Information

-

Document No.

-

TEMPLATE CHECK LIST

-

Report Title

-

Customer

-

Conducted on

-

Project Team Members:

1. Pre-Installation Admin

-

Facility Name:

-

Actual Project Address:

-

Additional Directions if needed:

-

Machine Type:

- Synergy Platform

- Synergy

- Infinity

- VersaHD

- Axess

- Precise

-

Optional items:

- Agility head

- XVI

- Iview

- Hexapod/ Iguide

- A.B.C.

- Clarity

- Response system

- Brain Lab

- C-Rad

- Mosaiq Sequencer

- Integrity

- Synergystiq

- Mosaiq Scheduling

- CCTV

-

Machine S/N:

-

Project Number:

-

Inspection W/O #:

-

Inspection type:

-

Site Status:

-

Has the hospital administration been notified of the proposed date of the equipment delivery?

-

Have the authorities been informed where public areas may be used for equipment delivery / access?

-

Any other considerations or comments on the above?

2. Access to site / Off-loading

-

Is the off loading area clear?

-

Will it be clear on the date of delivery?

-

What size is the off loading area?

-

Picture of staging area if applicable:

-

Is the off loading area flat and at the same height as the entrance to the hospital building?

-

Will arrangements be made for a shallow gradient ramp or leveled area to allow easier access of the equipment?

-

When will it be ready?

-

What is being used to offload truck?

-

Does the forklift have enough space to maneuver, allowing for the area that crates will take up when unloaded? (Approx 3,800 sq. ft)

-

Does the delivery meet guidelines for a "Standard Delivery"?

-

Did the Riggers visit the site for evaluation?

-

Does the above have a SWL of 850 kg/m2?

-

Is there enough truck parking space?

-

Is the unloading area clean and clear?

-

Has provisions been made to prevent dust and debris getting into the hospital and onto the equipment?

-

When will be ready?

-

Any obstacle in rigging or staging path require protection?

-

Are there any gradients on the access route into the hospital building?

-

What is the gradient of the slope?

-

Any other considerations or comments on the above?

3. Access to Hospital door to the Bunker

-

All floors must support a load of 2 tones. (a point load of 850 kg/m2) Can the floor withstand this load?

-

Have arrangements been made to correct this?

-

When arrangements will be made to correct this?

-

Is the minimum clear height on the access route to the treatment room higher than 2015mm?

-

Is the minimum clear width on the access route to the treatment room wider than 1150mm

-

Are there any tight corners to be negotiated?

-

Can the beam arm and gantry drum make the turn around the corner?

-

Is it necessary to remove any door frames?

-

Have arrangements been made for this work to be done?

-

Do any floor ducts or floor finishes require protection?

-

Have arrangements been made for this work to be done?

-

Are there any gradients on the route to, or inside the treatment room?

-

What are the gradients?

-

Is the ceiling height behind the fascia wall > 2.75 m to allow for Linac assembly? (This includes sprinkler heads, vents, lights, etc)

-

Has the access route been cleared of debris and swept clean?

-

Any other considerations or comments on the above?

4. Precise Table Pit

-

Has the Precise Table Pit been constructed?

-

Does it meet the specifications on Elekta drawings?

-

Is the Sismic zone?

-

-

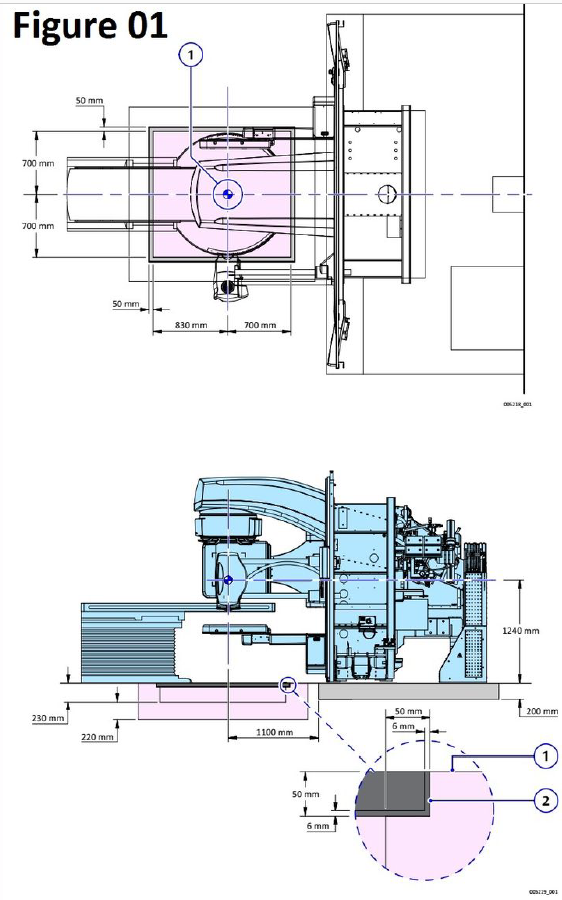

Has figure 1 been filled out completely

-

Pit depth from finished floor: (230mm +/- 2mm)

-

Pit internal width 1400mm:

-

Pit internal length 1530mm:

-

-

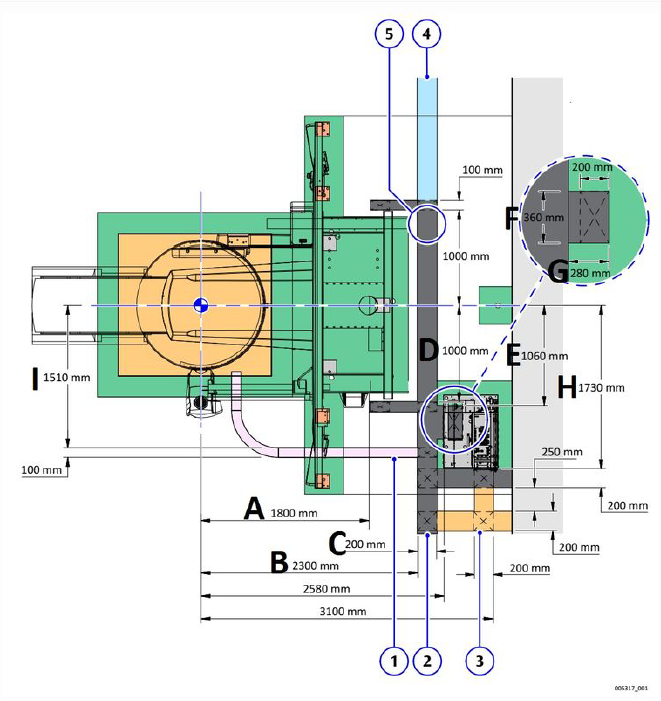

Has figure 2 been filled out completely

-

A - 1800mm

-

B - 2300mm

-

C - 200mm

-

D - 1000mm

-

E - 1060mm

-

F - 360mm

-

G - 280mm

-

H - 1730mm

-

I - 1510mm

-

-

Has figure 1 been filled out completely

-

Pit depth from finished floor: (230mm +/- 2mm)

-

Pit internal width 1400mm:

-

Pit internal length 1530mm:

-

-

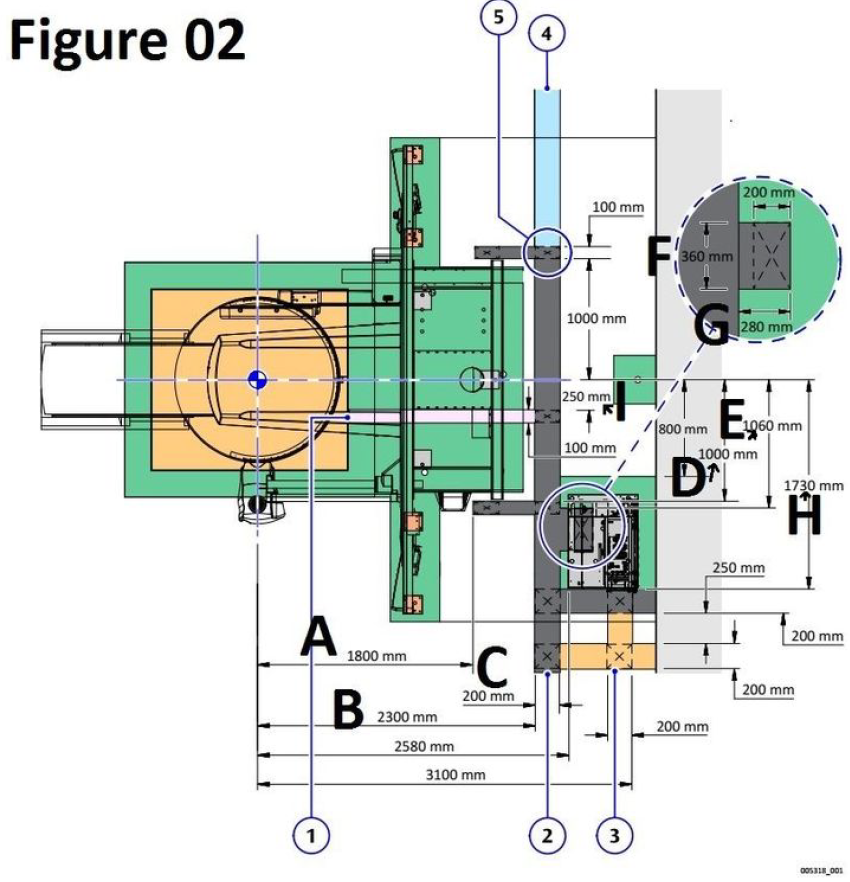

Has figure 2 been filled out completely

-

A - 1800mm

-

B - 2300mm

-

C - 200mm

-

D - 1000mm

-

E - 1060mm

-

F - 360mm

-

G - 280mm

-

H - 1730mm

-

I - 250mm

-

Are the mild steel angle frames (pit edging) that surround the Precise Table Pit (5 x 5 x 0.6) cm size and anchored into the concrete?

-

Isocenter to the lower wall (>3,30m):

-

Any other considerations or comments on the above?

5. Treatment Room

-

Has the concrete been poured on the floor?

-

All new concrete must have test cylinders poured and tested. Elekta requires copies of the test cylinder reports confirming concrete meets or exceeds our min. spec of 4500 psi compressive strength. If existing concrete to be used for any anchors, a core sample must be taken and tested confirming existing concrete meets or exceeds our min. spec of 4500psi comps dive strength. This report must be received by Elekta by the final site inspection date.

-

Has a copy of the concrete test results been received by Elekta?

-

What was the break test value shown on test results?

-

Was the concrete poured monolithic with no topping leveling layer?

-

How thick is the concrete slab under the table pit?

-

How thick is the concrete slab under the Base Gantry?

-

Signature of General Contractor Representative affirming constructed I/A/W Elekta requirements:

-

Does the concrete floor in the Gantry area meet levelness spec (+-5mm)

-

Does the final floor match with the steel angle PIT?

-

Has the final floor been laid?

-

If the final floor finish is not laid then the concrete floor must be sealed to reduce dust, has this been done?

-

When will this be done?

-

Have arrangements been made to protect the floor?

-

Has the wall covering been added?

-

Is ceiling finished?

-

When will this be done?

-

If there is a ceiling mounted I-Beam, have any struts or panels in the false ceiling been mounted across the path of the chain hoist and trolley?

-

When will they be removed?

-

What lifting facilities are available ?

- I-Beam

- A-Frame

-

Is the long axis of the beam parallel and vertically above the front/rear<br>axis (G-T axis) of the table pit (1.90m in front and 3.30m behind of<br>isocenter)?

-

What is the distance between the floor level and the floor ceiling level? (Mín 2600 to allow the hook can be raised when using the I-Beam)

-

Have all parts of the lifting system been load tested to 3.3 tons Static Load?

-

Has a copy of the certificate been sent to Elekta?

-

When will this be done?

-

Is a 3.3 ton (static load) chain hoist and trolley available?

-

Are installed the anchors embedded on the slab roof according to the SPG?

-

Does the cable ducts meet the requirements on Elekta site planning drawing?

-

What is the measured distance from control room floor box to Linac equip rm floor box?

-

Are the cable ducts finished?

-

Are they clear of debris, clean and with pull cables?

-

Have the laser recess (side & sagittal) been constructed to correct size and location in reference to isocenter? (L x W x AFF)

-

Is the treatment room fascia wall constructed?

-

What is the height of the opening? (2540mm)

-

What is the width of the opening? (4000mm)

-

Distance of fascia wall from isocenter? A/B (1220mm)

-

Is the opening of the fascia wall centered on the G-T line of isocenter?

-

Is there 02 supports on the top of customer wall to anchor the Elekta Fascia B poles

-

Has a space been left to allow the chain hoist on the I-Beam to pass?

-

How wide is it?

-

Is the 3-phase circuit breaker in position?

-

Is the circuit breaker (Electrical box) installed 1.80m to the right far away from isocenter?

-

Is power supplied to the above circuit breaker(s)?

-

Has the electrician checked for proper phase rotation? (CW)

-

is the Stabilizer/ UPS was purchased (by customer or Elekta) ?

-

Is the Stabilizer / UPS on the site?

-

Is the voltage stabilizer running, calibrated and connected to the 380v Linac power supply?

-

What are the following voltage measurements? (Required at time of final site verification)

-

Phase 1 voltage - maximum:

-

Phase 2 voltage - maximum:

-

Phase 3 voltage - maximum:

-

Single Phase voltage - maximum:

-

Measurement between neutro and ground (less than 1V)

-

Is the XVI Circuit breaker (SDX) installed? (3 Phase 400V +-5%)

-

What is the power output of the XVI circuit breaker?

-

Is the Client Interface Terminal Box (CITB) in position?

-

Has the Laser power plug system been tested and approved?

-

Has the emergency buttons been tested and approved with less than 01 Ohms?

-

Has the shielding and fascia door interlooks been tested and approved with less than 03 Ohms?

-

Has the Treatment Room Lights tested and approved?

-

Has the Radiation Warning Lights tested and approved?

-

Chiller cables ON/OFF are available?

-

Is installed the air conditioning ductwork?

-

Is the air conditioning system equipment on site ?

-

Is the air conditioning system functional?

-

Tested ?

-

Ductwork cleaned to remove the dust?

-

When will this be done?

-

State of the humidity of the air in the treatment room: (30/70%)

-

State of the temperature in the treatment room: (18/24 Celcius)

-

Is the final lighting installed?

-

Is the final lighting operational?

-

When will this be done?

-

Is a fire detection system installed in the treatment room? (In both the patient area or gantry areas)

-

State the type of fire detection system used:

-

The raceway of CCTV and Intercom system are cleaned and connecting the control area?

-

When will they be complete?

-

Are there pull string inside of the raceway/ conduits connecting the treatment room to the control area?

-

Is a functional sink with water and drain in the treatment room?

-

Has the treatment room been cleared of debris and swept clean?

-

When will this be done?

-

Is there In Room Monitor ?

-

Was planned space for monitor installation?

-

Are there 02 eletrical power plug and logic connection plug (Point to point)

-

Is there 1.1/2'' infrastructure (G-G) (pull cables) connection between In Room Monitor wall plate and the technical room?

-

Was planned space for monitor installation?

-

Are there 02 eletrical power plug and logic connection plug (Point to point)

-

Is there 2'' infrastructure (G-G) (pull cables) connection between In Room Monitor wall plate and the technical room)?

-

Is there Hexapod/IGuide system to be implemented?

-

Is there free space on the roof front of the I-beam? (500mm G-T axis and 300mm+-8mm A-B axis. IMPORTANT: The Iguide base has 300mm x 300mm )

-

Is it installed 1" infrastructure (H-H) (pull cables) between the IGuide and Hexapod box?

-

Does it need the Site adapted structure support?

-

Is there Remote Hexapod Monitor in the treatment room?

-

Was planned space for monitor installation?

-

Are there 02 eletrical power plug

-

Is it installed 1" infrastructure (C-C) (CAT6 RJ45) between the IGuide and Control Room?

-

New Clarity system to be implemented?

-

110/220V power plug available?

-

Is there 1" infrastructure (F-F)(pull cables) connection between the IGuide support and clarity wall plate?

-

Is there 1'' infrastructure (E-E) (pull cables) connection between clarity wall plate and the control room)?

-

Is it implemented the new infrastructure (Data connection RJ45 CAT 6) at treatment room?

-

Is it implemented the new infrastructure (Data connection RJ45 CAT 6) at CT room?

-

Is the camera support installed at CT (computer tomography) room (1950mm) ?

-

Is there isocenter's laser installed at CT room (different isocenter between machine and patient' position) ?

-

Check the LINAC isocenter

-

110/220V power plug available for camera and computer car?

-

New ABC system to be implemented?

-

110/220V power plug available?

-

Is there 1" infrastructure (D-D)(Data connection RJ45 CAT 6) connection between the control room and treatment area?

-

New Response system to be implemented?

-

How long the lenght of optical cable to be connected from RIC to Control Desk? (standard cable lenght 30m)

-

New QA (EPIGray or Perfraxion systems) to be implemented?

-

Logic connection plug available?

-

110/220V power plug available?

-

Any other considerations or comments on the above?

6. Chilled Water Supply

-

What is the voltage power to the chiller device?

-

Is the chiller water equipment purchased ?

-

Is on the site the chiller water equipment ?

-

Please attached the photo of the TAG equipment number

-

Is the Chilled water being supplied from:

- facility chilled water

- stand alone chiller

- city water

- water control box

-

Who is the manufacturer of chiller?

-

Is chiller running 24/7 or on/off with linac ?

-

Has Chiller been commissioned with chiller mfg / mechanical contractor?

-

Date scheduled?

-

Were the pipes tested by pressure ?

-

Is the temperature gauges in place?

-

Is the pressure gauges in place?

-

Is both supply and return line pressure valves installed?

-

Is the by-pass pressure valves installed?

-

Was it installed the electrical infrastructure for the remote control panel (in the bunker)?

-

Is the electrical cables available to connect into the CITB ?

-

Are the 1" (25mm) hose connector installed and in proper location?

-

Is the chilled water system fully operational?

-

State the chilled supply water pressure:

-

State the chilled supply water temperature:

-

State the chilled water flow rate:

-

Is site using city water as a back up?

-

City water temperature:

-

City water supply pressure:

-

City water return pressure:

-

City water flow rate:

-

City water filtration:

-

Any other considerations or comments on the above?

7. Radiation Protection

-

Has the shielding plan been approved by locally nuclear agency?

-

Has the radiation door been approved by the customer's Physicist?

-

Name of Customer's Physicist of Record?

-

Physicist contact number:

-

Is the Main Vault Entrance Door purchased ?

-

Is on site the Main Vault Entrance Door ?

-

Is the Main Vault Entrance Door installed ?

-

When will this be done?

-

Is the Main Vault Entrance Door operational?

-

Any other considerations or comments on the above?

8. Control Room

-

Is the control desk in position

-

Does the control desk has the minimum height to place the LINAC cabinet (W 60cm x H 70cm x dep 105 cm)

-

Is the Control Cabinet position clear?

-

Elekta monitors:

- Agility head

- XVI

- Iview

- Hexapod/ Iguide

- A.B.C.

- Clarity

- Response system

- Brain Lab

- C-Rad

- Mosaiq Sequencer

- Integrity

- Synergystiq

- Mosaiq Scheduling

- CCTV

-

Does the control desk size address to the quantity of Elekta monitors

-

Do the cable ducts meet the requirements on Elekta site planing drawings?

-

Are the LINAC cable ducts finished?

-

When will they be done?

-

Are the cable ducts clean, clear and with pull cables?

-

Do the cable duct covers fit correctly?

-

Are the single phase outlets installed?

-

When will they be?

-

Is single phase power supplied to them?

-

When is this expected to be complete?

-

How many 20 amperes outlets power is installed?

-

Who is responsible for installing CCTV & Intercom systems

-

Are there race rails supports?

-

Has the final floor been laid?

-

When will this be done?

-

Have the ceiling grid and ceiling tiles been installed?

-

When will this be done?

-

Is the air conditioning system functional, tested , and cleaned to remove dust?

-

When will this be done?

-

Is the final lighting installed?

-

Is the final lighting operational?

-

When will this be done?

-

Is site implementing a systems computer closet?

-

Does closet have adequate air flow?

-

Does closet have pullout shelving?

-

Have grommeted cable passages been cut in the control desk counter top (minimum 60mm of diameter)?

-

When will this be done?

-

Has the control area been cleared of debris and swept clean?

-

When will this be done?

-

New AQUA system to be implemented?

-

Is 80cm of free space available at planning desk?

-

110/220V power plug available?

-

Data connection RJ45 CAT 6 available, connected to the client network and functional?

-

Opening about 3" for cable pass?

-

New QA (EPIGray or Perfraxion systems) to be implemented?

-

Is 50 cm of free space available at planning desk?

-

110/220V power plug available?

-

Is there 1" infrastructure (Data connection RJ45 CAT 6) connection between the control area and treatment area?

-

Opening about 3" for cable pass?

-

Any other considerations or comments on the above?

9. Comand Room Networking

-

An IP Address is required for installation of your machine. You must provide the correct IP Address(es) within the first three (3) days of the system delivery. This Note is to inform you that failure to provide the IP Address(es) could result in an additional charge to the customer from Elekta.

-

Are the network RJ45 points installed?

-

Does the network RJ45 points active for the Elekta NSS?

-

What are the network addresses?

-

I.P. Address - LCS Cabinet:

-

I.P. Address - Secondary Impac Computer (Scheduler) :

-

I.P. Address - Network Printer:

-

Subnet Mask:

-

Default Gateway:

-

WINS/DNS Primary:

-

WINS/DNS Secondary:

-

What are the nodes names?

-

Is network available?

-

When will this be done?

-

Has the network been tested as functional?

-

When will this be done?

-

Are there some quantity of spare RJ45 points

-

Any other considerations or comments on the above?

10. Information for Elekta

-

Are 10 gallons of distilled water available? (De-mineralized water is not acceptable)

-

When will water be available?

-

Is a cylinder of SF6 available? ( size "B" or "C" is acceptable, min 99% purity required)

-

Who is providing SF6?

-

When will it arrive to site?

-

Expected day gases are to be on site?

-

Has provisions been made for disposing of, or recycling all packaging and crates?

-

It the site a new or existing building?

-

Has all building work been completed?

-

Is any hospital staff working on the access route?

-

Have arrangements been made for the area to be clear on the delivery day and the following day?

-

Is a lockable area available for the storage of the delivered equipment and tools?

-

How wide is the doorway?

-

What are the dimensions of the space?

-

Enter all facility contacts for Elekta Installation Engineers

Installers Contacts

-

Contact Name:

-

Contact Title:

-

Contact Phone:

-

List any individuals that will be working with the Elekta Engineers:

Contacts:

-

Name:

-

Title / Company:

-

Phone:

-

NOTE: The installation Engineer has no authority to change the set-up, configuration, or add a special requirement unless he has approval from Elekta's development department that it is safe to do so.

-

Give details of any locally agreed specials or changes to the end set-up, configuration of the Linac, or its options that are not mentioned on the order or approved by Elekta.

-

Any political issues or problems to be aware of?

-

State the communication arrangements with regards to the ordering and delivery of spare parts from Elekta to the hospital during installation.

-

This report was completed by:

-

Is the site approved to start the installation?

-

Signature:

-

Additional comments:

Inspection notes

-

Inspection Notes:

-

Site Pictures:

-

Truck Parking and Staging Area:

-

Rigging Path:

-

Bunker: include each wall, pit, floor raceway, back wall layout, and ceiling.

-

Control Room: include under countertop, computer closet/Cabinet:

-

Furniture (control room and bunker):