Title Page

-

Client Name

-

Site Name

-

Conducted on

-

Prepared by

-

Site Address

-

Contractor Company

-

Lead Tech name

-

Date of installation

-

State

- NSW

- ACT

- VIC

- QLD

- SA

- WA

- TAS

- NT

Switchboards

-

Go to the main switchboard. Take a photo of the main switchboard with the doors closed.

Connection point

-

Is the PV system connected to the correct NMI? (look for other meters, or unmetered sections)

-

Take photos showing that the PV system is connected to the correct NMI

Main Switchboard signage

-

All signs and labels should be permanent (e.g. traffolyte), readily visible and legible, securely attached

-

-

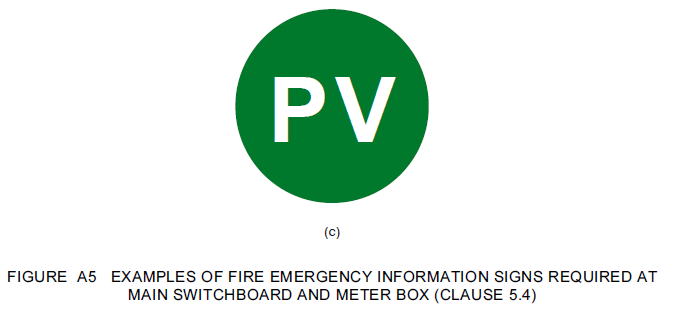

Is there a "PV" sign on or immediately adjacent to the main switchboard?<br><br>Must be 70mm, circular, green, REFLECTIVE, and readily visible to approaching emergency workers - refer AS/NZS 5033:2014 5.4.2

-

Take a photo of the main switchboard with the doors open.

-

-

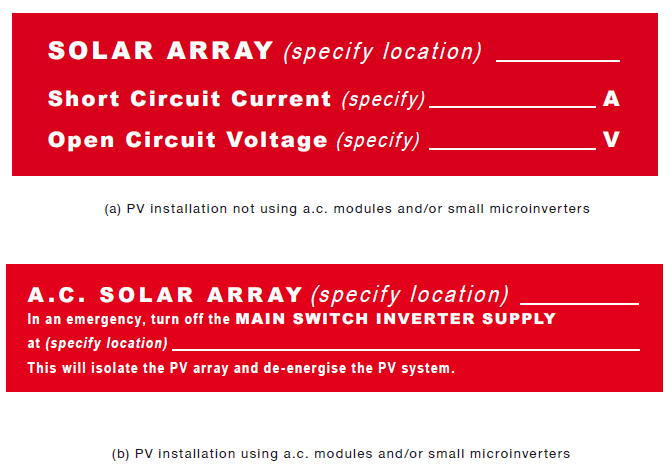

Is there a voltage and current sign on the main switchboard?<br><br>Must be filled in. Must be visible when switchboard door is open. Text must be 5mm high. Black text on red background also acceptable. Refer AS/NZS 5033:2014 5.4.1

-

-

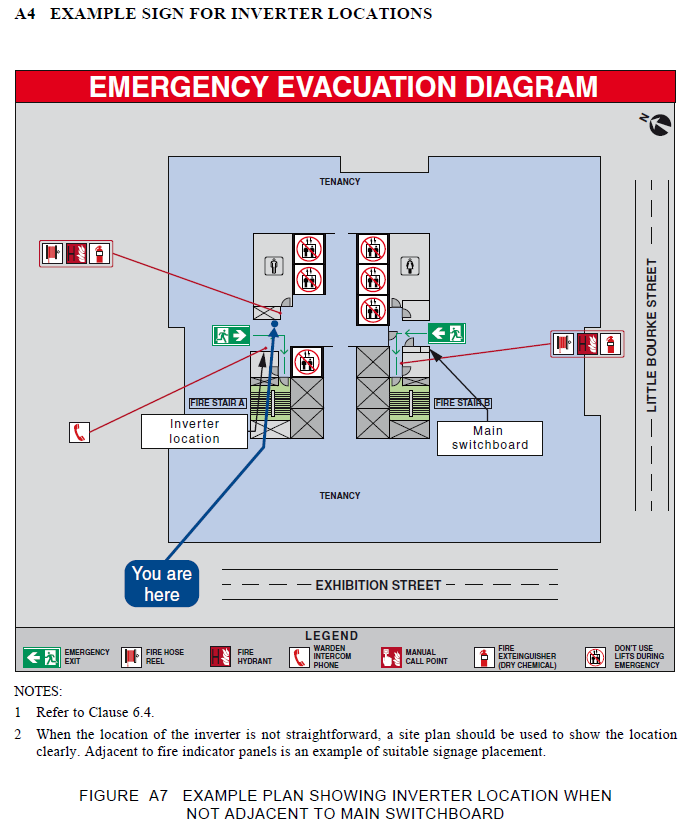

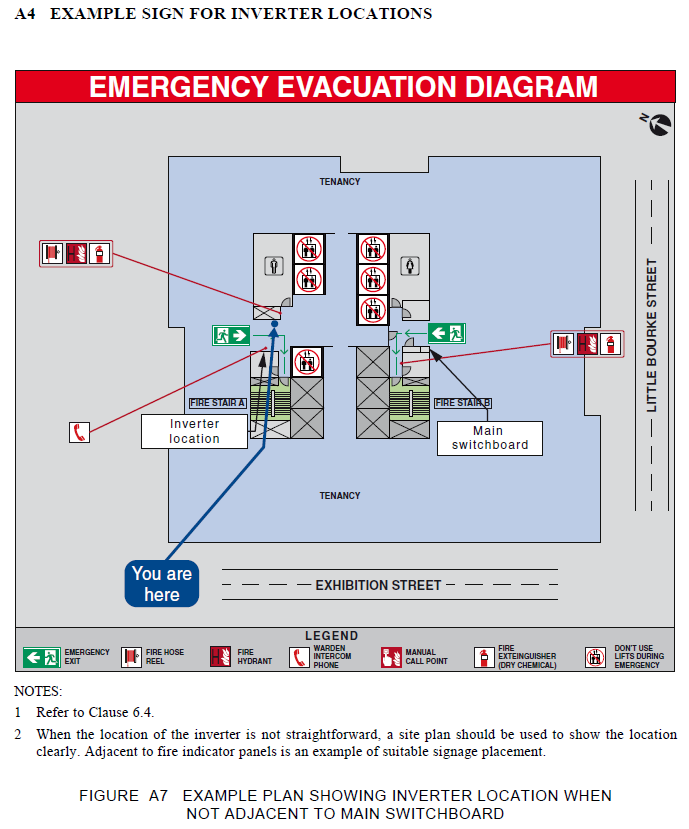

Is the inverter easy to find, or is there a map or plan at the main switchboard showing the inverter location?<br><br>Refer AS/NZS 4777.1:2016 6.4

-

Is the inverter connected directly to the main switchboard?

-

-

Is there a sign on the switchboard saying?<br><br>WARNING<br>MULTIPLE SUPPLIES<br>ISOLATE INVERTER SUPPLY AT DISTRIBUTION SWITCHBOARD ______________<br><br>___________ must state the PHYSICAL LOCATION of the switchboard that the inverter is connected to, not just the DB number.<br><br>Refer AS/NZS 4777.1:2016 6.3

-

Is there a laminated copy of the as-built single line diagram at the MSB?

-

Is the as-built single line diagram correct?

-

Go to the switchboard where the inverter is connected. Take photos with the doors closed and doors open.

Consumption monitoring

-

Has consumption monitoring been installed?

-

Take photos of consumption monitoring meter and CTs

-

Are the voltage inputs protected by either fuses or a dedicated MCB?

-

Have CTs been installed in the correct location? (i.e. on main incomer, not on a submain)

-

Is the CT polarity correct?

-

Is the CT ratio set correctly in the meter?

-

Does the meter have comms to the internet? (for solaredge devices, look for <S_OK> on the LCD; for all devices check the portal)

Switchboard where the inverter is connected (may be the main switchboard or a sub-DB)

Signage

-

-

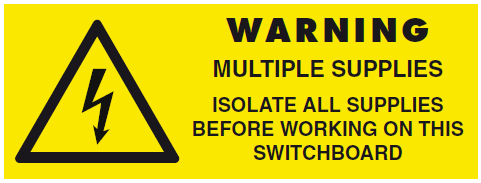

Is there a sign on the switchboard saying<br><br>WARNING<br>MULTIPLE SUPPLIES<br>ISOLATE ALL SUPPLIES BEFORE WORKING ON THIS SWITCHBOARD<br><br>Refer AS/NZS 4777.1:2016 6.2(a)

-

Is there a sign adjacent to the inverter CB saying<br><br>'MAIN SWITCH (INVERTER SUPPLY)'?<br><br>Refer AS/NZS 4777.1:2016 6.2(b)

-

Is there a sign adjacent to the incomer CB saying one of:<br><br>'MAIN SWITCH (NORMAL SUPPLY)'<br>'MAIN SWITCH (GRID SUPPLY)'<br>'MAIN SWITCH (MAINS SUPPLY)'<br><br>Refer AS/NZS 4777.1:2016 6.2(c/d)

-

Is the inverter immediately adjacent to (i.e. within arms length) and visible from the switchboard it is connected to?<br>OR<br>Is there a sign on the switchboard giving the location of the inverter?

Connection point

-

Is there a laminated copy of the as-built single line diagram at the switchboard?

-

Is the as-built single line diagram correct?

-

Does the MAIN SWITCH (INVERTER SUPPLY) actually isolate the inverter? (operate it to check)

Inverter CB and wiring

-

Is the inverter CB rating adequate for the inverter size?

-

What is the inverter CB make/model and rating?

-

Is the inverter CB the same make/model and rating as specified in the most recent approved drawings?

-

Can you safely view the inverter CB terminals?

-

Are terminals tight on Circuit Breaker?

-

Are the CB terminals free of signs of heat/hotspots?

-

Are the wire colours correct?

-

What size wire has been used (mm2)?

General

-

Are there any other issues or defects relating to switchboards?<br>(Add note with details)

Fire Panel Signage

-

Does the building have a fire panel?

-

-

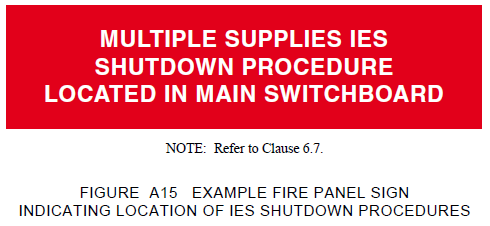

Is there a sign at the fire panel stating ‘MULTIPLE SUPPLIES’ explaining where to find the inverter shutdown procedures?<br><br>Refer AS/NZS 4777.1:2016 6.7

-

-

Is the inverter easy to find, or is there a map or plan at the fire panel showing the inverter location?<br><br>Refer AS/NZS 4777.1:2016 6.4

-

Are there any other issues or defects relating to the fire panel?<br>(Add note with details)

Inverter

-

Take photos of the inverter

-

What is the inverter make/model/rating?

-

Are all the inverters the same make/model and rating as specified in the most recent approved drawings?

Access

-

Is there adequate access/egress to inverter location? (min 600mm as per AS/NZS 3000)

-

Is the maximum DC array voltage above 600Vdc?

-

Is the inverter installed in a secured lockable enclosure, accessible only by authorised personnel?<br><br>(Refer Verdia spec)<br>

-

Does the access door/gate have a sign saying<br><br>WARNING: HAZARDOUS VOLTAGE<br>AUTHORIZED ACCESS ONLY<br><br>Refer AS/NZS 5033:2014 5.5.4

Inverter Location (AS/NZS 4777.1:2016 5.3.1 and AS/NZS 3000:2007 2.9.2.5)

-

Upright, firmly secured to the wall?

-

Well ventilated?

-

Protected from ingress of vermin, insects, water, and dust?

-

Exposed to direct sunlight?

-

If the inverter were to catch fire or generate smoke, would it compromise any fire/emergency escape routes? (AS4777.1 5.3.1, AS3000 2.10.2.5.h)

-

Is there adequate clearance for ventilation and maintenance?

Inverter Signage

-

Is there a permanent sign on/adjacent to the inverter detailing the emergency shutdown procedure?<br><br>Refer AS/NZS 4777.1:2016 6.7 and AS/NZS 5033:2014 5.5.3

-

Is the shutdown procedure specific to this system? e.g. do the names of switches in the procedure match the labels on the switches?<br><br>Refer CEC installer guidelines May 2017 8.7.1

-

Are all the switches/equipment referred to in the procedure adjacent to (<3m) AND visible from the shutdown procedure?<br><br>Refer AS/NZS 4777.1:2016 6.7

-

Does the shutdown procedure include a warning that "isolation of the energy source by shutting down the inverter and isolating the IES may not de-energize the energy source and further actions may be required"?<br><br>Refer AS/NZS 4777.1:2016 6.7

Inverter operation

-

Is the inverter date and time correct?

-

Is the inverter running?

What temperature is the inverter running at?

Communications

-

Is the inverter connected to comms/monitoring?

-

Are all the inverter communications daisy chained with Cat5/6 shielded cable?

-

All socket outlets for modems / switches etc have RCD protection, OR are "located in a position that is not likely to be accessed for general use; and clearly marked to indicate the restricted use of that socket-outlet and that RCD protection is not provided for that socket-outlet"? (AS/NZS 3000:2007 2.6.3.2.3.3)

-

Is the modem supplied from a dedicated MCB?

-

Is the MCB supplying the modem labelled?

SolarEdge Systems

-

Is this a SolarEdge system?<br>

-

Is the total length of the communications cable less than 1,000 metres?

-

Is there a surge protector for the communications port of every device?

-

Are there multiple inverters?

-

Is the communications cabling terminated at the first and last inverter as per the inverter manual?

-

Do the inverter stickers on the ‘physical layout template’ match the actual installation?

-

Attach a copy of the SolarEdge Physical Layout Template

General

-

Are there any other issues or defects relating to the inverter?<br>(Add note with details)

Cabling - Ground

-

Take photos of cabling, conduits, and trays

DC cables / enclosures

-

Are all DC cables marked "PV1-F"?

-

Are all DC cables segregated from AC cables?

-

If PV array voltage exceeds 600Vdc, is all DC cabling in HEAVY DUTY conduit, or covered cable tray, such that it is not accessible without the use of a tool?<br><br>Refer AS/NZS 5033-2014 3.1

-

Are all DC cables / conduits / trays marked with the word "SOLAR" at minimum 2m intervals?<br><br>Refer AS/NZS 5033-2014 5.3.1

-

-

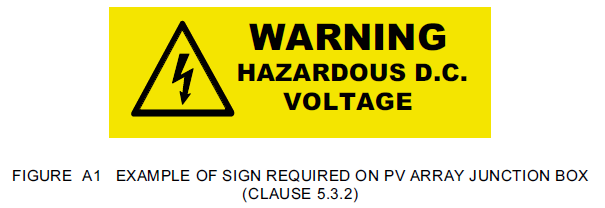

Are all PV array/string junction boxes labelled "WARNING: HAZARDOUS D.C. VOLTAGE"?<br><br>Text must be black on yellow background.<br><br>Refer AS/NZS 5033-2014 5.3.2

Conduits

-

Are conduits fixed with saddles at maximum 1m intervals, with two fixings per saddle? (Verdia spec)

-

Are all conduit bends made with elbow fittings, or bent smoothly, with no kinks, discolouration, or bubbling?

-

Are all PVC conduits out of direct sunlight? (Verdia spec)

-

Are all conduit entries and joints sealed and glued to prevent vermin/insect/water/dust ingress? (Verdia spec)

Cable trays / support systems

-

Are there any cable trays / ladders present?

-

Do all cable trays have pitched covers, including over bends and tees? (Verdia spec)

-

Are all cable tray bends/tees well made and neatly fixed and painted?

-

Are cables fixed to the support system by proprietary nylon ties, straps or saddles, at 1000 mm centres for vertical runs and 2000 mm centres for horizontal runs? (Verdia spec)

-

Are cable trays and ladders mounted at least 50mm clear from roof panels?<br>Cable trays and ladders shall not be directly screwed or fixed to roofing under any circumstances. (Verdia spec)

-

Are cable trays adequately bonded and earthed?

General

-

Do all cables have adequate mechanical protection, UV protection, labelling, and support?

-

Are there any other issues or defects relating to ground-level cabling?<br>(Add note with details)

Current Transformers

-

Does this project include current transformers?

-

Are the CT's safely accessible for inspection?

-

Take photos of the CTs

-

Are the CT nameplate ratings in accordance with the most recent approved drawings?

-

Are the transformers correctly connected as per the system requirements?

-

Is there adequate clearance between the primary and secondary circuit wiring?

-

Are the bolted electrical connections tight? (Use the calibrated torque-wrench method for verification)

-

Are all the shorting blocks in the correct position, either grounding or open as required?

-

Where is the CT grounding point?

-

Take a photo of the CT grounding point

Isolators

AC Isolators (at inverter)

-

Is an AC isolator ADJACENT (AS3000 1.4.6 definition is "next to or adjoining without obstruction and within arms reach") to the inverter?

-

Take photos of the AC isolator(s) showing make/model, labels, and IP/current/voltage ratings

-

What is the brand / IP rating / current rating / voltage rating of the isolator(s)?

-

Are the isolator(s) the same make/model and rating as specified in the most recent approved drawings?

-

Is the IP/current/voltage rating adequate?

-

Is there a SIGN on the AC isolator saying:<br><br>INVERTER A.C. ISOLATOR<br><br>Refer AS/NZS 4777.1:2016 6.8

-

Is the isolator fixed securely to the wall with at least two screws?

-

Is the isolator appropriately sealed to prevent ingress of vermin/insects/water/dust. i.e.<br>- conduits entries sealed and glued<br>- conduits bottom/side entry with a drip loop if outdoors<br>- pips installed over screw holes

-

Is the isolator capable of being secured (padlocked) in the open position?<br><br>Refer AS/NZS 5033:2014 4.3.5.2(e)

-

Is the inverter immediately adjacent to (i.e. within 3 metres and visible from) the switchboard where it is connected?

DC Isolators (at inverter)

-

Take photos of the DC isolator(s) showing make/model, labels, and IP/current/voltage ratings

-

What is the brand / IP rating / current rating / voltage rating of the isolator?

-

Are the isolator(s) the same make/model and rating as specified in the most recent approved drawings?

-

Is the IP/current/voltage rating adequate?

-

-

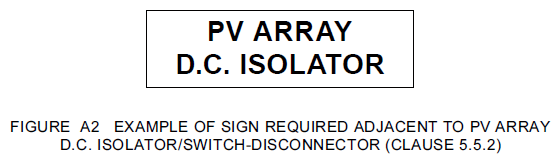

Is there a SIGN on the DC isolator saying:<br><br>'PV ARRAY D.C. ISOLATOR'<br><br>Refer AS/NZS 5033-2014 5.5.2

-

-

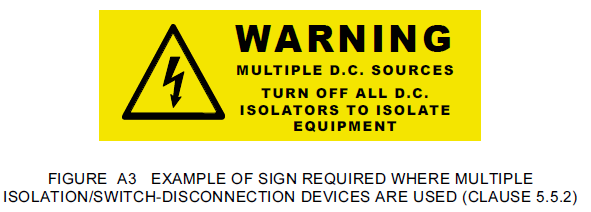

If there are multiple DC isolators feeding one inverter, does the inverter have a sign saying:<br><br>WARNING: MULTIPLE D.C. SOURCES<br>TURN OFF ALL D.C. ISOLATORS TO ISOLATE EQUIPMENT<br><br>Refer AS/NZS 5033-2014 5.5.2

-

Is the isolator fixed securely to the wall with at least two screws?

-

Is the isolator appropriately sealed to prevent ingress of vermin/insects/water/dust. i.e.<br>- conduits entries sealed and glued<br>- conduits bottom/side entry with a drip loop if outdoors<br>- pips installed over screw holes

-

Is the isolator capable of being secured (padlocked) in the open position?<br><br>Refer AS/NZS 5033:2014 4.3.5.2(e)

DC Isolators (rooftop)

-

Is there safe access to the roof?

-

Take photos of the DC isolator(s) showing make/model, labels, and IP/current/voltage ratings

-

What is the brand / IP rating / current rating / voltage rating of the isolator?

-

Is the IP/current/voltage rating adequate?

-

-

Is the isolator marked with an identification name or number according to the PV array wiring diagram?<br><br>Refer AS/NZS 5033-2014 5.5.1

-

Is each isolator mounted adjacent to the panels which it isolates?<br>(i.e. is it clear which panels are connected to each isolator?)

-

Do the labels on the rooftop isolators correspond with the labels on the ground-level isolators?

-

Is the isolator fixed securely to the bracket/strut with at least two screws?

-

Is the isolator appropriately sealed to prevent ingress of vermin/insects/water/dust. i.e.<br>- conduits entries sealed and glued<br>- conduits bottom/side entry with a drip loop if outdoors<br>- pips installed over screw holes

-

Is the isolator capable of being secured (padlocked) in the open position?<br><br>Refer AS/NZS 5033:2014 4.3.5.2(e)

-

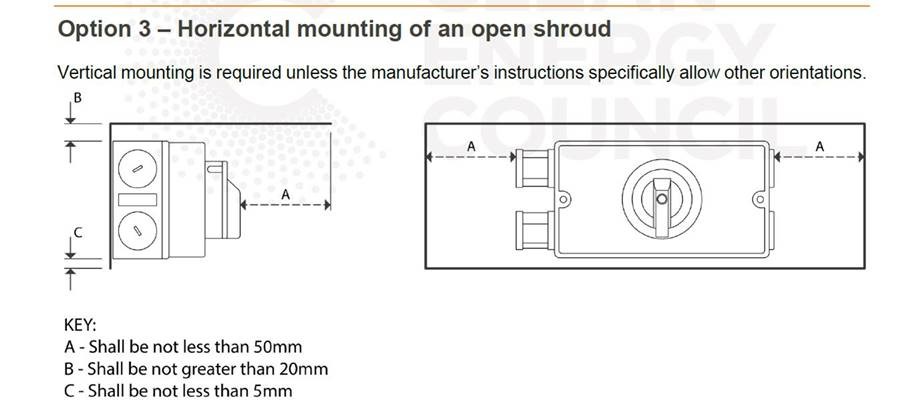

Is the isolator shielded from direct sunlight? (Verdia spec) & is it compliant to the standards, if horizontally mounted must be as per diagram.

-

Does the shield comply with AS5033

General

-

Are there any other issues or defects relating to isolators?<br>(Add note with details)

Cabling - Rooftop

-

Is there safe access to the rooftop?

-

Take photos of cabling, conduits, and trays

DC cables / enclosures

-

Are all DC cables marked "PV1-F"?

-

Are all DC cables segregated from AC cables?

-

If PV array voltage exceeds 600Vdc, is all DC cabling in HEAVY DUTY conduit, or covered cable tray, such that it is not accessible without the use of a tool?<br><br>Refer AS/NZS 5033-2014 3.1

-

Are all DC cables / conduits / trays marked with the word "SOLAR" at minimum 2m intervals?<br><br>Refer AS/NZS 5033-2014 5.3.1

-

-

Are all PV array/string junction boxes labelled "WARNING: HAZARDOUS D.C. VOLTAGE"?<br><br>Text must be black on yellow background.<br><br>Refer AS/NZS 5033-2014 5.3.2

Conduits

-

Are conduits fixed with saddles at maximum 1m intervals, with two fixings per saddle? (Verdia spec)

-

Are all conduit bends made with elbow fittings, or bent smoothly, with no kinks, discolouration, or bubbling?

-

Are all PVC conduits out of direct sunlight? (Verdia spec)

-

Are all conduit entries and joints sealed and glued to prevent vermin/insect/water/dust ingress? (Verdia spec)

Cable trays / support systems

-

Are there any cable trays / ladders present?

-

Do all cable trays have pitched covers, including over bends and tees? (Verdia spec)

-

Are all cable tray bends/tees made using standard catalogue manufactured accessories? (Verdia spec)

-

Are cables fixed to the support system by proprietary nylon ties, straps or saddles, at 1000 mm centres for vertical runs and 2000 mm centres for horizontal runs? (Verdia spec)

-

Are cable trays and ladders mounted at least 50mm clear from roof panels?<br>Cable trays and ladders shall not be directly screwed or fixed to roofing under any circumstances. (Verdia spec)

-

Are cable trays adequately bonded and earthed?

General

-

Do all cables have adequate mechanical protection, UV protection, labelling, and support?

-

Are there any other issues or defects?<br>(Add note with details)

Rooftop General

-

Is there safe access to the rooftop?

-

Take photos of rooftop

Structural

-

Have the PV modules been installed in accordance with the structural certification?

-

Have exclusion zones been maintained as per the structural certification?

-

Have panels been installed at the correct tilt angle, as per the structural certification?

Rooftop safety equipment

-

Is all existing rooftop safety equipment still usable (e.g. anchor points not covered by panels)?

-

Is there safe access to the rooftop for maintenance of the panels, gutters, TV antennas, etc? (can you get everywhere on the roof without having to walk near a live edge or walk on top of panels?)

Earthing

-

Is the array earthed as per manufacturer’s instructions and in such a way to ensure Earth Bond is continuous even if a panel is removed?

-

Are the Earth connections made using acceptable methods i.e. Purpose made fitting, spayed with paint to prevent corrosion?

-

Are DC cables longer than 50m installed in earthed metallic conduit or trunking?<br><br>Refer AS/NZS 5033:2014 3.5.2(d) - shielding as an overvoltage protection measure

PV Modules and Racking

-

Are all the panels in the array the same make/model and rating?

-

Are all panels free from shading?<br>(check that DC isolators / junction boxes don't cause any shading)

-

Are all panels installed at a minimum 10 degree tilt?

-

Have any plastic cable ties been used?

-

Are there any cables touching the roof?

-

Has the racking and/or tilt kit been installed as per the manufacturers specifications? i.e. A minimum of two screws in the tilt kit feet, exclusion zones are clear.

Optimisers (SolarEdge Only)

-

Is this a SolarEdge system (with optimisers)?

-

Are all the optimisers in each string the same make/model and rating?

-

Do the optimiser stickers on the ‘physical layout template’ match the actual installation?

-

Are all string lengths less than 700 metres from the inverter positive terminal to the inverter negative terminal?

Penetrations

-

Have all roof penetrations been made with an approved collar flashing & boot e.g. dectite?<br>NB Grinding a tile and passing the conduit between tiles is not an acceptable method as it is in breach of AS/NZS 3000 (clause 3.9.4.3.1)<br>Conduit passing through a hole in a steel roof and then sealed with silicon is in breach of Standards Australia Handbook 39-1997 (clause 8.6)

-

Inspect roof mounting and roof interfaces for water tightness.

Roof condition

-

From a visual inspection - is the property free of any obvious signs of damage? e.g. cracked tiles

-

From a visual inspection, where required have tiles been ground adequately to sit flat in their original positions?

-

Has all rubbish and debris (e.g. loose screws) been removed?

General

-

Are there any other issues or defects on the rooftop?<br>(Add note with details)

Testing/Commissioning Documentation

-

Is this a Stockland project?

Commissioning supervisor

-

Is the person supervising the testing & commissioning a licensed electrician and CEC-accredited installer?

-

Name

-

Provide a photo of their electrician's licence

-

Provide a photo of their CEC accredited installer card

Equipment

-

Has all test equipment being used been calibrated within the last 12 months?

-

Provide photos of all test equipment, showing the test/calibration stickers/tags

Commissioning tests

-

What is the resistance of the earth electrode? (HV only)

-

What is the resistance of the lightning protection system (if present)?

-

Have phase rotation tests been carried out and are the results satisfactory?

-

Have all tests required to demonstrate the operation of the automatic connection and disconnection of the PV system to and from the electricity network been carried out and are the results satisfactory?

-

Have all tests required to prove that the PV system can export power to the site internal electrical loads been carried out and are the results satisfactory?

Please attach photos/copies of site acceptance test results/reports:

-

SWMS for commissioning tasks

-

Earth electrode measurement (HV only)

-

Insulation resistance of all AC circuits

-

Earth loop impedance of all AC circuits

-

Insulation resistance of all DC circuits

-

Phase rotation tests on inverter AC outputs

-

Open circuit voltages and short circuit currents for all PV strings

-

In-situ IV-curve tests (for string inverter systems only)

-

Thermal images of in-service arrays

-

Tests to demonstrate the operation of the automatic connection and disconnection of the PV system to and from the electricity network

-

Tests to prove that the PV system can export power to the site internal electrical loads

General Issues

-

Any other issues?