Title Page

User Information

-

Name

-

Address

-

Identifier

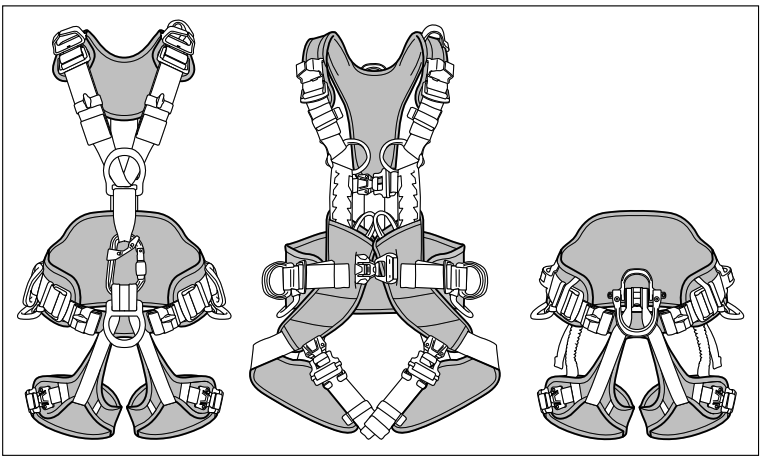

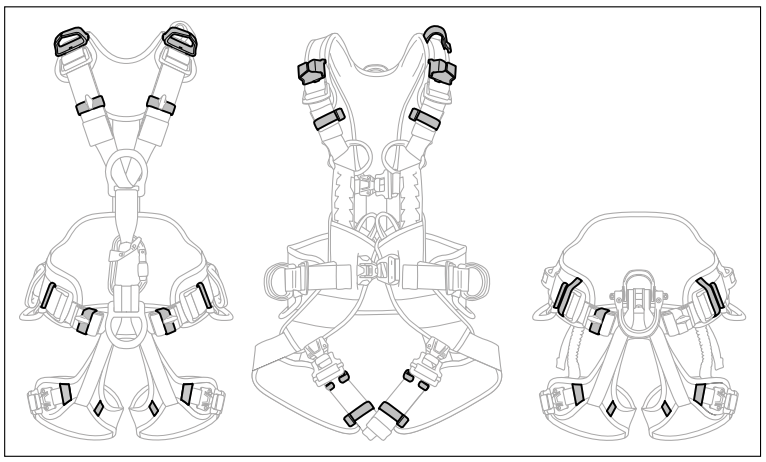

PPE Information

-

Model

-

Serial Number

-

Year of Manufacture

-

Date of Purchase

-

Date of First Use

-

1. Known product history: Usage conditions or exceptional event during use (examples: fall or fall arrest, use or storage at extreme temperatures, modification outside manufacturer's facilities...) :

Preliminary product history

-

Is the serial number and the CE mark present and legible?

-

Verify the presence and legibility of the serial number and the CE mark.

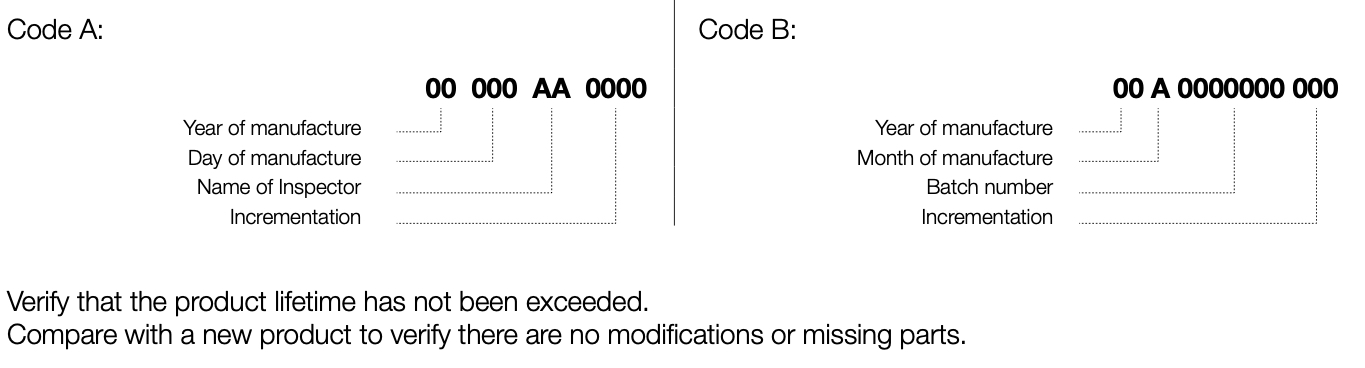

Note: the serial number code on our products is evolving. Two types of code will coexist. See below for details on each serial number code. -

Has the product lifetime been exceeded?

-

Note: The AVAO BOD FAST International Version harness has a Warranty of 3 Yrs.

-

After comparing to a new device, are there any modifications or missing elements?

-

Overall preliminary observation assessment

-

Please create an issue using the QR code below. Include this link (https://marketplace.safetyculture.com/petzl-astro-bod-fast-international-version-colour-black-yellow/) to replacement harness to ensure correct replacement is provided and to reduce time to replace.

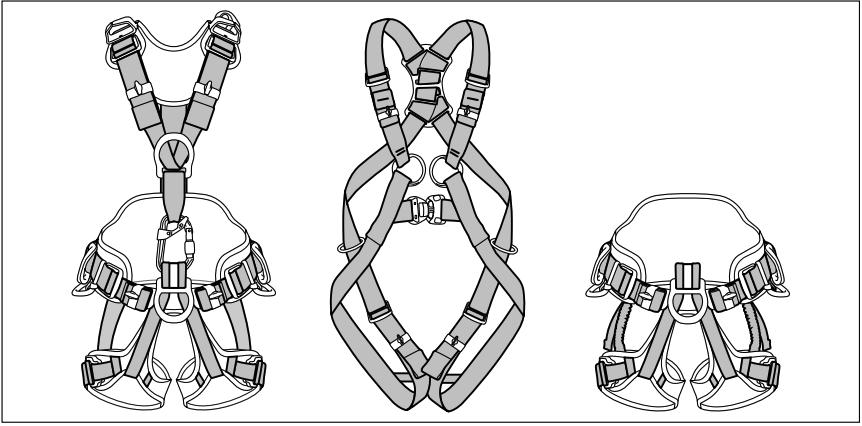

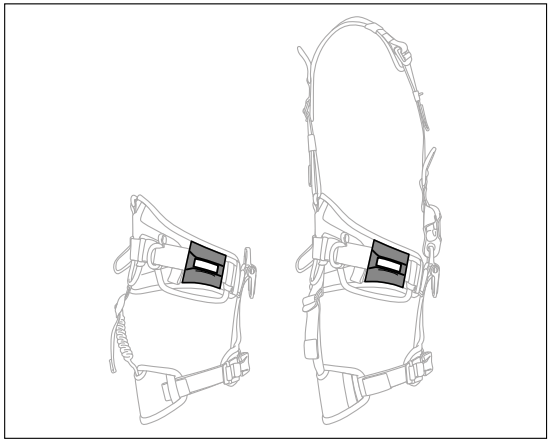

Checking the condition of the straps

-

-

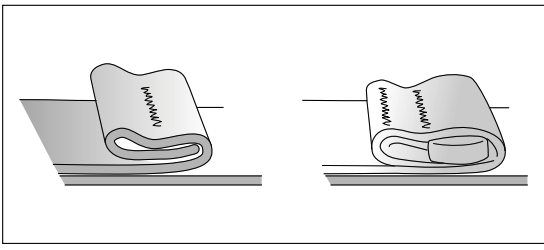

After a close inspection of waistbelt straps, leg loops, leg loop/waistbelt linkage and shoulder straps were any signs of cuts, swelling, damage and wear due to use, to heat, and to contact with chemicals identified? Be sure to check the areas hidden by the buckles

-

-

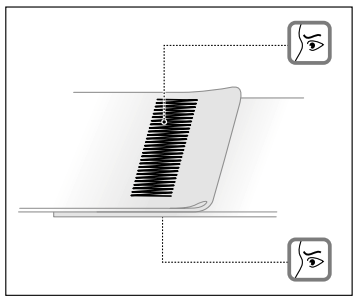

After closely inspecting the condition of both sides of the safety stitching were any loose, worn or cut threads identified? The safety stitching is identified by thread of a different colour than that of the webbing.

-

-

Were you able to verify that hems are present on the strap ends?

-

-

Overall strap condition assessment

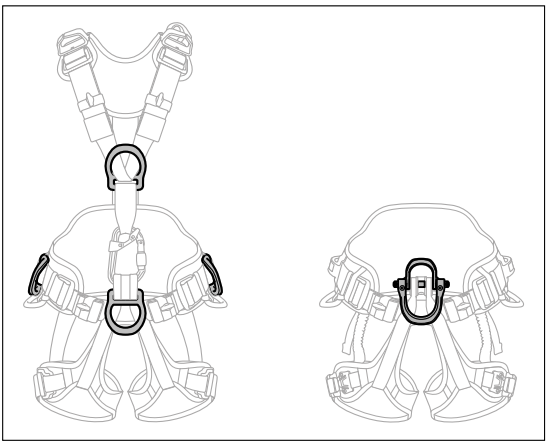

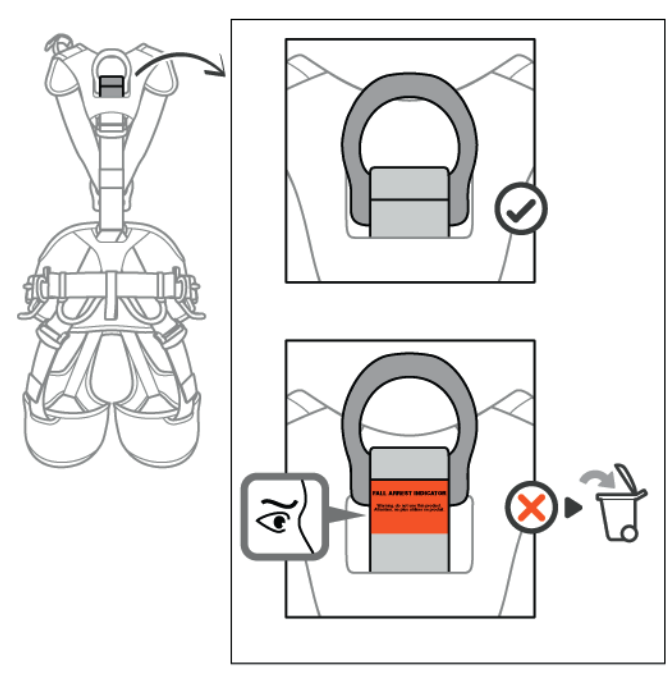

Checking the attachment points

-

-

After close inspection of the condition of the metal attachment points were any defects identified (eg. marks, cracks, wear, deformation, corrosion...)

-

-

After close inspection of the condition of the textile attachment points were any defects identified (eg. cuts, wear, tears...)

-

-

After close inspection of the condition of the plastic attachment points were any defects identified (eg. cuts, wear, tears, cracks.....)

-

-

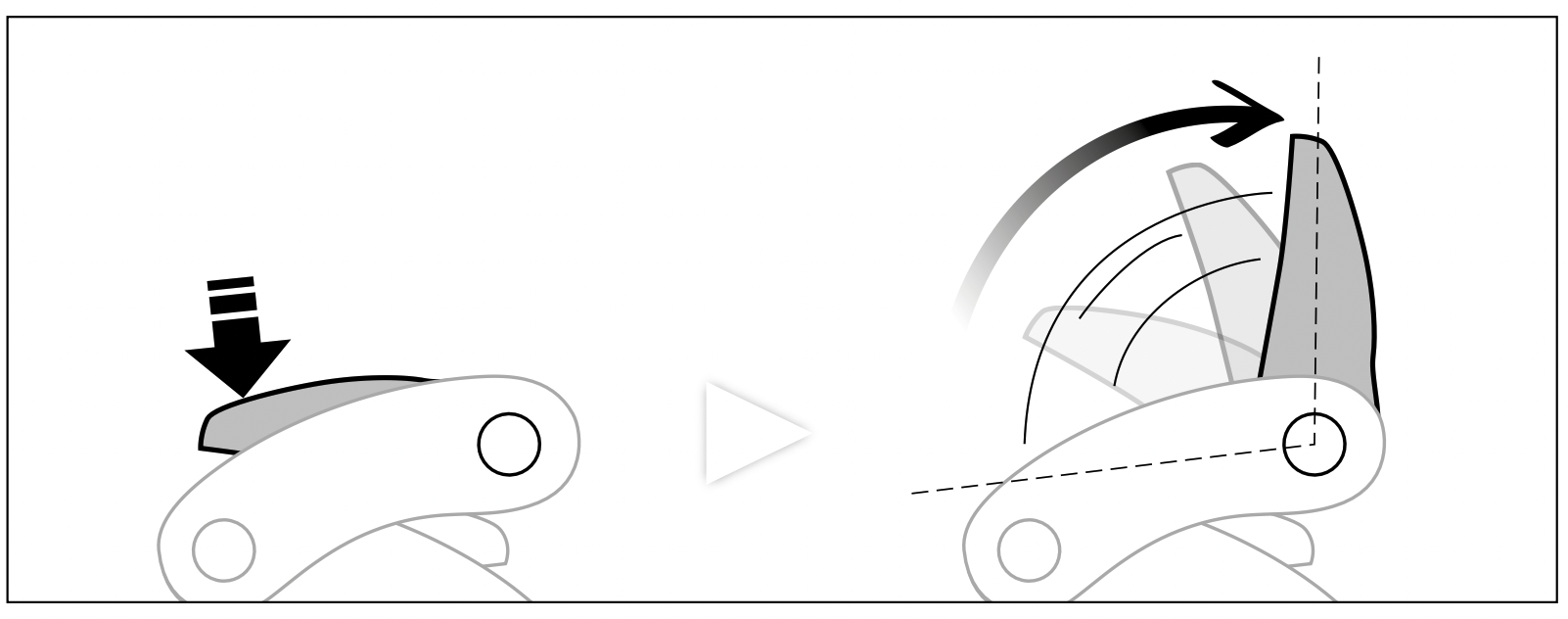

The fall arrest indicator near the dorsal attachment point will show red if the harness has sustained a shock load greater than 400 daN. Is this indicator showing red?

-

Overall attachment point assessment

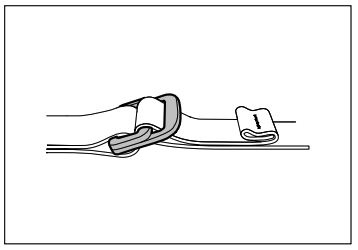

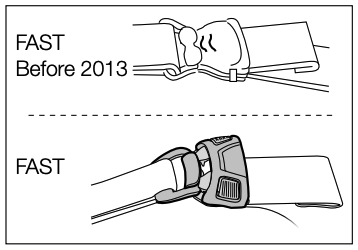

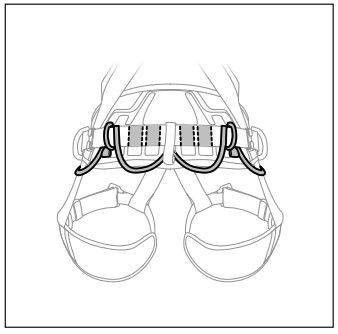

Checking the condition of the adjustment buckles

-

-

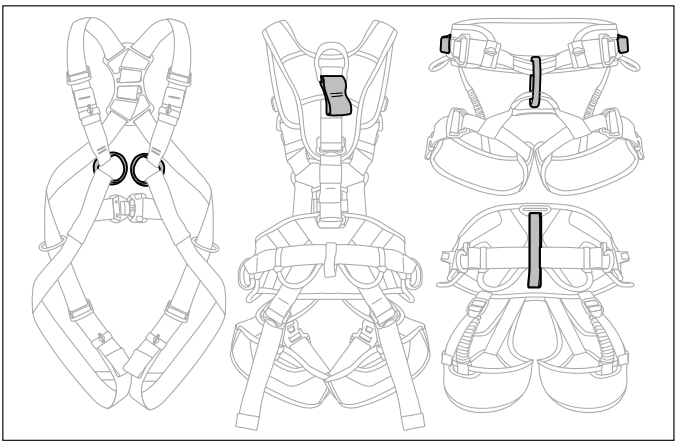

After close inspection of the condition of the DOUBLEBACK adjustment buckles were any defects identified ((marks, cracks, wear, deformation, corrosion...)?

-

-

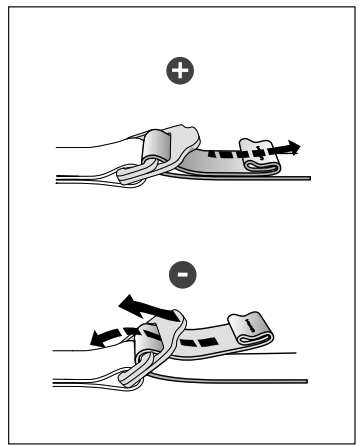

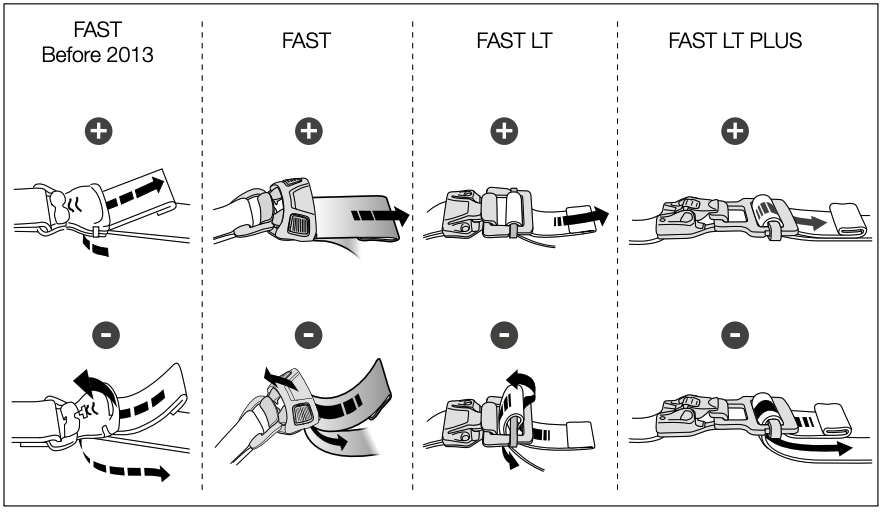

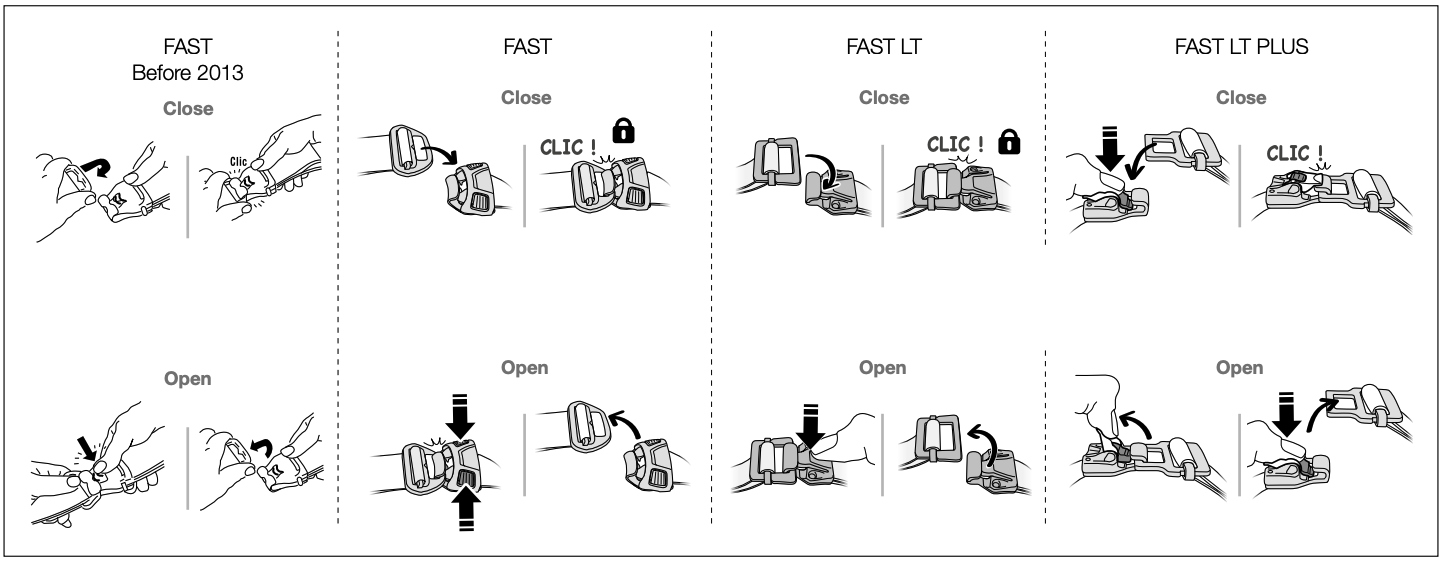

After close inspection of the condition of the FAST adjustment buckles were any defects identified (marks, cracks, wear, deformation, corrosion...)?

-

-

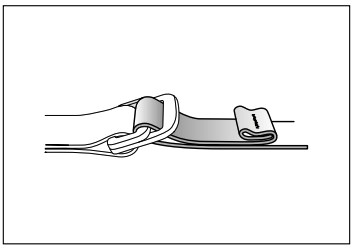

After close inspection of the straps are correctly threaded, with no twists?

-

Check that the buckles are operating correctly.

-

-

-

Are all buckles operating correctly?

-

Overall adjustment buckle assessment

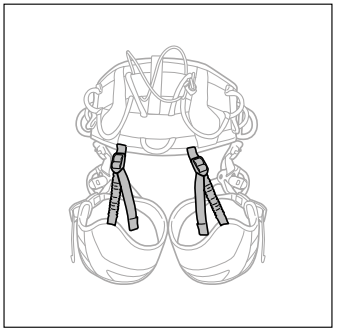

Checking the condition of the comfort parts

-

-

After close inspection of the waist, leg and shoulder foams were any defects identified (cuts, wear tears... )?

-

-

After close inspection of the elastic and/or plastic keepers were any defects identified (cuts, wear tears, cracks... )?

-

-

After close inspection of the leg loop elastics were any defects identified (cuts, wear tears,... )?

-

-

After close inspection of the equipment loops were any defects identified (cuts, wear tears, cracks... )?

-

Overall comfort part assessment

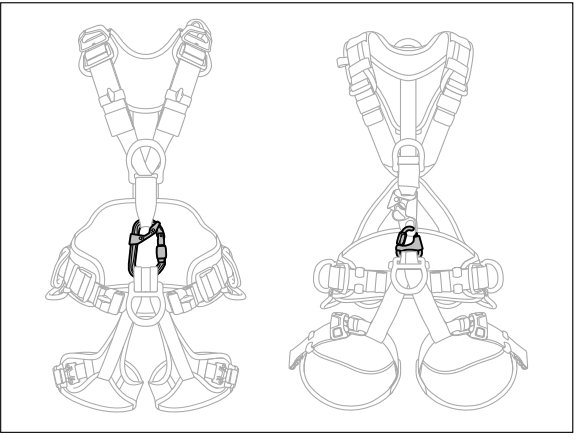

Checking the condition of the chest/seat harness connector (if any)

-

For connector inspection, search for the inspection template for you specific connector model at https://public-library.safetyculture.io/ or download an inspection form from Petzl.com.

-

If the harness features a chest/seat harness connector, is it present?

-

If there is a connector present is it one of the following models? Verify that the connector is the correct model and that it is correctly attached to the harness.

-

-

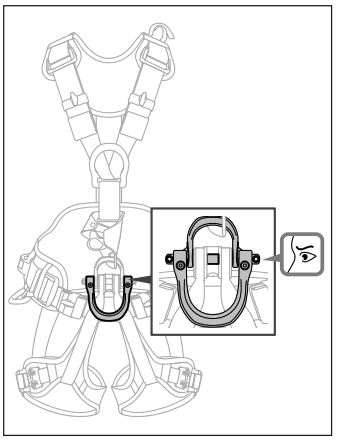

After close inspection of the gated attachment point were you able to verify that the screws on the gated attachment point are present and properly tightened?

-

Overall assessment of chest/seat harness connector

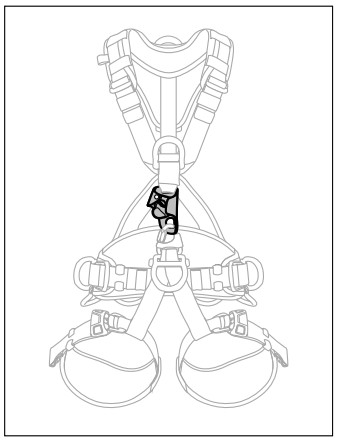

Checking the condition of the CROLL rope clamp (if any)

-

-

For rope clamp inspection, see the inspection form for your rope clamp model at https://public-library.safetyculture.io/ or at Petzl.com.

- Yes

- No

-

Overall CROLL rope clamp assessment

Examples of worn harnesses that should be repaired or retired

-

Cut equipment loop

-

Cut load adjustment strap

-

Damaged protective fabric

-

Damaged protective fabric

-

Reversed bar

-

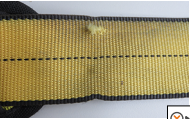

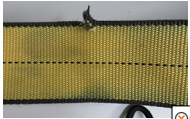

Damaged webbing

-

Marking on webbing

-

Cut webbing

-

Damaged webbing

-

Damaged webbing

-

Unstitched hem

-

Damaged attachment point

-

Fall indicator is visible

-

Damaged safety stitching

-

Damaged attachment point

-

Damaged attachment point

-

Damaged attachment point

-

Worn out D-ring

-

Broken buckle

-

Corrosion

-

Corrosion

-

Traces of paint

-

Buckle not working