Information

-

Job Number

-

Ship

-

Location

- NAVSTA

- NASSCO

- BAE

- NASNI

- CMSD

-

Conducted on

-

Auditor

- Ron Pivaro

- Juan Saludes

- Henry Huffman

- Carlos Sosa

Administrative

-

Site specific emergency procedures reviewed?

-

All personnel posses OSHA 10 hour card?

-

Does job box and equipment have CORRECT POC's?

-

Do boom lift and forklift operators have their training cards?

-

Is scaffold in good condition and GREEN TAGGED?

-

Any Confined Space entry to be coordinated?

-

Any hot work notifications required

-

Paint sample results reviewed?

-

Are any containment inspections required? (Usually for over water projects such as catwalks)

-

Is the first aid kit on site and fully stocked?

-

Is eye wash station or eye wash bottles on site?

PPE and Hand Tools

-

Safety glasses, hard hats, and ear plugs are always required on YYK jobs, is anyone currently not in compliance

-

Take a look at the crews steel toes boots, is any metal showing, is there sufficient heel depth and are the boots not ripped or torn

-

Take a look at a few of the crews hard hats to check suspension and for cracks. Review reasons and procedure with employee

-

Is all protective equipment maintained in a sanitary condition and ready for use, such as respirators in bags

-

Do you have eye washing facilities within the work area?

-

Has this job foreman been directed to ensure and ENFORCE proper use of PPE?

-

Confirm hand tools currently being used are in good condition by talking to users, visually check as well.

-

Review bad inform employees of hazards related to faulty or improperly used equipment

-

Foreman will ensure PPE IS IN USE AT ALL TIMES

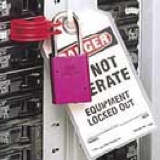

Electrical

-

Are portable electrical tools and equipment grounded or of the double insulated type?

-

Are electrical appliances such as vacuum cleaners and blowers grounded?

-

Do extension cords being used have a grounding conductor?

-

Ensure multiple plug adapters are not in use

-

Check wiring and cords for fraying, cuts or deterioration and remove and replace promptly

-

In wet or damp locations, are electrical tools and equipment appropriate for the use or location or otherwise protected?

-

Are all disconnecting switches and circuit breakers labeled to indicate their use or equipment served?

-

Are all energized parts of electrical circuits and equipment guarded against accidental contact by approved cabinets or enclosures?

-

Is sufficient access and working space provided and maintained about all electrical equipment to permit ready and safe operations and maintenance?

-

Are all unused openings (including conduit knockouts) in electrical enclosures and fittings closed with appropriate covers, plugs or plates?

-

Are electrical enclosures such as switches, receptacles, junction boxes, etc., provided with tight-fitting covers or plates?

Walking, Tripping & Falling

-

Is this work in a bilge?

-

Has crew been briefed by safety department on dangers in bilge?

-

Are "DECK PLATES REMOVED" signs posted?

-

Are "RESTRICTED ACCESS YYK PERSONNEL ONLY" signs posted?

-

Are "CAUTION HOT STEAM PIPE" signs posted?

-

Is there sufficient lighting?

-

Are aisles and passageways kept clear?

-

Are holes in the deck or other walking surface covered or otherwise made safe?

-

Is there a safe clearance for walking in aisles where motorized or mechanical handling equipment is operating?

-

Are means available to clean and remove spilled materials immediately?

-

Are materials/equipment stored so that sharp projectiles will not interfere with the walkway?

-

Are changes of direction or elevations readily identifiable?

-

Are aisles or walkways that pass near moving or operating machinery, welding operations or similar operations arranged so employees will not be subjected to potential hazards?

-

Is adequate headroom provided for the entire length of any aisle or walkway? If not is tape, flags etc identifying hazardous areas

-

Are standard guardrails provided wherever aisle or walkway surfaces are elevated more than 30 inches above any adjacent floor or the ground?

-

Are bridges provided over pipes and similar hazards?

Portable Ladders

-

Have the ladders been inspected for damage?

-

Is the non-slip safety feet on each ladder in good condition?

-

Are ladder rungs and feet free of grease and oil?

-

If ladders are used to gain access to elevated platforms is the ladder extending 36" above the elevated surface?

-

Are portable ladders used with the base in place so that slipping will not occur, or it is lashed in place?

-

Are any ladders placed on boxes or other unstable bases to obtain additional height?

-

Is the ladder blocking any exit, hatch, scuttle doorway, etc.?

Compressors & Compressed Air

-

Is this a diesel compressor and if so is the APCD permit posted?

-

Are compressors equipped with pressure relief valves, and pressure gauges?

-

Is the belt drive system totally enclosed to provide protection for the front, back, top, and sides?

-

Are safety collars in place at all connectors?

-

Is it strictly prohibited to direct compressed air towards a person?

-

When using compressed air for cleaning, do employees use personal protective equipment?

-

Is it prohibited to use compressed air to clean up or move combustible dust if such action could cause the dust to be suspended in the air and cause a fire or explosion hazard?

-

Add signature

Hazardous Chemical Exposures

-

Are MSDS's on site?

-

Are employees aware of the potential hazards involving various chemicals stored or used in the workplace-- such as acids, bases, caustics, epoxies, and phenols?

-

Are employees prohibited from eating in areas where hazardous chemicals are present?

-

Are flammable or toxic chemicals kept in closed containers when not in use?

-

Are drums and containers stored on spill containment pallets or pans?

-

Are metal flammable storage drums grounded properly to prevent sparks and fire?

-

Is the HAZMAT locker labeled with POC's and in a secondary containment?

-

Are secondary labels available and being properly used?

-

Is sufficient ventilation in place?

-

Which type of respirator cartridge is required for this job?

-

Are those respirator cartridges on site in sufficient quantity?

-

Who is responsible for HAZMAT disposal?

-

Are sufficient labels available for disposal?

-

Are secondary containments in place?

-

Are compressed gas cylinders in use at job site?<br>If YES utilize

Spraying Operations

-

Is containment inspection required? (Usually on over water jobs such as a catwalk)

-

Is adequate ventilation assured before spray operations are started?

-

Is mechanical ventilation provided when spraying operation is done in enclosed areas?

-

When mechanical ventilation is provided during spraying operations, is it so arranged that it will not circulate the contaminated air?

-

Is the spray area free of hot surfaces?

-

Is the spray area at least 20 feet from flames, sparks, operating electrical motors and other ignition sources?

-

Are portable lamps used to illuminate spray areas suitable for use in a hazardous location?

-

Is approved respiratory equipment provided and used when appropriate during spraying operations?

-

Do solvents used for cleaning have a flash point of 100 F or more?

-

Is the spray area kept clean of combustible residue?

-

Are paint mixing and staging areas in a secondary containment?

-

Is foreman actively enforcing PPE policy particularly in regards to eye protection?

-

Foreman initials for PPE

Protection During Contamination Producing Operation & Maintaining Cleanliness During Job Period

-

3.1.1 Prior to installation accomplish an inspection of protective covering to identify the current condition of equipment and surface prep area?

-

3.1.1.1 Submit one legible copy in hard copy or electronic media of the result of inspection to supervisor, prior to beginning of contamination producing operation <br>**This must be signed by supervisor or ship force**

-

Install filter material on intake of supply and exhaust e d of ventilation system

-

Install double curtain baffles at the entrance of each access

-

Inspect the protective covering at the beginning of shift

-

Maintain cleanliness of work site daily

-

Remove protective covering and dispose of at completion

-

Add signature

Flammable & Combustible Materials

-

Are combustible scrap, debris and waste materials (I.e. oily rags) stored in covered metal receptacles and removed from the worksite promptly?

-

Are approved containers and tanks used for the storage and handling of flammable and combustible liquids?

-

Are all flammable liquid kept in closed containers when not in use (e.g. Parts cleaning tanks, pans)?

-

I liquified petroleum gas stored, handled and used in accordance with safe practices and standards?

-

Are all solvent wastes and flammable liquids kept in fire-resistant covered containers until they are removed from the worksite?

-

Is vacuuming used whenever possible rather than blowing or sweeping combustible dust?

-

Are employees trained in the use of fire extinguishers?

-

Are extinguishers free from obstructions or blockage?

-

Are all extinguishers serviced, maintained and tagged at intervals not to exceed one year?

-

Are safety cans used for dispensing flammable or combustible liquids at a point of use?

Auditor Notes and Signature

-

Notes and summary (if necessary)

-

Auditor

-

Signature