Página de Título

-

Local onde foi conduzido

-

Customer identification

-

Realizado em

-

Preparado por

-

Local

1 LIST OF ABBREVIATIONS

-

• ABNT: The Brazilian Association for Technical Standards Cat: Safety Category CC:

• CC: Control Category (B, 1, 2, 3, 4); the category already decisively (deterministically) dictates the safety-related quality of an SRP/CS. While CC B and CC 1 deal with the quality of the component used, higher categories demand additional components (channels) which are able to compensate for the failure of individual components.

• CCF: Common Cause of Failure is when multiple faults resulting from a single cause produce a dangerous failure. A car that has a malfunction in 4 brakes at the same time, for instance.

• DC: Degree of diagnostic coverage, the capability for fault detection, which is usually automatic.

• EC: Europe Community

• EN: Regional Standard, used by the European Union, not available for public distribution.

• IEC: International Electrotechnical Commission

• ISO: International Organization for Standardization

• MTTfd: Mean time to failure dangerous. Time to a dangerous failure of a component or mechanism. This information should not be confused with the guaranteed service life.

• NBR: Brazilian Standard Reference

• NR: Regulatory Standard

• OM: Other Measures

• PFH/PFHd: Probability of Dangerous Failure per Hour

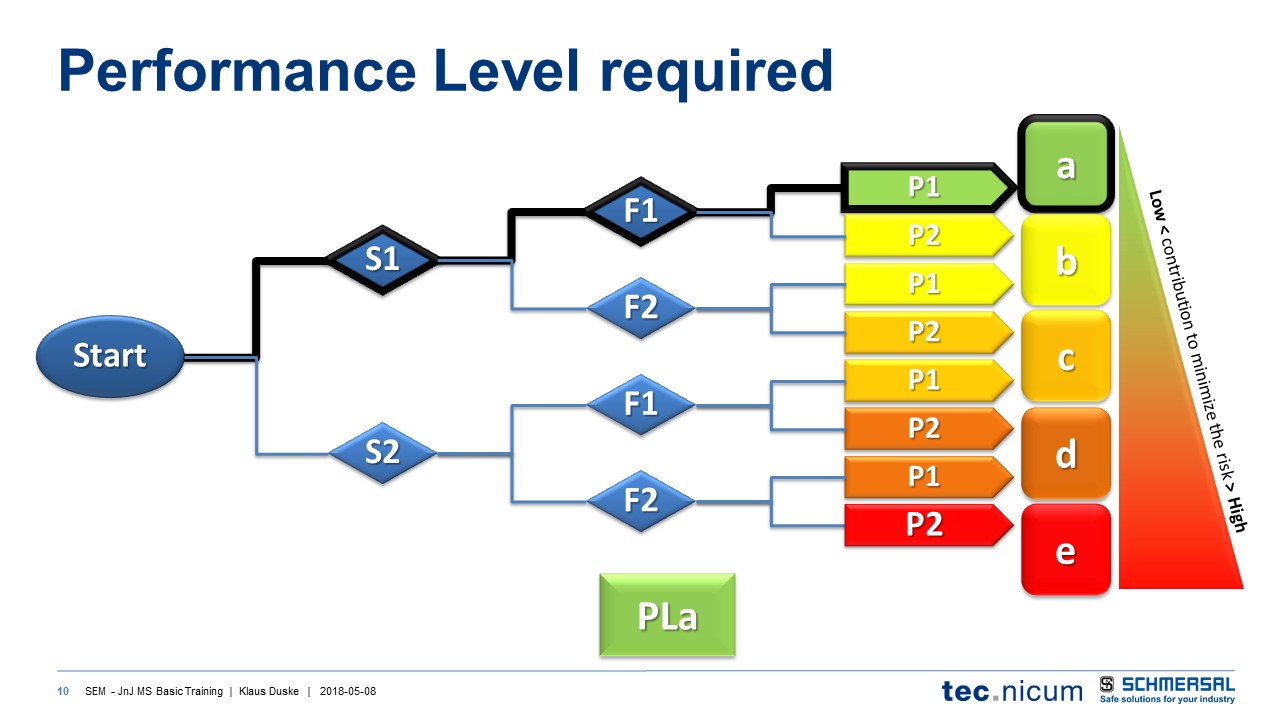

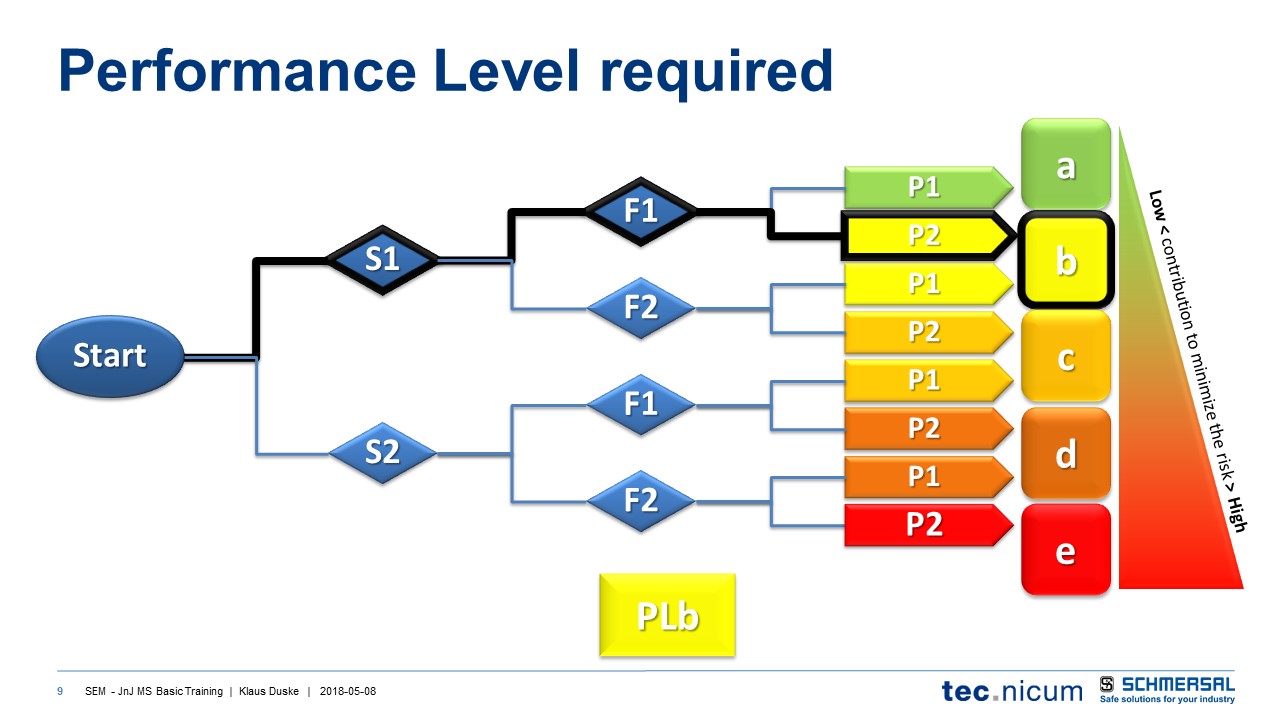

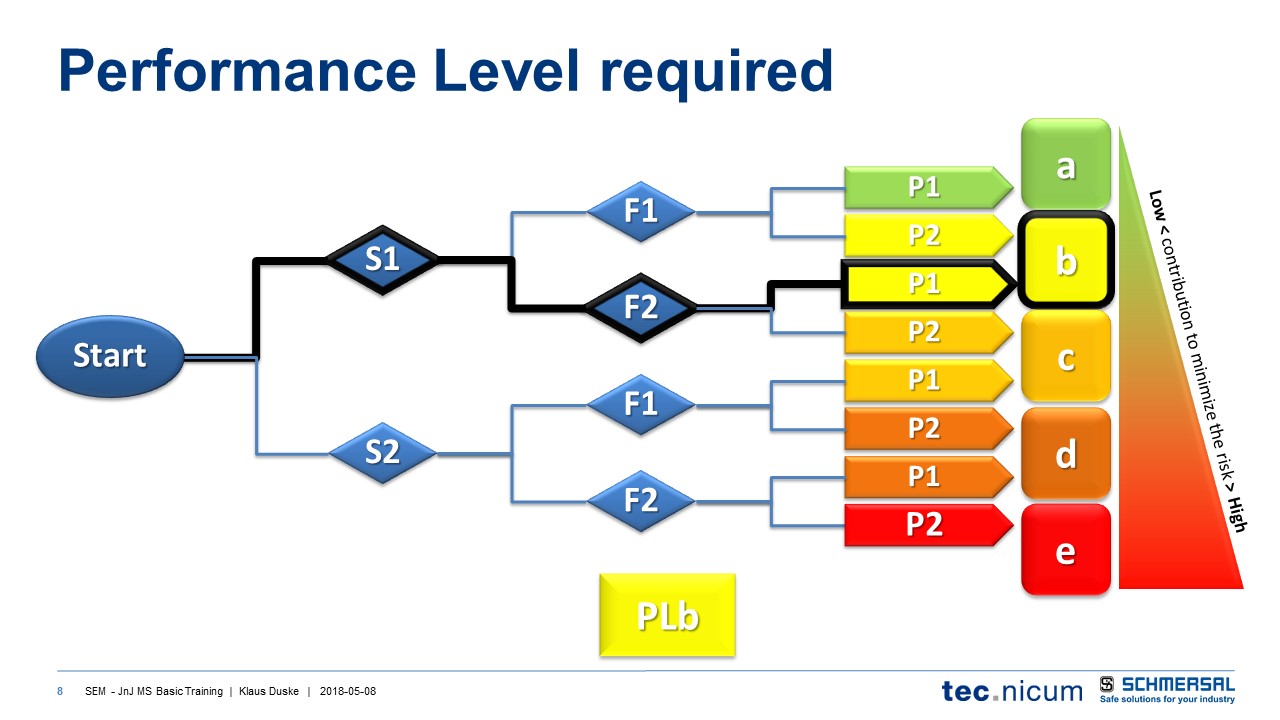

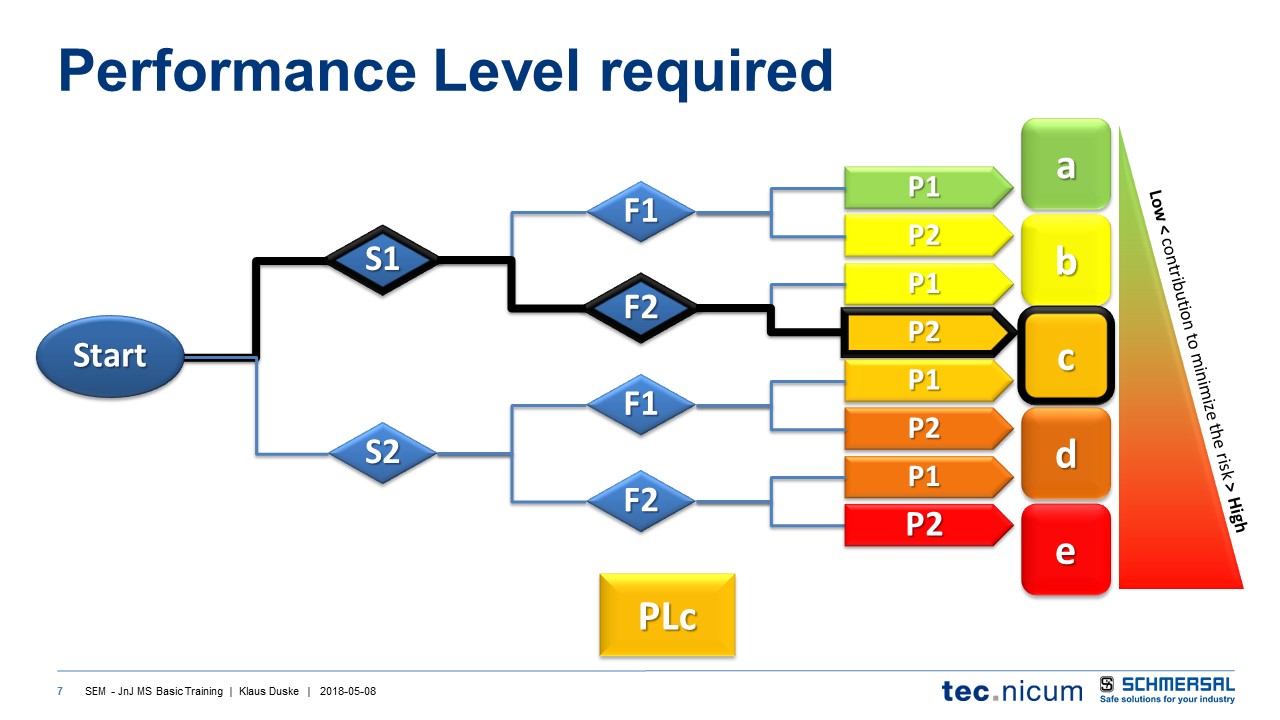

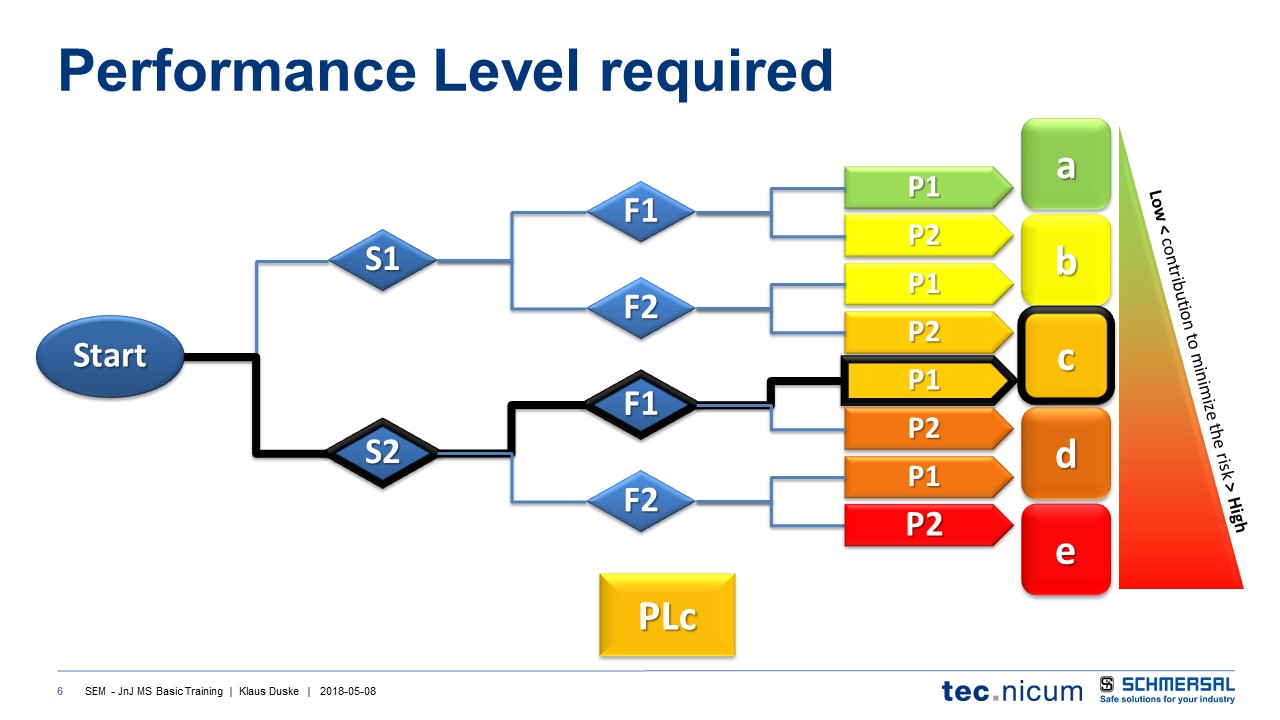

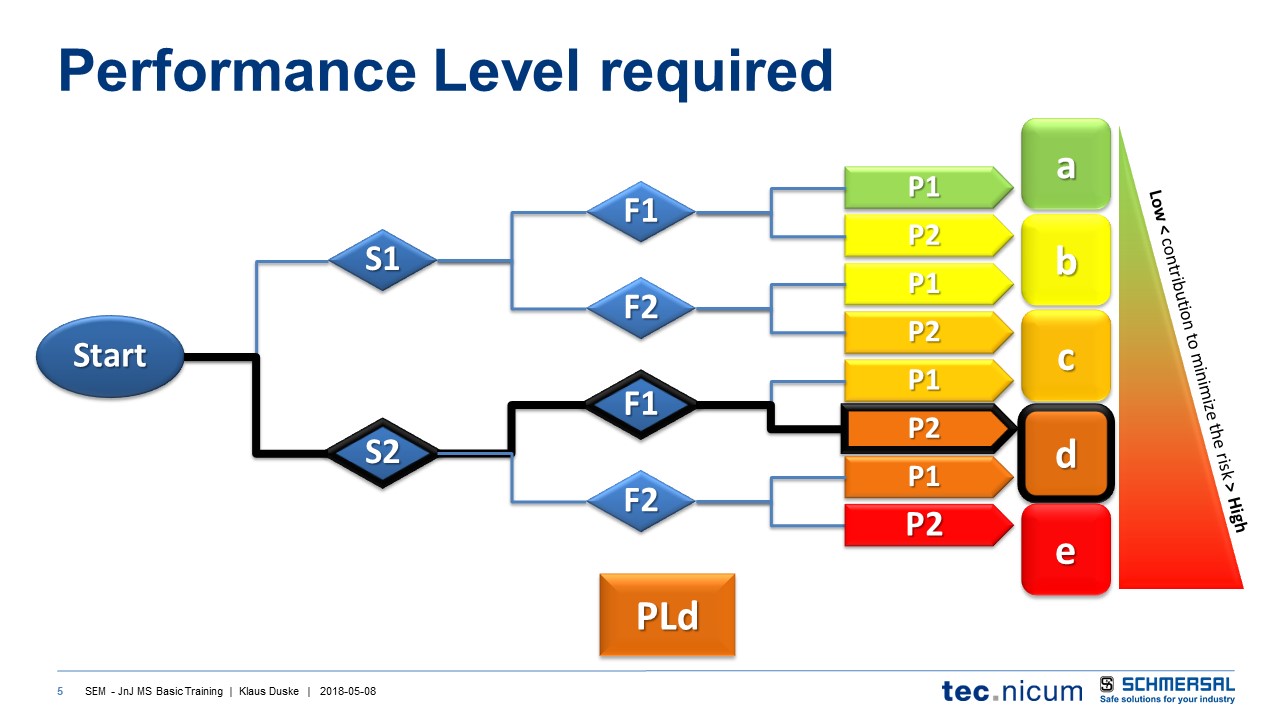

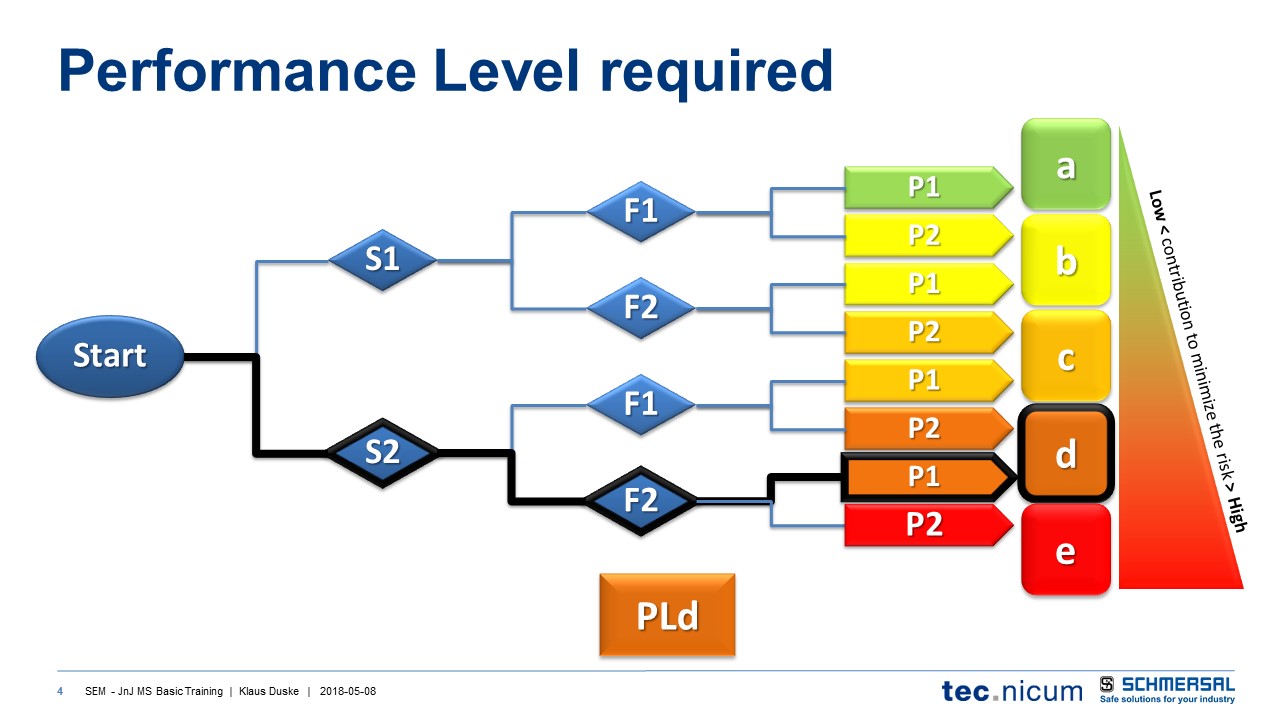

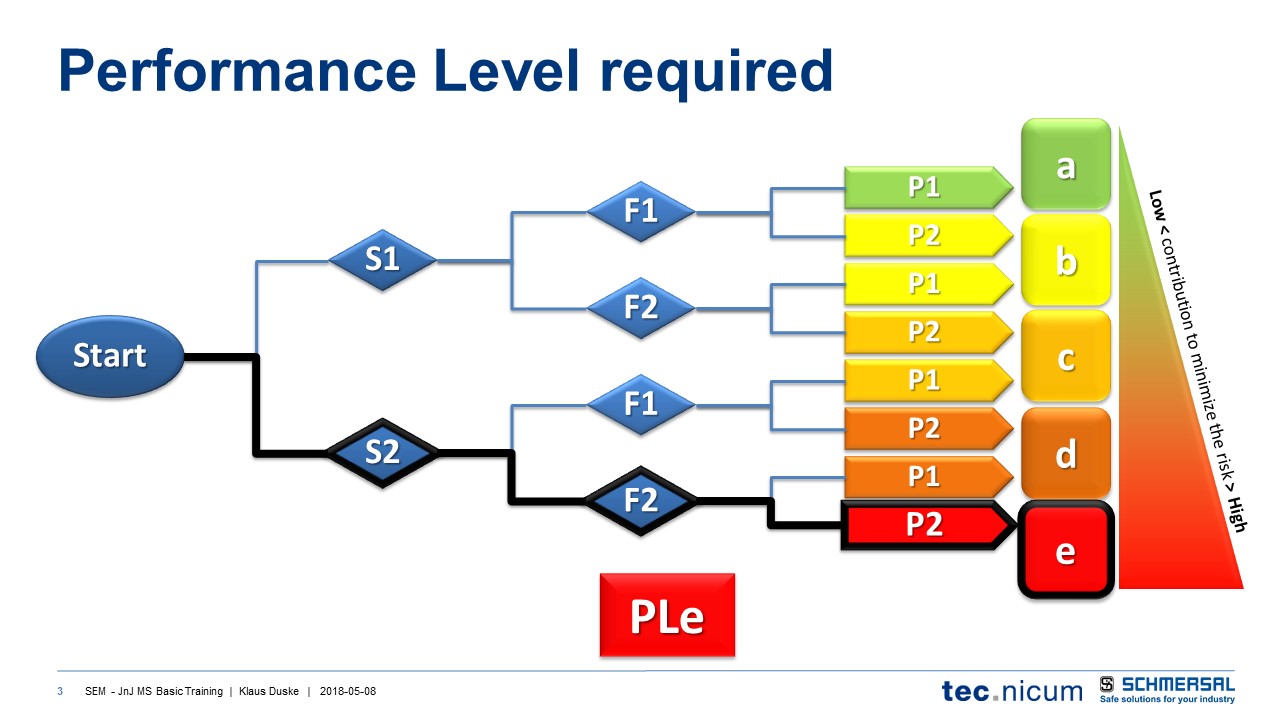

• PL: Performance Level (EN ISO 13849-1:2006) There are 5 PL’s (a, b, c, d, e), whereby the safety-related quality increases from “a” to “e” in line with the growing level of risk to be covered.

• PLr: Required Performance Level (based on risk evaluation).

• SIL: Safety Integrity Level (EN IEC 62061:2005) There are 3 SIL’s (1, 2, 3), whereby the safety-related quality increases from “1” to “3” in line with the growing level of risk to be covered.

• SILCL: SIL Claim Limit (EN IEC 62061:2005) Maximum Safety Integrity Level (SIL) that can be claimed for an electrical safety system, taking account of architectural constraints and systematic safety integrity.

• SRB: Safety Relay Modules (Sicherheits-Relais-Bausteine)

• SRP/CS: Safety Related Part of Control Systems Sub-PL/Sub-SIL: PL or SIL at subsystem level. A subsystem is a system which, with reference to a partial task, already performs a safety function appropriately (for example an input module which safely detects inputs).

• B10d value: Number of cycles until 10 % of components in a random sample of at least 7 prototypes have failed dangerously This is for components affected by wear, i.e. mechanical, pneumatic and electromechanical components.

• T10d Value: Guide value for a preventive replacement (10 % of the B10d value). With this value approximately 63 % of all components have already failed dangerously. Here the EN ISO 13849-1:12006 standard recommends replacement.

2 GENERAL INFORMATION FOR RISK ASSESSMENT

-

2.1 Legal obligations

Directive 2006/42 / EC is a revised version of the Machinery Directive, the first version which was adopted in 1989. The new Machinery Directive applies are in force since December 29th , 2009. The Directive has the dual purpose of harmonizing health and requirements safety for machinery at a high level of basic health protection and safety, ensuring the free movement of machines on the Market Community. The revised Machinery Directive does not introduce radical changes compared to previous versions. This makes it clear and consolidates the provisions of Guidelines in order to improve their practical application. The Machine Directive states that machinery should not present any risk (Risk Assessment according to ISO 14121-1). Since there is no zero risk in technology, the goal is to achieve an acceptable residual risk. If safety is dependent on control systems, these must be designed so that the probability of functional errors is sufficiently low. In order to find all essential health and safety it would be reasonable to use harmonized standards which have been created in accordance with a mandate from the European Community and are published in the Official Journal of the European Communities (Compliance Assumption). This is the only way to avoid spending extra time and effort demonstrating compliance in the event of a claim.

The Risk Assessment procedure is described with its health essential safety requirements related to the design and construction of machinery which may be found in Annex I of the Machinery Directive as follows:

The machine manufacturer or their authorized representative shall ensure that the Risk Assessment is compliant in order to determine the health and safety requirements that are applied to machines. Machinery must be designed and constructed taking into account the Risk Assessment results.

By the iterative process of Risk Assessment and Risk Reduction, the manufacturer or their authorized representative shall:

• Determine the limits of the machines which include its intended use and any bad foreseeable use;

• To identify the hazards that can be generated by machines and situations associated with danger;

• To estimate the risks, taking into account the severity of possible injuries and damage health and the probability of these happen;

• Assess the risks in order to determine when the risk reduction is required according to the purpose of the Machinery Directive;

• Eliminate the hazards or reduce the risks associated with the hazards by application Protective measures:

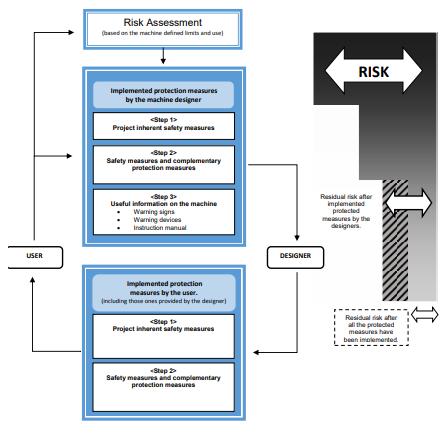

2.2 Approach used for risk reduction

1) Define the machine limits;

2) Determine all hazardous areas;

3) Identify hazards in accordance with ISO 12100 [If available, machine specific standards (Type C standards must be considered)];

4) Estimated Risk in accordance to ISO 12100;

5) Risk Assessment and if necessary, risk minimization with the following measures: The sequence of measures should be observed thoroughly.

Step 1) Inherent safety through projects and constructive measures

Step 2) Technical protective measures

Step 3) Informative measures

6) Result Documentation -

2.3 Schematic representation of the risk reduction process

3 EXAMPLES OF HAZARDS ASSOCIATED WITH THE MACHINES

4 RISK ASSESSMENT AND RISK REDUCTION PROPOSALS

-

ABNT ISO 12100 will be used during the Risk Assessment of the machine(s), which meets the assessment process with its harmonized standard.

Within ABNT ISO 12100, Risk Analyses are under its bases and principles of general guidelines.

In addition, ABNT ISO 12100 standard specifies principles of technical guidelines in order to support technical designers to design safe machines.

The assessment of machinery risks and determination of the Safety Integrated Level (SIL) necessary are performed by using the EN 62061: 2005 + Corr. 212008. Each determined PFH value is converted to a performance level (PL) ccording to EN 13849-1. Brazil adopts safety category B, 1, 2, 3 and 4 according to NBR 14153.

4.1 Areas subject to hazards and risks

The standard way of evaluation by ACE Schmersal is used for the evaluation

procedure of different hazards and risks derived from the machine. The evaluation criteria

are taken from EN 62061: 2005 + Corr.2: 2008.

According to ISO 12100 an estimate of risk and evaluation will be provided for

each particular hazard. In addition to it, all phases of a machine's life are considered in

accordance with ISO 12100.

Note: In order to make the reasons clear, this document only considers life stages in which

hazards have been identified or were considered significant.

4.2 Parameters used for Risk Assessment according to EN 62061: 2005 + Corr. 2: 2008 and Hazard Rating Number (HRN) method.

Risk Assessment must be made for each individual hazard, the following risk parameters should mandatorily be evaluated.

5 CUSTOMER AND CONSULTANCY CONTACT INTERFACES

-

CONTACT PERSONS

CONTACT PERSON BY CONSULTING COMPANY

-

Name

-

Function

-

e-mail

-

Phone

CONTACT PERSON AT THE CUSTOMER

-

Name

-

Function

-

e-mail

-

Phone

6 INSPECTION

RISK ASSESMENT OF THE MACHINES

-

Machine

-

Type

-

Identification

-

Sector

-

Panoramic Pictures

-

Identification Picture

-

Function

-

Machine limits

-

Additional limits

Necessary Primary Safety Functions at this machine

-

Primary Safety Functions

-

Is this safety function avaiable?

-

Does the safety function attend PLr?

Necessary Secondary Safety Function at this machine

-

Secundary Safety Function

-

Is this safety function avaiable?

-

Does the safety function attend PLr

Machine parts

-

Name of machine part:

-

Foto from machine part

Hazards

-

Hazard type:

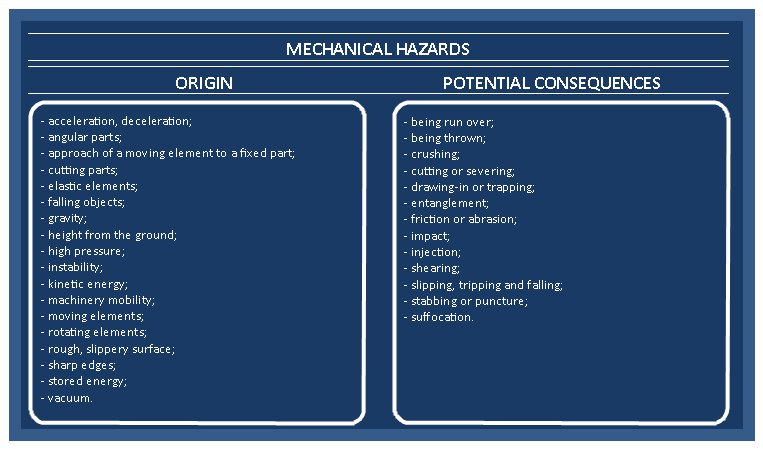

- Mechanical Hazards

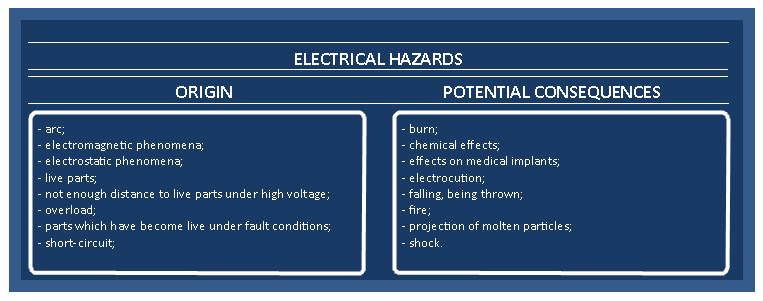

- Electrical Hazards

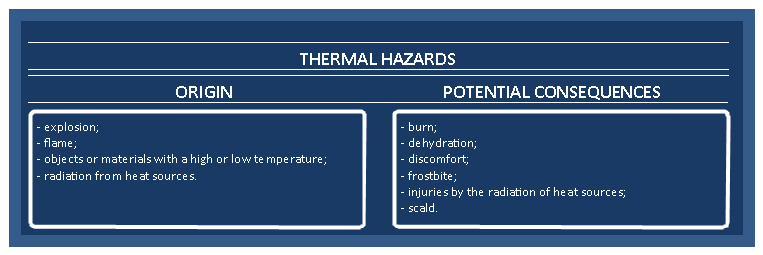

- Thermal Hazards

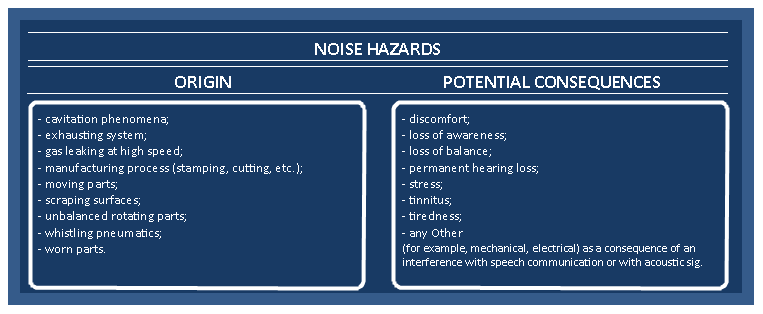

- Noise-related Hazards

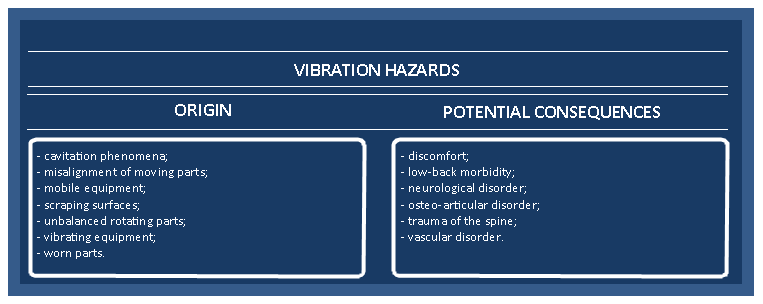

- Vibration-related Hazards

- Radiation-related Hazards

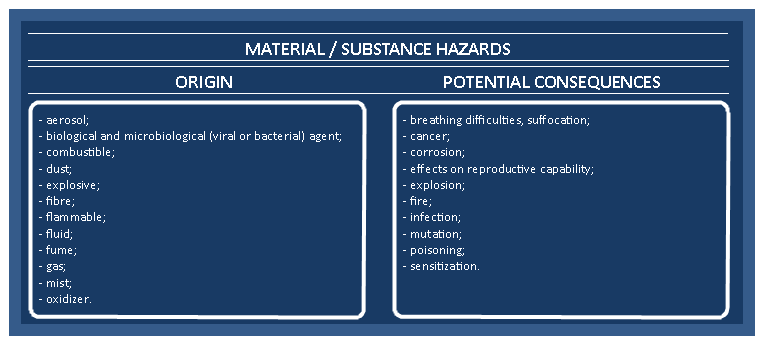

- Materials, Hazardous Substances

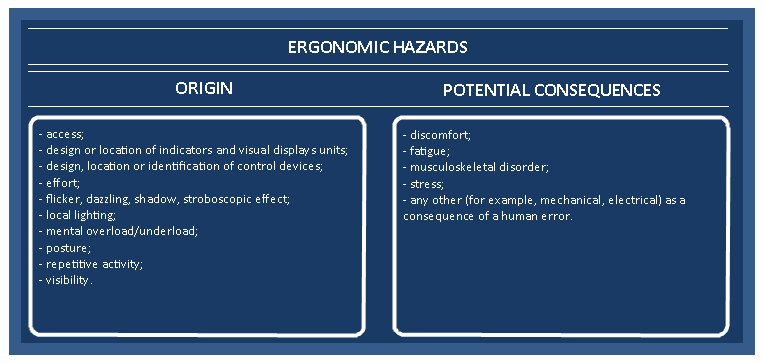

- Ergonomic Hazards

- Hazards associated with the environment in which the machine is used

- Hazard Combinations

-

Source

- acceleration, deceleration;

- sharp edges;

- moveable piece approaching to a fixed part;

- cutting of parts;

- elastic pieces;

- object falling;

- gravity;

- height from the ground;

- high pressure;

- instability;

- kinetic energy;

- machine mobility;

- moving parts;

- rotating elements;

- rough surface, slippery;

- sharp edges;

- energy stored;

- vacuum.

-

Potential consequences

- running over;

- throwing;

- crushing;

- cutting and mutilation;

- getting trapped or tangled;

- getting stuck;

- friction and abrasion;

- impact;

- injection;

- scraping;

- slipping, stumbling and falling;

- drilling;

- suffocation.

-

Source

- electric arcs;

- electromagnetic phenomena;

- exposed circuits;

- low dielectric strength;

- exposed circuits under fault conditions;

- short circuit;

- thermal radiation;

-

Potential consequences

- burning;

- chemical effects;

- effects on medical implants;

- electrocution;

- falling or throwing;

- fire;

- projection of sparks;

- shock.

-

Source

- explosion;

- fire;

- objects or materials with high or low temperature;

- radiation from hot springs.

-

Potential consequences

- burning;

- dehydration;

- discomfort;

- freeze;

- damage caused by radiation of hot sources;

- scald.

-

Source

- cavitation phenomenon;

- exhaust system;

- gas leaking at high speed;

- production processes (stamping, cutting, etc.);

- moving parts;

- friction surfaces;

- unbalanced rotating parts;

- tire noise;

- worn parts.

-

Potential consequences

- discomfort;

- loss of consciousness;

- loss of balance;

- permanent hearing loss;

- stress;

- buzz;

- tiredness;

- others (eg mechanical, electrical) due to worn parts. interference in communication or acoustic signals

-

Source

- cavitation phenomenon;

- misalignment of moving parts;

- mobile equipment;

- friction surfaces;

- unbalanced rotating parts;

- equipment that vibrates;

- worn parts.

-

Potential consequences

- discomfort;

- lumbar morbidity;

- neurological dysfunction;

- osteo-articular disorders;

- spine trauma;

- vascular disorders.

-

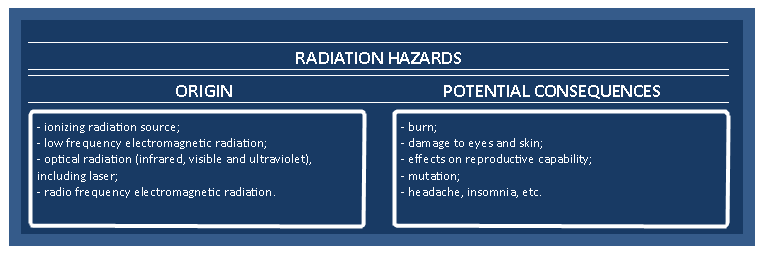

Source

- ionizing radiation sources;

- low frequency electromagnetic radiation;

- optical radiation (infrared, visible or ultraviolet), including laser;

- electromagnetic radiations in radiofrequency

-

Potential consequences

- burning;

- damage to the eyes and skin;

- effects on reproductive capacity

- mutations

- headache, insomnia, etc;

- carcinogenic effects.

-

Source

- aerosols;

- agents biological and microbiological (viral or bacterial);

- fuels;

- dust;

- explosives;

- fiber;

- flammable objects;

- fluids;

- fumes;

- gases;

- mixtures;

- oxidants.

-

Potential consequences

- difficulty breathing, choking;

- cancer;

- corrosion;

- effects on reproductive capacity;

- explosions;

- fire;

- infections;

- mutations;

- poisoning;

- sensitivity disorders.

-

Source

- access;

- project or location indicators, indicators and dashboards;

- design, location or identification of control devices;

- efforts;

- twinkling, glowing, shadow, strobe effect;

- spot light;

- mental overload, idle;

- posture;

- repetitive activity;

- visibility.

-

Potential consequences

- discomfort;

- fatigue;

- musculoskeletal disorders;

- stress;

- others (eg mechanical, electrical) due to human errors.

-

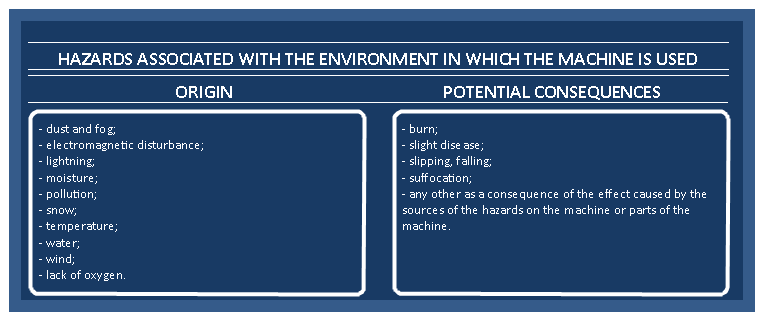

Source

- dust or fog;

- electromagnetic disturbance;

- lightning;

- humidity;

- pollution;

- snow;

- temperature;

- water;

- wind;

- lack of oxygen.

-

Potential consequences

- burn;

- mild illnesses;

- falling or slipping;

- suffocation;

- any other consequence of the effect caused by sources hazards of the machine or its specific parts.

Life cicle

-

Measured life cicle:

-

Activity description

Hazard level required

-

Severety

-

Frequency

-

Probability to avoid

-

PLa

-

PLb

-

Probability to avoid

-

PLb

-

PLc

-

Frequency

-

Probability to avoid

-

PLc

-

PLd

-

Probability to avoid

-

PLd

-

PLe

HRN AT THE ORIGINAL CONDITION OF THE MACHINE

-

Probabillity of Occurence (PO)

-

Degree of Possible Harm (DPH)

- Scratch or bruise = 0,1

- Laceration or mild ill-effect = 0,5

- Break of minor bone or minor illness (temporary) = 2

- Break of major bone or major illness (temporary) = 4

- Loss of one limb, eye, hearing (permanent) = 6

- Loss of two limbs or eyes (permanent) = 10

- Fatality = 15

-

Frequency of Exposition (FE)

- less than 1 per year = 2

- between 1 every 2 weeks and 1 per year = 3

- between 1 per day and 1 every 2 weeks = 4

- between 1 per hour and 1 per day = 5

-

Number of Persons Exposed to the Risk<br>(NP)

Safety measures applyable:

-

Adminstrativ actions

- Lockout / Tagout

- Manual

- Work and safety procedures

-

Adminstrativ actions

-

Technical actions

- Optical stop

- Bimanual

- Emergency buttons

- Emergency key

- Master key

- Contactors

- Light curtains

- Ladder and ramp

- Running machine

- Hydraulic

- Drag measurement

- Inertia monitoring

- Control panel

- Panel or electrical parts

- Safety crankset

- Platform

- Pneumatics

- Fixed protection

- Mobile protection with lock

- Mobile protection without blocking

- Reset

- Mechanical retention

- Noise

- Scanner

- Safety Mat

- Thermal

- Vibration

- Others

-

Technical actions

HRN AFTER IMPLEMENTED RECOMENDATIONS

-

Probabillity of Occurence (PO)

-

Degree of Possible Harm (DPH)

- Scratch or bruise = 0,1

- Laceration or mild ill-effect = 0,5

- Break of minor bone or minor illness (temporary) = 2

- Break of major bone or major illness (temporary) = 4

- Loss of one limb, eye, hearing (permanent) = 6

- Loss of two limbs or eyes (permanent) = 10

- Fatality = 15

-

Frequency of Exposition (FE)

- less than 1 per year = 2

- between 1 every 2 weeks and 1 per year = 3

- between 1 per day and 1 every 2 weeks = 4

- between 1 per hour and 1 per day = 5

-

Number of Persons Exposed to the Risk<br>(NP)

7 CONCLUSIONS

-

FINAL CONSIDERATIONS