Information

INFORMATION TO BE COMPLETED PRIOR TO INSPECTION

-

Property Address

-

Trim File Number

-

PROPERTY OWNER/S NAME

SUMMARY TO BE COMPLETED AT END OF INSPECTION

-

Date and Time at start of inspection

-

REASON FOR INSPECTION

- Renewal inspection

- Re-inspection - Follow up

- Inspection prior to Penalty Infringement Notice

-

Number of systems on the property

-

System Type

- Septic Tank

- Trench

- Pump out

- AWTS

- Spray Irrigation

- Sub- surface Irrigation

- Greywater (laundry water)

- Biological Filtration System

- composting Toilets

- Ecomax

- Mound

-

Disposal Method

- Trench

- Pumpout

- Spray Irrigation

- Sub-surface Irrigation

- Mound

- Evapo-transpiration Beds

- Pop-up sprinklers

-

Risk Ranking

-

Inspection Result

- 5 year approval

- 1 year approval

- FAIL

- LETTER

- Works satisfactory - works may proceed

- Works unsatisfactory - further works required

- Local Government order

- Issue operational Approval with conditions

-

Inspecting Officer

- Jason Haig

- Emma Clunas

- Alison McVey

- Melissa Moyle

- Shane Keys

- Tom Roose

- Andrew Gibbes

- Thelma Marr

- Greg Howarth

- Catherine Watts

- Nathaly Jones

-

Conditions for fail letter

- 1. Warning signs must be installed on the property.

- 2. Submit a plan to Council for a second irrigation area. Primary and secondary effluent disposal areas should be established etc

- 3. The application area must be sited at least 6 metres from down gradient boundary, 15 metres from the dwelling etc

- 4. Surface spray irrigation must not be used on fruit trees and vegetable plants.

- 5. All irrigation lines must be laid underground with a minimum 100mm ground cover.

- 6. Sprinklers must be attached to the irrigation line that throw no more than 2 metres and produce coarse droplets with a maximum plume height of 400mm above finished ground level.

- 7. The irrigation area must be away from recreation areas

- 8. Al pipework and fittings must comply with all parts of AS 1477

- 9. Instal additional sprinklers in the irrigation area.

- 10. Relace the inspection cap to prevent stormwater ingress and vermin from entering the tank and breeding.

- 11. Ensure that all sprinklers used for irrigation of treated effluent are purple.

- 12. Ensure that all hose on the ground surface used for irrigation of treated effluent is purple.

- 13. Slash and remove cut grass from the effluent disposal area.

- 14. The septic tank needs to be de-sludged.

- 15. Provide a dedicated area free from livestock for the absorption trench.

- 17. To help ensure the efficient operation of your system the following additional actions are recommended:

-

Comments

DESKTOP ASSESSMENT PRIOR TO SITE VISIT

-

INSTRUCTIONS: Undertake the desktop assessment prior to the site visit. Use the snipping tool to insert relevant GIS images and any documents from TRIM (ie site plan, previous inspections or wastewater reports)

SITE INSPECTION RISK ASSESSMENT CHECKLIST

SITE INSPECTION

-

Traveling to site - vehicle

-

Entering/exiting vehicle

-

Working outdoors, solar/UV radiation, heat stress or insect bite.

-

Unrestrained dogs on site

-

Moving vehicles or machinery on site

-

Electric fencing

-

Livestock present on property

-

Remote area

-

Other hazards

-

OK to continue inspection. OFFICERS SIGNATURE

INSPECTION DETAILS

-

PHOTO OF SEPTIC TANK

-

PHOTO OF DISPOSAL AREA

-

System Type

TYPE OF SYSTEM

-

What type of system

-

Have service reports been sent to Council? (23)

-

Does the system have quarterly maintenance by a service contractor?

-

Is the system operational at the time of inspection? (27)<br>Eg - chlorine tablets, UV lamp

-

Is the irrigation line buried? (24)

-

No garden hoses and fittings being used for irrigation? (30)

-

Are irrigation warning signs present? (28)

-

Is there sufficient irrigation area? (25)

-

Is effluent being evenly distributed? (29)

-

Is the effluent disposal area greater than 15 m to dwellings? (13)

-

Is the effluent disposal area greater than 6 m up/3m down to driveways & property boundaries? (12)

-

Is the effluent disposal area greater than 3 m to paths and walkways? (14)

-

Is the effluent disposal area greater than 6 m to swimming pools? (15)

-

Is the surface drip or trickle irrigation area greater than 6 m up gradient/ 3 m down gradient to pools, property boundaries, driveways & buildings? (16)

-

Is the disposal area showing signs of stress? (33)

-

Is trench performing ok?

-

Is greywater being disposed of satisfactorily? (32)

-

If there is a grease trap, is it satisfactory?

-

Is the absorption system greater than 12 m if up gradient/3m if down gradient to the property boundary? (17)

-

Is the effluent disposal area greater than 6 m up/ 3 m down to pools, driveways and buildings? (18)

-

Is the absorption area adequately isolated from livestock?

-

Is there a pump-out contract? (35)

-

Does the operator have pump-out receipts? (37)

-

Is greywater being disposed of satisfactorily? (38)

-

Is there a draw line with a cam lock? (36)

-

If there is a grease trap, is it satisfactory? (31)

-

Is the mound dry and appear to be operating ok?

-

Is there an external door, shute to collect the humus?

-

Does the fan operate continuously?

-

Is the compost humus used in an environmentally safe manner?

-

Does the system appear to not require attention?

Buffer distances

-

Is the effluent disposal area greater than 100 m to permanent surface waters? (9)

-

Is the effluent disposal area greater than 250 m to domestic groundwater? (10)

-

Is the effluent disposal area greater than 40 m to other waters (eg intermittent waterways, dams)? (11)

PERFORMANCE STANDARDS

-

Does the system comply with the performance standards?

-

Does the system prevent the spread of disease by micro-organisms? (1)

-

Does the system prevent the spread of foul odours? (2)

-

Does the system prevent the contamination of water? (3)

-

Does the system prevent the degradation of soil and vegetation? (4)

-

Does the system discourage insects and vermin? (5)

-

Does the system minimise any adverse impacts on the amenity of the premises and surrounding lands? (7)

-

Does the systems provide for he re-use of resources (including nutrients, organic matter and water? (8)

Comments

-

Time at end of inspection

-

Site Plan - All On-site Effluent System Components Identified

-

Signature

Further information

FURTHER INFORMATION ABOUT ON-SITE SEWAGE MANAGEMENT

Why the need for an approval to operate?

-

In 1997, an incident occurred where wastewater was found to be discharged into Wallis Lake, near Port Macquarie. The discharge came from a number of domestic septic tanks. As the Lake was used for aquaculture, an outbreak of Hepatitis A occurred, resulting in 444 people contracting the disease and one fatality.

As a result, a review was undertaken and it found that councils were best placed to inspect and regulate the use of on-site sewage management system. Changes were made to the Local Government Act 1993 to require everyone with an on-site sewage management systems to obtain an approval to operate the system.

The maximum time that an approval can be granted is five years and an approval is not transferable on the sale of a property.

Protecting your on-site sewage management system and effluent disposal area

-

There are a number of simple things that you can do to protect your on-site sewage management system:

• use a sink strainer to reduce waste reaching your septic tank;

• clean the grease trap regularly (where fitted);

• don’t discharge bleach, whiteners, nappy soakers etc into the system;

• don’t discharge hygiene products, condoms, tampons, nappies and cotton buds into the system;

• don’t use more than recommended amounts of disinfectants and detergents;

• repair leaking taps and cisterns;

• have the sludge pumped out every 4-5 years;

• grow grass in your effluent disposal area and keep it regularly mown;

• divert stormwater away from the area;

• don’t drive or park vehicles over the area; and

• keep livestock out of the area to avoid compacting of the soil.

If the system becomes smelly, flush a cup of lime (calcium oxide) down the toilet each day for 7 days. This will reduce the pH and encourage bacterial growth, which reduces the odour. -

Failing system?

-

If today’s inspection found that your system is not operating satisfactorily, it may not mean that you need to replace or upgrade your tank. Often the only work required is to repair or replace the effluent disposal area.

Depending on the circumstances, Council may:

• ask for work to be done;

• ask you to submit details of work that you propose to do so that the system complies;

• issue a Local Government Order to carry out work or submit details;

• issue an Environmental Protection Notice under the Protection of the Environment Operations Act 1997; or

• take other regulatory action.

Designing an effluent disposal area

-

The design of an effluent disposal system is based upon two key factors - the amount of wastewater generated by the household, and the soil type.

WASTEWATER – the amount of wastewater that is generated by a household is generally determined to be 290 litres per bedroom (plus any study) per day for dwellings on mains water supply, and 230 litres per day for tank supply.

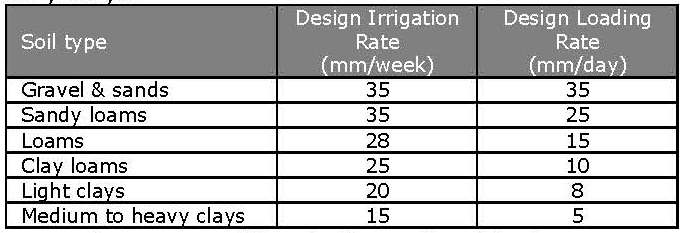

SOIL – the type of soil is used to determine how much area is required to absorb the effluent produced by the household. The soil type is determined from 500 mm below the effluent disposal layer and is classified into one of six general categories: gravels & sands; sandy loams; loams; clay loams; light clays and medium to heavy clays. -

SOIL TYPE DESIGN IRRIGATION RATE DESIGN LOADING RATE

(mm/week) (mm/day)

Gravel & Sands 35 35

Sandy Loams 35 25

Loams 28 15

Clay Loams 25 10

Light Clays 20 8

Medium to heavy clays 15 5 -

Information on how to determine soil classifications can be found at: http://www.dpi.nsw.gov.au/__data/assets/pdf_file/0005/164615/soil-texture.pdf http://vro.dpi.vic.gov.au/dpi/vro/vrosite.nsf/pages/soilhealth_texture_pdf/$FILE/QRG_Texture.pdf

-

The most common effluent disposal methods are absorption trenches (generally associated with septic tanks) and spray irrigation.

ABSORPTION TRENCHES are generally used to dispose of primary treated effluent (that is, effluent that has only been treated by detention).

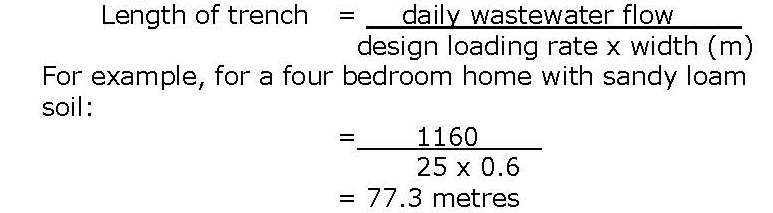

To determine the size of absorption trench required, the following formula is used: -

Length of trench = daily wastewater flow

____________________________

design loading rate x width (m)

For example, for a four bedroom home with sandy loam soil:

= 1160

––––––––––––––––––––

25 x 0.6

= 77.3 metres -

Other important factors to take into consideration when designing an absorption trench are:

• individual trenches cannot exceed 20 metres in length;

• trenches must be a minimum of 1 metre apart;

• maximum width of a trench is 0.6 metres; and

• bottom of trenches must be level.

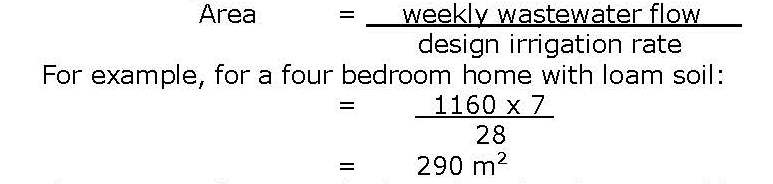

SPRAY IRRIGATION is used to dispose of secondary treated effluent, most commonly from an aerated wastewater treatment system (AWTS) where disinfection occurs.

To determine the size of spray irrigation area required, the following formula is used: -

Area = weekly wastewater flow

______________________

design irrigation rate

For example, for a four bedroom home with loam soil:

= 1160 x 7

–––––––––

28

= 290 square metres -

The irrigation line must be buried so that the moveable length of line cannot extend beyond the approved area.

SUBSURFACE IRRIGATION may be used with secondary effluent that hasn’t been disinfected. The area required is determine in the same way as that for spray irrigation.

In both cases, Council’s policy requires you to designate a reserve area that could be used in the future if the effluent disposal area is damaged or requires resting.

Further information:

-

Further information is available on Council’s website at www.shoalhavencitycouncil.nsw.gov.au or call Council during office hours on (02) 44293111 and speak to an Environmental Health Officer.