Title Page

-

Site conducted

-

Conducted on

-

Prepared by

-

Project Name:

-

Please Specify:

Pre-Trenching Checklist

-

Trench Location? i.e. R54 LV Access road crossing

-

Has consultation about the intent to trench been communicated between the relevant people? i.e principal contractor, supervisors, work crew members. If unsure contact your supervisor.

-

No trenching to occur until all relevant people have been notified.

-

Has the area been cleared of all underground services?

-

Ensure all underground services are positively identified prior to moving forward.

-

Has the trench alignment been clearly identified?

-

Set out trenching to allow for correct alignment, if required contact Supervisor or Survey.

-

Is a JSA or Risk Assessment required?

-

Please complete JSA or Risk Assessment prior to trenching activities.

-

Have all required materials been delivered and ready for placement? i.e. Bedding sand, backfill material, pipes etc.

-

Have all materials pre-ordered and ready for installation/placement if possible.

-

Has foundation testing been pre-booked with Geo-technical tester?

-

Ensure tester is available to conduct foundation testing.

-

Ensure correct testing is completed. Refer to ITP, IFC's and technical specifications if required.

-

Has a foundation inspection been pre-booked?

-

Ensure foundation booking has been made prior to trenching activities.

-

Have ITP ready for sign-off at foundation inspection.

Excavation Activities

-

Is the machine suitable for the task? - Consider depth, width of trench - material type - proximity to other equipment.

-

Is suitable edge protection available? i.e. fencing, barricading, bunding etc.

-

Have the ground conditions been inspected?

-

Is shoring/battering or benching required? Inspect trench condition, depth and width to determine requirements.

-

Persons conducting a business or undertaking (PCBUs) who propose to excavate a trench at least 1.5 metres deep must ensure, so far as is reasonably practicable, that the work area is secured from unauthorised entry including inadvertent entry. Additionally, the PCBU must minimise the risk to any person arising from the collapse of the trench by ensuring that all sides of the trench are adequately supported

-

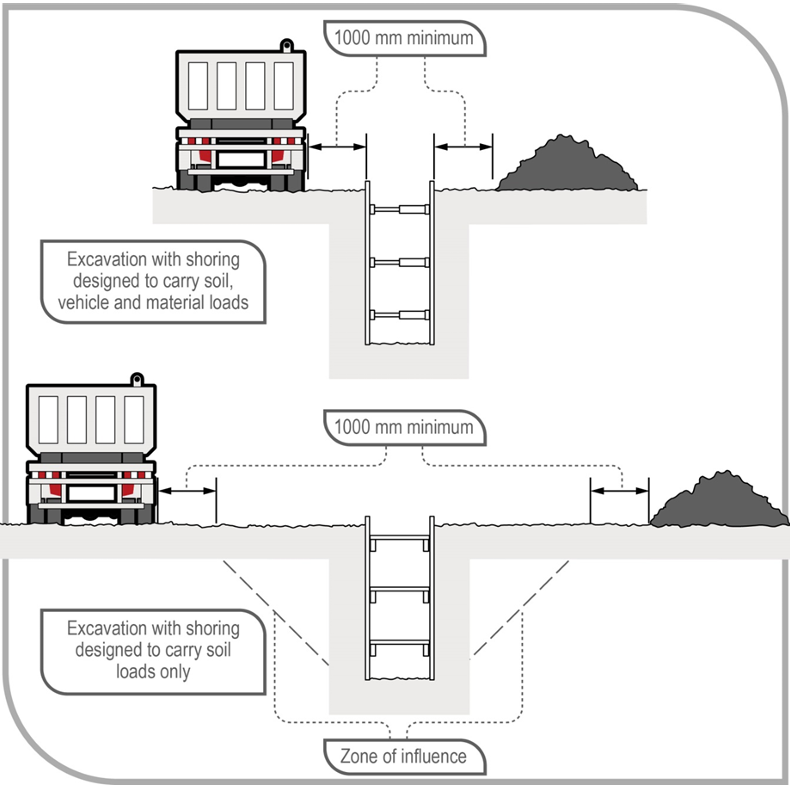

Has the excavated material been placed outside of 'Zone of Influence'?

-

Please see example of 'Zone of Influence'. Any material will add a load to the area where it is placed. It is important materials are not placed or stacked near the edge of an excavation as this would put persons working in the excavation at risk, including by potentially causing a collapse of the side of the excavation.

-

Under no circumstances should anyone enter the trench if material/loads are inside the 'zone of influence'.

-

Is the floor of the trench in level, clean condition? Ensure that all loose material is removed from excavation.

-

Has suitable access been given for entry/exit points?

-

Has Survey been completed on excavated trench? Ensure trench floor is surveyed on both edges, also survey centerline on trenches greater than 1.8m wide.

Installation of bedding and backfill materials

-

Ensure that any trench inspections and testing requirements have been completed prior to placing ANY material into trench.

-

Has the bedding sand been placed evenly to the required thickness? see IFC drawings and ITP's for details.

-

Has testing been undertaken on bedding sand? Refer to IFC's and ITP's for minimum requirements. Check layer thickness, compaction requirements and moisture specs.

-

Have components been placed into trench evenly? Check to ensure it is centrally located with minimum stand-off distances from side walls etc. Refer to IFC, ITP's for details.

-

Has the haunching material been placed and compacted/wet into required layer thickness? Refer to IFC's, ITP's for details.

-

Has testing been carried out on Haunch material? Refer to IFC's and ITP's for minimum requirements. Check layer thickness, compaction requirements and moisture specs.

-

Has Survey been completed on top of pipe? Survey top of pipe centerline.

-

Has backfill material been identified for all layers above haunch? Refer to IFC's and ITP's for details.

-

Is buried service marker tape installed?

-

Have all changes in backfill material type been surveyed? i.e. Bedding sand to select fill transition. This ensures conformance requirements are met.

-

Have testing requirements for backfill been identified? Refer to IFC's and ITP's for details. Check layer thickness, compaction requirements and moisture specs.

-

Has backfill been completed and area made clean and tidy?

-

Has ITP been reviewed and all available line items been signed off?

Checklist Sign-off

-

Notes/Comments:

-

Date and Time:

-

Crew Member Sign-off - I have reviewed and completed all sections above.

-

Supervisor Sign-off