Page de titre

-

Inspection and Test Plan for installation of the Cryostat Top Lid preservation system

-

Daher ref.: IO-CTL-2022-017

-

IO ref.: ITER_D_8CMX97

-

Performed on

-

Performed by

-

Concerned Step

Technical check

-

In addition to usual good practices, conformity of activities shall be stated through below technical checks.

-

ITP Step #

-

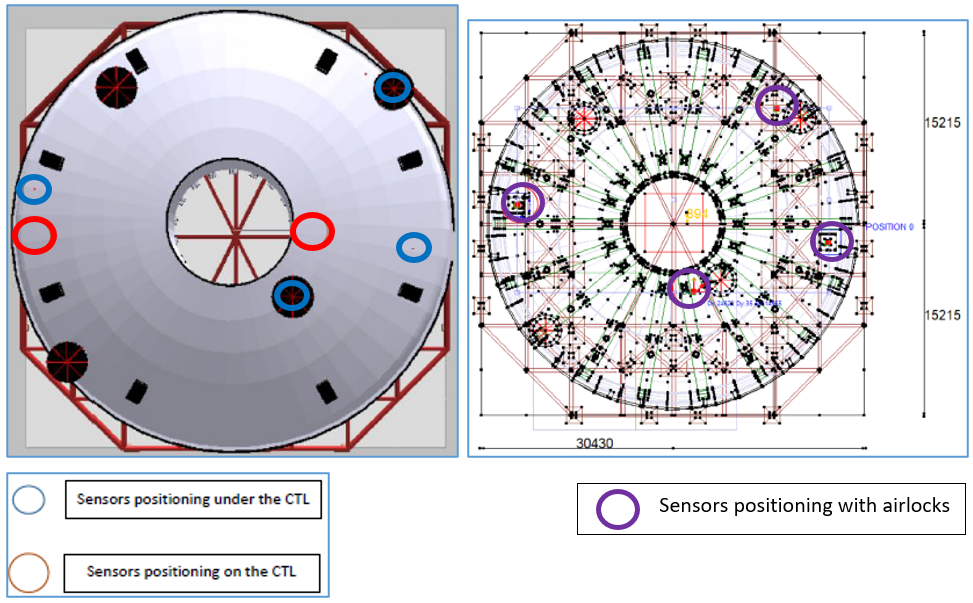

Protocol sensors positioning_8L9X4Q

-

Use of clean shoes or protective shoes to walk on the CTL

-

Inform Daher manager

-

No scratches to CTL

-

Inform Daher manager

-

Sensors positions

-

Position of sensors as per drawings

-

Inform Daher manager

-

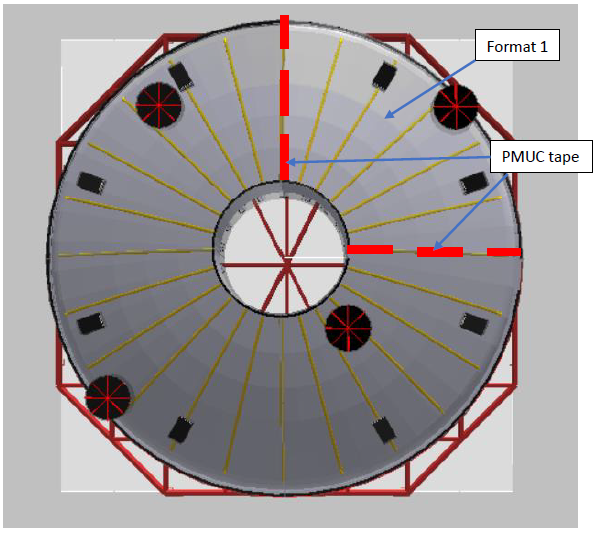

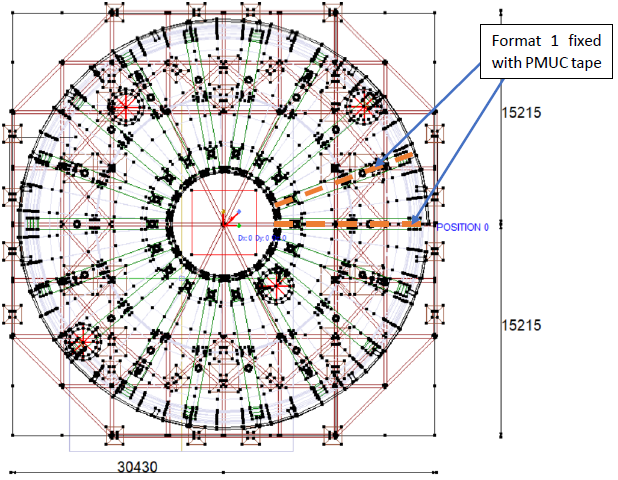

Use of double-sided PMUC or plastic clamps depending on sensors positions

-

Inform Daher manager

-

Control of communication with the system

-

Inform Daher manager

-

Protocol installation of VCI cover_8L9C8M

-

Use of clean shoes or protective shoes to walk on the CTL

-

Inform Daher manager

-

No scratches to CTL

-

Inform Daher manager

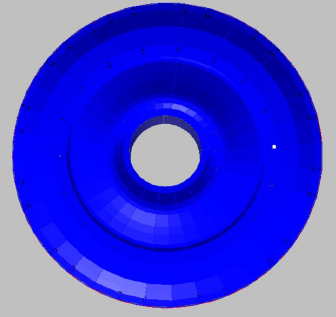

Upper part of the VCI cover

-

Upper part of VCI cover position (#1 as example) with 6 PMUC tapes of 1m lenght

-

Position of the 4 formats of the upper part of VCI cover as per drawings

-

Aspect of the welds

-

Aspect of welds covered by standard adhesive

Lower part of the VCI cover

-

Lower part of VCI cover position (#1 as example) with 10 PMUC tapes of 1m lenght

-

Position of the 18 formats of the lower part of VCI cover as per drawings

-

Aspect of the welds

-

Aspect of welds covered by standard adhesive

-

Protocol installation of shrink film_8L9WQS

-

Use of clean shoes or protective shoes to walk on the CTL

-

Inform Daher manager

-

No scratches to CTL

-

Inform Daher manager

Upper part of the Shrink cover

-

Overview of Upper part of shrink cover (from 15 to 20 strips (~17m long and ~6m wide) to cover the CTL)

-

Shrink films

-

Assembly and interfaces

Lower part of the Shrink cover

-

Overview of Lower part of shrink cover (from 15 to 20 strips (~15m long and ~6m wide) to cover the CTL)

-

Shrink films

-

Assembly and interfaces

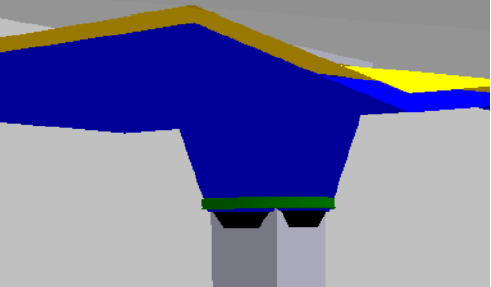

Shrink cover heat-shrink

-

Overview for shrink wrap around the pillars

-

Aspect of shrink films

-

Assembly and interfaces

-

Protocol installation of external cover_8L9NQQ

-

Use of clean shoes or protective shoes to walk on the CTL

-

Inform Daher manager

-

No scratches to CTL

-

Inform Daher manager

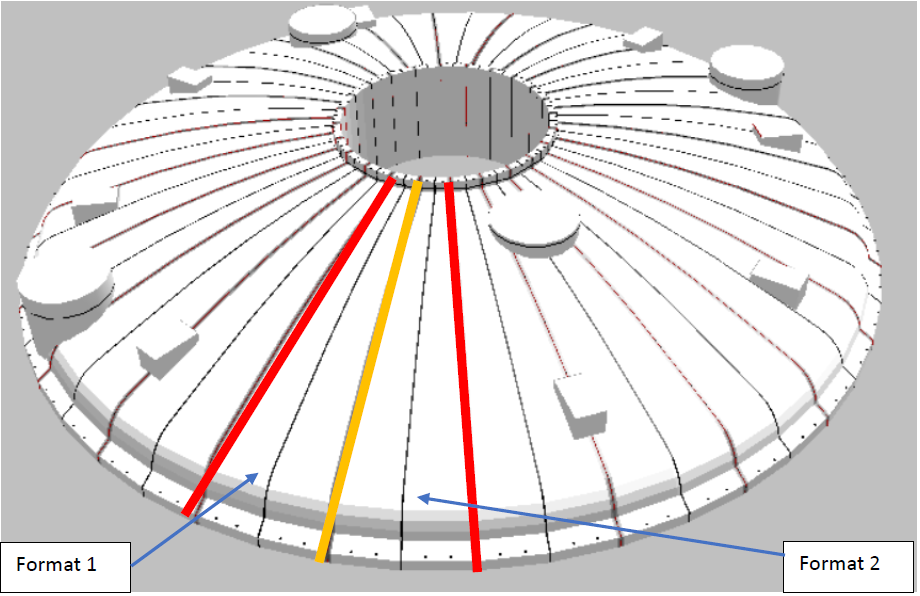

Upper part of the external cover

-

Overview of upper parts format 1 and 2 positions

-

Installation of the 20 upper part formats of the external cover

-

Aspect of formats of the upper part

-

Assembly and fixation between formats of the upper part

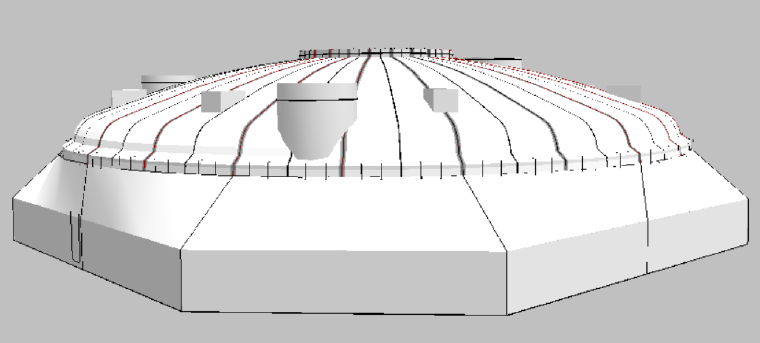

Lower part of the external cover

-

Overview of assembled lower parts

-

Installation of the 24 outter lower part formats of the external cover

-

Installation of the 24 inner lower part formats of the external cover

-

Aspect of formats of the lower part

-

Assembly and fixation between formats of the lower part

After installation of the upper and the lower parts

-

Tension of the external cover

-

Protection of the protruding edges of the frame with protective foam

After transfert of the CTL to the final position

-

Fixation of the lower part of the external cover to the concrete slab

-

Tighten of the cover to avoid the phenomenon of abrasion with the wind

-

ISO view of the lower part of the external cover

-

Protocol installation of airlocks_8L9N7F

-

Use of clean shoes or protective shoes to walk on the CTL

-

Inform Daher manager

-

No scratches to CTL

-

Inform Daher manager

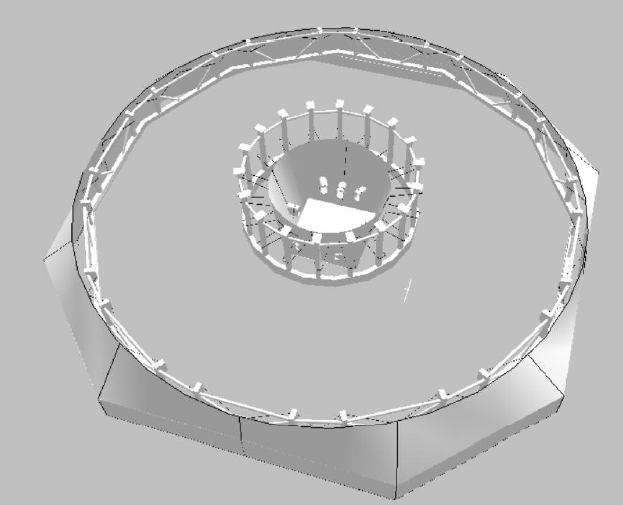

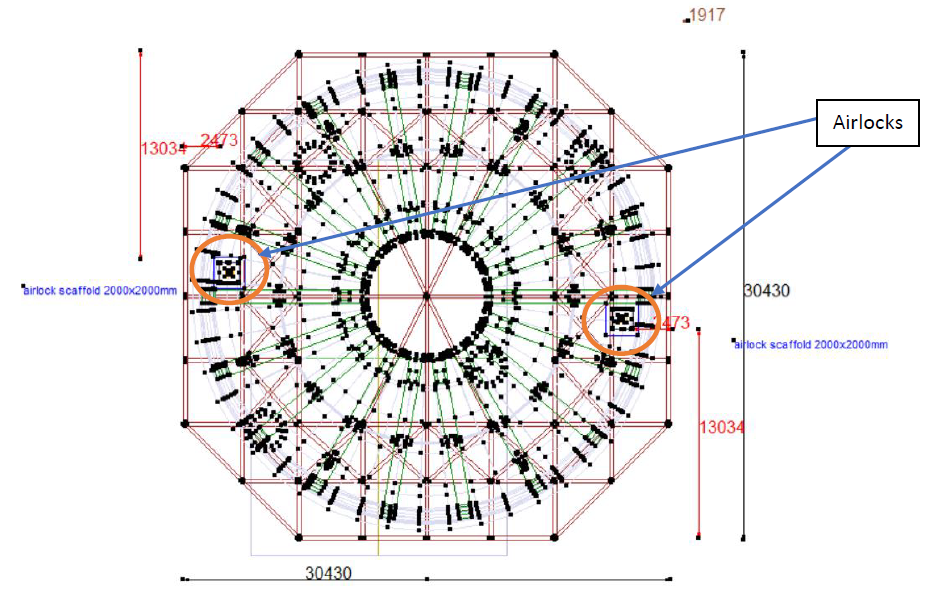

Permanent scaffold of the CTL

-

Overview of permanent scaffold

-

Location of permanent scaffold

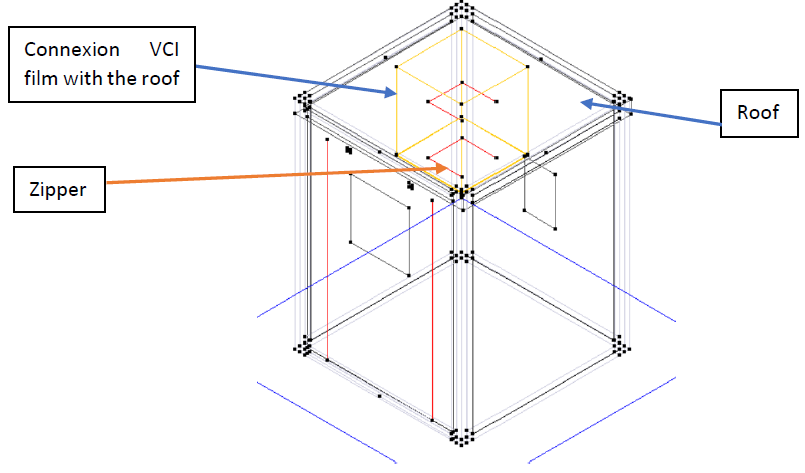

Airlocks assembly

-

ISO view of airlock

Airlock #

-

Panels connections

-

Roof connection with the VCI sleeve and resistant adhesive

-

VCI sleeve connection to the airlock (with an airtight seal)

-

Accessibility of the monitoring system sensor

-

The concerned step in the ITP ref. IO-CTL-2022-017 has been signed by involved parties

MANAGEMENT OF CHANGE

-

This section aims to support involved parties in leading the Management of Change (MoC) in case of any pragmatic gap between the operation described in the Method Statement and the onsite operation. A risk assessment shall be organized by the person responsible for the concerned activity on site with the involved people.

-

Is there any changes to the pre-defined method ?

DEVIATION

-

Shall we deviate from the initial Method Statement ?

-

JUSTIFICATION

-

Shall new calculations be performed ?

-

JUSTIFICATION

RISK ANALYSIS

-

Technical / quality risk

-

DESCRIPTION OF THE RISK / IMPACT

-

MODIFICATIONS / MITIGATION MEASURES

-

IMPACT ON OPERATION ORGANIZATION

-

Human risk

-

DESCRIPTION OF THE RISK / IMPACT

-

MODIFICATIONS / MITIGATION MEASURES

-

IMPACT ON OPERATION ORGANIZATION

-

Environmental risk

-

DESCRIPTION OF THE RISK / IMPACT

-

MODIFICATIONS / MITIGATION MEASURES

-

IMPACT ON OPERATION ORGANIZATION

APPROVAL

-

In case it is mutually agreed with involved parties to deviate from initial Method Statement, the proposed modifications shall be reported and approved by the Daher representative.

NB: the report maybe hand written drawing or scheme with essential details on the verso of this sheet. Pictures of the present hand written MoC can immediately be sent to Daher by SMS, email, etc.

Signature of attendees

-

Name

CLOSURE OF THE TECHNICAL CONTROL

Validation of the OSS report

-

Function

-

Name