Title Page

-

Site conducted

-

-

Job No.

-

Picture of Customers Machine

-

Machine Make

-

machine Model

-

Machine Serial number

-

Contact Name

-

Conducted on

-

Prepared by

Permit to Work Finish

-

Have you handed the Work Permit Back

-

Has KNDS Yellow Copy been removed from the machine so they can resume work ?

-

Have you Notified Carl Smith KNDS Why the Machine cannot be Run ?

-

IS KNDS Yellow Work permit still on machine to show machine is not workable ?

-

Why ?

Permit to work

-

Have you got the Permit to work in your hand before you start - NO WORK TO BE CARRIED OUT WITHOUT A WORKING PERMIT

-

Have KNDS put there yellow Copy on Display on the machine ?

Fluids and Air

Hydraulics

-

Remove old oil if possible & refill to correct level

-

Change or clean filters

-

Check Pressure Gauges & Settings

-

Leaks and hose damage

Lubrication System

-

Replace oil clean filter and tank

-

check pressure gauges and settings

-

Check operations of all Metering units

-

Grease all points S

Spindle Cooler

-

Replace oil and clean filter

Gearboxes

-

Change oil

-

Check for leaks and Noise

Coolant System C

-

Clean Filters

-

Check for leaks over whole system

-

Check Pump for Noise and heat

-

Clean Tank and refill

Pneumatic System

-

Clean Air & oil units , replace filters

-

Check and Adjust air & oil pressure

-

Check over all the machine for Air leaks , tighten up air gun on machine.

Mechanical

Spindle Chucks and Drawbars

-

Check the condition

-

Check the Tool Clamp and unclamp Stroke

-

Check the Y/Z brake operation

-

Check and Record the Spindle Preload

-

Check the Drive belts for tension , record numbers for details

-

Check the Spindle for bearing Noise

-

Check Spindle nose for scoring and Drive dog damage

Automated Tool Changer

-

Check ATC Function ability on all tools

-

Check Finger and Pockets for wear

-

Check the Magazine ATC Function

Automatic Pallet Changer

-

Check the APC for correct operation

-

Check the clamping face for Wear

-

Check all hydraulic Valves and Hoses

Internal Machine

Turrret

-

Record the turret radial alignment

-

Record the turret squareness in Z plane

-

Record the turret centerline, adjust if necessary

-

Record turret index Pocket to PC

-

Change the turret oil (if applicable)

-

Check rotary tool drive belts.

Tailstock

-

Check operation

-

Check the tailstock Pressure

-

Check the cone of the tailstock for run out and wear

Axis

-

Check the condition of all sides & remove all swarf ect.

-

Check condition of slide away guards and wipers

-

C axis (if applicable) - check brake faces

-

Check for noise from ball screws, bearings, on X,Y & Z axis

Record Gridshift Parameters

-

X axis Paramater reading

-

Y axis Paramater reading

-

Z axis Paramater reading

-

B axis Paramater reading

Backlash Paramater reading

-

X axis Paramater reading

-

Y axis Parameter reading

-

Z axis Paramater reading

-

B axis Paramater reading

Tool Eye Probe

-

If Manual Tool Presetter is Installed check for damage and recalibrate probe

External Machine Parts

Swarfe Conveyor

-

Check operation and condition

-

Check Sprockets and chains

Guarding

-

Check for Functionabilty on rollers

-

Check for 100% vision in window

-

Check Machine Light works

-

Guard interlock is it working correctly

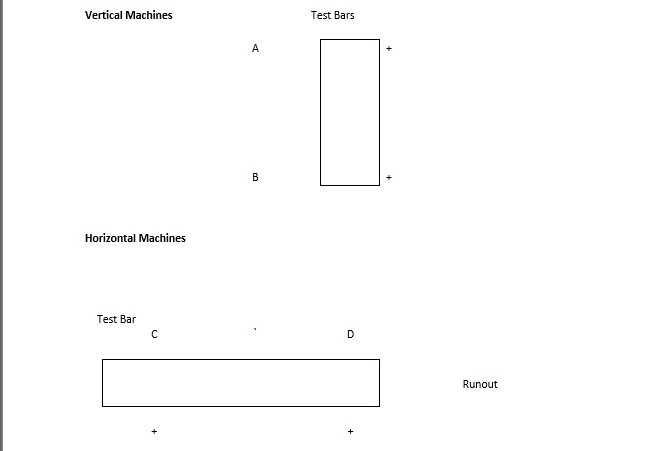

Alignments

-

-

Side reading A

-

Front reading A

-

Side reading B

-

Front reading B

-

Side reading C

-

Front reading C

-

Side reading D

-

Front reading D

-

Notes

Electrical

-

Check Mains Voltage Record readings L1 L2 L3 between Legs

-

Check 24v record control voltage

-

Check Memory Back up Batteries and Record the Battery Details

-

Batteries Changed Over 12 month What are the Battery Details and Voltage .

-

Check Work Lamps

-

Check for tightness of magnetic switches, replays, thermal relays, fuses & circuit breakers

-

Check push buttons & switches

-

Check function of each emergency stop

-

Check function of each door interlocks

-

Check and adjust spindle load meter

-

Check for dirt & oil in electrical cabinets

-

Check & clean electrical cabinet filter & fans

-

Check external cables for damage

-

Check brushes (yellow cap motors only)

Final Page

-

Notes

-

From this Service what needs following up ?

-

Have you informed and demonstrated to the customer

-

Have you left the workplace Tidy ?

-

Video of Machine in automatic / Cycling - Proof of machine in working order after service.

-

Time and Date complete

-

Carl Smith only to sign or Designated Deputy on the work Permit

-

TMS engineer Signature