Title Page

-

-

Conducted on

-

Inspector

HARNESS INSPECTION

-

Provide notes for any "Fail" or "At Risk" answer. Also provide notes for any item which should be monitored.

HARNESS REFERENCE INFO

-

Identification Number (i.e. serial, part, etc.)

-

Date / Year of First Use

-

Date of Manufacture

LABELS AND MARKINGS (See 1)

-

Labels are intact and legible

-

Appropriate ANSI / OSHA Markings

-

Impact Indicator (Signs of Deployment)

HARDWARE (BUCKLES & D-RINGS)

-

Shoulder Adjustment Buckles (See 2)

-

Leg & Waist Buckles / Other Hardware (See 3)

-

D-Rings / Attachment Points (See 4)

-

Corrosion / Pitting / Cracks / Nicks

MATERIAL (WEBBING)

-

Straps: Shoulder / Chest / Leg / Back

-

Stitching: Broken / Loose / Frayed / Missing

-

Excessive Wear

-

Cuts / Burns / Holes

-

Chemical Exposure

-

Heat / UV Damage

LANYARD INSPECTION

-

Provide notes for any "Fail" or "At Risk" answer. Also provide notes for any item which should be monitored.

LANYARD REFERENCE INFO

-

Identification Number (i.e. serial, part, etc.)

-

Date / Year of First Use

-

Date of Manufacture

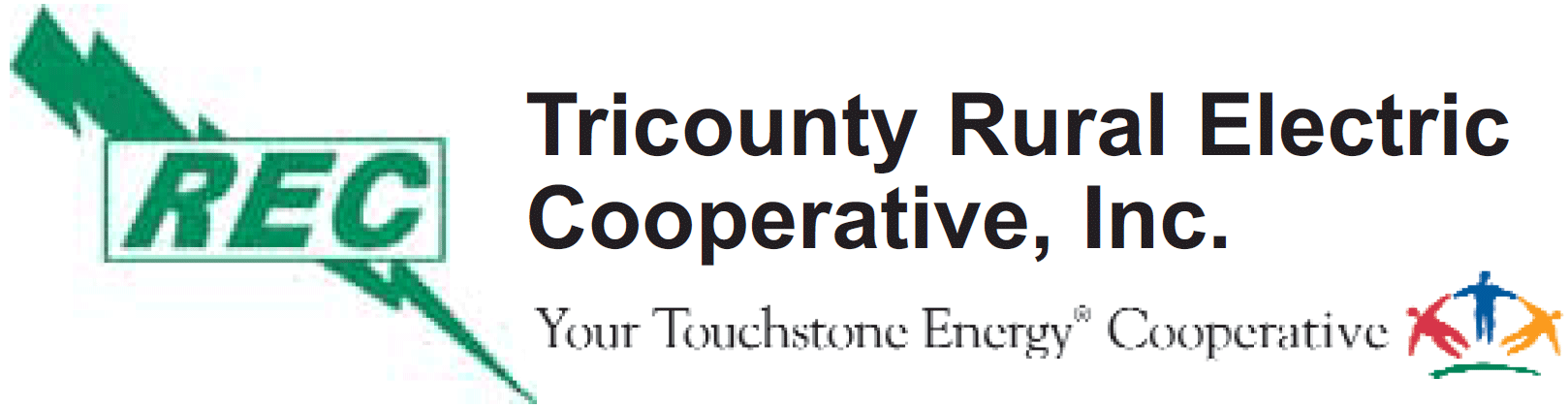

LABELS AND MARKINGS (See 1)

-

Labels are intact and legible

-

Appropriate ANSI / OSHA Markings

-

No Signs of Deployment

CONNECTORS (See 2)

-

Connector (Self-Closing & Locking)

-

Hook Gate / Mechanisms Operate Freely

-

Corrosion / Pitting / Cracks / Nicks

-

Compatible Harness / Lanyard Connection

MATERIAL (WEBBING) - See 3

-

Stitching: Broken / Loose / Frayed / Missing

-

Termination (Stitch / Splice)

-

Lanyard Webbing Length

-

Excessive Wear or Damage

-

Cuts / Burns / Holes

SHOCK PACK (If Present) - See 4

-

Cover / Shrink Tube (DO NOT REMOVE)

-

Damage / Fraying / Broken Stitching

-

No Signs of Deployment

WOOD POLE FALL RESTRICT DEVICE & SECONDARY LANYARD

-

Provide notes for any "Fail" or "At Risk" answer. Also provide notes for any item which should be monitored.

WPFRD REFERENCE INFO

-

Identification Number (i.e. serial, part, etc.)

-

Date / Year of First Use

-

Date of Manufacture

SECONDARY LANYARD REFERENCE INFO

-

Identification Number (i.e. serial, part, etc.)

-

Date / Year of First Use

-

Date of Manufacture

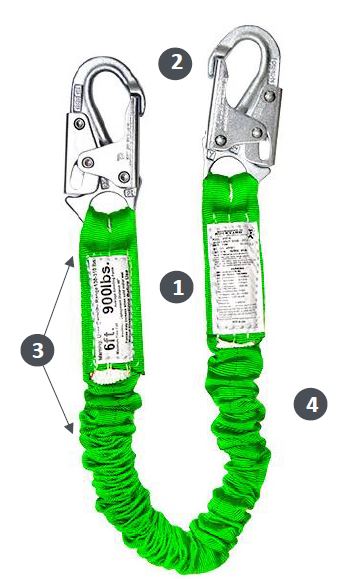

CONNECTORS

-

Locking Carabiners / Snaphooks (See 1)

-

Latch Movement / Spring Tension

-

Moving Pieces Operate Freely

-

Web Grabs / Cam Buckles (See 2)

-

Burns / Cracks / Deformation / Corrosion

HARDWARE

-

Rivets not Loose or Bent

-

Bolts not Loose or Bent

-

D-Rings / Pass-Thru Devices (See 3)

-

General Cracks / Deformation / Corrosion

MATERIAL (WEBBING & ROPE)

-

Outer Strap / Rope (See 4)

-

Inner Strap / Rope (See 5)

-

Fold-Over / Splices (See 6)

-

Excessive Wear (Indicator)

-

Abrasions / Cuts / Frays

STITCHING (See 7)

-

Stitching: Broken / Loose / Frayed / Missing

BODY BELT & CLIMBERS

-

Provide notes for any "Fail" or "At Risk" answer. Also provide notes for any item which should be monitored.

BODY BELT REFERENCE INFO

-

Identification Number (i.e. serial, part, etc.)

-

Date / Year of First Use

-

Date of Manufacture

CLIMBERS REFERENCE INFO

-

Identification Number (i.e. serial, part, etc.)

-

Date / Year of First Use

-

Date of Manufacture

CLIMBING BELT (MATERIAL)

-

Abrasion / Fraying / Cracking / Cuts / Wear

-

Electrical Arc-Flash / Chemical Exposure

-

Stitching: Loose / Cut / Broken / Frayed (See 1)

-

Holes on Straps: Not Elongated or Modified (See 2)

-

Tool Loops / Rings Securely Attached (See 3)

HARDWARE (BELT AND CLIMBERS)

-

Cracks / Nicks / Distorted / Bent

-

Electrical Arc-Flash Burns / Rust / Corrosion

-

Rivets / Attachment Points (See 4)

-

General Cracks / Deformation / Corrosion

CLIMBERS (STRAPS AND PADS)

-

Abrasion / Fraying / Cracking / Cuts / Wear

-

Electrical Arc-Flash / Chemical Exposure

-

Stitching: Loose / Cut / Broken / Frayed (See 5)

-

Holes on Straps: Not Elongated or Modified

CLIMBERS (SHANKS / GAFFS)

-

Gaffs Properly Sharpened (Gaff Gauge Test)

-

Effective Gaff Guards in Place

-

Cracks / Deformed / Marks / Gouges

-

Stirrup: Wear / Proper Adjustment

COMPLETION

INSPECTOR NAME AND SIGNATURE

-

Add signature