Information

-

Document No.

-

Name of Supervisor/Leading Hand

-

Name of worker conducting assessment?

-

Site Number and Location

-

Conducted on

-

Task Being Carried Out

- Copy Change

- Graffiti Clean

- Maintenance

- Vegetation

- Site Measure

- Site Inspection

- Private Job

- Site Clean Up

- Installation

-

Have all workers on site read and understood the SWMS and Site Cards for this site?

-

Read SWMS and Site Card immediately

Quality Check

-

Correct Screws on site and checked?

-

Aerobridge Fixing Form (Screw and Tracking Count)?

-

Tracking checked for right site?

-

Tracking Location installed correctly and securely?

-

Correct Banner for the right Site?

-

ITP Checklist completed?

-

Quality Checklist completed?

-

Banner Correctly installed visually checked and photo taken to supply client

-

Sweep Completed for loose debris?

Site/Access Hazards

-

Have all workers sanitized or washed their hands before starting work?

-

It is the team leader's responsibility to ensure all workers are practicing good hygiene

-

Are the weather conditions suitable for safe work?

-

Insert photo of weather hazard

-

Select from list regarding weather hazards

- Work is indoor, not relevant

- Extra installers will minimise risk

- Changing install method will minimise risk

- Site needs to be held

-

Ring coordinator immediately and submit a site hold form

-

Are there any obstructions to the access point of the site?

-

Ensure objects are moved to a suitable and safe area to access site

If objects cannot be moved, stop works and call Coordinators immediately -

Does this site require you to sign in with Site Management or Security?

-

If yes who was contacted?

-

Are workers able to maintain a physical distance of 1.5m from depot staff and members of the public?

-

Can all material and equipment used be transported to the site safely?

-

Explain method?

-

Has worksite been cordoned off correctly?

-

Equipment used to secure worksite?

- Witches hats

- Barricades

- Tape

- Signage

- Other

-

For other, describe cordon method

Ladders

-

Which ladder are you using?

- Fibreglass Extension 22ft

- Fibreglass Extension 30ft

- Aluminium Extension 22ft

- Aluminium Extension 30ft

- Aluminium Extension 40ft

- Aluminium Step Ladder

- Fibreglass Step Ladder

- Aluminium Platform 1.8m

- Fibreglass Platform 1.8m

- Fibreglass Platorm 2.4m

- Aluminium Platform 2.4m

-

Are the ladders free from major dents or cracks?

-

Are the ladders safe to use?

Traffic Management Checklist

-

Have all work vehicles been parked correctly and in a safe zone?

-

If not, explain how the hazard can be eliminated

-

Are clearances between workers and adjacent traffic being maintained?

-

Has the 'Workers Above"sign been placed on site?

-

Have safety barriers (where used) been installed correctly?

-

Have needs of other road users been provided for?<br>(eg. pedestrians, cyclists, wheelchairs)

In case of emergency

-

In case of emergency - call 000, stay calm and describe the situation clearly to emergency operator. If its a minor incident, near miss or verbal altercation you can call USI - Matthew Lombardi, Steve Balbi or Lee Swale.

-

Are all installers aware of emergency procedures for this site?

-

Hold site until all workers are aware of emergency procedures

-

Has an ambulance pick up point been identified?

-

Hold site until all workers are aware of emergency procedures

-

What is the Pick up point location and suburb?

-

What is the nearest cross street?

-

Is there an abseiler on site

-

Do you have the safety rescue pulley on site?

Electrical Hazards

-

Have all Electrical Hazards been identified and recorded on Site Cards

-

What hazards have been added to site cards?

-

Are there Overhead Power lines (OHPL)?

-

What is the distance (m) and voltage (kV)?

-

What hazard elimination method has been used?

-

List other method used to eliminate hazard of OHPL?

-

If working near an electrical area like switchboard, have precautions been taken?

-

What precautions have been taken?

-

Why can no precautions be taken?

-

Insert photo of any electrical hazards?

Height Hazards

-

Are all workers using fall protection devices like harnesses and are they wearing helmets?

-

Why are workers not wearing fall protection?

-

Are there any height hazards for this site?

-

What is the install method for this site?

- Fixed ladder

- Portable ladder

- Scaffold

- EWP

- Abseil

- Other

-

What size ladder is used for this site?

-

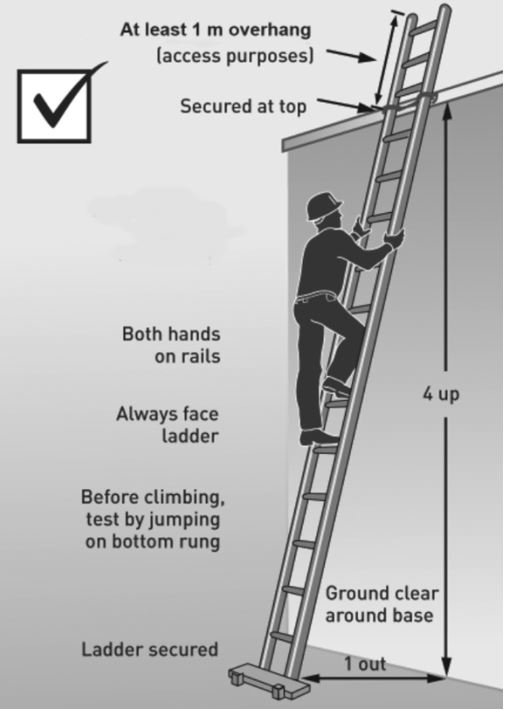

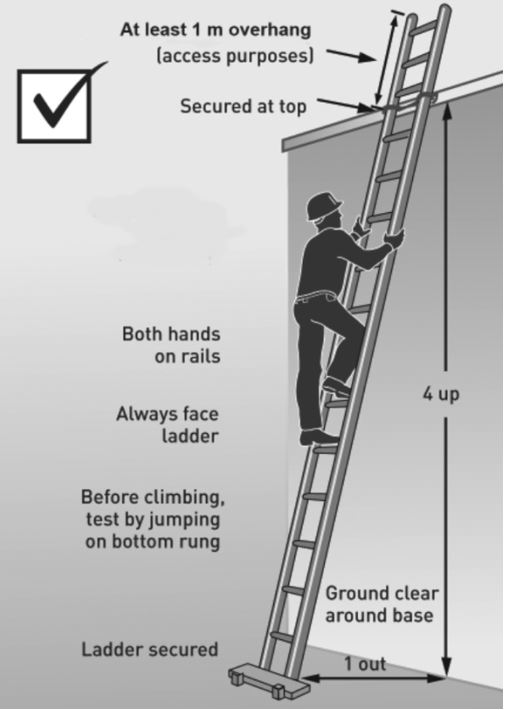

Please show ladder set up, secured and using correct access point

-

Ladders must be placed at a slope of 4:1

-

Can ladder be placed on even ground and secured to sign?

-

How is ladder secured?

- Ladder brackets

- Ratchets

-

Insert photo of ladder hazards?

-

Is ladder being used by one person at a time, footed correctly and the climber has three points of attachment?

-

Describe restrictions in ladder use?

-

Is scaffold in good working order?

-

Insert photo of scaffold hazard

-

Who is ticketed operator?

-

Has operator deemed EWP suitable to task, set up on firm, level ground and completed logbook?

-

Explain EWP hazards?

-

Are all workers trained and deemed competent by management?

-

Hold install and call coordinators immeditely

-

Are all ropes and gear in good condition?

-

Hold installs and ring Coordinator immediately

-

Are anchor points assessed as suitable?

-

Hold installs and call Coordinator immediately

-

Explain other height hazards that may exist?

-

undefined

- Fibreglass Extension 22ft

- Fibreglass Extension 30ft

- Aluminium Extension 22ft

- Aluminium Extension 30ft

- Aluminium Extension 40ft

- Aluminium Step Ladder

- Fibreglass Step Ladder

- Aluminium Platform 1.8m

- Fibreglass Platform 1.8m

- Fibreglass Platorm 2.4m

- Aluminium Platform 2.4m

-

Insert photo of ladder set up, secured at correct access point

-

Ladder must be placed at a slope of 4:1

-

Have all permanent anchor points been inspected, tested and Certified?

-

Are the inspection tags for permanent anchor points in date

-

Are all permanent anchor points / static lines on site considered safe?

-

Hold install and call coordinators immeditely

-

Insert photo of height hazards

Tool Safety

-

Are all tools in good condition and been accounted for?

-

Explain tool hazards

-

Are tools and equipment able to be secured when used at heights

-

Explain tool hazards

-

Are all tools required to be used able to be kept inside cordoned off area?

-

Explain tool hazards

Chemical Hazards

-

Is there an MSDS for all chemicals being used on site?

-

Stop work and ring a Coordinator immediately

-

Have chemical spill procedures been discussed?

-

Stop work and ring a Coordinator immediately

M5 specific hazards

-

Is work being completed on M5

-

Was M5 controller contacted?

-

Will you ensure gates are locked after installation?

General Comments/ Further informtion

-

Supervisors must make sure to write down and discuss hazards and controls as well as any other hazard not recorded elsewhere on the risk assessment

-

Insert toolbox talk topics

Have you discussed the following Toolbox Topics?

-

Falls from Heights

-

Avoiding Manual Handling when folding/unfolding skins

-

Access points/Ladder Brackets

-

Static Lines

-

Anchor Points

-

Inspecting Harness including double yokes, lanyard & shock absorbers

Sign Off Section

-

Supervisor sign off: this risk assessment have been checked by me and verified as true and correct

-

Insert Supervisors name

-

Does the site card or power card require updating for this site

-

Once both the risk assessment and SWMS have been consulted and completed, please sign below to state that you have read and understood all the safety conditions

-

Insert Worker signature

-

Insert Worker signature

-

Insert Worker signature

-

Insert Worker signature

-

Insert Worker signature

-

Insert Worker signature

-

Insert Worker signature

-

Insert Worker signature

-

Insert Worker signature

-

Insert Worker signature

-

Insert Worker signature

-

Insert Worker signature

-

Insert Worker signature

-

Insert any photos of miscellaneous hazards here