available

-

Have 90° fittings been used (swivel fittings not to be used)

-

Are ties provided every 4m (vertically) in height

-

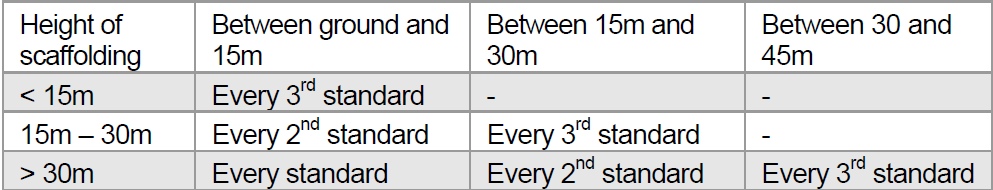

Are ties provided as per AS1576 - Vertical = every 4m<br> Horizontal = 3rd bay

-

-

Where drilled in anchors being used are engineering drawings/calculations, etc are available on site

-

Do the ties obstruct access along the full length of the working and access platforms

-

Sheeted or netted scaffolds fitted with additional ties to resist wind loads

Temporary Ladders

-

Are ladders adequately secured at the top and bottom

-

Is the ladder in good condition

-

Are ladders no less than 1:4 or no more than 1:6 slope

-

Is the ladder extended 900-1000mm above the landing platform

-

Are temporary ladders no more than 6m between successive ladder landings

Platforms (General)

-

Are platforms free from obstruction

-

Are planks in good condition and a minimum 220mm wide

-

Do planks overhang supports by 150mm - 300mm

-

Are planks adequately secured when they overlap

-

Are loads on any given platform easily distributed

-

Are standards correctly positioned I.e. staggered

-

Is the duty of the scaffolding suitable for the task i.e. heavy medium or light

-

Is the scaffold width appropriate for the duty e.g. heavy duty 5 planks

-

Are signs erected on the bays indicating duty of the bays i.e. scaffold tag

-

Are any of the platform bays being used to stack/store materials e.g. Bricks, Formwork

-

Does the weight of these materials exceed the rated WLL per platform bay

-

Is there any material etc. being stacked/stored above the height of the handrail

-

Is there any signage indicating scaffolding incomplete where required

-

Are openings at working platform level covered and secured e.g. plywood (17 mm), planks

Temporary Stairways

-

Has separate stairway access been provided to access scaffolding

-

Is the stairway a minimum 500mm wide

-

Is the access landing a minimum 500mm x 450mm

-

Is a handrail provided along each stairway

Bracing

-

Has face bracing been provided i.e. longitudinal at no more than 3 bays apart, unless other wise specified

-

Has been provided at the end of the scaffolding i.e transverse bracing

-

Does the bracing extend the full height of the scaffolding

Hop up brackets

-

If hop up brackets are 500 mm above or below the working platform, has adequate fall prevention been provided

Access

-

Is the access along the working platform - minimum 450mm wide for persons and tools only (2 planks)

-

Is the access along the working platform - minimum 675 wide for persons and materials (3 planks)

-

Are incomplete scaffolding platforms blocked off and/or signs used

-

Is there suitable access to and from the working platform e.g. from the building to the scaffold

-

Is there safe access between working platform during use, erection and dismantling

Edge Protection

-

Is edge protection provided where a person or object could fall (2m or more)

-

Handrail, mid rail and toe board or brick guard provided

-

Where guard rails and toe boards (150mm) only are being used is a suitable infill such as brick guards or infill panels being used

-

Are guard rails erected between 900mm and 1100mm above the platform

-

Where brick guards are being used is the mesh aperture no more than 50mm x 50mm

-

Where the gap between the scaffolding and supporting structure is more than 225mm has edge protection been provided

Workers using the scaffolding

-

Do the workers on site using the scaffold alter the scaffolding themselves

-

Are the workers on site that are using the scaffolding aware that any alterations to the scaffolding is to be done by a scaffolder

Mobile Scaffold

-

Is there mobile scaffold on site?

Documentation, Signage and Procedures

-

Tagging system on scaffolds above 4 metres (if tagging systems on equipment below 4 metres, system must be maintained)

-

Tagging system fitted on each entry point

-

Tagging system legible, durable and up to date

-

If incomplete scaffold has Warning signs for incomplete scaffold have been fitted

-

Mobile scaffold above 4 metres high has been erected by licensed scaffolder. Mobile scaffold below 4 metres has been erected by trained personnel.

-

Are checklists in place

Construction of Scaffold

-

Mobile scaffold complies with suppliers specifications and safety regulations

-

Has scaffold been braced correctly

-

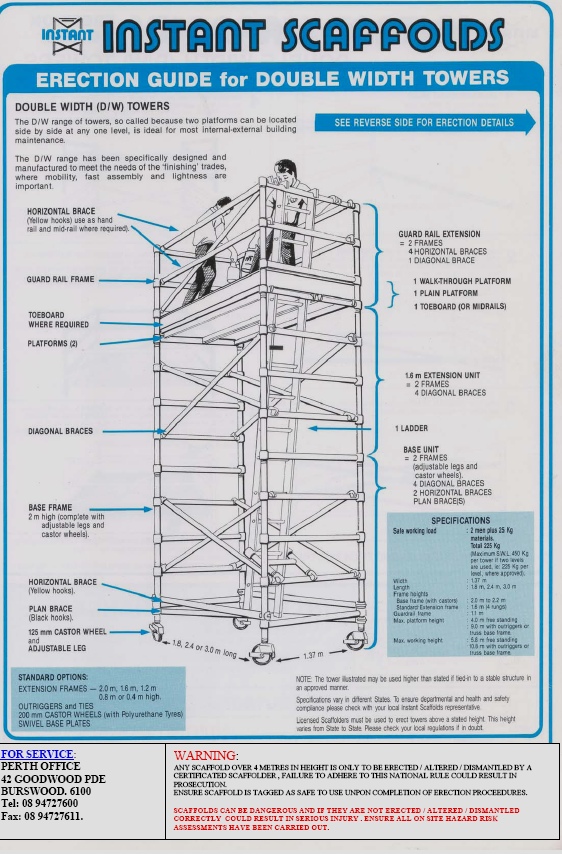

Mobile scaffold has equipment and comments in place as per Manufacturers specifications and diagram attached

-

-

Has scaffold been erected on firm even surface

-

Ladder correctly fitted where scaffold over 2 m

-

Castors in good condition and locked

-

Outriggers and ties fitted where required

-

Working platform fully decked

Edge Protection

-

Top rail fitted

-

Mid rail fitted

-

Kick boards fitted

Suspended Scaffold

-

Is there suspended scaffolding on site?

Documentation and procedures

-

Handover certificate provided and scaffold tag available on site

-

Are the daily pre operation checks being carried out and recorded in a log book

-

Are procedures in place to inspect the scaffolding every 30 days

-

Are procedures in place to inspect the scaffolding every time it is altered/moved

-

Has the suspended stage been erected by a certified person as per drawings/instructions

-

Has the necessary written instructions and checklists been provided by the user e.g. safety equipment, emergency procedures, communication

-

Have operators been trained in the safe use of the suspended scaffolding e.g. safety equipment, emergency procedures, communication

-

Have the operators been inducted on the use of the suspended scaffolding

-

Are drawings/calculations available onsite for such things as the suspension rig design and number of counter weights per needle

-

Are drawings available where the needles are supported by scaffold tubing

-

Are daily pre operational checks carried out prior to the swinging stage being used and recorded in a log book

-

Is there effective means of communication between the occupants of the suspended scaffolding and those ground level

-

Is the maintenance records available on site for all comments e.g. cradle, hoists, ropes, etc.

-

Does the cradle have a compliance plate

Cradle

-

Is the cradle assembled correctly and in good repair with no obvious defects e.g. cracked welds

-

Is there a system in place to prevent the cradle from coming into contact with the structure

-

Is there safe access along the entire length of the platform

-

SWL/WLL clearly marked on the cradle

-

Is there a system in place to prevent overloading of the cradle

-

Is there a system in place to prevent the suspended scaffolding coming into contact with OHPL

-

Is there a system in place to prevent lateral movement

-

Is the width of the platform between 450mm and 900mm

-

Is there a system to secure the suspended scaffolding stage when it is not in use

-

Is a guardrail, mid rail, and toe board provided along the length of the platform

-

Where access and egress is not from ground level is the cradle secured to prevent movement

Access

-

Has safe access been provided for workers to enter and leave the cradle from ground level

-

Where access and egress is not from ground level has suitable fall protection been provided e.g. harnesses and (2) lanyards (per harness) been provided

-

Is there a safe point of attachment for harnesses if being worn

-

Where access and egress is not from ground level has the cradle been secured against movement

Suspension rig counter weights

-

Are the counter weights individually labelled with their weights in kgs

-

Are the counter weights installed as per design/drawings

-

Are counter weights purpose designed

-

Are they secured to the needles so that removal requires the use of a tool

Suspension rig - needles and supporting beams

-

Has the suspended scaffolding been erected as per drawings/instructions

-

Is the outboard ends of the needles higher than the inboard ends

-

Do the needles have a positively fixed stop at the end of each needle to prevent ropes from slipping off

-

Are anchorage bolts used in conjunction with lock-nuts

-

Friction anchors and chemically inserted anchors are not to be used

-

Are chains/slings protected if running over sharp edges

-

Is there a primary and secondary rope fitted to each needle

-

Are all wire ropes independently attached to the suspension rig

-

Is excess rope allowed to hang freely below the cradle,or inserted into a rope winder to prevent kinking

-

For long periods of time, is the access rope and cables stored in the cradle

-

Are unauthorised persons prevented from accessing the suspension rig

Hoists

-

Are the scaffolding hoists in good condition with no obvious damage/defects

-

Has weather proof covers been provided for hoists

-

Is the wire rope being used the correct size and type for the hoist (refer to compliance plate)

-

Is each hoist provided with a secondary protection device

Falling materials

-

Has the area below the suspended scaffolding been blocked/barricaded off to prevent persons being hit by falling materials

-

Is there a system in place to prevent hand tools from falling out of the platform e.g. tool lanyard or meshing cradle

Electrical

-

Has an adequate power supply been provided for the suspended scaffolding

-

Is there easy access to the power supply switch board

-

Has the electrical cable been installed to prevent accidental removal from the switchboard

-

Are unauthorised persons prevented from accessing the electrical supply board

-

Does the suspended electrical cable have adequate running clearance

-

Is the suspended electrical cable of sufficient length and correct size

-

Is there a system place to prevent damage to electrical cables

-

Have all electrical leads /components, etc. been tested as required by each state

-

Is the central control box fully enclosed, lockable, shatterproof and waterproof

-

Are the operating buttons/levers of a "dead man" type

Corrective Actions

- Corrective Actions

-

Description

-

Add media

-

Risk Rating

-

Action by

-

Date completed

-

Completed sign off