Information

-

Customer

undefined

-

-

Site Address

-

Post code

-

Site Number

-

Date of Inspection

-

Inspected by

-

Site reference (if applicable)

Preventative Maintenance and Safety Check

-

Risk assessments and method statements must be carried on all sites to ensure that the risk of injury or fatality is eliminated to users or members of the general public as a result of system design

Barriers

-

Control type

- open entry, controlled exit

- controlled entry, open exit

- controlled entry & exit

Standard Preventative Maintenance

-

Barrier location (1)

-

Barrier direction

- entry

- exit

-

Take a photo of barrier from entrance side of this barrier

-

Manufacturer

-

Model

-

Loops fitted

- Yes

- No

-

IR beams fitted

- Yes

- No

-

Warning lights fitted

- Yes

- No

-

Correct and adequate signage

- Yes

- No

-

Length of barrier (mm)

-

Safety/Op Equipment

-

All equipment in good working order/free from physical defect

-

Please provide details and photographs

-

Photographs

-

All equipment and fixings inspected and rectified as appropriate

-

Please provide details and photographs

-

Photographs

-

All electrical and electronic equipment inspected

-

Please provide details and photographs

-

Photographs

-

All moving parts greased and oiled as required

-

Please provide details and photographs

-

Photographs

-

Test all systems on automatic operation

-

Please provide details and photographs

-

Photographs

-

Test the efficiency of the safety devices

-

Please provide details and photographs

-

Photographs

-

Test thrust force and use of safety beams to prevent crushing

-

Please provide details and photographs

-

Photographs

-

Check the condition of systems wiring to ensure safety to all

-

Please provide details and photographs

-

Photographs

-

Check emergency systems

-

Please provide details and photographs

-

Photographs

-

Test systems on manual operation

-

Please provide details and photographs

-

Photographs

-

Additional barriers

-

Barrier location (2)

-

Barrier direction

- entry

- exit

-

Take a photo of barrier from entrance side of this barrier

-

Manufacturer

-

Model

-

Loops fitted

- Yes

- No

-

IR beams fitted

- Yes

- No

-

Warning lights fitted

- Yes

- No

-

Correct and adequate signage

- Yes

- No

-

Length of barrier (mm)

-

Safety/Op Equipment

-

All equipment in good working order/free from physical defect

-

Please provide details and photographs

-

Photographs

-

All equipment and fixings inspected and rectified as appropriate

-

Please provide details and photographs

-

Photographs

-

All electrical and electronic equipment inspected

-

Please provide details and photographs

-

Photographs

-

All moving parts greased and oiled as required

-

Please provide details and photographs

-

Photographs

-

Test all systems on automatic operation

-

Please provide details and photographs

-

Photographs

-

Test the efficiency of the safety devices

-

Please provide details and photographs

-

Photographs

-

Test thrust force and use of safety beams to prevent crushing

-

Please provide details and photographs

-

Photographs

-

Check the condition of systems wiring to ensure safety to all

-

Please provide details and photographs

-

Photographs

-

Check emergency systems

-

Please provide details and photographs

-

Photographs

-

Test systems on manual operation

-

Please provide details and photographs

-

Photographs

-

Additional barriers

-

Barrier location (3)

-

Barrier direction

- entry

- exit

-

Take a photo of barrier from entrance side of this barrier

-

Manufacturer

-

Model

-

Loops fitted

- Yes

- No

-

IR beams fitted

- Yes

- No

-

Warning lights fitted

- Yes

- No

-

Correct and adequate signage

- Yes

- No

-

Length of barrier (mm)

-

Safety/Op Equipment

-

All equipment in good working order/free from physical defect

-

Please provide details and photographs

-

Photographs

-

All equipment and fixings inspected and rectified as appropriate

-

Please provide details and photographs

-

Photographs

-

All electrical and electronic equipment inspected

-

Please provide details and photographs

-

Photographs

-

All moving parts greased and oiled as required

-

Please provide details and photographs

-

Photographs

-

Test all systems on automatic operation

-

Please provide details and photographs

-

Photographs

-

Test the efficiency of the safety devices

-

Please provide details and photographs

-

Photographs

-

Test thrust force and use of safety beams to prevent crushing

-

Please provide details and photographs

-

Photographs

-

Check the condition of systems wiring to ensure safety to all

-

Please provide details and photographs

-

Photographs

-

Check emergency systems

-

Please provide details and photographs

-

Photographs

-

Test systems on manual operation

-

Please provide details and photographs

-

Photographs

-

Additional barriers

-

Barrier location (4)

-

Barrier direction

- entry

- exit

-

Take a photo of barrier from entrance side of this barrier

-

Manufacturer

-

Model

-

Loops fitted

- Yes

- No

-

IR beams fitted

- Yes

- No

-

Warning lights fitted

- Yes

- No

-

Correct and adequate signage

- Yes

- No

-

Length of barrier (mm)

-

Safety/Op Equipment

-

All equipment in good working order/free from physical defect

-

Please provide details and photographs

-

Photographs

-

All equipment and fixings inspected and rectified as appropriate

-

Please provide details and photographs

-

Photographs

-

All electrical and electronic equipment inspected

-

Please provide details and photographs

-

Photographs

-

All moving parts greased and oiled as required

-

Please provide details and photographs

-

Photographs

-

Test all systems on automatic operation

-

Please provide details and photographs

-

Photographs

-

Test the efficiency of the safety devices

-

Please provide details and photographs

-

Photographs

-

Test thrust force and use of safety beams to prevent crushing

-

Please provide details and photographs

-

Photographs

-

Check the condition of systems wiring to ensure safety to all

-

Please provide details and photographs

-

Photographs

-

Check emergency systems

-

Please provide details and photographs

-

Photographs

-

Test systems on manual operation

-

Please provide details and photographs

-

Photographs

-

Additional barriers

-

Barrier location (5)

-

Barrier direction

- entry

- exit

-

Take a photo of barrier from entrance side of this barrier

-

Manufacturer

-

Model

-

Loops fitted

- Yes

- No

-

IR beams fitted

- Yes

- No

-

Warning lights fitted

- Yes

- No

-

Correct and adequate signage

- Yes

- No

-

Length of barrier (mm)

-

Safety/Op Equipment

-

All equipment in good working order/free from physical defect

-

Please provide details and photographs

-

Photographs

-

All equipment and fixings inspected and rectified as appropriate

-

Please provide details and photographs

-

Photographs

-

All electrical and electronic equipment inspected

-

Please provide details and photographs

-

Photographs

-

All moving parts greased and oiled as required

-

Please provide details and photographs

-

Photographs

-

Test all systems on automatic operation

-

Please provide details and photographs

-

Photographs

-

Test the efficiency of the safety devices

-

Please provide details and photographs

-

Photographs

-

Test thrust force and use of safety beams to prevent crushing

-

Please provide details and photographs

-

Photographs

-

Check the condition of systems wiring to ensure safety to all

-

Please provide details and photographs

-

Photographs

-

Check emergency systems

-

Please provide details and photographs

-

Photographs

-

Test systems on manual operation

-

Please provide details and photographs

-

Photographs

-

Additional barriers

-

Barrier location (6)

-

Barrier direction

- entry

- exit

-

Take a photo of barrier from entrance side of this barrier

-

Manufacturer

-

Model

-

Loops fitted

- Yes

- No

-

IR beams fitted

- Yes

- No

-

Warning lights fitted

- Yes

- No

-

Correct and adequate signage

- Yes

- No

-

Length of barrier (mm)

-

Safety/Op Equipment

-

All equipment in good working order/free from physical defect

-

Please provide details and photographs

-

Photographs

-

All equipment and fixings inspected and rectified as appropriate

-

Please provide details and photographs

-

Photographs

-

All electrical and electronic equipment inspected

-

Please provide details and photographs

-

Photographs

-

All moving parts greased and oiled as required

-

Please provide details and photographs

-

Photographs

-

Test all systems on automatic operation

-

Please provide details and photographs

-

Photographs

-

Test the efficiency of the safety devices

-

Please provide details and photographs

-

Photographs

-

Test thrust force and use of safety beams to prevent crushing

-

Please provide details and photographs

-

Photographs

-

Check the condition of systems wiring to ensure safety to all

-

Please provide details and photographs

-

Photographs

-

Check emergency systems

-

Please provide details and photographs

-

Photographs

-

Test systems on manual operation

-

Please provide details and photographs

-

Photographs

-

Additional barriers

-

Barrier location (7)

-

Barrier direction

- entry

- exit

-

Take a photo of barrier from entrance side of this barrier

-

Manufacturer

-

Model

-

Length of barrier (mm)

-

Safety/Op Equipment

-

All equipment in good working order/free from physical defect

-

Please provide details and photographs

-

Photographs

-

All equipment and fixings inspected and rectified as appropriate

-

Please provide details and photographs

-

Photographs

-

All electrical and electronic equipment inspected

-

Please provide details and photographs

-

Photographs

-

All moving parts greased and oiled as required

-

Please provide details and photographs

-

Photographs

-

Test all systems on automatic operation

-

Please provide details and photographs

-

Photographs

-

Test the efficiency of the safety devices

-

Please provide details and photographs

-

Photographs

-

Test thrust force and use of safety beams to prevent crushing

-

Please provide details and photographs

-

Photographs

-

Check the condition of systems wiring to ensure safety to all

-

Please provide details and photographs

-

Photographs

-

Check emergency systems

-

Please provide details and photographs

-

Photographs

-

Test systems on manual operation

-

Please provide details and photographs

-

Photographs

Automation

-

Battery back up (Yes/No)

-

Fire Drop unit (Yes/No)

-

Radio Controlled (Yes/No)

-

Digital Keypad (Yes/No)

-

Token (Yes/No)

-

Touch/card/fob (Yes/No)

Key Type

-

Key Type

-

Key Number

-

Key box available

-

Manual Key in box

-

Manual instructions in box

Report on any required works

-

Check safety systems are compliant, shared pedestrian use, internal key pad, Push to exit bars, Break glass, Gaps and External Beams.

-

System complies with EN SAFETY regulations

-

Supply details

-

All tests carried out in line with manufacturers guidelines

-

Supply details

-

System has been tested and conforms to machinery directive Machinery Directive 2006/42/EC

-

Supply details

Electrical Check

-

Electrical certificate available for barrier and in date

- Yes

- No

-

Does electrical installation appear sound, safe and in reasonable condition

- Yes

- No

-

Supply details

-

Source off power

-

Breaker size

-

Cable type

-

Cable size

-

Correct containment used

-

Details

-

Spur for barrier / gate in waterproof containment

-

Details

-

All wiring at barrier / gate checked for loose or badly made connections

-

Details

-

Additional Information

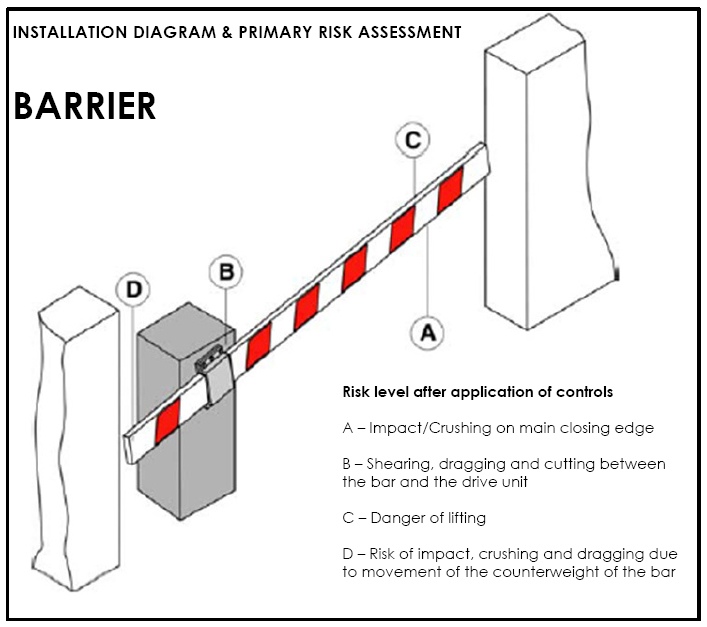

Installation diagram and assessment

-

Identify (if relevant) potential hazards at points labelled on diagram, and comment below

-

Include Diagram from library

-

A - impact / crushing on main closing edge

-

B - shearing, dragging and cutting between the bar and the drive unit

-

C - danger of lifting

-

D - risk of impact, crushing and dragging due to movement of counterweight

-

Comments

Overall condition / Performance of system / additional information

-

Any additional comments

-

Any additional photos

Defect list & recommendations

-

Defects (list defects that need attention)

-

Recommendations (list items you would recommend)

-

Engineer

-

Client representative (if available)