Title Page

-

Customer Name:

-

Customer postcode:

-

Conducted on

-

Prepared by

-

Location

Pre-Installation photos

-

Photo of electrical pre-install area (this is where you intend to put the sub board and add any miscellaneous items such as henley blocks etc)

-

Photo of intended location of battery & inverter (See Job Pack as to where that is – and ensure customer is happy with this location)

-

Photo(s) of intended DC cable run (take multiple photos and annotate to show the run)

-

Photo(s) of intended AC cable run (take multiple photos and annotate to show the run)

-

Photo of Inverter SN:

-

Photo of WIFI Dongle SN:

-

Type of Battery

-

Photo of Battery(s) SN:

-

Photo of CHINT grid meter(s) SN: (if applicable)

-

Photo of Generation meter SN:

Inverter checklist

-

Make sure ALL covers are off when commissioning. Apply covers when finished

-

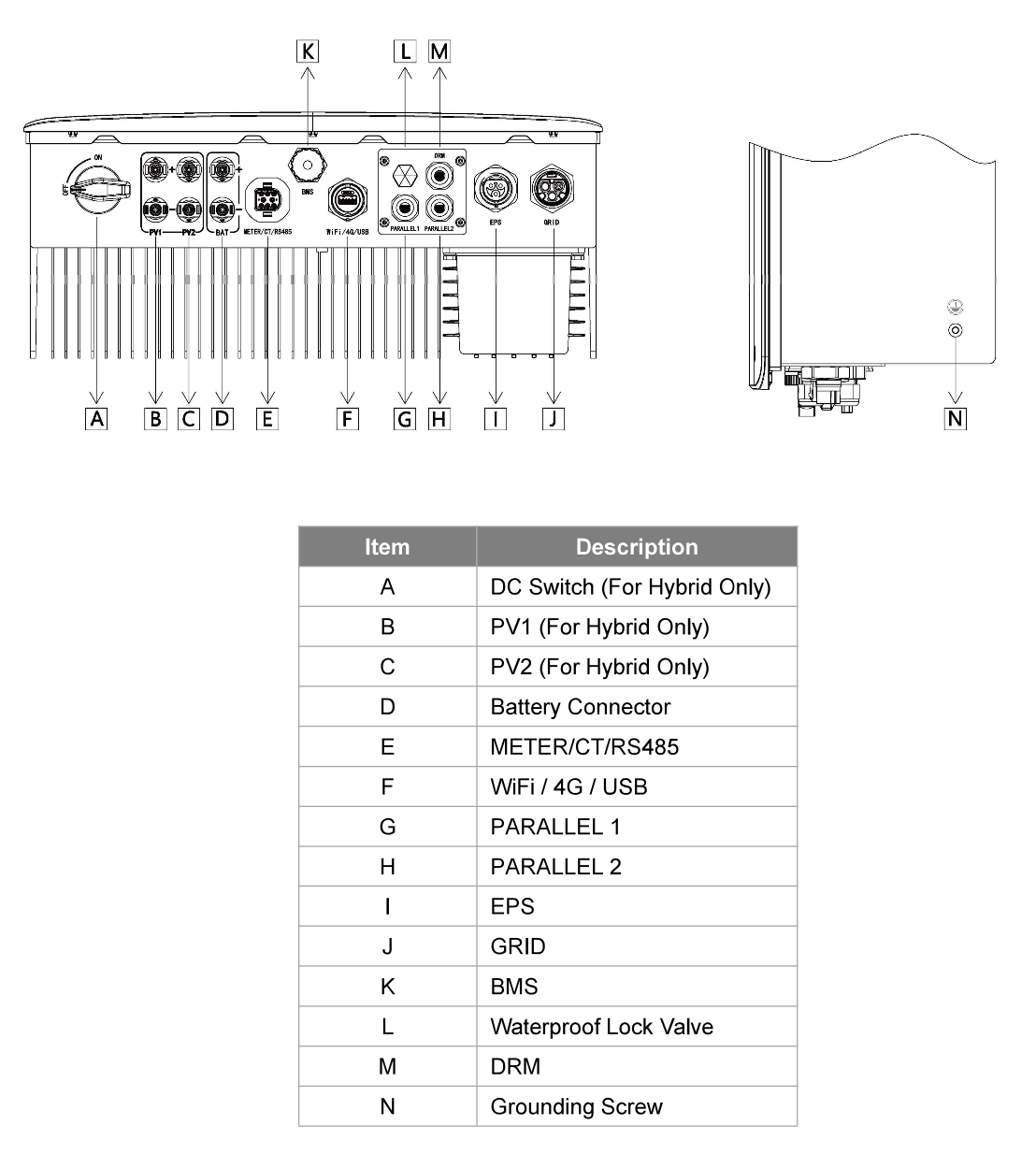

Terminals of the Fox inverter

-

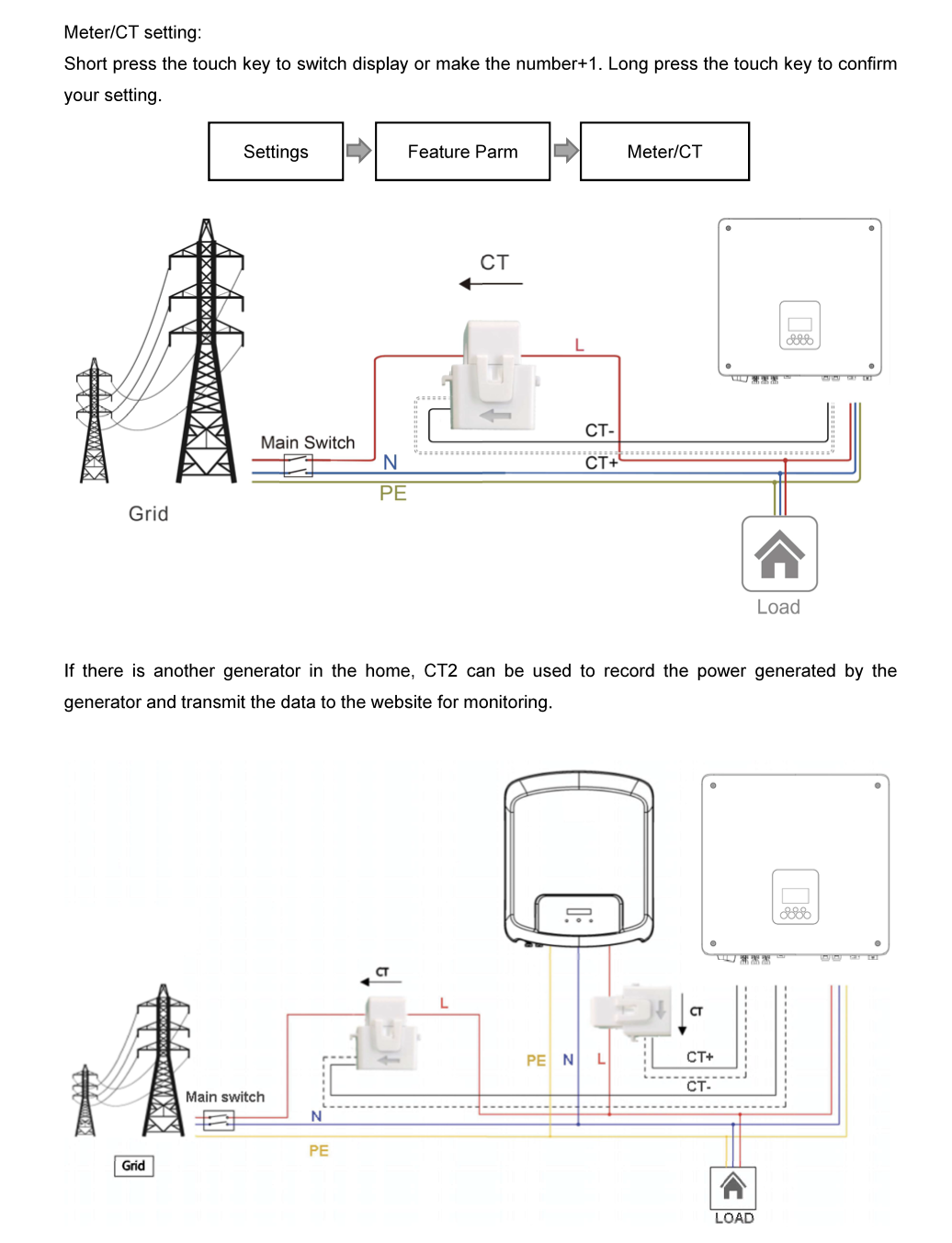

CT setting and orientation

-

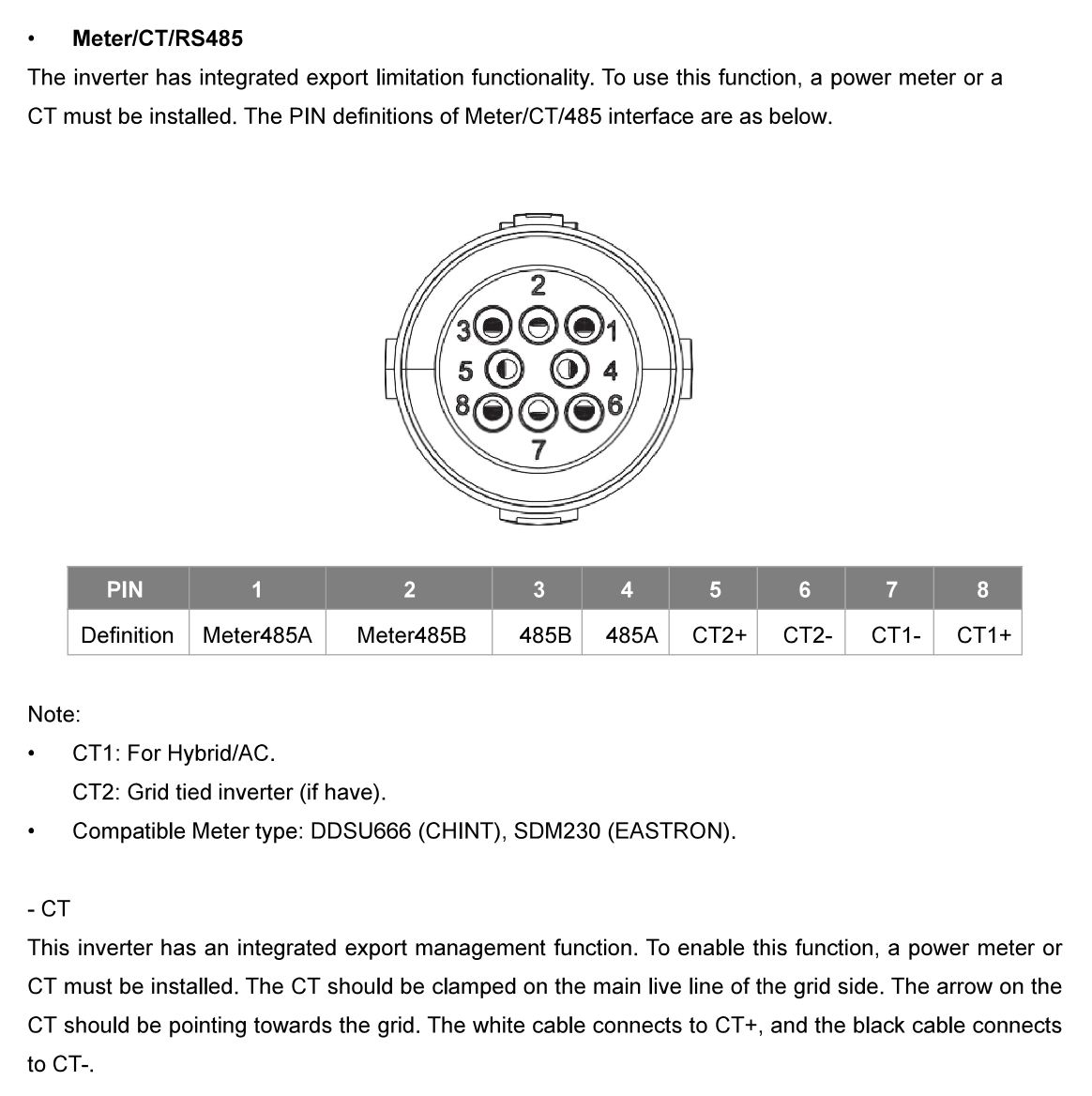

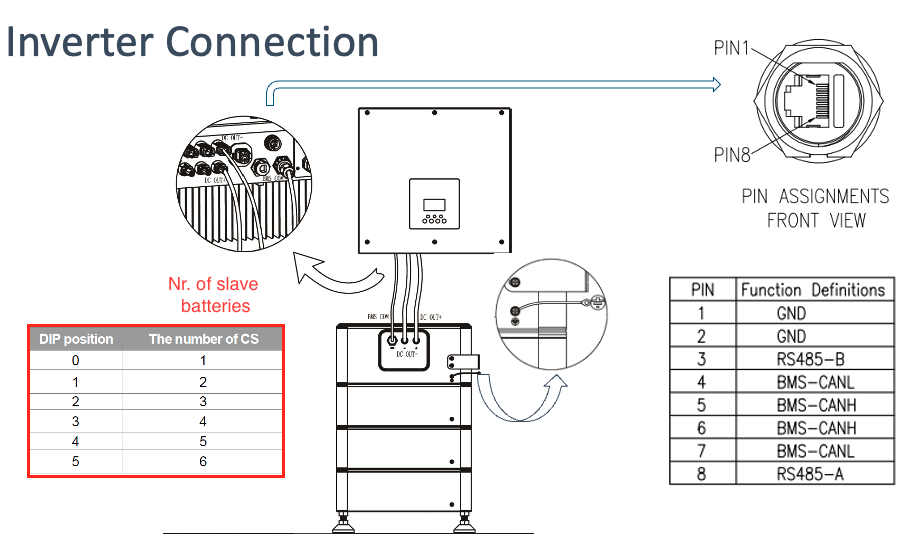

PIN Connections for H1 Fox inverter

-

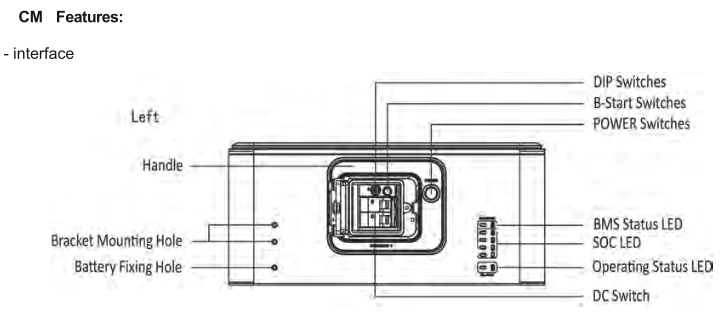

Battery control

-

so scriu mai sus

-

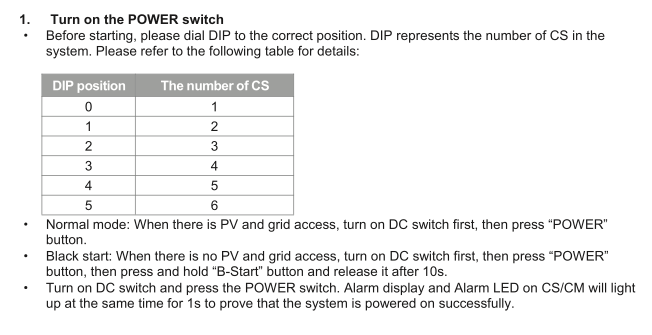

Inverter Connection (DIP switch on Master battery (CM)), (CS = slave)

-

Turn-ON the battery

-

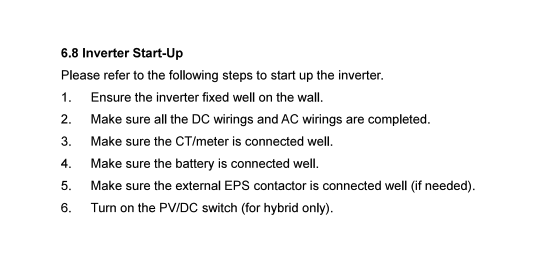

Inverter Sart-UP:

-

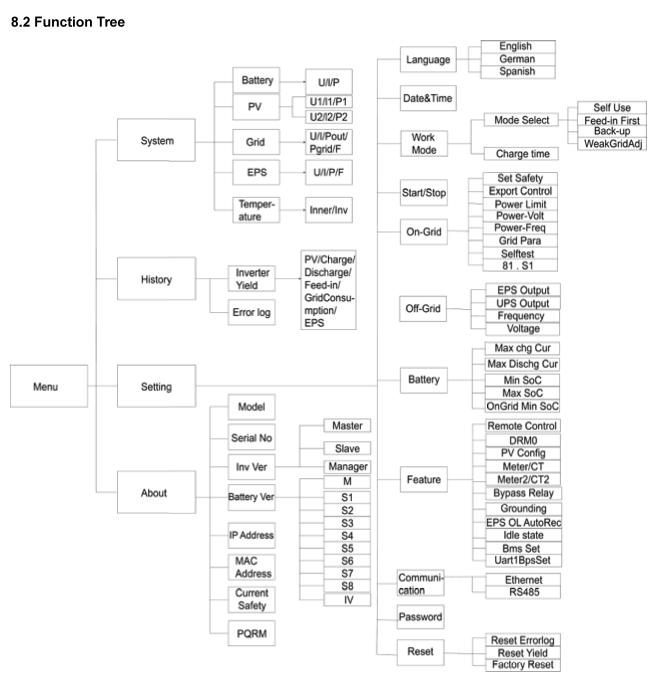

Menu Function Tree

Post-installation pictures

DC Run

-

Photo of DC cable(s) entry into property – proving IP65 entry adequately waterproofed with silicon, CT1 or any other waterproof membrane/fire retardant

-

Photo of DC cable run (please take 1 photo for every room the cable has to run through) - WITH STICKERS

Battery and Inverter

-

Photo of battery and inverter – (showing adequate clearances around them and isolators/generation meter)

-

Battery and inverter Bonding

Nr of Battery stacks

-

H2

-

H3

-

H4

-

H5

-

H6

-

H7

-

Photo of Battery and Inverter data connection

-

Photo of the inverter's LCD on showing its working

-

Photo(s) of all Inverter's connections

-

Photo(s) of hazard stickers on Inverter and battery

AC Run

-

Photo of AC cable entry into property – proving IP65 entry adequately waterproofed with silicon, CT1 or any other waterproof membrane

-

Photo of AC cable run (please take 1 photo for every room the cable has to run through)

Consumer unit & Mains electrical

-

Photo of handover documents (inc SLD and shutdown procedure) placed near the inverter

-

Photo(s) of consumer unit with cover OFF (showing connections of the PV breaker, RCD, SPD and grid meter)

-

Photo(s) of consumer unit with cover ON (showing the PV breaker, RCD, SPD and grid meter)

-

Photo of CT clamp around LIVE outgoing meter tail – with arrow pointing towards GRID

-

Picture of overall electrical install showing sub-board, CT clamp, Henley/Lucy blocks and main earthing terminal (COVERS ON)

-

Screenshot of system working

Test Results

-

Photo of total impedance for PV circuit – Zs (Ω)

-

Photo of external earth fault impedance - Ze (Ω)

-

Photo of prospective fault current – PFC (KA)

-

Photo of insulation resistance – (MΩ) - AC side

-

Photo for string 1 (V):

-

Photo for string 2 (V):

Declarations

-

I confirm the install has been installed within accordance of BS7671 regulations

-

I confirm the inverter and battery are installed in a convenient location (as determined by the Customer), should allow easy access for future operations and maintenance personnel, and have sufficient space for cooling as defined by the manufacturer specifications.

-

Have you ensured all electrical items are secured and not loose?

-

Have you checked the Garage Unit / Sub-board for IP4x rating if installed inside? (If installed outside must be IP6x rated)

-

Can you confirm that you have recorded the MCB and RCD ratings?.

-

The RCD bus-bar link to MCB is correct (original bus bar or 25mm link) torque connections (1.7Nm)?

-

Confirm Henley block connections and ensure double insulated tails are correctly installed with no inner sheath showing torque connections (2.5Nm)?

-

Inspect AC isolator for IP4x rating, torque connections (1.7Nm)?

-

Check Generation meter/modem, trunking, IP4X, Torque connections(1.7Nm) and general installation condition on fireproof backing?

-

Visually make sure all connections do not have any copper showing at the terminals?

-

Checked all labels and applied all stickers?

-

Have you confirmed the Generation meter have been sealed ?

-

Have you pulled out the main fuse?

-

Have you confirmed the main fuse has been sealed

-

Is the app showing a load? - with the PV going direct to load or to the battery

-

Have you done a high load (kettle) test to check if the system is behaving correctly

-

Have you showed the customer the main isolation points of the system

-

Have you walked the customer through a reset procedure

-

Have you walked the customer on how the app works?

-

Has the site been cleaned, and waste removed?

-

Have all members of mounting structure been earthed? (if applicable)

-

Have all cables been laid in adequate conduit/ copex? (if applicable )

-

Have all wall / roof penetrations been adequately sealed?

-

Have inverters / battery been installed on fire-proof surface?

-

Have all safety distances near inverter and battery been respected?

-

Is any gas / water piping / equipment in the vicinity of the equipment?

-

Has the system been configured and its functioning state been verified?

-

Has it been verified whether installation area may be subject to water ingress / flooding?

-

Have all pre-existing and later damages in the installation area been recorded?

-

Has all equipment been installed according to the installation manuals and guidelines?

Signatures

-

I confirm this installation has been installed within MCS guidelines and the customer is happy and content with installation (including battery/inverter location, cable runs and sub-board placement)

-

Are they happy with the installation?

-

What is the customer not happy with?

-

Has the customer been shown how to use the app?

-

Reasons?

-

Customers Signature

-

Has the customer been shown how to use the app?

-

Reasons?

-

Customers Signature