Title Page

-

Project Name

-

Project Number

-

Project Manager

-

Site Safety Coverage

-

Type of project

-

Prepared by

-

Location

-

Weigand Project Supervisor(s)

-

Conducted on

Project Review

-

Project start date

-

Projected completion date

-

What type of construction? (select all that apply)

- New Construction

- Renovation of Existing Structure

- Addition to Existing Structure

-

What is the square footage of new construction?

-

How many floors of new construction?

-

A fire extinguisher, rated not less than 2A, shall be provided for each 3,000 square feet of the protected building area, or major fraction thereof. Travel distance from any point of the protected area to the nearest fire extinguisher shall not exceed 100 feet.

-

One or more fire extinguishers, rated not less than 2A, shall be provided on each floor. In multistory buildings, at least one fire extinguisher shall be located adjacent to stairway.

-

What type of storage for Gas and Diesel is needed?

- Tank

- Can(s)

- Service Truck direct to equipment

- None

-

Tanks shall not be nearer than 20 feet from any building.

-

Within 200 feet of each portable tank, there shall be a 12-foot-wide access way to permit approach of fire control apparatus.

-

Storage areas shall be kept free of weeds, debris, and other combustible material not necessary to the storage.

-

At least one portable fire extinguisher having a rating of not less than 20-B units shall be located not less than 25 feet, nor more than 75 feet, from any flammable liquid storage area located outside

-

Cans should be protected from collision damage

-

If you have more than 4 cans, a storage rack should be supplied from the shop. At least one portable fire extinguisher having a rating of not less than 20-B units shall be located not less than 25 feet, nor more than 75 feet, from any flammable liquid storage area located outside

-

How many fire extinguishers will be needed for the New Construction?

-

What is the square footage of Renovated space?

-

How many floors of Renovation?

-

Will an existing fire suppression system be in place?

-

All sprinkler head shall be guarded in the work space or relocated to prevent incidental activation.

-

Will the fire suppression system need to be disabled at any time?

-

A fire extinguisher, rated not less than 2A, shall be provided for each 3,000 square feet of the protected building area, or major fraction thereof. Travel distance from any point of the protected area to the nearest fire extinguisher shall not exceed 100 feet.

-

One or more fire extinguishers, rated not less than 2A, shall be provided on each floor. In multistory buildings, at least one fire extinguisher shall be located adjacent to stairway.

-

What type of storage for Gas and Diesel is needed?

- Tank

- Can(s)

- Service Truck direct to equipment

- None

-

Portable tanks shall not be nearer than 20 feet from any building.

-

Within 200 feet of each portable tank, there shall be a 12-foot-wide access way to permit approach of fire control apparatus.

-

Storage areas shall be kept free of weeds, debris, and other combustible material not necessary to the storage.

-

At least one portable fire extinguisher having a rating of not less than 20-B units shall be located not less than 25 feet, nor more than 75 feet, from any flammable liquid storage area located outside

-

Storage area shall not be nearer than 20 feet from any building.

-

Cans should be protected from collision damage

-

At least one portable fire extinguisher having a rating of not less than 20-B units shall be located not less than 25 feet, nor more than 75 feet, from any flammable liquid storage area located outside

-

If you have more than 4 cans, a storage rack should be supplied from the shop

-

How many fire extinguishers will be needed for the renovation?

-

A fire extinguisher, rated not less than 2A, shall be provided for each 3,000 square feet of the protected building area, or major fraction thereof. Travel distance from any point of the protected area to the nearest fire extinguisher shall not exceed 100 feet.

-

One or more fire extinguishers, rated not less than 2A, shall be provided on each floor. In multistory buildings, at least one fire extinguisher shall be located adjacent to stairway.

-

How many fire extinguishers will be needed for the renovation?

-

Will our renovation block an emergency evacuation route?

-

Can the evacuation route be rerouted so it doesn't enter our work space?

-

All signage will need to reflect the changed evacuation route.

-

Emergency exit routes must be kept free and clear of material and obstructions at all times

-

Combustible loads in corridors or in spaces open to the route must be kept to a minimum

-

If the exit route must be obstructed, the supervisor shall notify the building owner and be sure that temporary measures are taken to protect the safety of building occupants.

-

What is the square footage of the New Addition?

-

How many floors of New Addition?

-

A fire extinguisher, rated not less than 2A, shall be provided for each 3,000 square feet of the protected building area, or major fraction thereof. Travel distance from any point of the protected area to the nearest fire extinguisher shall not exceed 100 feet.

-

One or more fire extinguishers, rated not less than 2A, shall be provided on each floor. In multistory buildings, at least one fire extinguisher shall be located adjacent to stairway.

-

What type of storage for Gas and Diesel is needed?

- Tank

- Can(s)

- Service Truck direct to equipment

- None

-

Portable tanks shall not be nearer than 20 feet from any building.

-

Within 200 feet of each portable tank, there shall be a 12-foot-wide access way to permit approach of fire control apparatus.

-

Storage areas shall be kept free of weeds, debris, and other combustible material not necessary to the storage.

-

At least one portable fire extinguisher having a rating of not less than 20-B units shall be located not less than 25 feet, nor more than 75 feet, from any flammable liquid storage area located outside

-

Storage area shall not be nearer than 20 feet from any building.

-

Cans should be protected from collision damage

-

At least one portable fire extinguisher having a rating of not less than 20-B units shall be located not less than 25 feet, nor more than 75 feet, from any flammable liquid storage area located outside

-

If you have more than 4 cans, a storage rack should be supplied from the shop

-

How many fire extinguishers will be needed for the new addition?

-

Are we self-performing any work?

-

What is Weigand self-performing?

- General Conditions

- Demolition

- Building Concrete

- Site Concrete

- Masonry

- Masonry Restoration

- Casework Carpentry

- Architectural Woodwork Carpentry

- Interior Blocking Carpentry

- Exterior Blocking Carpentry

- Metal Siding

- Waterproofing

- Door and Hardware

- Metal Framing and Drywall

- Ceilings

- None

-

Will personnel be exposed to a 6' fall or more?

- Roof Work

- Aerial Lift Work

- Leading Edge Exposure

- Excavations, when the excavation cannot be readily seen because of plant growth or other visual barrier.

- Shafts (Elevator, Mechanical, Etc.)

- Trash Shoot Access

- Material Access

- Man Basket

- Other

- None

-

Man Basket must be approved by your safety rep. or the director before use.

-

What fall protection will be need for Weigand employees when working from the roof?

-

What fall protection will be needed for Weigand employees when working in an aerial lift?

-

What fall protection will be need for Weigand employees when exposed to a leading edge?

-

What fall protection will be needed for excavations?

-

What fall protection will be needed for open shafts?

-

What fall protection will be need for trash shoots?

-

What fall protection will be needed for material access points?

-

What fall protection will be needed for the other fall hazards listed?

-

List the other types of 6' fall exposure(s) and what will be done to eliminate them.

-

What Pre Meeting will be required for this project?

- Demolition

- Excavation

- Masonry

- Steel Erection

- Roofing

- Pre-Cast Erection

- Pile Driving

- Critical Lift

- Crane Lift

- Specialized Move and/or High Value Product (Example: Jack and slide a MRI machine)

- Health Care

- No pre-meetings will be required for this project

-

What are the training requirements needed by Weigand? (select all that apply)

- Fall Protection

- Aerial/Platform Lift

- Lull/Fork Lift

- Rigging/Signaling

- Confined Space

- Mast Climber

- Suspended Scaffold/Swing Stage

- Other

- Silica

- First Aid/CPR/AED

-

Please list the other training's required

-

What equipment will be needed for the project. (select all that apply)

- Scaffolding

- Mast Climbers

- Suspended Scaffold

- Aerial lift and/or Scissor lift

- Material Handling Equipment (Example: Lull, Fork Lift)

- Crane

- Other

- No Equipment will be needed for this project

-

How will risk be eliminated when using Scaffolding? (Access, Fall Protection, Bracing, Tie in, ext.)

-

How will risk be eliminated when using a Mast Climber? (Access, Fall Protection, Bracing, Tie in, ext.)

-

How will risk be eliminated when using Suspended Scaffolding?

-

How will risk be eliminated when using an Aerial Lift?

-

How will risk be eliminated when using a MHE?

-

How will risk be eliminated when other equipment is involved? (Please list the other equipment before explanation.)

-

How will the risk be eliminated when using a crane?

-

Will Weigand have any rental equipment on this project?

-

If subs must use any Weigand rented equipment "Attachment E" must be signed.

-

Weigand employees shall be covered under a union drug test policy or our internal testing pool.

Project Documentations, Layout, Postings

-

All Weigand projects must have a Large yellow Weigand sign posted at the gate or a small yellow Weigand sign posted at the entrance door.

-

All Weigand projects must have periodically placed "No Trespassing" signs posted along its boundaries.

-

A Code of Conduct needs created by the superintendent and it must be signed by all entering a Weigand project. (COC's located on Egnyte under Field Forms, Safety, Job Trailer Set Up)

-

Orientation stickers need provided (contact your safety rep for project specific stickers)

-

Each person entering the Weigand job-site for the first time must watch the orientation video. (Video located on Egnyte under Field Forms, Safety, Safety Video, Orientation Video)

-

Exit Signage: Exits shall be marked by a readily visible sign. Access to exits shall be marked by readily visible signs in all cases where the exit or way to reach it is not immediately visible to the occupants.

-

An Emergency Action Plan needs created by the superintendent and posted in the job trailer or office space, posted at the main entrance of the building and at each stairwell on each floor. All EAP posting need an air horn with them.

-

The medical provider needs posted in job trailer or office space. (notify safety rep to create)

-

First aid kits are required in the job trailer or office space and in all job boxes.

-

Federal/State Labor law poster required for all Weigand employees to view.

-

Weigand Manual is required in the job trailer or office space.

-

SDS posting required for all Weigand employees to use.

-

Silica and Table 1 posting required for job trailers

-

Other signage that needs posted. (select all that apply)

- Confined Space

- Each floor must be labeled at stairwell

- Do Not Enter

- Emergency Exit Only

- Overhead Power Lines

- Other

- None

-

What is the other signage that is needed?

Security

-

What security measures will be in place? (select all that apply)

- Perimeter fencing

- Lockable Exterior Door(s)

- Land Barriers

- Access Gate(s)

- Temporary Lockable Door(s)

- Video Survallence

- Security Guard

- Trailer Alarm System

- Badging

- Sign in/out

- Motion/Flood Lights

- Other

- No Security measures will be needed

-

Please list the other security measures needed.

-

Why will security measures not be needed?

Hot Work

-

Will there be hot work that involves burning, welding, cutting, brazing, soldering, grinding, using fire- or spark-producing tools, or other work that produces a source of ignition.

-

Can the objects to be welded, cut, or heated be moved to a designated safe location?

-

If the object to be welded, cut, or heated cannot be moved and if all the fire hazards cannot be removed, positive means shall be taken to confine the heat, sparks, and slag, and to protect the immovable fire hazards from them.

-

Briefly describe the designated safe location.

-

Suitable fire extinguishing equipment shall be immediately available in the work area and shall be maintained in a state of readiness for instant use.

-

When the welding, cutting, or heating operation is such that normal fire prevention precautions are not sufficient, additional personnel shall be assigned to guard against fire while the actual welding, cutting, or heating operation is being performed, and for a sufficient period of time after completion of the work to ensure that no possibility of fire exists. Such personnel shall be instructed as to the specific anticipated fire hazards and how the firefighting equipment provided is to be used.

-

When welding, cutting, or heating is performed on walls, floors, and ceilings, since direct penetration of sparks or heat transfer may introduce a fire hazard to an adjacent area, the same precautions shall be taken on the opposite side as are taken on the side on which the welding is being performed.

Enviromental

-

Asbestos was used in almost every public and commercial building constructed before the 1980's in the United States. Though it is rarely found in modern building materials, the material can still be found in pipe covers, flooring, fireproofing insulation and many adhesives among other construction materials.

-

Consumer Product Safety Commission passed regulations prohibiting the use of lead-containing paints for products manufactured after February 27, 1978. Lead is a heavy metal commonly found in roofing materials, paints, plumbing pipes.

-

Has Weigand received copies of environmental assessments, asbestos surveys, or air quality studies obtained for the project?

-

These copies must be reviewed by the safety department before work begins?

-

Can any existing hazardous material(s) be disturb by removal of demolition material, resurfacing floors, or building additions?

-

The Safety Department needs to be notified of the hazardous material that may be disturbed.

-

What hazardous materials will be disturbed?

-

Has an outside source been requested/engaged to monitor/review/test for environmental hazards?

-

The Safety Department must be informed of the process.

-

Other potential environmental hazards in our work space? (select all that apply)

- Mold

- PCB's

- Other

- None

-

The safety department must be notified of any other environmental hazards.

-

Please list the other potential environmental hazard that may be present.

-

Is Weigand or an outside source taking steps to remove the mold?

-

What are the steps to remove the mold?

-

Has the source of the mold corrected?

-

The mold must documented and the owner must be made aware before work begins.

-

The Safety department must be notified of any PCB's that may be disturbed.

ICRA

-

Will an ICRA plan be needed?

-

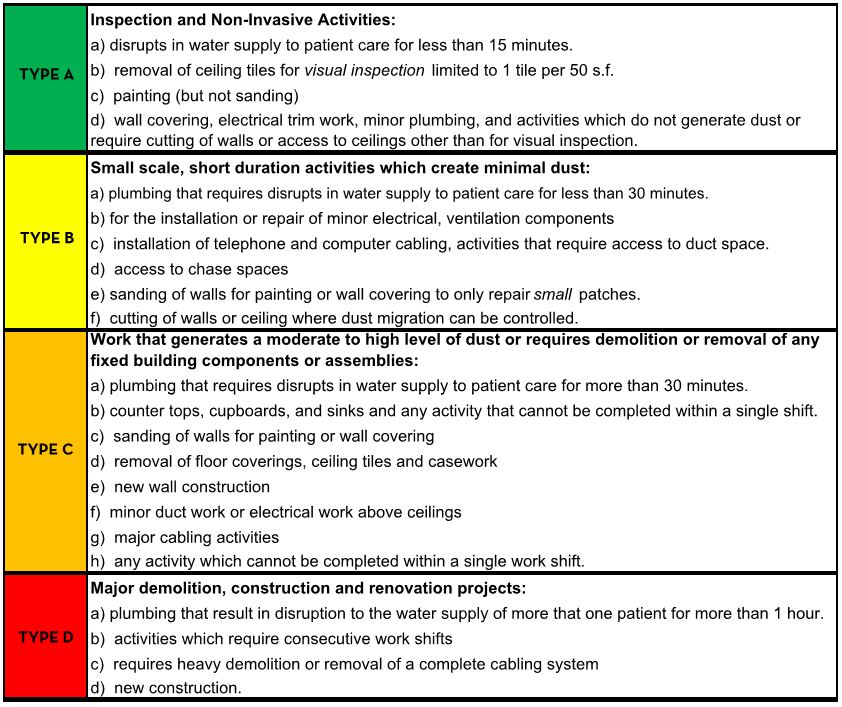

What type of construction activity is required? (use the table below)

-

Types of Construction Activity

-

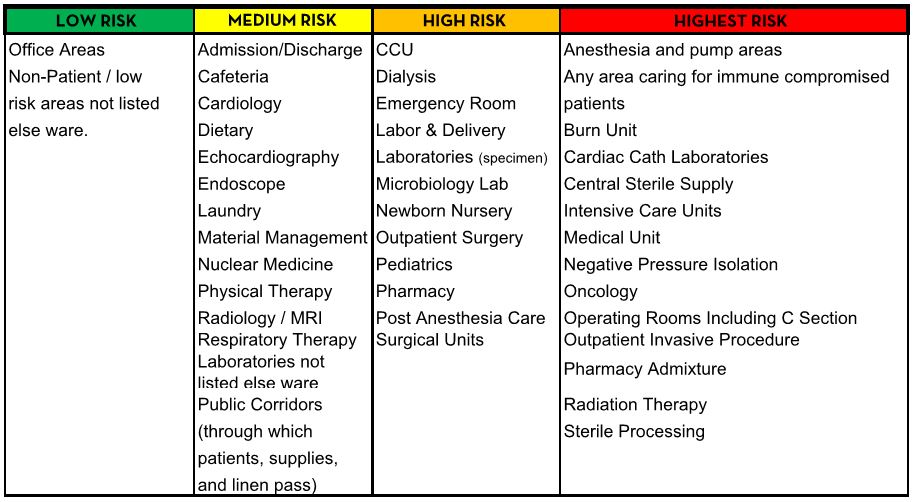

What are the Patient Risk Groups that will be affected? (use the table below)

-

Patient Risk Groups

-

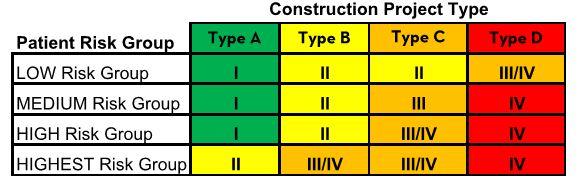

What is the ICRA class? (use the matrix below)

- Class 1

- Class 2

- Class 3

- Class 4

-

Class Identification Matrix

-

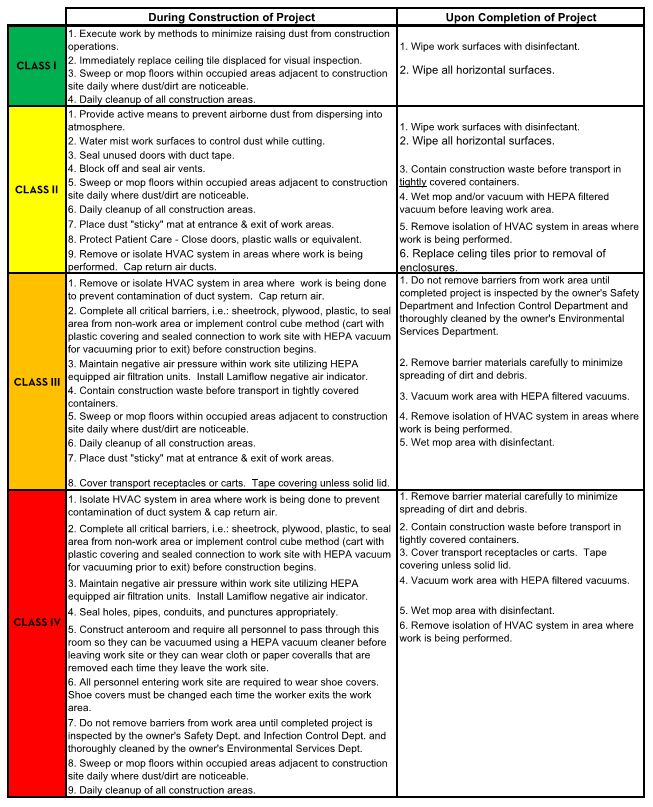

Review the Infection Control Precautions for your project.

-

What Impact will the project have on Interim Life Safety measures (select all that apply)

- Fire alarm system

- Fire suppression system

- Exit signs

- Routes of egress

- Existing medical gas system

- Existing electrical systems

- Existing sanitary piping

- Existing water piping

- Existing HVAC

-

What systems will have planned outages (select all that apply)

- Electrical

- Water

- Sanitary

- HVAC

- Medical gas system

- Oxygen supply system

- Other

-

What other systems will need to be planned for an outage?

-

Is there any medical gas systems in our project area?

-

How will the supply lines and control boxes be labeled and protected?

-

Fire Alarms, fire suppression systems, and exit signs shall remain intact and operational unless written consent is granted by the owner with approval from owner's insurance company. If existing system needs to be compromised, then temporary systems are to be put in place.

-

What types of barriers will be needed?

- Plastic w/ Zip Poles (48 hours only)

- Metal Studs and Drywall

- Edge Guard (hard plastic)

-

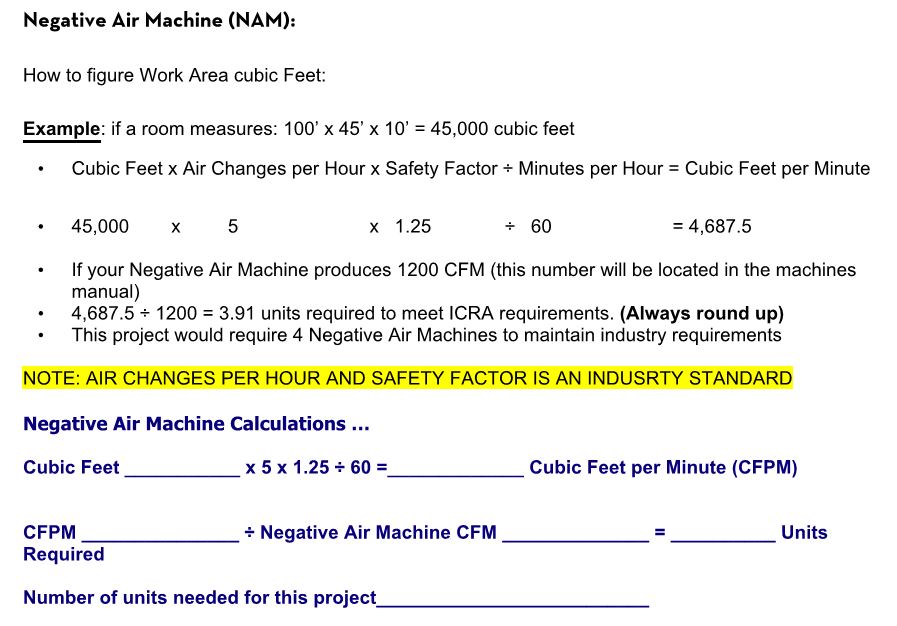

How many negative air machines will be needed? (use the instructions below)

- 1

- 2

- 3

- 4+

- None

-

Negative Air Machine Calculation Instructions

-

Who is filling out the ILSM and ICRA daily checklists and where will it posted?

-

Housekeeping in and out of the space must be a priority

-

Will personnel badges be needed

-

What permits will be required?

- Above Ceiling Permits

- Hot Work Permits

- Ladder Permits

- None

-

Each space must have the category posted at the entrance

-

ICRA orientation stickers need provided

-

Each person entering the Weigand job-site for the first time must watch the ICRA video. (Video located on Egnyte under Field Forms, Safety, Safety Videos, ICRA Video.)

-

A posting for the shut off valve must be created by the Project Manager and needs displayed inside each work space that has sprinklers. The Superintendent must discuss with all personnel in there orientation.

-

Clean tightly covered carts are required outside of space.

-

Sticky mats are required when entering clean spaces from the construction area. (additional resources may be needed)

Signatures

-

Safety Representative

-

Project Manager

-

Superintendent

-

Other (add Name - Title)

-

Other (add Name - Title)

-

Other (add Name - Title)

-

Other (add Name - Title)

-

Other (add Name - Title)

-

Other (add Name - Title)