Title Page

-

Vehicle Registration

-

Model

-

Fleet no

-

Conducted on

-

Fitter

-

Milage

-

Chassis Hours

-

Superstructure Hours

Walkround

-

Check all lights (Amber beacons, driving lights, trailer lights, etc)

-

Check operation of horn

-

Check reflective markers

-

Check turn left Speaker

-

Check reversing alarm (must be white noise)

-

Check camera's (security and cleanliness)

-

Check condition of mirrors

-

Check condition or fit cross rail compliant stickers and FORS silver id sticker

-

Check general condition of exterior

-

Check spill kit (present and serviceable)

-

Check fire extinguisher (present, date no more than 1 year old, pressure, type,)

-

Check toolbox

-

Check Jump leads and nato sockets

Driving into the workshop

-

Check reverse camera picture

-

Check gauges and dials

-

Check Steering ball joints and linkages

-

Check steering box

-

Check torque rods

Chassis

-

Check outrigger feet security and stowage

-

Check outrigger rams and securing pins

-

Check outriggers and housings for cracks

-

check chassis spirit level for security

-

Check wheel bearing free play

-

Check king pins

-

Check suspension rams and pins

-

Check wheels for cracks

-

Remove brake drums and inspect brake lining wear

-

Check and adjust brakes

-

Replace reduction hub oil

-

Check and lubricate prop shafts

-

Check/Replace diff oil as applicable

-

Replace transfer box oil

-

Check Torque converter oil

-

Check Gearbox oil

-

Check clutch oil

-

Check clutch free play and operation

-

Check brake fluid level

-

Drain air recivers

-

Check air drier operation

-

Check pneumatic system for leaks

-

Check Hydraulic hoses and valve blocks for leaks and damage

-

Lubricate brake control pedal pivot pins

-

Check PTO operation

-

Check diff lock operation

-

Check transfer box low and high range selection

-

Check oil level in hydraulic pump drive gearbox

-

Check battery security and electrolyte level

-

Check operation of cab heater

-

Replace night heater fuel filter

-

Check hydraulic oil level

-

Grease all nipples

-

Top up auto lube grease

Chassis Engine

-

Replace engine oil

-

Replace oil filter

-

Replace fuel filters

-

Clean sediment Screens

-

Clean/Replace air filters as applicable

-

Clean breathers

-

Check radiator hoses (including oil cooler and intercooler)

-

Clean radiator

-

Check and adjust coolant strength to 50%

-

Check water pump and alternator bearings for play (including idlers)

-

Check belt tension/condition

-

Check security of engine mountings

-

Check condition and security of exhaust/manifold

-

Check operation and security of exhaust brake

-

Check emergency shut down system operation

-

Check condition of spark arrestors/silencers

Superstructure Engine

-

Replace engine oil

-

Replace oil filter

-

Replace fuel filter

-

Clean sediment screens

-

Clean/Replace air filters

-

Replace engine to pump coupling with new style @ 5000hrs

-

Check radiator hoses (including oil cooler and intercooler)

-

Clean radiator

-

Check and adjust coolant strength @ 50%

-

Check coolant level

-

Check water pump and alternator bearings (including idlers)

-

Check belt tension and condition

-

Check security of engine mountings

-

Check condition and security of exhaust/manifold

-

Check emergency shutdown operation

-

Check air dryer operation

Superstructure

-

Check jib fold winch gearbox oil

-

Check trolly winch gearbox oil

-

Check slew motor's gearbox oil

-

Check hoist winch gearbox oil

-

Check jib fold rope and rope slack mechanism

-

Check and Grease trolley sheaves

-

Check and grease jib sheaves and grease points (including Fly jibs)

-

Check main and fly jib bins

-

Check and grease hook block's sheaves

-

Check hook block safety catch and transport stowage position

-

Erect crane and adjust speed's as necessary

-

Check Aux crane operation and rope condition

-

Check hoist rope condition

-

Check trolley rope condition

-

Check erecting rope and sheaves

-

Luff crane and check self snap alarm

-

Check hoist and trolley limits in luff

-

Check correct operation of crane (including limits host, and trolley)

-

Lift known weight and check SLI for correct operation (including 90% and 100% cut outs)

-

Check audible and visual warning lights and Siren

-

Check correct operation of stretched jib

-

Adjust trolley rope tension as necessary

-

Check camera for security and operation

-

Check hydraulic oil level

-

Check cab heater for operation

-

Replace cab night heater fuel filter

-

Check panel indicator lamps (half rig, luff, 4 falls, etc)

-

Check working lamps

-

Check electrical cabinet for tidiness and security

-

Grease crane as per manufactures greasing schedule

Lift

-

Check whisker switch

-

Check slack rope switch

-

Check overload switch

-

Check condition and date of inertia reel

-

Lubricate and check operation of safety catch

-

Check date and condition of safety harness

-

Check condition of lift structure

Road Test

-

Check operation of retarder

-

Check operation of foot brakes

-

Check Parking brake operation

-

Check operation of rear/all wheel steering

-

Check coolant temperature

Rope Inspection

-

Main hoist including anchor

-

Auxiliary Hoist including anchor

-

Trolley including anchor

-

Erection including anchor

-

Jib Fold

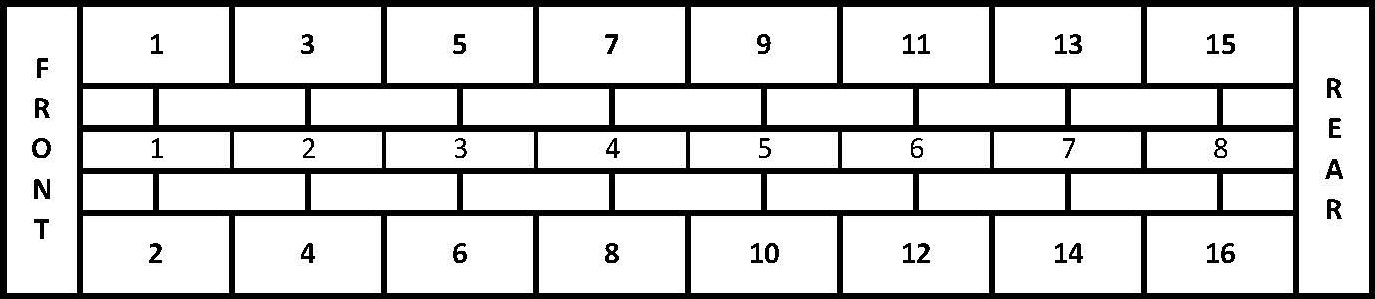

Tyre condition

-

-

1

-

Tread depth

-

Tyre pressure (BAR)

-

Condition

-

Condition

-

2

-

Tread Depth

-

Tyre pressure

-

Condition

-

Condition

-

3

-

Tread depth

-

Tyre pressure

-

Condition

-

4

-

Tread depth

-

Tyre pressure

-

Condition

-

5

-

Tread depth

-

Tyre pressure

-

Condition

-

6

-

Tread depth

-

Tyre pressure

-

Condition

-

7

-

Tread depth

-

Tyre pressure

-

Condition

-

8

-

Tread depth

-

Tyre pressure

-

Condition

-

9

-

Tread depth

-

Tyre pressure

-

Condition

-

10

-

Tread depth

-

Tyre pressure

-

Condition

-

11

-

Tread depth

-

Tyre pressure

-

Condition

-

12

-

Tread depth

-

Tyre pressure

-

Condition

-

13

-

Tread depth

-

Tyre pressure

-

Condition

-

14

-

Tread depth

-

Tyre pressure

-

Condition

-

15

-

Tread depth

-

Tyre pressure

-

Condition

-

16

-

Tread depth

-

Tyre pressure

-

Condition

DECLARATION AND FILTERS USED

-

ALL WHEEL NUTS TORQUED TO 650NM

-

NAME AND SIGNATURE OF PERSON TORQING WHEEL NUTS

-

ALL WHEEL NUT FITTED WITH COVER INDICATORS

-

NAME AND SIGNATURE OF PERSON CHECKING/FITTING WHEEL NUT COVER INDICATORS

-

REASON FOR NOT CHECKING/FITTING WHEEL NUT COVERS

-

NAME AND SIGNATURE OF PERSON CHECKING/FITTING WHEEL NUT COVER INDICATORS

-

Filters used

NAME AND SIGNATURE'S OF ALL FITTERS THAT COMPLETED THE SERVICE

-

Fitters Signature

-

Fitters Signature

-

Fitters Signature

-

Fitters Signature

-

Fitters Signature