Information

-

Date

-

Project Number/Name

-

Safety Steward

-

Foreman

-

Field Superintendent

-

General Superintendent

-

Project Manager

-

Prepared by

-

Location

-

Risk Score

Operations

-

Operations at time of audit

1. Site, Lay Down Yard, and Storage Areas

-

1.01 Parking area identified and vehicles parked in an orderly fashion

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

1.02 Lay down areas and storage yards are organized

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

1.03 Adequate and sanitary restrooms available

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

1.04 Does wildlife present a risk

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

1.05 Housekeeping

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

1.06 Adequate containers provided for waste

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

1.07 Welding Rod Cans Disposed Of

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

1.08 Drinking water available

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

1.09 Trip Hazards

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

1.10 Site Security

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

1.11 Tool vans and trailers monitored

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

1.12 Safety signs in place

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

1.13 SDS - Hazard Communication

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

1.14 Materials are in their original containers or if not are stored in properly labelled containers

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

1.15 Designated Smoking Signs Posted As Needed

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

1.16 Smoking in designated areas only and cigarette butts disposed of properly

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

1.17 Open Holes

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

1.18 Other

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

2. General Safety Practices

-

2.01 Quality JSA's completed with all required signatures

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

2.02 Prejob Safety Meetings conducted

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

2.03 Pre-Task Plans Followed

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

2.04 Hazards Recognized

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

2.05 First Aid kits in office/tool trailer with adequate and non-expired contents<br>

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

2.06 PSSP / Emergency Response Plan posted

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

2.07 Adequate phone signal for emergency communication

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

2.08 Adequate number and contents of spill kits on site (Including pads and buoys)

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

2.09 Stop work authority utilized and Good Catches are being submitted

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

2.10 Self audits being conducted

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

2.11 Pinch Points and Proper Hand Position

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

2.12 Proper Lifting/Pushing/Pulling/Turning/Reaching Techniques

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

2.13 Body Position Hazards (Line of Fire, Overhead Hazards)

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

2.14 BES minimum required PPE in use (Hard hat, safety toe boots, safety glasses, gloves)

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

2.15 Hearing Protection Available

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

2.16 High visibility traffic safety vests

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

2.17 Respiratory Protection

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

2.18 Gas Detectors

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

2.19 Other

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

3. Tool Storage, Power and Hand Tools

-

3.01 Tool storage trailer is organized and walkways are free from trip hazards

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

3.02 All cords and hoses not in use are coiled and stored properly

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

3.03 All extension cords have been inspected, have not been modified, and are free of cuts or damage

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

3.04 Ladders have been inspected, are free of damage or cracks, and meet minimum OSHA weight requirement of 250 pounds (29 CFR 1926.1053)

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

3.05 All harnesses and fall protection systems inspected and are in serviceable condition

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

3.06 Power Tools inspected and are in serviceable condition (not modified, factory guards in place, cords in good condition, etc...)

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

3.07 Hand tools are not modified or show evidence of "cheater bar" use

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

3.08 Proper tools are available and utilized on the job

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

3.09 Propane bottles are not stored inside tool trailer/connex

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

3.10 Other

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

4. Hot Work & Fire Protection

-

4.01 Fire extinguishers provided and inspected

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

4.02 Flammable liquid storage

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

4.03 Designated welding and cutting areas

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

4.04 Housekeeping, clutter or combustible materials in Hot Work area<br>

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

4.05 Hot Work Permit

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

4.06 Welding / Cutting hoses and cords

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

4.07 Gauges

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

4.08 Cylinders

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

4.09 Acetylene cylinder storage

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

4.10 Labeling

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

4.11 Other

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

5. Excavation & Trenching

-

5.01 Overhead Power Lines Identified

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

5.02 Goal Posts In Place as Required

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

5.03 Current 811 Locate

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

5.04 Line Crossings on Job

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

5.05 Proper sloping / trench box

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

5.06 Proper Access Every 25 Feet

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

5.07 Spoil piles 2 feet from edge

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

5.08 Trench Box Manufacturing Data Posted

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

5.09 Ladders used properly in trenches

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

5.10 Trench box condition

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

5.11 Adequate trench guard / barrier

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

5.12 Trenching competent person present

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

5.13 Other

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

6. Fall Protection

-

6.01 100% tie-off over 4 feet

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

6.02 Scaffolding installed and inspected

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

6.03 Guard Rails

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

6.04 Harness / Personal fall protection

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

6.05 Other

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

7. Equipment: Track-Hoe, Loaders, Forklifts, etc....

-

Equipment

-

Add media

-

Equipment Type

-

ID#

-

7.01 Overall Operating Condition

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

7.02 Daily Equipment Inspection Completed (All deficiencies noted)

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

7.03 Slings, chokers, and safety latches on hooks

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

7.04 Seatbelts used at all times

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

7.05 Leaks

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

7.06 Spotter Present & Alert

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

7.07 Clutter in cab

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

7.08 Butter Bar With Rounded Edges (If Required)

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

7.09 Equipment Properly Secured

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

7.10 Other

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

7.11 Compressor Hoses Wired & Whip Checks Installed

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

7.12 Trailer decking

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

7.13 Lifting/Suspended Loads

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

8. Special Operations

-

8.01 Traffic Control

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

8.02 Confined Space Operations

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

8.03 Crane Operations

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

8.04 Other

-

Hazard Type

- People

- Environment

- Assets

- Reputation

-

Risk Score

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

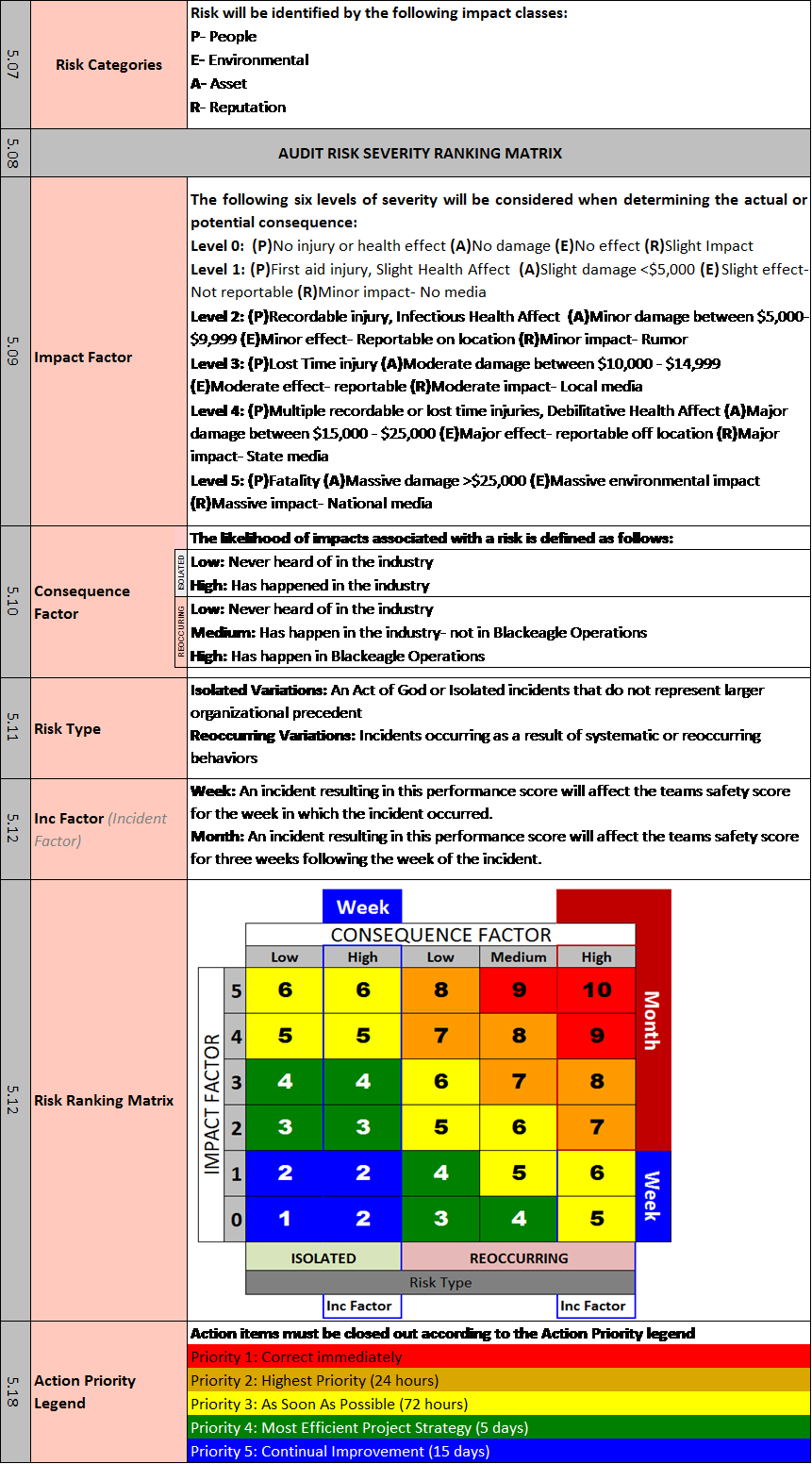

Risk Severity Matrix