Title Page

-

Site conducted

-

SOP 2-2 - Daily Pre-Operational Sanitation Checklist - Winnipeg

-

Conducted on

-

Prepared by

-

Location

Instructions

-

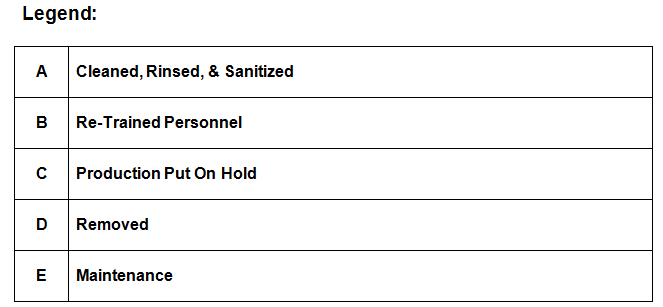

Inspect the areas for cleanliness. Inspect all machines with glass and brittle plastic compartments for breakage. If an item or area is non-compliant, select the appropriate non-compliance and describe additional notes under "Note" and attach an "Image". Select the appropriate corrective action taken based on the legend below. For items that require corrective action with a later completion date such as maintenance or group re-training, click "Action" to enter the corrective action required along with a description. Assign the corrective action to the appropriate employee. Once the corrective action is completed, the person responsible for completion is to sign under "Corrective Actions Performed by". The inspector should verify the effectiveness of the corrective actions and sign in the "Corrective Actions Verified By" section. Once all corrective actions are verified and the SOP form is completed, the inspector should assign Plant Management to review and sign off.

General

-

Vestibule

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Washroom 1 / Washroom 2

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Are foot dips available at all entryways?

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Are cold-holding units: Freezer at -18°C or less; Cooler at 4°C or less?

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed by

Processing Area

-

Wall & Floor

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Handwashing Sink

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Trench Drain

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Door / Door Frame / Door Handle

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Cooling Fans (Condensation, Dust, Mould)

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Tables (Top & Underside)

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Shelves

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

2-Compartment Sink

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Chemical Dispensers

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Ceiling Tiles

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Nigiri Machine

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Rice Sheeter

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Rice Cookers

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions Performed By

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Rice Cooker Pots

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Rice Bins

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Rice Soaking Containers / Lids

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

Work In Progress Cooler

-

Wall & Floor

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Door / Door Frame / Door Handle

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Shelves / Racks

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Cooling Fans (Condensation, Dust, Mould)

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

Freezer

-

Wall & Floor

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Door / Door Frame / Door Handle

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Shelves / Racks

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Cooling Fans (Condensation, dust, mould)

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

Warehouse Area / Receiving / Shipping Area

-

Wall & Floor

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Is the Chemical Cage locked?

- Locked

- Unlocked

-

Corrective Actions

- Locked Door

- Lock Broken - Report to Management

-

Corrective Actions Performed By

-

Items stored on pallets

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Racks / Shelves

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Allergen Shelves / Containers

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Drains

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

Dish Room

-

3-Compartment Sink

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Mop Station

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Drain

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Brushes (non-food contact surfaces)

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Mops (hang on holders to dry)

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Mop Buckets

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Squeegees / Brooms

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Drain Brush

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

Other Items

-

Carrot Shredder

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Peelers

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Mandolin

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Trays

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Baker's Racks

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Knife Dip Container

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Measuring Cups

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Bamboo Rolling Mat

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Knives

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Scales

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Cutting Boards

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Carts / Trolleys

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Brushes (food contact surfaces)

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Garbage Bins

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

Observations / Spot Check

-

Visually verify that vacuum-packaged seafood (i.e., smoked salmon) are cut open and that thawing conditions are optimal prior to start of production

-

Thawing vacuum-packed seafood cut open?

-

Check that the internal product temperature is ≤ 4.4°C. If it is ≤ 4.4°C, cut open the package to allow for airflow to control C. botulinum. If it is ≥ 4.4°C, discard the package.

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Are leftovers discarded as per Ingredient List and Storage Guidelines? (Refer to summarized guidelines below)

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Ingredient List and Storage Information

-

Proper thaw/opened date code recorded on WIP ingredients?

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Receiving date recorded on ingredients?

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

-

Hand-washing procedures followed?

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

Additional Comments / Corrective Actions

-

Specify non-conformance under "Notes" and select the appropriate non-conformance.

-

Additional Comments / Corrective Actions

- Compliant

- Dirty

- Food Debris

- ATP Fail

- Damaged

- Maintenance Issue (i.e., Rust)

- Excess Water (Pooling Water, Condensation)

- Ice Build-Up

- Other (Specify Non-Conformance)

- N/A

- N/O - In Use

-

Corrective Actions

- A = Cleaned, Rinsed & Sanitized

- B = Re-Trained Personnel

- C = Production Put On-Hold

- D = Removed

- E = Maintenance

-

Corrective Actions Performed By

Verification

-

Are the Corrective Actions Completed and Verified?

-

Describe any outstanding issues followed by the target completion dates. (Note: Assign an action to appropriate individuals for follow-up)

-

Inspector Name and Initial

-

Verified By Plant Manager