Title Page

-

Document No.

-

Site

-

What storage areas have been audited for example Bay 7 Row 1 - 12

-

Conducted on

-

Prepared by

-

Other participants

General

-

Are the walkways marked and free of debris (for example tags, timber, banding wire)?

-

Is signage available at each access point to the Wide Coil Storage Area stating "No Unauthorised Access"?

-

Example of signange to be used

-

Is the whole of the storage area used for Wide Coil fenced to prevent unathorised access?

-

Example of coil bay fenced

-

Is the Storage system of adequate strength to support weight of the coils and cope with the forces that may act on them during stacking process?

Stability of Stock

-

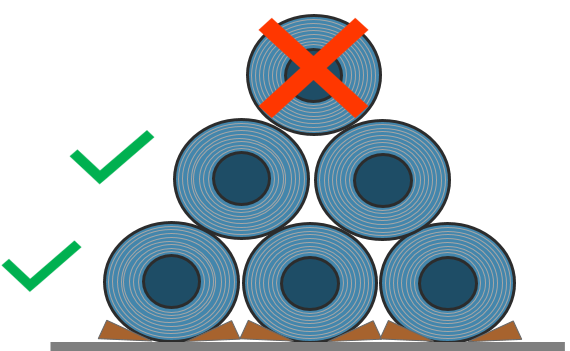

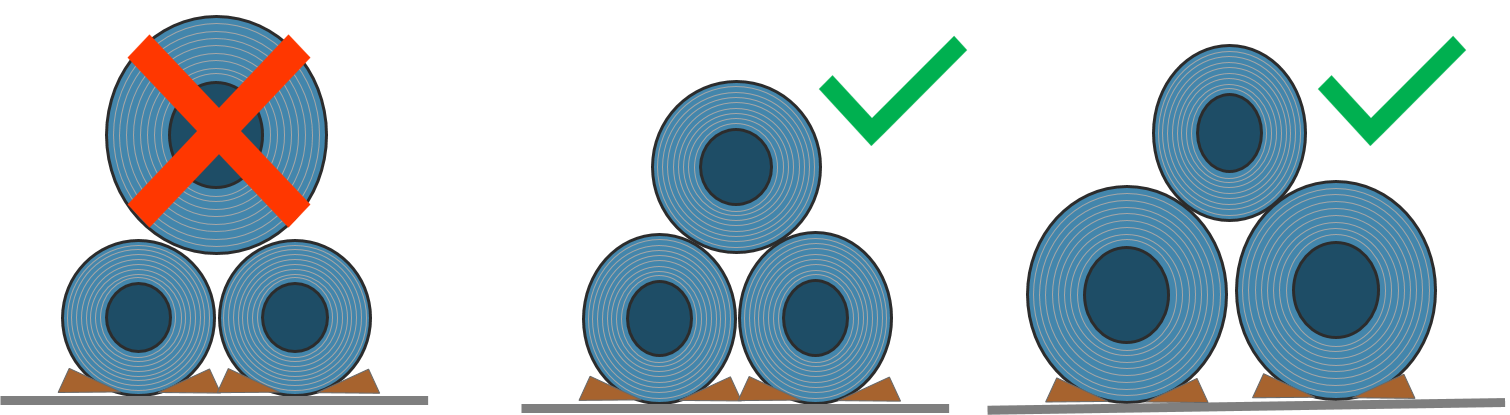

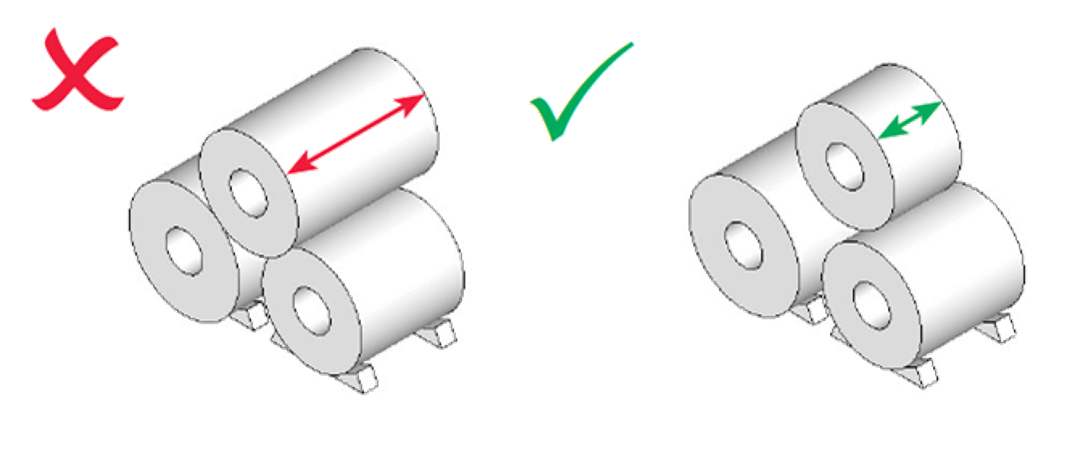

Are coils are only stored a maximum of two Levels high?

-

Stacks should not be stored more than two high.

Two layers is only permitted in the wide coil storage bay where fixed and secure storage systems are in place. -

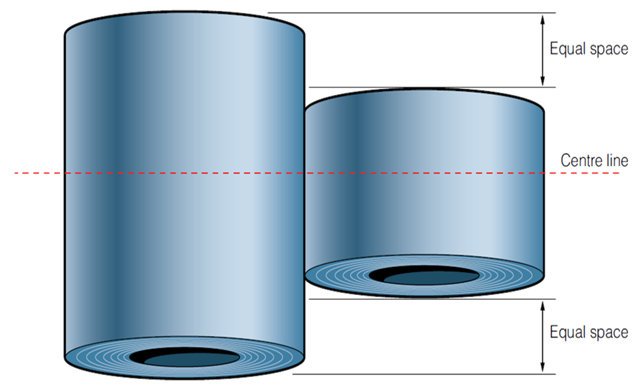

Are the coil Outside Diameters (OD) 10% of each coil next to each other in the row?

-

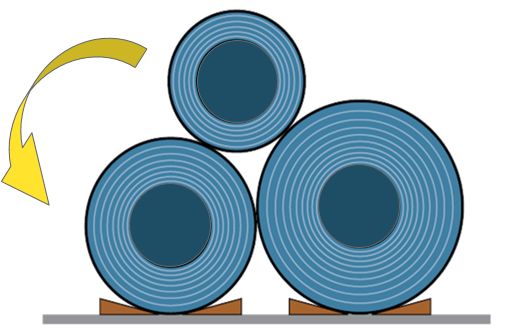

Varying coil diameters are used in the base layer which then causes coils in the upper layers to be stacked on differing diameter coils (causing upper layers to fall).

-

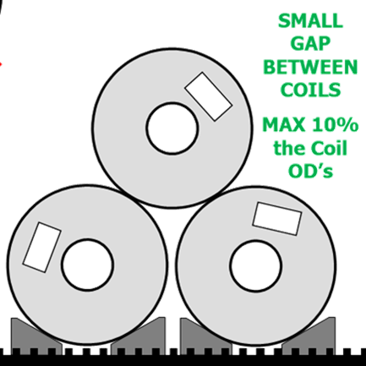

Coils in the base layer are not touching each other and the gap between each coil in the base layer is kept as small as possible (no more than 10% the coils outside diameter)?

-

Coils in the base layer should not touch each other, there should be a small gap left between them but this gap should not exceed more than 10% of the coils Outside diameter

-

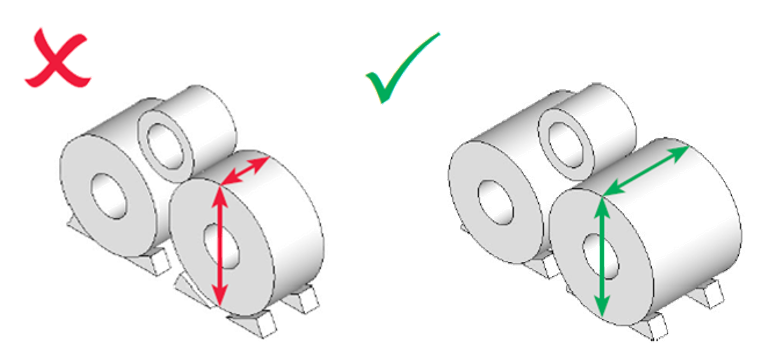

Are the coils stored on the second layer within 10% of the OD of the coils on the base layer?

-

The diameter of coils positioned on the top layer, can be up to a maximum of 10% larger diameter than either of the coils supporting it.

-

Are the OD of coils on the base layer no larger than 1.5 times of the width?

-

The base layer coils outside diameter (OD) cannot be more than 1.5 times the width of the coil.

-

Are the coils on the second layer no wider than 10% of the with of the coils supporting them?

-

Coils positioned on the top layer cannot be more than 10% wider than either of the coils supporting it.

-

Are the coils in the rows aligned centrally?

-

Poor alignment of coils within a stack causes it to turn or distort.

-

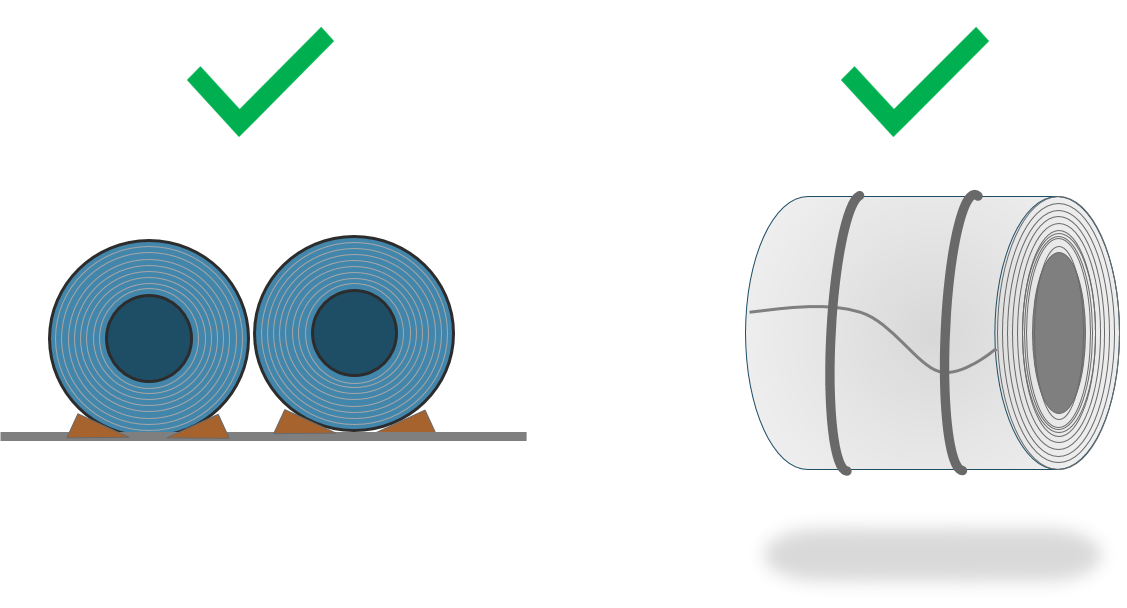

Are Coils that have been Returned To Stock (RTS) stored at ground level and have minimum to pheripheral bands?

-

Partially unwound coils (return to stock / RTS) must be stored at ground level.

A minimum of two peripheral bands around the coil

Handling

-

What is the Name of the person you are observing operating the crane?

-

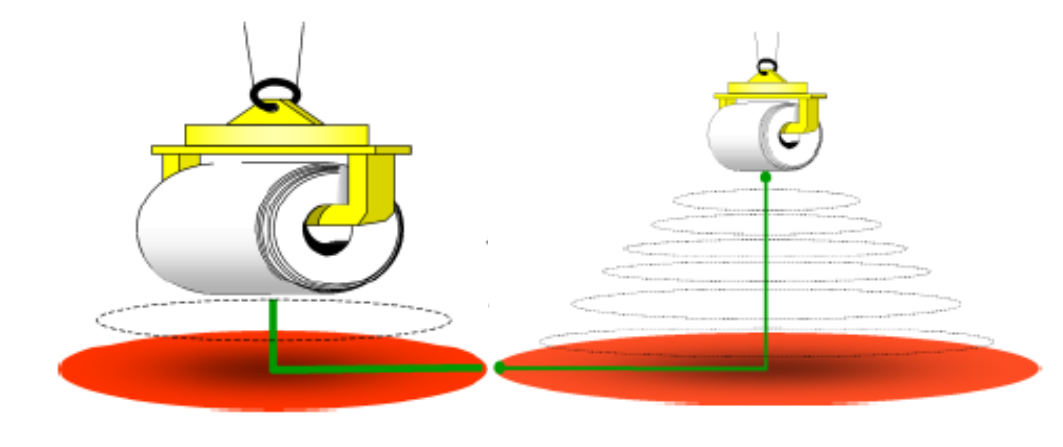

Does the crane operator always observe the safety cone principle?

-

The safety cone = an exclusion zone around the lifted item which is equal to the height the item is lifted. For example 1 meter lift, 1 meter away.

-

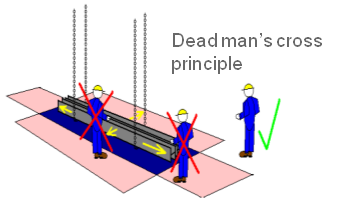

Does the crane operator always respect the deadmans cross?

-

The deadmans cross prinicple, means that if the you stand in the latitude or longitude of the crane lift you are at risk of being hit by the load during movement. The operator should always stand in the diagonal position.

-

Does the operator always follow the coil on the crane as it travels along the bay?

-

The crane operator should always follow the coil be moved and never be in front of the coil. This is to enable eye contact of the load at all times.

-

Does the crane operator always stop the crane before crossing a roadway, fork lift truck lane or pedestrian walkway beofre crossing with the lift?

-

When not is use is the crane attachment (mansaver or 'C' hook always lowered and stored in the correct storage area?

-

During periods when the crane is not used, the crane grab / attachment must be located on the grab stand or in the official parking place.

This can be defined as the OHC operator leaving the bay to work in another area. This also includes; break times, end of shift, toilet beaks etc.

During period of continuous use, the crane can be left suspended for short periods only if it is located over the coil stock area, never over walkways or any areas that create a safety risk.

Continuous use can be defined as the OHC operator working within the same bay on tasks that require the crane to complete imminently.

Audit sign off

-

Auditors signature

-

Site representative signature