Information

-

Client

- Seqwater

- QUU Maintenance

- QUU New Connections

- Eagle Farm Store/Office

- Port of Brisbane

- Project

-

What is the name of this project?

-

Conducted on

-

Location

-

Work order number

-

You can add another work order number here

Work order number

-

Ventia START Card; Specific Task Analysis & Risk Treatment (START) card is a process for ensuring employees identify and control Hazards in their work area prior to the start of work. The use of the START card contributes to implementing a safe work habit of checking your immediate surroundings and workplace conditions before starting any work.

START card must be completed before any work commences, all members of work crew (including subcontractors) must participate in the process (collaboration).

The START card can be reviewed and updated while work continues and if there are changes to the task or worksite. -

If the work is considered 'High Risk', you will need to complete this START card and a Safe Work Method Statement (SWMS)

-

If the work, tasks, or environment changes, the START card MUST be updated

-

All answers are expected to be YES or NOT APPLICABLE (NA). If the answer is identified as a NO a control MUST be identified and implemented

Task Type

-

Are you providing access only for others to the work site? <br>Example - you are only opening a gate or a door for others - Yes<br>You are excavating for others to access a pipe - you or your team are performing the work

PPE

-

Are you / others wearing steel cap boots, long sleeves, and long pants

-

Are you / others wearing safety helmet<br>Consider use of brim and / or use of sunscreen

-

Are you / others wearing safety glasses <br>Consider double eye protection required, e.g. for demolition saw, grinding, etc.

-

Are you / others wearing respiratory protection

-

Are you / others wearing gloves as required for task

-

Are you / others wearing hearing protection

-

Identify required PPE for the task and site.

Consider mandatory requirements, SDS and/or specific site requirements. -

List additional PPE requirements:

General Requirements - Worksite

-

Are all relevant licenses/tickets or qualifications held to carry out task?

-

List the controls implemented:

-

Do you have a plan to manage any weather exposure i.e. heat, cold, wind, that requires management?<br>For example, consider hot weather - frequent rotations and rest periods.

-

List the controls implemented:

-

Is path free of obstacles (trips,slips other hazards)? This includes long grass, dips in the ground, etc.

-

List the controls implemented:

-

Has the site layout / housekeeping been considered?<br>E.g. access / egress / plant and equipment positioning / dust suppression / limiting noise and vibration.

-

List the controls implemented:

-

Is lighting appropriate?

-

List the controls implemented:

-

Are people / residents / pedestrians / animals kept away from your work site?<br>Consider using traffic controllers to manage pedestrians / members of the general public. For people needing to frequently access buildings or driveways around your worksite, ensure hazards have been communicated.

-

List the controls implemented:

-

Are barricades and signs in position as required, and effective?

-

List the controls implemented:

-

Is plant and equipment (including hand tools) appropriate for the task available? Are operators competent in the use of equipment? Has the equipment been inspected prior to use?

-

List the controls implemented:

-

Is all electrical equipment (including hand tools) tested, tagged, and in date?

-

List the controls implemented:

-

If the boom of your equipment is within 3 meters of overhead power lines, do you have an Energex Authorised Spotter? This includes excavators, cranes, etc.

-

List the controls implemented:

-

Will you and / or others be able to perform the task/s without unacceptable risk of strain,sprain or other injury from manual handling?

-

List the controls implemented:

-

Is SDS available and in within five years of issue?

-

List the controls implemented:

-

Have all customers / Control Rooms been notified?

-

List the controls implemented:

-

Have all required permits been obtained, and implemented correctly?

-

List the controls implemented:

-

Are all Isolations and Information tags in place and understood?

-

List the controls implemented:

Traffic and Pedestrian Management

-

Does this task require traffic management (working or plant and equipment within six meters of the roadway, and / or modifying pedestrian access)<br>

-

If you are putting traffic devices on the roadway, do you have a White or Yellow Road Permit accessible on site?

-

Have you placed, as a minimum, orange T5 worker signage?

-

Do you have and have you viewed, a Traffic Management Plan (mud map from MUTCD or traffic guidance scheme) available on site?

-

If you have traffic controllers, do they have their accreditation with them?

-

Have you allowed safe pedestrian access around the work site?

-

Does a Ventia worker on site have Traffic Management Level Two accreditation?

Excavation

-

Are you excavating, including vacuum excavation and potholing, more than 200mm?

-

Have you reviewed and/or marked up the Excavation and Trenching SWMS?

-

Has the excavation been planned prior to commencement? I.e. where the spoil will be stored away from the excavation and out of the path of travel, determined exclusion zones, is the excavator the correct size for the expected excavation, etc.?

-

Shoring, benching and/or battering may not be required if written advice is received from a geotechnical engineer that all sides of the trench are safe from collapse.

-

Will there be excavations greater than 1.5 meters?<br>Consider keeping items , plant, and machinery away from the edge of the trench, access and egress, fall prevention, etc.

-

What ground support system are you implementing? Benching, battering, or shoring?

-

Under no circumstances can someone work outside of the ground support system.

-

If the excavation is less than 1.5 meters, is there is a risk of the trench or excavation collapsing (for example, because of soft soil, moisture content, vibration from traffic or plant)?

-

What ground support system are you implementing? Benching, battering, or shoring?

-

Under no circumstances can someone work outside of the ground support system.

-

Is the work being performed for Queensland Urban Utilities New Connections?

-

Are Dial Before you Digs (DBYD) available, and have you referred to them?

-

Have all services within 3 meters of the work zone been positively identified (using service location, ground penetrating radar, etc.) and marked (showing service type and known depth)

-

Has a spotter been determined for the duration of the excavation?

-

Water Asset Owner emergency number:

Queensland Urban Utilities (QUU) Faults and Emergency - 132 364 (Brisbane, Ipswich, Scenic Rim, and Sommerset area) -

Sewerage Asset Owner emergency number:

Queensland Urban Utilities (QUU) Faults and Emergency - 132 364 (Brisbane, Ipswich, Scenic Rim, and Sommerset area) -

Gas Asset Owner emergency number:

APA - 1800 427 532 -

Telecommunications or NBN Asset Owner emergency number:

Telstra - 1800 653 935 -

Electricity Asset Owner emergency number:

Energex - 131 962

Other Asset Owner emergency number (if applicable)

-

Other Asset Owner emergency number (if applicable)

-

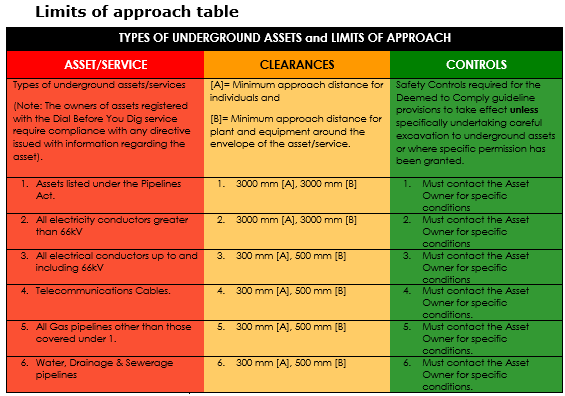

Limits of Approach Table

Soft dig (hand tools and non destructive excavation methods) shall be performed where excavation is within 3 meters of services (refer Limits of Approach table) to positively locate services position.

Where the works methodology cannot comply with the limits of approach for underground or overhead services, the Asset Owner must be contacted for specific controls (inspector on site, hand digging, etc.).

This information must be included on the SWMS -

Have all services been confirmed as isolated within the limits of approach?<br>Note that all mechanical excavation equipment must not be used closed than 500mm to a live underground service.<br>All service pipes / conduits / cables or similar located underground are to be considered 'live and in service' until confirmed otherwise by the utility authority / service owner - and as such they are not to be disturbed or damaged until this confirmation is received and endorsed by the workplace supervisor.

-

List the controls implemented:

-

Has the team leader / person in charge of the work confirmed all requirements and controls have been implemented?

-

What is the permit number of the complete and authorised permit?

Safe Work Method Statement (SWMS)

-

If any of the following activities are occurring, or the work is considered high risk, a SWMS is required:

Confined Space

Risk of Falls

Lifting Operations

Chemical Unloading

High Voltage Work

Isolations (working under permit)

Where High Risk Work Licences are being used

Environmental

-

Is the environment free from risk of land or water contamination, flora (lantana or other weeds) and fauna (snakes, ants, wasps, spiders) disturbance or hazards?

-

List the controls implemented:

-

Have you inspected the site for Fire Ants, and reported any suspected activity?

-

List the controls implemented:

-

Are you removing waste from site (e.g. contaminated soil, asbestos, oily rags, chemicals, batteries, etc.)?

-

You must complete a Waste Tracking Certificate (WTC)? This WTC must be submitted to your team leader within 24 hours.

-

List the controls implemented:

-

Are you moving soil or vegetation from a fire ant high risk suburb (for example, contaminated soil to Ti Tree)?

-

Have you ensured you are not spreading weeds and seeds via your clothing or on your plant and equipment, and when off road, are you staying to existing paths and tracks wherever possible?

-

List the controls implemented:

-

Is Plant and equipment clean and free of built up dirt or vegetative material before being transported to new areas?

-

List the controls implemented:

-

Are spill kits and sediment control available for emergencies?

-

List the controls implemented:

Water Quality and Disinfection

-

Prior to working on the water network (where water supply can be affected, such as water new connections), have all tools and equipment been disinfected? (Tools and equipment submerged in 1% fresh sodium hypochlorite for 30 minutes, then stored on disinfected plastic, water prevented from entering water supply pipes, etc.)

-

List the controls implemented:

-

Have all water network assets been appropriately disinfected upon completion of work? (Spraying with 1% fresh sodium hypochlorite)

-

List the controls implemented:

Emergency Plan

-

Has an Emergency Plan been discussed with everyone on site? <br>Ensure:<br>Key emergency contact information is available to all workers<br>Person leading communication (command and control),<br>Muster/Assembly point.<br>

-

Sketch site and intended muster point

-

Detail if required:

-

Is emergency equipment available and tested, and people know how to operate / use?

-

Is first aid kit available and in date?

-

List the controls implemented:

General Requirements - Worker

-

Would you consider yourself, and others on the worksite (including subcontractors) 'Fit for Work'?<br>Consider fatigue, drugs (including prescription) and / or alcohol.

-

List the controls implemented: Consider contacting your supervisor or member of the SHEQ Team

-

Have all workers, including all subcontractors, been inducted?

-

List the controls implemented:

Further Considerations

-

Has the scope of the task, weather, location or condition of assets on site, or other changed since commencing the work? What has been done to manage the change?

-

List the controls implemented:

-

Are there other hazards or considerations for this work site that have not already been identified?<br>You can list more than one as applicable for the task.

Please detail the hazard or consideration, and implemented controls

-

List the hazard and / or consideration not previously identified?

-

List the controls implemented:

Emergency Response Information

-

Fire, Rescue, Police, Ambulance: 000

-

RSPCA - 1300 264 625

Sign Off

-

All persons on site are to sign on and off of this START card

-

Enter the date and time starting on site

-

Enter date and time leaving site

-

Please sign, when prompted, please type your first and last name