Title Page

-

Date and Time of Inspection

-

Client (Contractor) That Flagging Services Are Being Provided To

-

Name of Person Completing Inspection

-

Location

Checklist

GENERAL INFORMATION

-

Project Name

-

Roadway Speed Classification

- Low Speed (35 MPH or less)

- Intermediate Speed (Between 40-50 MPH)

- High Speed (55 MPH or greater)

-

Posted Speed Limit

-

Weather/Light Conditions

- Sunny

- Raining

- Snowing

- Foggy

- Dark

- Cloudy

- Partly cloudy with sun

-

Traffic Conditions

HAZARD ASSESSMENT & DOCUMENTATION

-

Hazard Assessment Completed Prior to Start of Work? (Tailgate Meeting)

-

Did all employees print and sign the Hazard Assessment Document to indicate that they are aware of the hazards & controls associated with the work today?

-

Photo of Hazard Assessment Documentation (JSA, JHA, THA, Toolbox Talk, etc..)

TEMPORARY TRAFFIC CONTROL

ADVANCE WARNING SIGNS

-

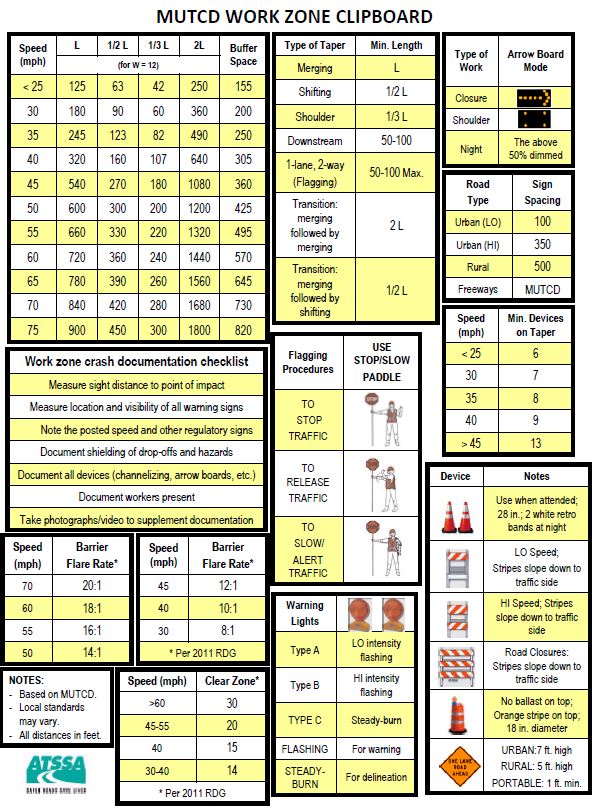

REFERENCE: MUTCD Work Zone Safety Clipboard)

-

Is the proper signage erected to warn drivers of what to expect? (Flagger ahead, be prepared to stop, one lane ahead, etc...)

-

Is there an appropriate number of signs placed in accordance with the standard?

-

Are all signs in good condition (clean, legible, and reflective)?

-

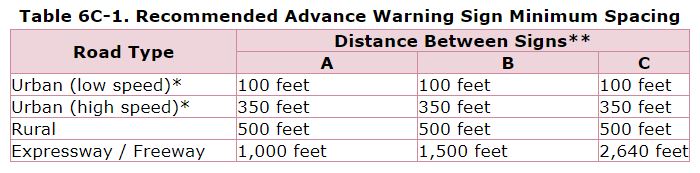

Do all sign placements (height, visibility, and spacing) conform to standard regulation? (Reference Below or us MUTCD Clipboard)

-

REFERENCE: Advanced Warning Sign Spacing

-

REFERENCE: MUTCD Work Zone Clipboard

CHANNELIZING DEVICES

-

Are all barricades in good condition?

-

Are all drums in good condition?

-

Are all safety cones in good condition?

-

REFERENCE: Safety cones in good condition

-

Are candy cane devices being used through the active work zone to heighten driver awareness boundaries?

-

REFERENCE: Cone Bars (Candy Canes)

-

Are all vertical panels in good condition?

-

Are all warning lights in good condition?

-

Do all channelizing devices have appropriate battery mount?

-

Do all channelizing devices have appropriate appropriate ballasting?

-

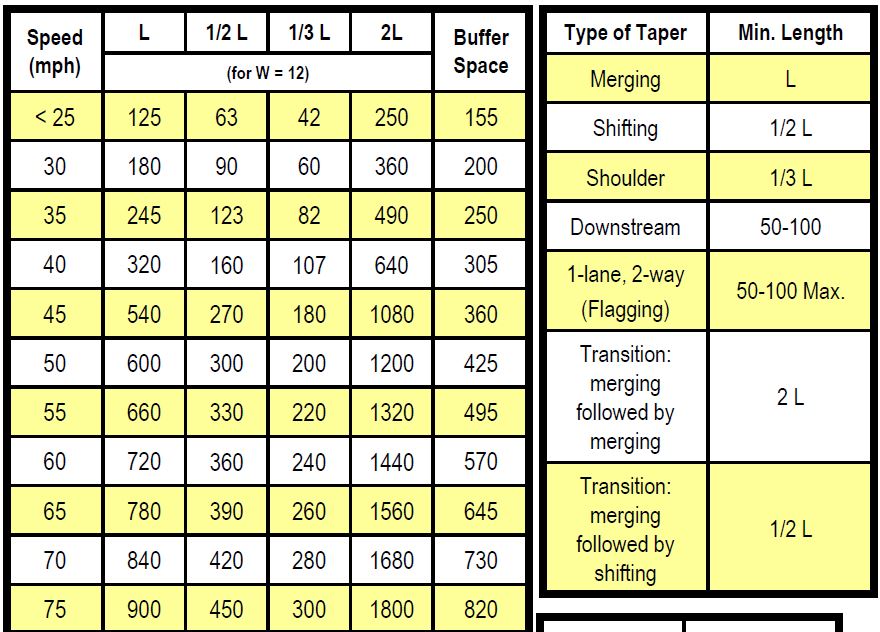

Do all channelizing devices have adequate spacing?

-

Do all channelizing devices have adequate taper length?

-

MUTCD Reference Table

-

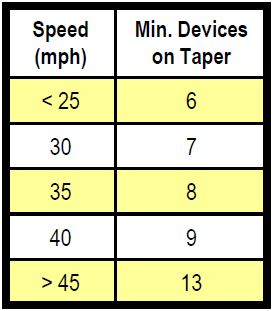

Is the number of devices placed appropriately?

-

REFERENCE: MUTCD Minimum Devices on Taper

FLAGGING

-

Are all flaggers trained/certified?

-

Are flaggers alert and fit for duty?

-

Are flagger's cell phones put away and not in use during flagging operations?

-

Is there an escape route established for flaggers?

-

Are flaggers standing in pinch or crush points (Between traffic & other objects)

-

Are the flagger stations preceded by advance warning signs?

-

Are flaggers clearly visible to approaching traffic?

-

Are flaggers facing oncoming traffic at all times?

-

Are the flagger stations illuminated? (Night time)

-

Are flaggers using proper signaling devices? (Stop/Slow Paddles)

-

Are there portable radios issued and being used by flaggers to communicate?

-

Do flaggers have a way to communicate with the contractor on site?

-

Are flaggers wearing high visibility class 3 vests?

-

REFERENCE: Class 3 Vest (Sleeves with reflective)

-

Are flaggers wearing additional required PPE? (Hard Hat, Safety Glasses, Safety Toe Boots)

ROADSIDE SAFETY

-

Are all barriers in good condition?

-

Are all barrier delineation lights in good condition?

-

Are all barrier delineation reflectors in good condition?

-

Is there an adequate drop-off delineation?

-

Is there an adequate clear zone?

COMPLETION

-

Coaching Opportunities (Issues & areas for improvement)

-

Did you have a (Coaching) conversation with employees to resolve outstanding issues?

-

Were all issues resolved?

-

Name and Signature of Supervisor or Safety Rep. Completing Audit

-

Name and Signature of Crew Leader

PHOTOS

-

Photo 1

-

Photo 2

-

Photo 3

-

Additional Photo

-

Additional Photo