Title Page

-

Customer Name:

-

Customer postcode:

-

Conducted on

-

Prepared by

-

Location

Pre-Installation photos

-

Photo of electrical pre-install area (this is where you intend to put the sub board and add any miscellaneous items such as henley blocks etc)

-

Photo of intended location of battery & inverter (See Job Pack as to where that is – and ensure customer is happy with this location)

-

Photo(s) of intended DC cable run (take multiple photos and annotate to show the run)

-

Photo(s) of intended AC cable run (take multiple photos and annotate to show the run)

-

Photo of Inverter SN:

-

Type of Battery

-

How many batteries are present?

-

How many batteries are on site?

-

Photo of Battery(s) SN:

-

Photo of Chint meter(s) SN:

-

Photo of Solar Generation meter (ID1 Meter) SN:

Inverter checklist

-

Make sure ALL covers are off when commissioning. Apply covers when finished

-

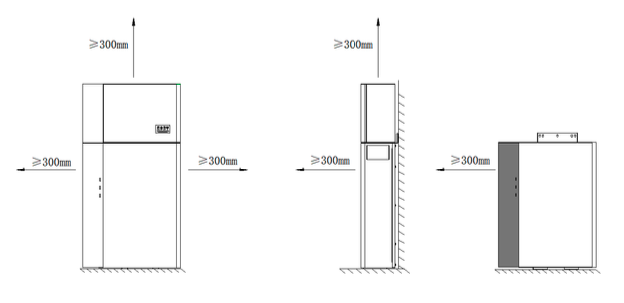

Spacing factor

-

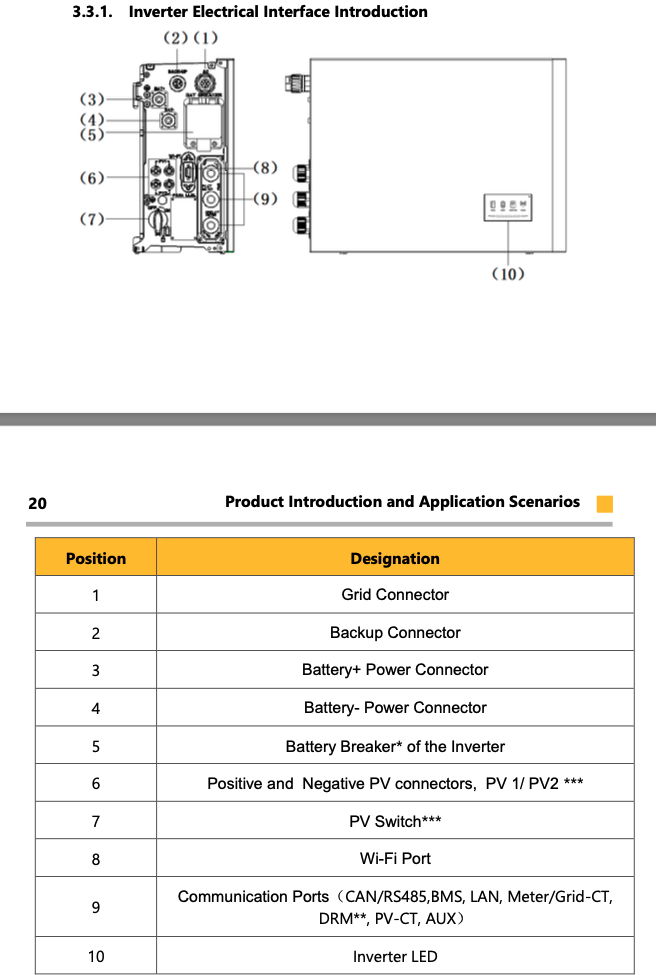

Terminals of the Alpha inverter

-

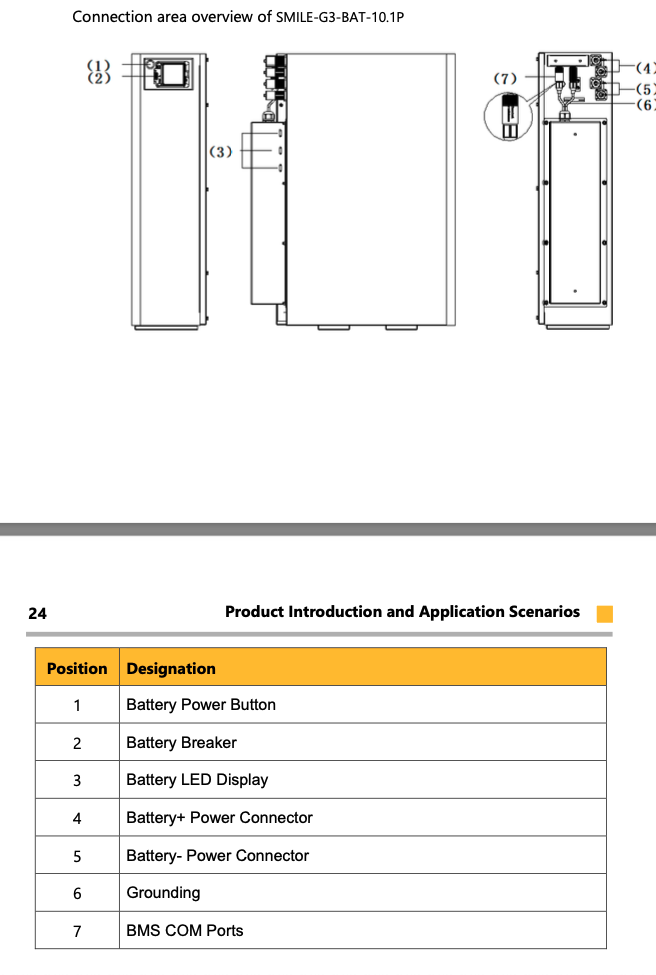

Battery connection area

-

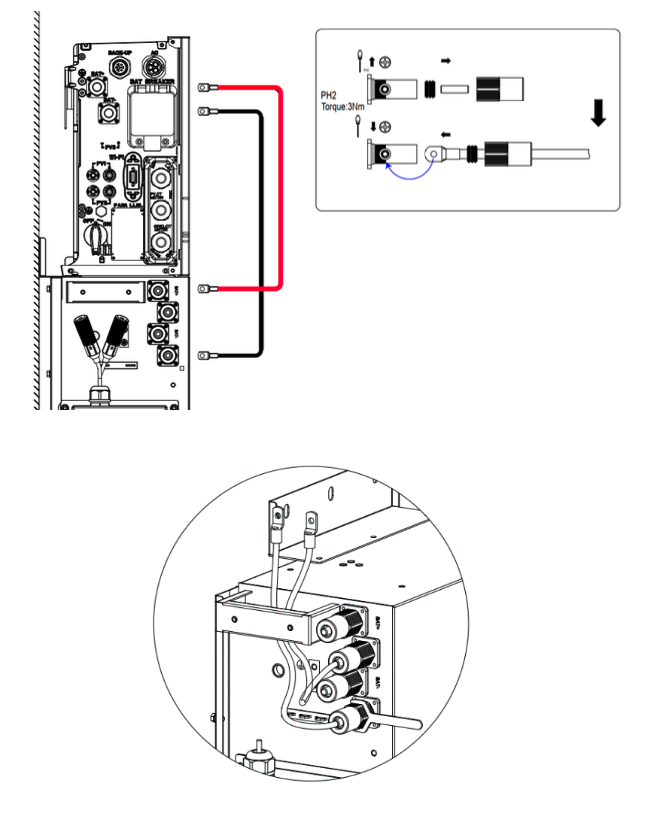

Inverter & Battery coupling

-

IMPORTANT: Terminal resistor must be installed on the last battery extension!

-

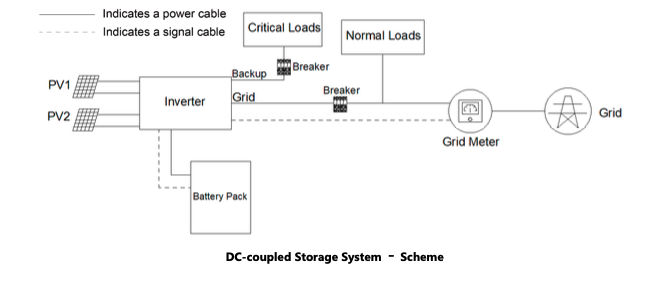

DC-coupled Storage System

-

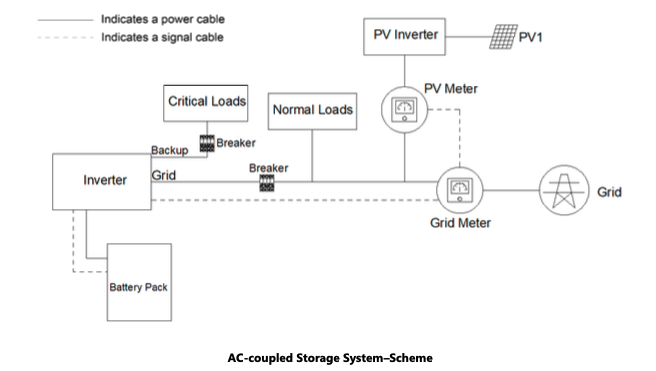

AC-coupled Storage System

-

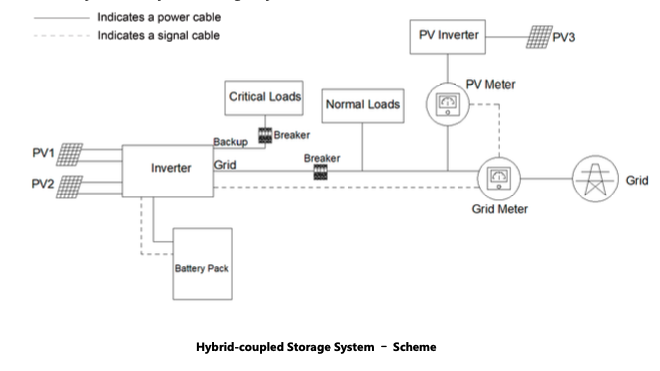

Hybrid-coupled Storage System

-

CT clamp - comes with Rj45 connection. Must use Rj45 socket as to extend the CT up to maximum 15 meters. Over 15 meters MUST use Smart Meter.

(it will download the file) -

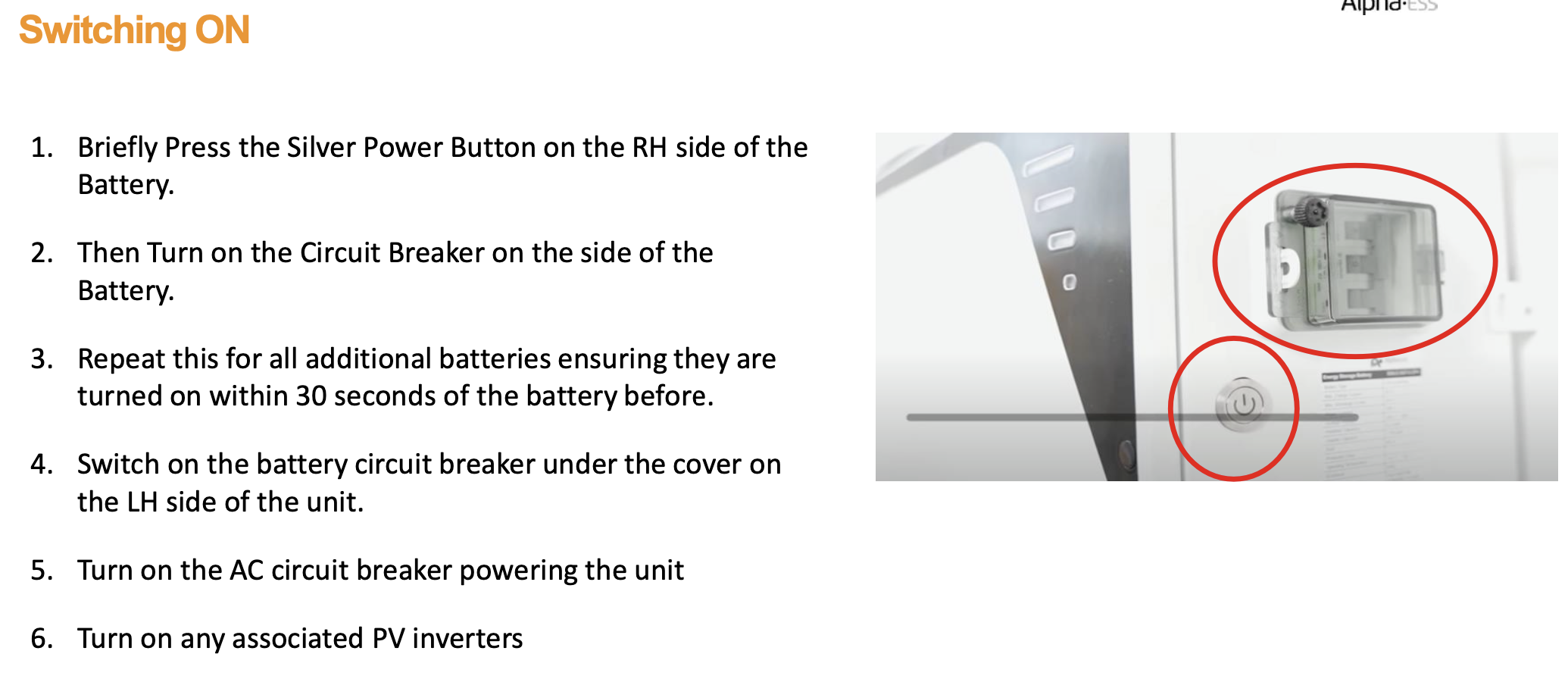

Turn-ON the battery

-

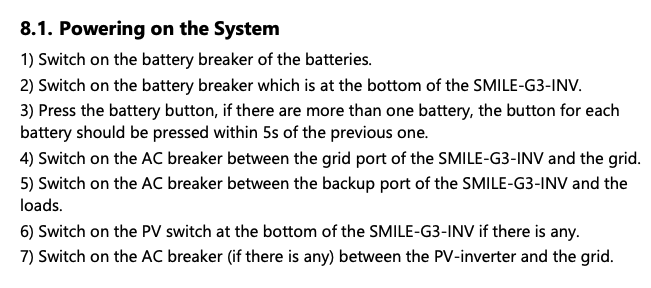

Powering ON the system:

-

Alpha Password to connect to WiFi: 12345678

-

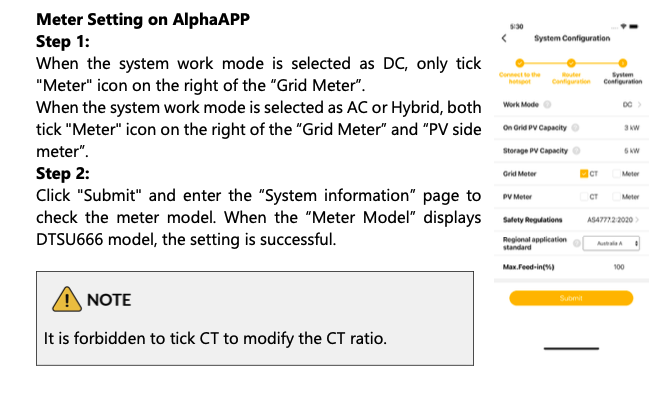

Important: On AlphaCloud/AlphaAPP please tick the right set up for the Grid Meter icon!

-

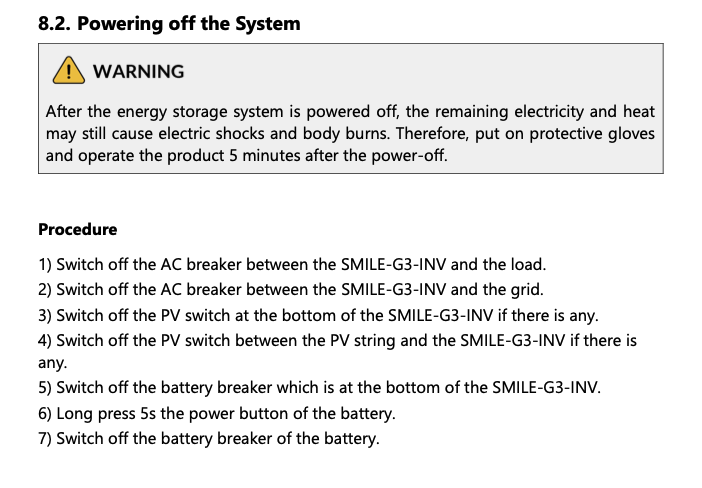

Powering OFF the system:

1. Press the power button on the battery for 6 seconds and after turn off the battery MCB.

2. Switch off the PV switch from the inverter.

3. Turn off the AC disconnector between the inverter and the load (if there is any).

4. Turn off the AC disconnector between the inverter and the grid. -

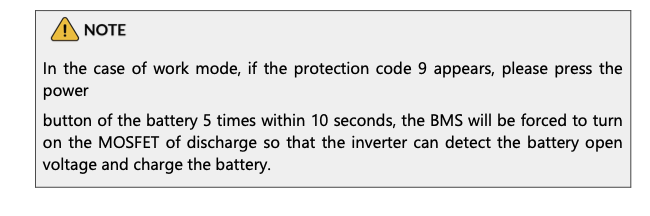

Protection code 9 appears:

Post-installation pictures

DC Run

-

Photo of DC cable(s) entry into the property – proving IP65 entry adequately waterproofed, CT1 or any other waterproof membrane/fire retardant

-

Photo of DC cable run (please take 1 photo for every room the cable has to run through) - WITH STICKERS

Battery and Inverter

-

Photo of the battery and inverter – (showing adequate clearances around them and isolators)

-

Battery and inverter Bonding

-

Number of Batteries

- 1

- 2

- 3

- 4

- 5

- 6

-

Photo of the last batteries terminal resistor

-

Photo of Battery and Inverter connections

-

Did you extend the CT clamp?

undefined

-

-

Photo of the CT Direction

-

Photo of the CT Extension

undefined

-

Take a photo of the CT Directioin

-

Photo of the inverter's display lights showing it's working

-

Photo(s) of all Inverter's connections

-

Photo(s) of hazard stickers on the Inverter and battery

AC Run

-

Photo of AC cable entry into the property – proving IP65 entry adequately waterproofed, CT1 or any other waterproof membrane

-

Photo of AC cable run (please take 1 photo for every room the cable has to run through)

Consumer unit & Mains electrical

-

Photo of handover documents (inc SLD and shutdown procedure) placed near the inverter

-

Photo(s) of consumer unit with cover OFF (showing connections of the PV breaker, RCD, SPD and grid meter)

-

Photo(s) of consumer unit with cover ON (showing the PV breaker, RCD, SPD and grid meter)

-

Photo of the of Dual Supply sticker around PV-DB or House-DB

-

Photo of CT clamp around LIVE outgoing meter tail – with arrow pointing towards GRID

-

Photo of the Solar on Roof sticker - around the meter

-

Picture of overall electrical install showing the connection for a sub-board including the meter tails.

-

Screenshot of the system working to be taken 10 minutes after commission

Test Results

-

Photo of total impedance for PV circuit – Zs (Ω)

-

Photo of external earth fault impedance - Ze (Ω)

-

Photo of prospective fault current – PFC (KA)

-

Photo of insulation resistance – (MΩ) - AC side

-

Photo for string 1 (V):

-

Photo for string 2 (V):

Declarations

-

I confirm the install has been installed within accordance of BS7671 regulations

-

I confirm the inverter and battery are installed in a convenient location (as determined by the Customer), should allow easy access for future operations and maintenance personnel, and have sufficient space for cooling as defined by the manufacturer specifications.

-

Have you ensured all electrical items are secured and not loose?

-

Have you checked the Garage Unit / Sub-board for IP4x rating if installed inside? (If installed outside must be IP6x rated)

-

Can you confirm that you have recorded the MCB and RCD ratings?.

-

The RCD bus-bar link to MCB is correct (original bus bar or 25mm link) torque connections (1.7Nm)?

-

Confirm Henley block connections and ensure double insulated tails are correctly installed with no inner sheath showing torque connections (2.5Nm)?

-

Inspect AC isolator for IP4x rating, torque connections (1.7Nm)?

-

Check Solar board and trunking/conduit is IP4X; Torque connections of MCB/RCD/RCBO (3.5-5Nm) and general installation condition / fireproof?

-

Visually make sure all connections do not have any copper showing at the terminals?

-

Checked all labels and applied all stickers?

-

Have you confirmed the Generation meter have been sealed ?

-

Have you pulled out the main fuse?

-

Have you confirmed the main fuse has been sealed

-

Is the app showing a load? - with the PV going direct to load or to the battery

-

Have you done a high load (kettle) test to check if the system is behaving correctly

-

Have you showed the customer the main isolation points of the system

-

Have you walked the customer through a reset procedure

-

Have you walked the customer on how the app works?

-

Has the site been cleaned, and waste removed?

-

Have all members of mounting structure been earthed? (if applicable)

-

Have all cables been laid in adequate conduit/ copex? (if applicable )

-

Have all wall / roof penetrations been adequately sealed?

-

Have inverters / battery been installed on fire-proof surface?

-

Have all safety distances near inverter and battery been respected?

-

Is any gas / water piping / equipment in the vicinity of the equipment?

-

Has the system been configured and its functioning state been verified?

-

Has it been verified whether installation area may be subject to water ingress / flooding?

-

Have all pre-existing and later damages in the installation area been recorded?

-

Has all equipment been installed according to the installation manuals and guidelines?

Signatures

-

I confirm this installation has been installed within MCS guidelines and the customer is happy and content with installation (including battery/inverter location, cable runs and sub-board placement)

-

Are they happy with the installation

-

What is the customer not happy with?

-

Has the customer been shown how to use the app?

-

Reasons?

-

Customer's signature