Title Page

User Information

-

Name

-

Address

-

Identifier

PPE Information

-

Model

-

Serial Number

-

Year of Manufacture

-

Date of Purchase

-

Date of First Use

-

1. Known product history: Usage conditions or exceptional event during use (examples: fall or fall arrest, use or storage at extreme temperatures, modification outside manufacturer's facilities...) :

Preliminary product history

-

• Verify the presence and legibility of the serial number and the CE mark.

• Verify that the product lifetime has not been exceeded.

• Compare with a new product to verify there are no modifications or missing parts. -

Overall preliminary observation assessment

-

Please create an issue using the QR code below. Include this link (https://marketplace.safetyculture.com/petzl-astro-bod-fast-international-version-colour-black-yellow/) to replacement harness to ensure correct replacement is provided and to reduce time to replace.

-

Checking the condition of the straps

-

• Check for cuts, swelling, damage and wear due to use, to heat, and to contact with chemicals. Check the waistbelt straps, leg loops, leg loop/waistbelt linkage and shoulder straps, if present. Be sure to check the areas hidden by the buckles.

• Check the condition of the safety stitching on both sides. Look for any threads that are loose, worn, or cut. The safety stitching is identified by thread of a different color than that of the webbing.

• Verify that hems are present on the strap ends. -

Overall strap condition assessment

Checking the attachment points

-

• Check the condition of the metal attachment points (marks, cracks, wear, deformation, corrosion...).

• Check the condition of the textile attachment points (cuts, wear, tears...).

• Check the condition of the plastic attachment points (cuts, wear, tears...).

• On the multi-standard NAVAHO and AVAO harnesses, check the fall arrest indicator. The indicator shows red if the dorsal attachment point sustains a shock load greater than 400 daN. -

Overall attachment point assessment

Checking the condition of the adjustment buckles

-

• Check the condition of the DOUBLEBACK adjustment buckles (marks, cracks, wear, deformation, corrosion...). • Check the condition of the FAST adjustment buckles (marks, cracks, wear, deformation, corrosion...).

• Check that the straps are correctly threaded, with no twists.

• Verify that the buckles operate properly. -

Overall adjustment buckle assessment

Checking the condition of the comfort parts

-

• Check the condition of the waist, leg and shoulder foams (cuts, wear, tears...).. • Check the condition of the elastic and/or plastic keepers (cuts, wear, tears...). • Check the condition of the leg loop elastics (cuts, wear, tears...).

• Check the condition of the equipment loops (cuts, wear, tears...). -

Overall comfort part assessment

Checking the condition of the chest/seat harness connector (if any)

-

• For connector inspection, see the inspection form for your connector model at Petzl.com.

• Gated attachment point: verify that the screws on the gated attachment point are present and properly tightened. • If the harness features a chest/seat harness connector, make sure that it is present.

• Verify that the connector is the correct model and that it is correctly attached to the harness. -

Overall assessment of chest/seat harness connector

Checking the condition of the CROLL rope clamp (if any)

-

• For rope clamp inspection, see the inspection form for your rope clamp model at Petzl.com.

-

Overall CROLL rope clamp assessment

Examples of worn harnesses that should be repaired or retired

-

Cut equipment loop

-

Cut load adjustment strap

-

Damaged protective fabric

-

Damaged protective fabric

-

Reversed bar

-

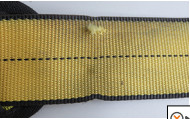

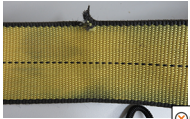

Damaged webbing

-

Marking on webbing

-

Cut webbing

-

Damaged webbing

-

Damaged webbing

-

Unstitched hem

-

Damaged attachment point

-

Fall indicator is visible

-

Damaged safety stitching

-

Damaged attachment point

-

Damaged attachment point

-

Damaged attachment point

-

Worn out D-ring

-

Broken buckle

-

Corrosion

-

Corrosion

-

Traces of paint

-

Buckle not working