Information

-

Audit Title

-

Business Stream

-

Document No.

-

Conducted on

-

Location

-

Personnel

PURPOSE

-

This checklist enables anybody to test the effectiveness of the WIS safety management system implementation at a Branch / Department. It also assists in identifying common hazards and HSE improvement opportunities.

INSTRUCTIONS

-

1. Familiarise yourself with the contents of this document (it will help with what to look for when walking the site).

2. Walk the site and talk to your host and other workers. Remember to positive reinforce and encourage safe work behaviours and role model good practices at all times.

3. Document your observations onto the Walk the Talk form and discuss them with your host. Focus on positives as well as any improvements.

4. Share the WTT findings (positive and improvement opportunities) with the branch workers.

5. Discuss your findings with the Branch / Department Manager and agree on required corrective actions - to be listed in the Corrective action summary in the last page and recorded in the online HSE management system. Encourage the site to enter their own corrective actions (as a form of consent to close out the corrective action over time).

6. On completion:

Record and upload completed WTT report in the online WTT register in PeopleSoft (or equivalent system) before the end of the month.

File your original in the Branch/Department GetSAFE files.

MOBILE EQUIPMENT LICENSE (forklift and stockpicker only)

-

Were operators able to show their licenses?

-

Were operators’ licenses recorded into site license register and details are up to date?

MOBILE EQUIPMENT PRE-START INSPECTIONS

-

Are pre-start inspections (5.23.3-5) conducted on daily basis on all forklifts and stockpickers?

-

Are Identified issues documented on checklist and addressed?

-

Are records of previous inspections kept at the branch (sighted inspection records for last 4 weeks)?

STOCKPICKER / ORDER PICKER

-

Are Height Safety and Fall Prevention Equipment (fall arrestor and harness) in good condition (no visible damage, wear and tear)?

-

Are fall arrestors and Harnesses inspected on regular basis (checklist 5.16.2)?

-

Are records of previous inspections kept at the branch (sighted last 2 inspection records)?

MOBILE EQUIPMENT TRAINING

-

Have all mobile equipment operators been trained on relevant Toolbox talks & SOPs?

-

Have all training competency forms been marked and training records kept at the branch?

-

Have all mobile equipment operators completed the annual Crown Forklift refresher training and records kept at the branch?

MOBILE EQUIPMENT PROCUREMENT

-

Was a procurement checklist (5.23.2) completed for any mobile equipment procured after May 2011 and kept on file at the branch?

KEY MANAGEMENT PROCESS

-

Is there a mobile equipment key register (5.23.1) maintained at the branch and signed by mobile equipment operators?

-

Is there any key/pass/code left on the mobile equipment when not in use?

MOBILE EQUIPMENT ATTACHMENT – jib attachment, drum lifter…

-

Are mobile equipment attachments certified for that particular piece of equipment (indicated on mobile equipment compliance plate)?

-

Have operators been trained on specific mobile equipment attachment SOP(s)?

Operator behavioural observation

-

3 Observed operator consistently complying with requirement during WTT,

2 Observed operator inconsistently complying with requirement during WTT OR minor issues observed,

1 Observed operator consistently not complying with requirement during WTT OR significant issue(s) observed,

NA not observed / not applicable

GETTING IN/OUT OF MOBILE EQUIPMENT

-

Operator uses 3 points of contact when getting in/out of mobile equipment

-

Operator fastens the seat belt once on the forklift (where available)

MOBILE EQUIPMENT DRIVING

-

Operator maintains a 3m exclusion zone between equipment and pedestrians

-

Operator reduces speed and sound horn at blind corners

-

Operator never drives with raised tynes

-

When front view is obstructed by carried load, operator drives the forklift in reverse at a reduced speed

-

Operator adapts travel speed based on environment and hazards

-

Operator stops mobile equipment and engages handbrake when required to interact with pedestrian standing within the 3m exclusion zone

TRUCK LOADING / UNLOADING

-

Prior to load/unload goods, operator assesses the load to ensure it is safe to load/unload

-

Operator ensures truck driver remains in the driver safety zone at all times during loading / unloading operations

-

Operator ensures forklift is suitable to load/unload goods (goods not too heavy / too long or too wide)

-

Operator does not try to load/unload unstable, unsecured, damaged goods

-

Operator stops truck loading / unloading when pedestrians enters exclusion zone

STOCKPICKER/ORDERPICKER

-

Operators are wearing a safety harness connected to the fall arrestor device at all times when operating equipment

-

Operators do not climb onto the pallet racking / pallet

-

Stockpicker cabin is lowered below 500mm from ground before travelling (except in stockpicker dedicated aisles)

TIME TO SHARE YOUR WTT FINDINGS WITH THE BRANCH STAFF

-

Feedback on observed behaviours and practices (good performance/behaviour & improvement opportunities) has been communicated to the staff (not just host) at the branch?

CORRECTIVE ACTION (CA) SUMMARY

-

Corrective action required?

-

Please enter CA description.

-

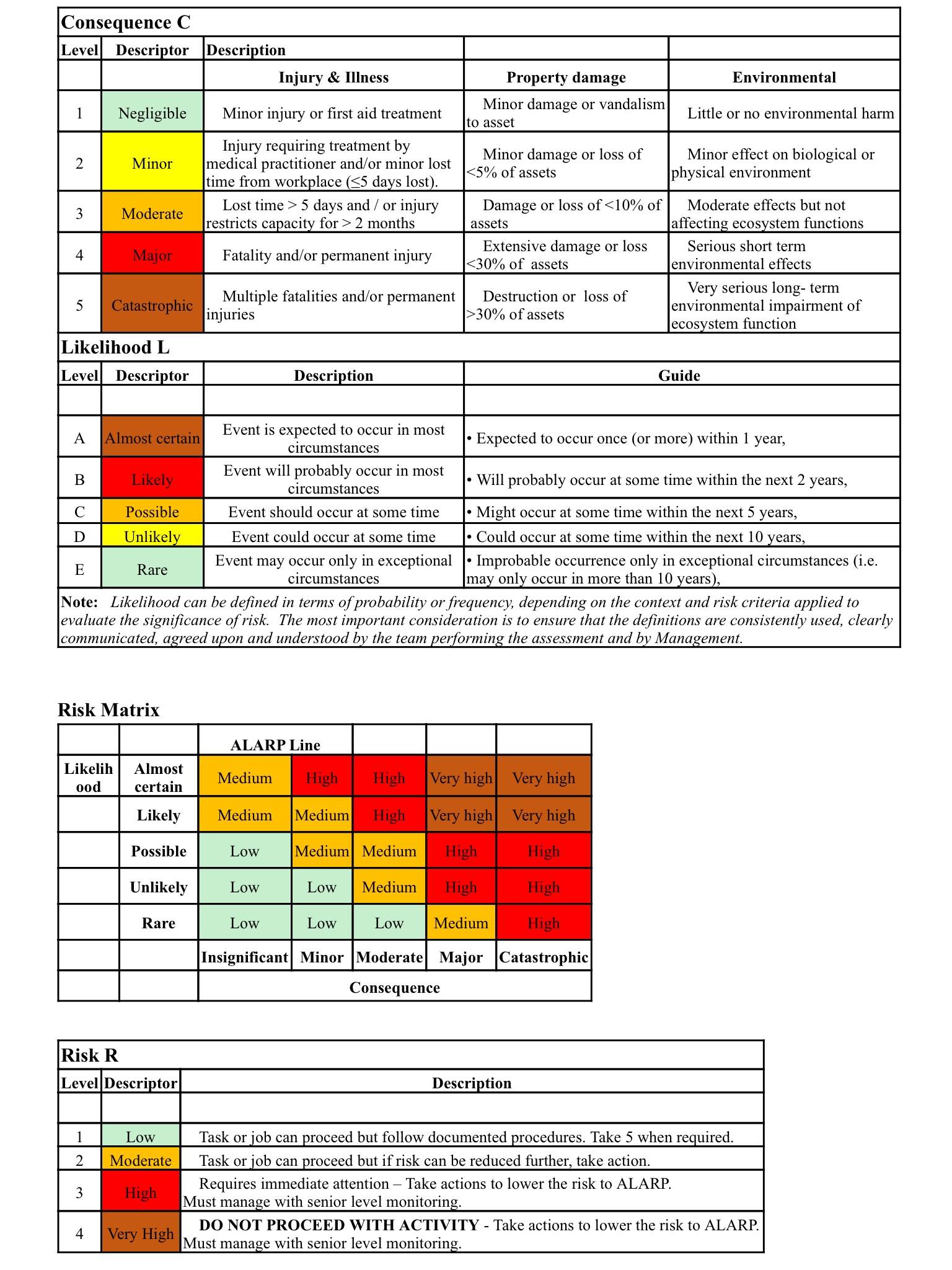

Use this Risk Management Matrix to assist.

-

(Enter Risk Level VH, H, M, L if No is selected)

-

Due Date

-

Corrective action required?

-

Please enter CA description.

-

(Enter Risk Level VH, H, M, L if No is selected)

-

Due Date

-

Corrective action required?

-

Please enter CA description.

-

(Enter Risk Level VH, H, M, L if No is selected)

-

Due Date

-

Corrective action required?

-

Please enter CA description.

-

(Enter Risk Level VH, H, M, L if No is selected)

-

Due Date

-

Corrective action required?

-

Please enter CA description.

-

(Enter Risk Level VH, H, M, L if No is selected)

-

Due Date

-

Corrective action required?

-

Please enter CA description.

-

(Enter Risk Level VH, H, M, L if No is selected)

-

Due Date

-

Corrective action required?

-

Please enter CA description.

-

(Enter Risk Level VH, H, M, L if No is selected)

-

Due Date

-

Corrective action required?

-

Please enter CA description.

-

(Enter Risk Level VH, H, M, L if No is selected)

-

Due Date

-

Corrective actions must be recorded in the online HSE management system

Any Other Comments?

-

Eg Did you observe any other hazards or unsafe acts that could result in an injury or incident?

-

Authorisation of Corrective Actions

-

Walk the Talk Completed by