Title Page

-

Site conducted

-

-

Job No.

-

Picture of Customers Machine

-

Machine Make

-

machine Model

-

Machine Serial number

-

Contact Name

-

Conducted on

-

Prepared by

Fluids and Air

Lubrication System

-

Check oil clean filter and tank

-

check pressure gauges and settings

-

Check operations of all Metering units Making sure oil is getting to slides

-

Grease all points Where possible

Gearboxes Remove Lid / Send Camera in

-

Check oil Bath

-

Check All gears are getting Lube

-

Check for leaks over whole system

-

Check Gears For Damage

-

Check and record amount hand wheel moves before all gears are engaged

Mechanical

-

Check all hydraulic Valves and Hoses

Internal Machine

Tool Post

-

Record the Toolpost squareness in Z plane

-

Record the Tool centerline, adjust if necessary

Tailstock

-

Check operation

-

Check the tailstock Pressure

-

Check the cone of the tailstock for run out and wear

Axis

-

Check the condition of all sides & remove all swarf ect.

-

Check condition of slide away guards and wipers

-

Check for End float, on X,Y & Z axis

-

Record X axis Backlash reading

-

Record Y axis Backlash reading

-

Record Z axis Backlash reading

External Machine Parts

Guarding

-

Check for Functionabilty on rollers

-

Check for 100% vision in window

-

Check Machine Light works

-

Guard interlock is it working correctly

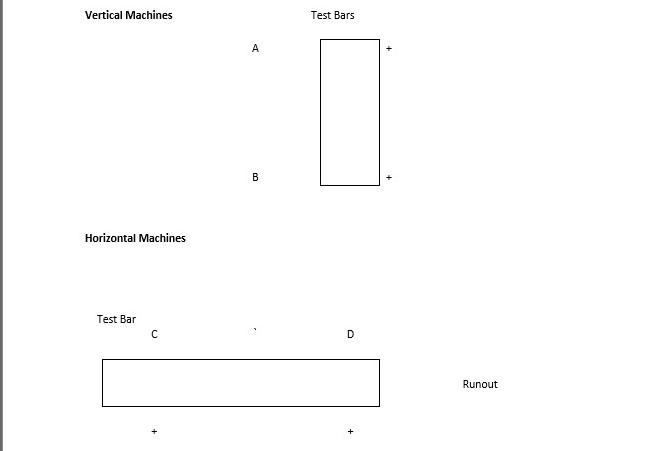

Alignments

-

-

Side reading A

-

Front reading A

-

Side reading B

-

Front reading B

-

Side reading C

-

Front reading C

-

Side reading D

-

Front reading D

-

Notes

Electrical

-

Check Work Lamps

-

Check push buttons & switches

-

Check function of each emergency stop

-

Check function of each door interlocks

-

Record spindle load meter

Final Page

-

Notes

-

Has the values for backlash Changed from the last Inspection ?

-

Video of Machine in automatic / Cycling - Proof of machine in working order after service.

-

Time and Date complete

-

Customer Signature

-

TMS engineer Signature