Information

-

This document is here to help and assist you in the Risk Assessment and to support the customer in delivering a safe and good service.

Please take a few minutes to complete all elements within this assessment as much as possible, once complete ensure that all signatures are completed.

Ensure that the customer receives a copy of this Risk Assessment.

Thank you for your co-operation. -

Machine Model

-

Date of work:

-

Machine Serial Number:

-

Customer Name/Dealer/location:

Hazard Identification

-

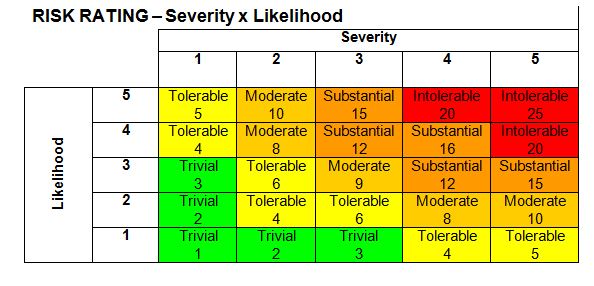

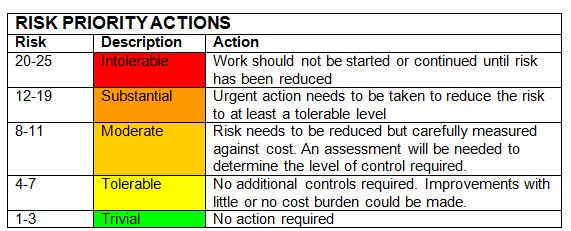

Please identify all hazards and rate using the 5x5 matrix. Please multiply both figures to gain the overall Risk Rating Priority. (Severity x Probability)

-

Identify the hazard.

Hazard identification

-

Identify Hazards

- Access and Egress

- Plant/Vehicle Movements

- Confined Space Entry

- Other workers in Vicinity

- Noise

- Vibration

- COSHH Substances

- Poor Weather conditions

- Poor Lighting

- Manual Handling - Lifting

- Air Born Particles

- Working at Height

- Unprotected Edges

- Fragile Surfaces

- Falling Objects

- Overhead Obstructions

- Mobile Cranes - Slinging

- Entanglement / Crushing

- Fire

- Blasting/ Explosion

- Hot Work / Weld Grind

- Climbing

- LPG / Oxy / Propane

- Combustible Materials

- Repetition

- Oxygen Enrichment/ Depletion

- Electrical

- Tracking Machine

- Pneumatic/Hydraulic

- Pressurised Systems

- Stored energy

- Slips, Trips and Falls

- Flying Particles

- Contact with Sharp Edges

- Vehicles and material movement

- Route of travel with part or machine

- Positioning and terrain on a 3rd party site and/or a Terex location

- Traffic control

- Other

-

Please state what the hazard is

-

Who might be harmed?

-

Probability Rating Task 1

-

Severity Rating Task 1

-

Please calculate your result by multiplying the Probability rating x Severity rating

-

Select Result

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

-

What countermeasures will be used?

Life Saving Behaviors

-

If there are any interlocks or guarding on the machine, can I confirm they work correctly?

-

Does the job involve lifting?

-

Can I follow my my lifting plan: No Plan, No Lift?

-

Contact manager to arrange for lifting plan to be emailed, or discuss the next steps to take.

-

Enter the Lifting plan number.

-

Can I stand clear of the danger Zone from unstable / suspended loads?

-

Contact site manger, and Service manager to plan a safer method of working

-

Is there a risk on site of anything falling and causing injury to others?

-

Please review your work area and remove those items that could fall on others.

-

Can I position myself in a safe zone in relation to moving equipment?

-

Contact the site manager to arrange a safer way of working.

-

Do I need to work at height?

-

Can i minimize the risk of falling?

-

Please indicate methods used to minimize the risk of falling at height

-

Please contact your manager to discuss the next step forward

-

Please contact your manager to discuss alternative plans.

-

Are there any confined spaces that I might enter and would need authorisation through a permit?

-

List the person responsible for coordinating a rescue plan, and state the rescue equipment to be used.

-

Have I PAUSED and asked for help from my supervisor if a condition is not safe or I cannot take these actions.

Method Statement and Risk Assessment

-

PLEASE ENSURE THAT ALL CONTENTS OF THIS RISK ASSESSMENT IS SHARED WITH ALL TM'S INVOLVED IN THIS ACTIVITY. ENSURE THERE IS FULL UNDERSTANDING AND AGREEMENT BEFORE COMMENCING JOB.

-

What type of work will be carried out?

- Commissioning

- Set Up

- Fault Finding

- Machine service

- Other

- NPPD Work

-

Method Statement : Please enter a step by step procedure of the work that will be carried out.

Method Statement

-

Step:

-

Do you have the required permit and is this valid for your task?

-

Please select the valid permits

- Hot Work Permit

- Confined Spaces Permit

- Working at Height Permit

- Electrical Permit

- Site Authorisation Sheet

-

Have you reported in?

-

Have you completed a site induction?

-

Are you aware of the customers site safety rule, emergency procedures and rescue plans?

-

Please make sure that people within the site know you are working in the area, and ensure you have a point of contact within the job site before commencing job.

-

Please select the PPE required for this job

- Safety Footwear

- Overalls

- Gloves

- Safety Helmet

- Safety Glasses

- Ear Protection

- Fall Arrest Harness and Lanyard

- High Vis Clothing

- Waterproofs

- Visor

- Goggles

- Dust Mask

-

Do I have the correct tools and equipment? Are those tools and equipment in good working order? Do all the tools and equipment have the correct guarding in place and functional?

-

Are the tools to be used in a good and safe condition?

-

Please remove tools from service and inform manager of the defaults.

-

Please take photos of any faulty equipment.

-

Please indicate what tools/equipment are required to complete the work safely? Or what item of tooling is not fit for purpose. Please inform your manager.

-

Please take photos of any faulty equipment

-

If using hazardous substances, are you aware of all the relevant safety data sheets and hazardous information?

-

Please contact your manager and request the COSHH document

-

Can I spill or pollute something?

-

Ensure substances are secure and material is in the correct container, to prevent spills or pollute the environment you are working in. Understand the sites spills process and how to clean up, ensure spill kits are close by.

-

WARNING - If you are not able to ensure your own safety to any of the above questions, JOB PAUSE, ASSESS and RESOLVE the issue with the customer. If this is not possible then escalate this to your relevant supervisor/manager.

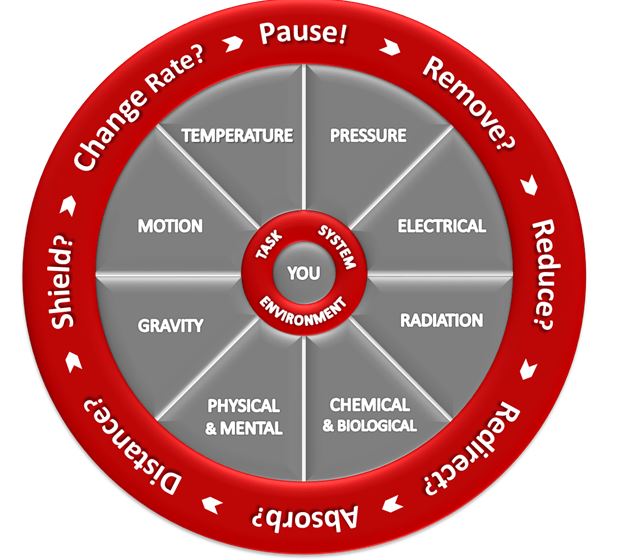

Control of Hazardous Energies

-

Are you working with hazardous energies?

-

Hazardous Energies can be in many forms. Please look at the diagram and select as appropriate

-

What type of energy will you be working with?

- Gravity

- Pressure

- Electrical

- Motion

- Temperature

- Biological and Chemical

-

What could happen if you did not control the energy?

-

How will you control the energy?

-

How will you verify the control?

-

Please identify the specific steps for re-energizing.

-

What are the specific triggers to Pause this Job and re-evaluate?

Confirmation

-

Are you happy that you can process with this job in a safe manner?

-

Please contact your manager with any concerns before beginning the job.

-

Acknowledgement of Receipt: I hereby declare I understand the nature of the work to be carrede out, the hazards involved and the precautions required. Only plant an equipment specified in this document will be worked on and no attempt will be made by me or anyone under my control to use or work on any other plant/equipment. All personnel involved in the work will be competent to undertake the task delegated to them and all plant, machinery and appliances will be in worth condition with current relevant certificates . All site notices, rules and instructions will be observed in full.

-

Service Engineer Signature

-

Team Member/ other workers Name and Signature

Team member/ Other Workers

-

Signature:

Near Misses

-

Accidents are sadly a feature of everyday life; they are not planned and certainly not wanted.

The company is committed to best practice in HSE performance to meet its responsibilities for the health, safety and wellbeing of its team members, visitors and others who may be affected by its work activities.

DEFINITIONS

Hazard – Something with the potential to cause harm, including ill health, injury, loss of product and/or damage to plant and property.

A Near Miss - An undesired event in which there was no injury; however, under slightly different circumstances could have resulted in personal harm – Terex

An Accident - an undesired event which results in:

Harm to people (fatality, occupational injury or occupational illness) and/or

Damage to vehicles, assets, facilities and/or

Damage to the environment -

Please state any accidents, near misses or Hazards experienced while completing this job.