Information

-

Audit Title

-

Client / Site

-

Conducted on

-

Prepared by

-

Location

-

Personnel

GENERAL

-

Is Woodruff Construction the General Contractor for this project?

-

Are postings in place?

-

Comprehensive Fed / State poster

-

Emergency phone numbers

-

Address of site

-

Is today's date between February 1 and April 30?

-

Is injury summary (OSHA 300A) posted?

-

photos

-

Action taken or needed

GENERAL SAFETY AND HEALTH SUBPART C

HOUSEKEEPING

-

Work areas, passageways and areas around stairs and buildings are clear of debris and scrap

-

CORRECTED

-

Are materials stacked and stored in an orderly fashion?

-

Is scrap and debris collected and disposed of as work progresses?

-

photos

-

Action taken or needed

OCCUPATIONAL HEALTH AND ENVIRONMENTAL CONTROLS SUBPART D

MEDICAL SERVICES AND FIRST AID

-

Are first aid kits easily accessible?

-

CORRECTED

-

Are kits checked on a weekly basis?

-

Does kit contain ANSI minimum requirements?

-

1 absorbent compress 32 sq in with no side smaller than 4 in

-

at least 16 adhesive bandages - 1x3

-

1 roll of adhesive tape - 2.5 yd

-

6 0.14 oz antibiotic treatment

-

10 0.14 oz of antiseptic

-

6 applications of burn treatment

-

first aid guide

-

2 pairs of medical exam gloves

-

4 sterile pads - 3x3

-

1 triangular bandage - 40" x 40" x 56"

-

Are all supplies unexpired?

-

Is there personnel on site trained in first aid and CPR?

-

Are they certified?

-

Is this information posted?

-

Are they on site now?

-

photos

-

Action taken or needed

SANITATION

-

Is there an adequate supply of potable water?

-

-

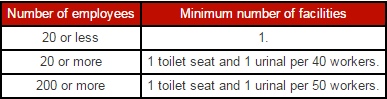

Is there an adequate number of toilets?

-

Action taken or needed

OCCUPATIONAL NOISE EXPOSURE

-

Is noise level a concern?

-

Proper hearing protection being used?

-

CORRECTED

-

Action taken or needed

RADIATION

-

Are lasers being used?

-

Lasers are not set up near head level of workers

-

CORRECTED

-

Are lasers being operated by qualified and trained employees?

-

Are lasers turned off when left unattended for extended periods of time?

-

Is ionizing radiation a concern?<br>example X-rays

-

Action taken or needed

GASES, VAPORS, FUMES, DUSTS, MISTS

-

Are workers protected from exposure?<br>examples: lead, asbestos

-

Proper respiratory protection is being worn

-

CORRECTED

-

Action taken or needed

ILLUMINATION

-

Is there sufficient lighting on site?

-

Are lights protected?

-

Action taken or needed

VENTILATION

-

Is there sufficient ventilation?

-

Action taken or needed

HAZARD COMMUNICATION

-

Is there a written hazard communication program on site?

-

Posted location of MSDS/SDS

-

List of chemicals on site w/ product identifier that is referenced on the appropriate SDS

-

Container labeling - product identifier (corresponding to SDS) and words, pictures, symbols or any combination thereof

-

Are workers informed of hazard of non-routine tasks, e.g. unlabeled pipes

-

Action taken or needed

PPE SUBPART E

-

Are all workers wearing the appropriate PPE for their task?

-

Are fall arrest components in good condition?

-

Are dust masks available?

-

Is hearing protection available?

-

hard hats and safety glasses are worn

-

Action taken or needed

FIRE PROTECTION AND PREVENTION SUBPART F

FIRE EXTINGUISHERS

-

Are extinguishers inspected monthly?

-

Are extinguishers serviced yearly?

-

Is there a fire extinguisher conspicuously located within 100' of every working area

-

Is there an extinguisher located adjacent to every stairway of multi-story buildings?

-

photos

-

Action taken or needed

Propane Storage

-

Are propane containers properly stored outside?

-

500lbs or less-0' from building

501-6000lbs-10' from building

6001-10,000lbs-20' from building

over 10,000lbs-25' from building -

Are containers protected from vehicles?

-

Is there a 20BC fire extinguisher at location?

-

photos

-

Action taken or needed

TEMPORARY HEAT

-

Is temporary heat being used on site?

-

Is there 3' clearance between radiant heaters and combustibles?

-

CORRECTED

-

Is there sufficient ventilation?

-

CORRECTED

-

Heaters are not directed at propane tanks within 20'

-

CORRECTED

-

Is there 6' of clearance between heater and container?

-

CORRECTED

-

photos

-

Action taken or needed

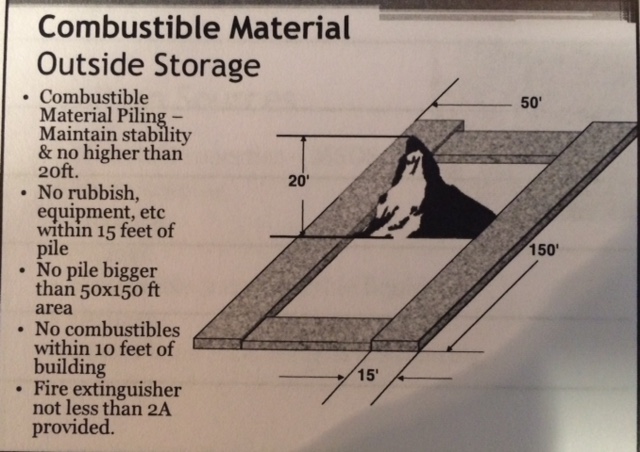

STORAGE - COMBUSTIBLE MATERIALS

-

Is combustible material stored indoors or outdoors?

-

Indoor Storage

-Does not affect exit

-Non-compatible materials segregated by a barrier with a 1 hr resistance

-Clearance of sprinklers at least 36" between material and sprinkler

-Clearance around lights and heating units

-Clearance of 24" around path of travel to fire door

-No material stored withing 36" of fire door opening -

Outdoor Storage

-

Indoor Storage

-Does not affect exit

-Non-compatible materials segregated by a barrier with a 1 hr resistance

-Clearance of sprinklers at least 36" between material and sprinkler

-Clearance around lights and heating units

-Clearance of 24" around path of travel to fire door

-No material stored withing 36" of fire door opening -

Outdoor Storage

-

Are combustible materials properly stored?

-

photos

-

Action taken or needed

STORAGE - FLAMMABLE AND COMBUSTIBLE LIQUIDS

-

Are flammable/combustible liquids stored indoors or outdoors?

-

Outdoor Storage

-Does not exceed 1100 gallons in any one pile

-Not stored within 20' of a building

-5' clearance between piles

-Liquid control -- grading, curbs or drains

-Portable tank storage must be over 20' from building

-Tanks must be equipped with emergency venting -

Is there a 20B fire extinguisher 25'-75' away?

-

Indoor Storage

-Approved containers for flammable liquids in quantities of 5 gallons or less

-No more than 25 gallons stored outside of cabinet

-Over 25 gallons must be stored in a cabinet

-Not stored near stairways or exits -

Is there a 10B fire extinguisher within 50'?

-

Indoor Storage

-Approved containers for flammable liquids in quantities of 5 gallons or less

-No more than 25 gallons stored outside of cabinet

-Over 25 gallons must be stored in a cabinet

-Not stored near stairways or exits -

Is there a 20B fire extinguisher within 10' of exterior of room?

-

Outdoor Storage

-Does not exceed 1100 gallons in any one pile

-Not stored within 20' of a building

-5' clearance between piles

-Liquid control -- grading, curbs or drains

-20B fire extinguisher located 25-75' away from liquid storage

-Portable tank storage must be over 20' from building

-Tanks must be equipped with emergency venting

- -

Is there a 10B fire extinguisher within 50'?

-

Are flammable/combustible materials properly stored?

-

photos

-

Action taken or needed

HAND AND POWER TOOLS SUBPART I

-

Is the right tool being used for the job?

-

Are all guards and handles in place?

-

Removed and tagged until guard is replaced

-

Are all electric power tools grounded or double insulated?

-

Removed and tagged

-

Are all tools maintained in a safe condition?

-

photos

-

Action taken or needed

WELDING AND CUTTING SUBPART J

-

Are oxygen and fuel cylinders stored on site?

-

STORAGE

-cylinders secured in upright position

-20' or a 5' high-1/2 hour rated fire wall separating oxygen and any fuel or combustible material

-

Is oxygen/fuel stored properly?

-

Is Woodruff or subs welding or using cutting torches?

-

Do all cylinders have labels?

-

Are valve protection caps in place?

-

Are cables in good condition

-

Only 4" per foot of hose may be taped to secure hoses together

-

Is a fire extinguisher readily accessible for work area

-

photos

-

Action taken or needed

ELECTRICAL SUBPART K

-

Is Woodruff's GFCI policy being followed by all workers?

-

CORRECTED

-

Is temporary lighting on it's own circuit?

-

CORRECTED

-

Are breaker box panels covered?

-

CORRECTED

-

Are all openings on breaker boxes covered?

-

CORRECTED

-

Are all circuits labeled?

-

CORRECTED

-

Are breaker positions labeled?

-

CORRECTED

-

Is a 3-4 working space maintained around electrical equipment?

-

CORRECTED

-

Are work areas and passageways kept clear of cords

-

CORRECTED

-

Wire and cords are not resting on or secured directly to metal supports i.e. nails, wire or staples

-

CORRECTED

-

photos

-

Action taken or needed

SCAFFOLDS SUBPART L

-

Do Woodruff employees or subs have scaffolding on site?

-

Name of company using scaffold

-

Name and company of competent person

-

Are inspections conducted prior to each shift?

-

Are inspections current?

-

What kind of scaffold

- Supported

- Suspended

-

If equipped are castors pinned and locked while in use?

-

Is scaffolding resting on a proper footing?

-

Are all components compatible and in place?

-

Is there a ladder or other means of access if over 24" from point of access ?

-

Is there proper fall protection in place at a height of 10'?

-

top rail-42" or crossing point of brace-38-48"

mid rail-21" or crossing point of brace-20-30" -

Planking a minimum of 18" wide

-

Platform fully planked

-

Planking is of scaffold grade

-

Less than 1" of gap between planks

-

Planking is equipped with cleats or extend 6-12" over ends

-

12" of overlap or secured to prevent movement

-

Platform no more than 14" from face of work

-

Does height exceed 4:1 ratio?

-

Scaffold is secured horizontally every 30'

-

Scaffold is secured vertically every 20' - frames<3' wide every 26' -frames>3'wide

-

photos

-

Action taken or needed

AERIAL LIFTS

-

Does Woodruff or subs have aerial lifts on site?

-

Is the lift in use?

-

load limits observed

-

Work area clear of electrical hazards

-

level and solid surface

-

clear travel path

-

holes and openings are protected

-

fall protection in place

-

access gate closed

-

tools and materials secure in basket

-

Aerial lift safety checklist

aerial lift

-

Who's machine

- Woodruff

- Rental

- Sub

-

make

-

model

-

ID number

-

rental company

-

make

-

model

-

Are daily inspections being done?

-

placards, warnings, or operational, instructional and control markings legible

-

lights, horn, back up alarm

-

safety features not rigged or bypassed

-

guardrail system

-

anchor points

-

operator manual, ANSI manual, AEM manual, service/maintenance manual

-

Action taken or needed

-

photos

FALL PROTECTION SUBPART M

-

Unprotected sides and edges

-

Wall openings

-

Are all holes 2 -12" covered?

-

Is leading edge work being done?

-

Leading edge fall protection

-

Is there a hoist area?

-

Hoist area fall protection

-

Is work being done over dangerous equipment?

-

Work over dangerous equipment under 6' fall protection

-

Work over dangerous equipment over 6' fall protection

-

Is roof work being done?

-

ROOF WARNING LINES

34-39" above working surface

must be 6' from edge

must be 10' from edge when machinery is present -

Low slope fall protection

- guardrail

- safety net

- PFAS

- warning line/guard rail

- warning line/safety net

- warning line/PFAS

- warning line/safety monitir

- *safety monitor

- N/A

-

Steep slope fall protection

-

Is precast erection happening?

-

Precast erection fall protection

MOTOR VEHICLES, MECHANIZED EQUIPMENT SUBPART O

-

Does Woodruff or subs have heavy machinery on site?

-

Heavy machinery safety checklist

vehicle

-

Who's machine?

-

make

-

model

-

ID number

-

rental company

-

make

-

model

-

head lights

-

brake lights

-

glass

-

wipers

-

horn

-

back up alarm

-

mirrors

-

seat belts

-

manuals

-

capacity chart

-

hatches and guards in place

-

Action taken or needed

-

photos

EXCAVATIONS SUBPART P

-

Is there an excavation or trench on site at this time?

-

What is the name of the company excavating/trenching or working in excavation/trench?

-

Has Iowa One Call been given 48 hour notification?

-

Have adjacent structures been stabilized or supported?

-

Are barricades and or fences in place 6' from edge or hole monitoring being done?

-

Are there bridges or walkways over the excavation/trench?

-

Are they equipped with a guardrail?

-

Is there a warning system in place for vehicles?

-

Are there workers in the excavation/trench?

-

Name and Company of the competent person

-

Are inspections being conducted daily or as conditions warrant by the competent person?

-

All workers must exit the excavation/trench until this is corrected.

-

Are inspection logs current?

-

Is the excavation/trench over 4' deep?

-

What kind of protective system is in place?

- sloping

- benching

- shoring

- trench box

- none

-

All workers must exit the excavation/trench until this is corrected.

-

Is a 2' buffer maintained around the perimeter of the excavation/trench?

-

All workers must exit the excavation/trench until this is corrected.

-

Is proper ingress and egress provided within 25' of each employee?

-

All workers must exit the excavation/trench until this is corrected.

-

Is the excavation greater than 20' in depth?

-

Name of PE who designed the protective system

-

Is there a protective system in place?

-

Has the competent person listed above determined there is no indication of a possible cave-in?

-

All workers must exit until the competent person has determined there is no indication of a possible cave-in.

-

Is a 2' buffer maintained around excavation?

-

All workers must exit until the competent person has determined there is no indication of a possible cave-in.

-

photos

-

Action taken or needed

CONCRETE AND MASONRY SUBPART Q

CONRETE

-

Does Woodruff have concrete work on site?

-

Fall protection

- safety net

- PFAS

- positioning device

- N/A

-

Are the drawings or plans, including all revisions, for the jack layout, formwork (including shoring equipment), working decks, and scaffolds, available in site?

-

Is reinforcing steel protected?

-

Is ground personnel cleared out of overhead route/location of concrete bucket?

-

Do concrete buckets have safety devices to prevent accidental dumping?

-

Are powered troweling machines equipped with safety release to prevent auto pilot?

-

photos

-

Action taken or needed

MASONRY

-

Does Woodruff have masonry work on site?

-

Fall protection for overhand brick laying

-

Fall protection for overhand brick laying reaching 10" below

-

Has the limited access zone been properly established?

-

The limited access zone shall be established prior to the start of construction of the wall.

The limited access zone shall be equal to the height of the wall to be constructed plus four feet, and shall run the entire length of the wall.

The limited access zone shall be established on the side of the wall which will be unscaffolded.

The limited access zone shall be restricted to entry by employees actively engaged in constructing the wall. No other employees shall be permitted to enter the zone.

The limited access zone shall remain in place until the wall is adequately supported. -

Are walls over 8' braced?

-

photos

-

Action taken or needed

STEEL ERECTION SUBPART R

-

Does Woodruff have steel erection on site?

-

Fall protection

-

photos

-

Action taken or needed

STAIRWAYS AND LADDERS SUBPART X

-

Are there slippery conditions on stairs?

-

Are all ladders in good condition?

-

damaged ladder(s) have been removed from service and tagged to prevent use

-

Are ladders being used properly?

UNSAFE LADDER USAGE

-

WHO, WHAT, WHERE, WHY, HOW

-

Are changes in 19" or more equipped with a step?

-

Are stairs with 4 or more risers/higher than 30" equipped with a hand rail and stairrail system along unprotected side?

-

The height of handrails shall be not more than 37 inches nor less than 30 inches from the upper surface of the handrail to the surface of the tread, in line with the face of the riser at the forward edge of the tread.

Stairrails installed shall be not less than 36 inches (91.5 cm) from the upper surface of the stairrail system to the surface of the tread, in line with the face of the riser at the forward edge of the tread.

Midrails, when used, shall be located at a height midway between the top edge of the stairrail system and the stairway steps. -

photos

-

Action taken or needed

CRANES AND DERRICKS SUBPART CC

-

Are cranes being used by Woodruff or subs?

-

Is the cab in order?

-

Is the swing radius delineated and protected?

-

Is work being done at a safe distance from overhead power lines?

-

Does the crane have a proper footing?

-

Is the crane equipped with outriggers?

-

Are they fully deployed?

-

Are loads calculated and properly rigged?

-

Is overhead path planned and workers alerted?

-

Is the inspection log with the crane and up to date?

-

Are load capacities in the cab?

Near Miss Reporting

-

Near misses