Title Page

-

Assessment Number

-

Description of area or process being assessed

-

Site/Building

-

Conducted by:

-

Conducted on

Equipment, Process, Environment and Person

Guidance

-

Aim to control the hazards identified in this risk assessment - a score near to zero is the aim - each point scored increases the risk.

Add follow up actions against each red score point to mitigate the risk.

Type of equipment in use

-

Select which equipment is in use (ideally do a separate assessment for each additional piece of access equipment)

- Ladder

- Mobile Steps

- Mobile Elevated Work Platform (MEWP)

- Scaffold

- Stairs

- Platform

- Fork Lift Cage

- Hop up Step

- Above Trench/Hole in ground

- Other (Specify)

-

Describe type of access equipment being used

-

Serial or Asset Number

-

Photograph of access equipment

Environmental conditions

-

Select all environmental conditions that apply (each scores one point)

- Wet

- Slippery

- Cold

- Windy

- Unstable surface

- Poor visibility

- Other (Specify)

-

Describe environmental condition

-

Select what elements the process involves from the list:

- Carrying heavy loads up or down

- Lengthy periods at height

- Use of tools and items at height

- Carrying bulky loads up or down

- Other (Specify)

-

Describe process element

Task and location

-

Describe the task being carried out

-

Can the working at height task be avoided?

-

Consider alternative processes (for example by using extendable tools, moving items to ground level etc)

-

Is the task near to a doorway (which might mean people could walk into access equipment or doors could knock the person from the access equipment)

-

Is the task near to a traffic route (which might mean vehicles could impact the access equipment)

-

Is the task near to a pedestrian route (which might mean items dropped could impact on pedestrians)

-

How long is the working at height to take place for? How long with the worker be at height?

-

How High in Metres is the work?

Information about the Person working at height

-

Is the user trained and competent to use the access equipment?

-

Is the user trained wearing suitable clothing and footwear?

-

Is the user strong enough of sufficient height and reach etc to carry out the task?

-

Is the user too heavy for the duty of the equipment?<br><br>(Consider the user + the load weights combined)

-

Does the user have special requirements (disabled, pregnant, young etc) ?

-

Enter the actions to be implemented to mitigate any risks

Getting worker safely to where they need to work at height

-

Guidance:

Make sure that the equipment can be accessed without risking the worker's safety (for example having a safe method for getting onto the back of containers or lorries, or climbing up onto platforms etc)

Is the worker carrying loads of materials or equipment when accessing the equipment which could compromise their safety? -

Are there hazards related to accessing the area to work at height?

-

Describe the hazard and how the worker might be harmed

-

Who might be harmed?

- Operator

- Production Engineer

- Maintenance

- Visitor

- Driver

- Warehouse Operative

- Customer

- Surveyor

- Installation Engineer

- Other

-

You selected other, please specify:

-

What controls already exist?

-

What is the likelihood of harm?

-

What is the severity?

-

Total Score of likelihood x severity

- 1 - No Action is required

- 2 - No Action is required

- 3 - No action is required

- 4 - No action is required

- 5 - Planned action within 60 days

- 6 - Planned action within 60 days

- 8 - Planned action within 60 days

- 9 - Planned action within 60 days

- 10 - Planned action within 30 days

- 12 - Planned action within 30 days

- 15 - STOP PROCESS - Action required immediately

- 16 - STOP PROCESS - Action required immediately

- 20 - STOP PROCESS - Action required immediately

- 25 - STOP PROCESS - Action required immediately

-

Risks are broadly acceptable with current control measures, and should be monitored to ensure that this level does not change - MARK SAFE

-

Risks could be improved with additional control measures if reasonably practical (see hierarchy of control) - MARK AT RISK

-

Risks are tolerable short term, but action is REQUIRED To improve within the timescale defined MARK AT RISK

-

Risks are intolerable and additional control are REQUIRED to improve it immediately. Process must be stopped until control measures are introduced MARK AT RISK

-

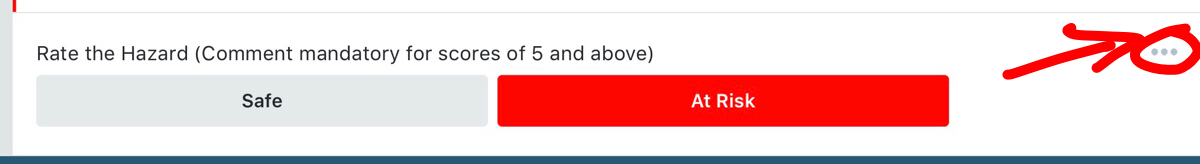

Rate the Hazard (Comment mandatory for scores of 5 and above)

Suitability of the access equipment for the task

-

Guidance:

Is the equipment suitable for the task - for example are ladders long enough to reach without standing on the top rung, is the duration such that a platform or scaffold would be better than an ladder? Is the access equipment strong enough for the task (considering the loads that it might carry)? Do workers have to reach excessively when using the equipment?

take into account the factors such as working environmental conditions, Nature, frequency and duration of the task and the risks to everyone where the equipment will be used

'

Is the equipment stable and secure - are ladders tied off and footed for example, are platforms on solid level ground?

The HSE offer guidance on type of equipment to use on the on line Work at Height Access Information Toolkit (WAIT) -

Link: (internet access required)

http://www.hse.gov.uk/work-at-height/wait/wait-tool.htm -

Are there hazards related to the suitability of the equipment being used for the task? <br>

-

Describe the hazard and how the worker might be harmed

-

Who might be harmed?

- Operator

- Production Engineer

- Maintenance

- Visitor

- Driver

- Warehouse Operative

- Customer

- Surveyor

- Installation Engineer

- Other

-

You selected other, please specify:

-

What controls already exist?

-

What is the likelihood of harm?

-

What is the severity?

-

Total Score of likelihood x severity

- 1 - No Action is required

- 2 - No Action is required

- 3 - No action is required

- 4 - No action is required

- 5 - Planned action within 60 days

- 6 - Planned action within 60 days

- 8 - Planned action within 60 days

- 9 - Planned action within 60 days

- 10 - Planned action within 30 days

- 12 - Planned action within 30 days

- 15 - STOP PROCESS - Action required immediately

- 16 - STOP PROCESS - Action required immediately

- 20 - STOP PROCESS - Action required immediately

- 25 - STOP PROCESS - Action required immediately

-

Risks are broadly acceptable with current control measures, and should be monitored to ensure that this level does not change - MARK SAFE

-

Risks could be improved with additional control measures if reasonably practical (see hierarchy of control) - MARK AT RISK

-

Risks are tolerable short term, but action is REQUIRED To improve within the timescale defined MARK AT RISK

-

Risks are intolerable and additional control are REQUIRED to improve it immediately. Process must be stopped until control measures are introduced MARK AT RISK

-

Rate the Hazard (Comment mandatory for scores of 5 and above)

Condition of the access equipment

-

Guidance:

Is equipment (for example scaffolding) assembled and installed in accordance with manufacturer's instructions and industry guidelines?

Note Where the Safety of the equipment depends on how it has been installed, then it MUST be inspected in that position by a competent person BEFORE IT IS USED.

- Working platforms which are used for construction and which workers could fall from more than 2 metres must be inspected by a competent person after assembly in position, after any event affecting its stability and at intervals not exceeding 7 days

Is the equipment exposed to conditions that will allow it to deteriorate and result in a dangerous situation?

Is equipment inspected at regular intervals? (Including inspecting when something occurs which might affect it's stability or safety (weather, accidental damage etc)

Are statutory inspection records available for:

- Fixed (e.g. Scaffold around building)

- Mobile (MEWP or Scaffold Tower)

- Ladders/Steps

Is rented equipment (e.g. MEWP) accompanied by a clear indication as to when the last thorough examination has been completed? -

Are there hazards related to the condition of the equipment being used for the task? <br>

-

Describe the hazard and how the worker might be harmed

-

Who might be harmed?

- Operator

- Production Engineer

- Maintenance

- Visitor

- Driver

- Warehouse Operative

- Customer

- Surveyor

- Installation Engineer

- Other

-

You selected other, please specify:

-

What controls already exist?

-

What is the likelihood of harm?

-

What is the severity?

-

Total Score of likelihood x severity

- 1 - No Action is required

- 2 - No Action is required

- 3 - No action is required

- 4 - No action is required

- 5 - Planned action within 60 days

- 6 - Planned action within 60 days

- 8 - Planned action within 60 days

- 9 - Planned action within 60 days

- 10 - Planned action within 30 days

- 12 - Planned action within 30 days

- 15 - STOP PROCESS - Action required immediately

- 16 - STOP PROCESS - Action required immediately

- 20 - STOP PROCESS - Action required immediately

- 25 - STOP PROCESS - Action required immediately

-

Risks are broadly acceptable with current control measures, and should be monitored to ensure that this level does not change - MARK SAFE

-

Risks could be improved with additional control measures if reasonably practical (see hierarchy of control) - MARK AT RISK

-

Risks are tolerable short term, but action is REQUIRED To improve within the timescale defined MARK AT RISK

-

Risks are intolerable and additional control are REQUIRED to improve it immediately. Process must be stopped until control measures are introduced MARK AT RISK

-

Rate the Hazard (Comment mandatory for scores of 5 and above)

-

Guidance:

Is equipment (for example scaffolding) assembled and installed in accordance with manufacturer's instructions and industry guidelines?

Note Where the Safety of the equipment depends on how it has been installed, then it MUST be inspected in that position by a competent person BEFORE IT IS USED.

- Working platforms which are used for construction and which workers could fall from more than 2 metres must be inspected by a competent person after assembly in position, after any event affecting its stability and at intervals not exceeding 7 days

Is the equipment exposed to conditions that will allow it to deteriorate and result in a dangerous situation?

Is equipment inspected at regular intervals? (Including inspecting when something occurs which might affect it's stability or safety (weather, accidental damage etc)

Are statutory inspection records available for:

- Fixed (e.g. Scaffold around building)

- Mobile (MEWP or Scaffold Tower)

- Ladders/Steps

Is rented equipment (e.g. MEWP) accompanied by a clear indication as to when the last thorough examination has been completed?

Hazards relating to working with tools and materials at height

-

Guidance:

Are there appropriate measures in place to prevent materials or objects falling (for example mesh, barriers, toe boards etc)

If it is not reasonably practical to stop objects or materials falling, are there suitable measures to make sure no-one can be injured? (E.g. Exclusion zones top keep people away)

Is it possible to disturb items./materials whilst working at height that could fall? (For example product on racking, tiles, etc) -

Are there hazards related to the working with tools and materials at height<br>

-

Describe the hazard and how the worker might be harmed

-

Who might be harmed?

- Operator

- Production Engineer

- Maintenance

- Visitor

- Driver

- Warehouse Operative

- Customer

- Surveyor

- Installation Engineer

- Other

-

You selected other, please specify:

-

What controls already exist?

-

What is the likelihood of harm?

-

What is the severity?

-

Total Score of likelihood x severity

- 1 - No Action is required

- 2 - No Action is required

- 3 - No action is required

- 4 - No action is required

- 5 - Planned action within 60 days

- 6 - Planned action within 60 days

- 8 - Planned action within 60 days

- 9 - Planned action within 60 days

- 10 - Planned action within 30 days

- 12 - Planned action within 30 days

- 15 - STOP PROCESS - Action required immediately

- 16 - STOP PROCESS - Action required immediately

- 20 - STOP PROCESS - Action required immediately

- 25 - STOP PROCESS - Action required immediately

-

Risks are broadly acceptable with current control measures, and should be monitored to ensure that this level does not change - MARK SAFE

-

Risks could be improved with additional control measures if reasonably practical (see hierarchy of control) - MARK AT RISK

-

Risks are tolerable short term, but action is REQUIRED To improve within the timescale defined MARK AT RISK

-

Risks are intolerable and additional control are REQUIRED to improve it immediately. Process must be stopped until control measures are introduced MARK AT RISK

-

Rate the Hazard (Comment mandatory for scores of 5 and above)

Hazards relating to working near fragile surfaces

-

Guidance:

Are there fragile surfaces near the working area. Is there potential for any of:

- Leaning equipment against fragile surfaces which could give way

- Worker supporting their weight on fragile surfaces

- Worker could walk on or traverse fragile surfaces

- Securing equipment to fragile surfaces

Fragile surfaces could be: Roof lights, fibre panels, corroded metal, cement board panels slates and tiles, glass panels, rotting wood/chipboard etc -

Are there hazards related fragile surfaces nearby<br>

-

Describe the hazard and how the worker might be harmed

-

Who might be harmed?

- Operator

- Production Engineer

- Maintenance

- Visitor

- Driver

- Warehouse Operative

- Customer

- Surveyor

- Installation Engineer

- Other

-

You selected other, please specify:

-

What controls already exist?

-

What is the likelihood of harm?

-

What is the severity?

-

Total Score of likelihood x severity

- 1 - No Action is required

- 2 - No Action is required

- 3 - No action is required

- 4 - No action is required

- 5 - Planned action within 60 days

- 6 - Planned action within 60 days

- 8 - Planned action within 60 days

- 9 - Planned action within 60 days

- 10 - Planned action within 30 days

- 12 - Planned action within 30 days

- 15 - STOP PROCESS - Action required immediately

- 16 - STOP PROCESS - Action required immediately

- 20 - STOP PROCESS - Action required immediately

- 25 - STOP PROCESS - Action required immediately

-

Risks are broadly acceptable with current control measures, and should be monitored to ensure that this level does not change - MARK SAFE

-

Risks could be improved with additional control measures if reasonably practical (see hierarchy of control) - MARK AT RISK

-

Risks are tolerable short term, but action is REQUIRED To improve within the timescale defined MARK AT RISK

-

Risks are intolerable and additional control are REQUIRED to improve it immediately. Process must be stopped until control measures are introduced MARK AT RISK

-

Rate the Hazard (Comment mandatory for scores of 5 and above)

Hazards relating to conducting work at height

-

Guidance:

Are there hazards relating to hitting the worker head on joists, shelving, light fittings etc

Are there hazards relating to over-reaching

Are there hazards relating to using power tools

Does the user always have three point contact whilst working at height on ladders

Is there possible contact with overhead and hidden power cables

Is there a possibility of falling from height (may require fall arrest, barriers etc as a control) -

Are there hazards related to carrying out the work at height?<br>

-

Describe the hazard and how the worker might be harmed

-

Who might be harmed?

- Operator

- Production Engineer

- Maintenance

- Visitor

- Driver

- Warehouse Operative

- Customer

- Surveyor

- Installation Engineer

- Other

-

You selected other, please specify:

-

What controls already exist?

-

What is the likelihood of harm?

-

Guidance:

Are there hazards relating to hitting the worker head on joists, shelving, light fittings etc

Are there hazards relating to over-reaching

Are there hazards relating to using power tools

Does the user always have three point contact whilst working at height on ladders

Is there possible contact with overhead and hidden power cables -

What is the severity?

-

Total Score of likelihood x severity

- 1 - No Action is required

- 2 - No Action is required

- 3 - No action is required

- 4 - No action is required

- 5 - Planned action within 60 days

- 6 - Planned action within 60 days

- 8 - Planned action within 60 days

- 9 - Planned action within 60 days

- 10 - Planned action within 30 days

- 12 - Planned action within 30 days

- 15 - STOP PROCESS - Action required immediately

- 16 - STOP PROCESS - Action required immediately

- 20 - STOP PROCESS - Action required immediately

- 25 - STOP PROCESS - Action required immediately

-

Risks are broadly acceptable with current control measures, and should be monitored to ensure that this level does not change - MARK SAFE

-

Risks could be improved with additional control measures if reasonably practical (see hierarchy of control) - MARK AT RISK

-

Risks are tolerable short term, but action is REQUIRED To improve within the timescale defined MARK AT RISK

-

Risks are intolerable and additional control are REQUIRED to improve it immediately. Process must be stopped until control measures are introduced MARK AT RISK

-

Rate the Hazard (Comment mandatory for scores of 5 and above)

Hazards relating to emergency situations

-

Guidance:

Is there suitable provision for emergency and rescue for workers? - for example evacuation, medical emergency, falls

Consider all potential scenarios -

Are there hazards related to emergency provision<br>

-

Describe the hazard and how the worker might be harmed

-

Who might be harmed?

- Operator

- Production Engineer

- Maintenance

- Visitor

- Driver

- Warehouse Operative

- Customer

- Surveyor

- Installation Engineer

- Other

-

You selected other, please specify:

-

What controls already exist?

-

What is the likelihood of harm?

-

Guidance:

Are there hazards relating to hitting the worker head on joists, shelving, light fittings etc

Are there hazards relating to over-reaching

Are there hazards relating to using power tools

Does the user always have three point contact whilst working at height on ladders

Is there possible contact with overhead and hidden power cables -

What is the severity?

-

Total Score of likelihood x severity

- 1 - No Action is required

- 2 - No Action is required

- 3 - No action is required

- 4 - No action is required

- 5 - Planned action within 60 days

- 6 - Planned action within 60 days

- 8 - Planned action within 60 days

- 9 - Planned action within 60 days

- 10 - Planned action within 30 days

- 12 - Planned action within 30 days

- 15 - STOP PROCESS - Action required immediately

- 16 - STOP PROCESS - Action required immediately

- 20 - STOP PROCESS - Action required immediately

- 25 - STOP PROCESS - Action required immediately

-

Risks are broadly acceptable with current control measures, and should be monitored to ensure that this level does not change - MARK SAFE

-

Risks could be improved with additional control measures if reasonably practical (see hierarchy of control) - MARK AT RISK

-

Risks are tolerable short term, but action is REQUIRED To improve within the timescale defined MARK AT RISK

-

Risks are intolerable and additional control are REQUIRED to improve it immediately. Process must be stopped until control measures are introduced MARK AT RISK

-

Rate the Hazard (Comment mandatory for scores of 5 and above)