Title Page

-

Document No.

-

Site conducted

-

Conducted on

-

Prepared by

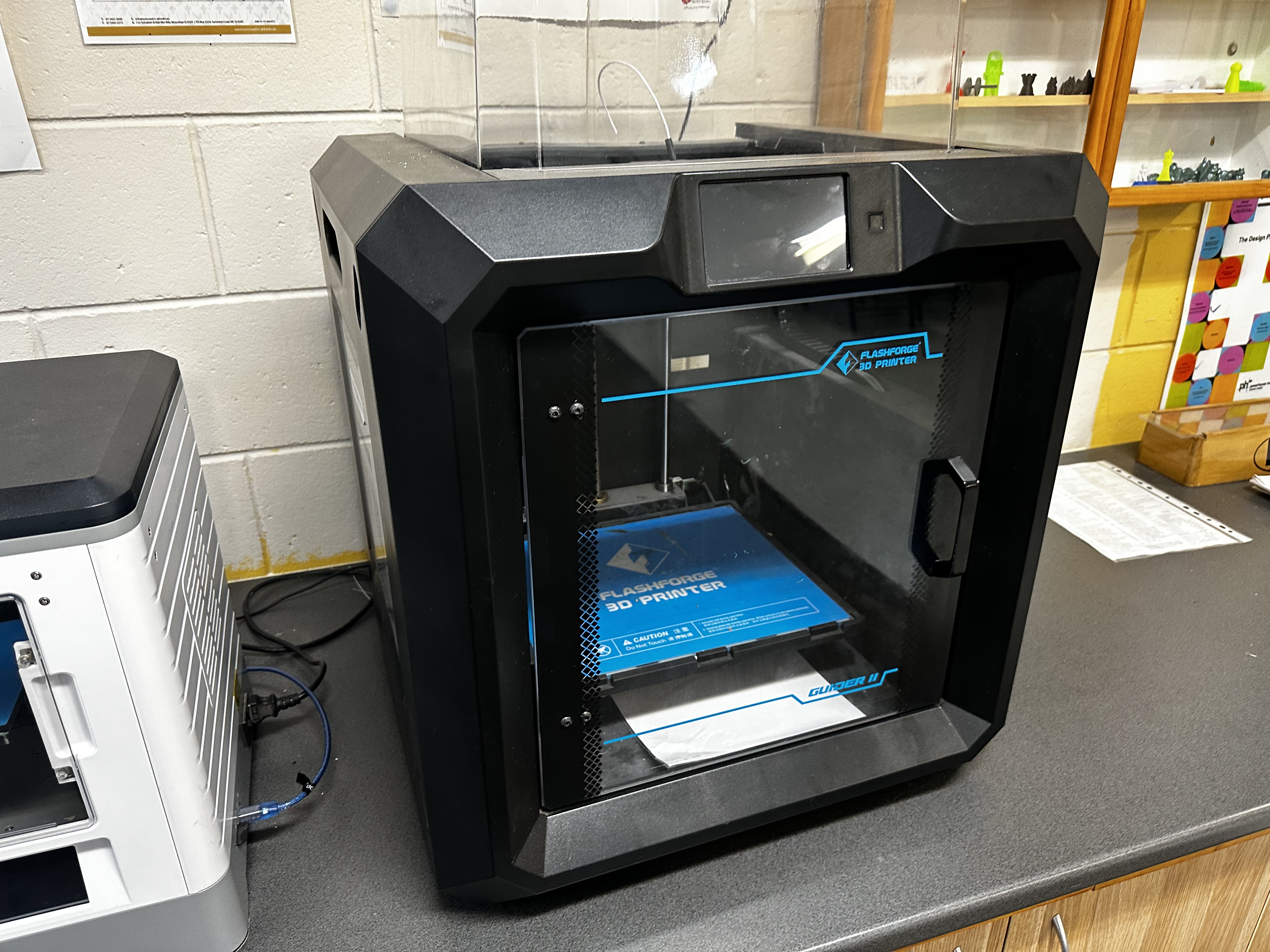

Asset

-

Have participating students completed the 3D Printing OnGuard module?

-

Have participating students been shown how to use the 3D Printing by a qualified teacher?

-

Is the area around and inside the printer clean?

-

Is the operators manual available?

-

Is the SOP sheet on display?

-

Are equipment Maintenance Records kept?

-

All guards are in place and in good working order for this plant/equipment?

-

Is Suitable personal protective equipment (PPE) is available to be used by all operators

-

Does This plant/equipment complies with relevant safety standards?

-

Are procedures in place for the disposal of all waste materials around all work spaces where 3D Printer activities are to be performed?

-

Is this 3D Printer equipment regularly maintained to help minimise the risk of exposures to these hazards?

-

Is there sufficient natural ventilation provided to the work area around the 3D Printer?

Electrical

-

Visual checks are made of the power leads, switches and plugs on the 3D Printer. Internal electrical wiring and/or switches should be isolated and guarded.

-

Electrical safety inspections, testing and tagging, etc. are completed regularly as per guidelines for all corded power equipment

-

Warning “Danger” tags (or similar) are affixed when the 3D Printer equipment under repair or maintenance preventing workers from using it.

Exposure

-

3D Printers are regularly cleaned and maintained to help minimise the risk of exposures to these hazards.

-

Hazardous substance risk assessments are completed for potentially toxic moulded plastic materials and for any toxic gasses and fumes resulting from the heating process.

Sign Off

-

Completed by

-

Sign